In-Ex Gardenmate 20 User manual

OWNER’S MANUAL

FOR

In-Ex Gardenmate 20

12V SPRAYER

In-Ex™

PO Box 1010, 145 Harts Road

Tiritea, Palmerston North

Ph:06 354 6060

Fax:06 355 3199

E-Mail: sales@c-dax.co.nz

www.c-dax.co.nz

2

In-Ex Gardenmate 20

OWNER’S MANUAL

(Pt.No.2400-7105 Issue 5, Jan 2016)

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................................3

DESCRIPTION ...........................................................................................................................................3

SPECIFICATIONS......................................................................................................................................3

WARRANTY AND LIABILITY ................................................................................................................3

INSTALLATION.........................................................................................................................................5

INSTALLING THE BATTERY..................................................................................................................5

THEORY OF OPERATION .......................................................................................................................7

OPERATING INSTRUCTIONS.................................................................................................................7

OPERATING HINTS..................................................................................................................................7

MAINTENANCE........................................................................................................................................8

TROUBLESHOOTING...............................................................................................................................9

FLOJET SPRAY PUMP RELACEMENT PARTS ..................................................................................10

GARDENMATE 20 PARTS DIAGRAM.................................................................................................11

Throughout this manual there are highlighted text boxes containing warnings, cautions and notes.

Warnings are mandatory instructions to prevent serious injury or permanent damage.

Cautions are advisory instructions to ensure reliable operation of the equipment.

Notes are for convenient operation.

WARNING

Making pesticides is a most dangerous time as it involves handling the concentrated material. For toxic

compounds, use protective clothing such as overalls, hat, gloves, boots and respirator.

When using concentrated sprays, full protection is necessary.

When using diluted sprays, wear at least a hat, long-sleeved cotton overalls and boots. If you use pesticides

regularly it is a good idea to always wear a respirator to avoid cumulative effect … other protection may be

required –check the label. It may have specific directions for that particular chemical.

Protective clothing should always be properly cared for. Rinse heavily contaminated clothes in the open before

washing in the laundry.

Wash and dry these clothes every day –but keep them separate from other washing.

Respirators need special care … clean respirator after spraying. Use soapy water then rinse and allow to dry

completely before storing in a clean plastic bag. Replace canisters in respirator after every 8 hours use.

3

INTRODUCTION

Congratulations. You have just purchased a Gardenmate 20L sprayer from In-Ex. These units are specifically

developed for the accurate placement of liquid pesticides and fertilisers on turf, flowers and shrubs or any other

area where maintenance of carefully cultured turf is important.

DESCRIPTION

The Gardenmate 20 sprayer is a garden/lifestyle sprayer ideal for small area use. Each unit comprises a non-

corrosive polyethylene tank, a 12V pump and a spray gun with adjustable nozzle.

SPECIFICATIONS

(Specifications subject to change without notice)

Dry Weight / Dimensions / Capacity (all approx)

Power Consumption Flojet: ~3Amps (at 20PSI)

Pump 12 VDC Flojet 7.6 Lpm

Tanks Non-Corrosive, medium density, UV stabilised polyethylene

Filtration Triple filter system comprising; fine mesh tank strainer, large capacity 50 mesh

suction filters, and spray gun filter

Controls Toggle ‘on/off’ switch located on unit

Spray gun Flexible lance-style spray gun with adjustable nozzle

Hose Each unit is supplied with 5m of spray hose

Battery 12 Volt, 10 Amp-hour,

NOTE: Charger supplied as optional extra

1. WARRANTY AND LIABILITY

Use of the equipment

1.1 You must satisfy yourself as to the suitability of the equipment for your intended use(s) of the

equipment.

Your relationship with the retailer

1.2 Where you consider you have a warranty claim (or any other claim) in relation to the equipment,

you must contact the retailer who sold you the equipment, not C-Dax directly. The retailer is

responsible for liaising with C-Dax in respect of your claim.

Warranty

1.3 C-Dax warrants to the original purchaser that the equipment is sold free from defects in materials

and workmanship for a period of 12 months from date of first retail sale (6 months from date of

first retail sale if the equipment is sold in the U.K.) subject to the terms set out below.

1.4 C-Dax will at its option repair or replace the defective equipment (or part of the equipment) or

notify the retailer of the equipment to refund the purchase price for such defective equipment to

you in the event of a breach of this warranty, subject to the terms set out below.

Unit

Dry Weight

(Kg)

Capacity

(L)

Width

(mm)

Height

(mm)

Length

(mm)

GardenMate 20

12.5

20

400

1020

520

4

Liability

1.5 Except for the warranty set out in clause 1.2 above, all warranties and representations (including

those expressed or implied by law) in respect of the equipment or advice relating to the

equipment provided to you by C-Dax are excluded to the extent permitted by law.

1.6 Notwithstanding anything else in this manual, C-Dax’s maximum liability to you (in the event that

such liability exists) in respect of any breach of warranty, any matter set out in this manual, or for

defective equipment or advice relating to the equipment provided is limited at C-Dax’s option to:

(a) repairing or replacing the equipment (or part of the equipment); or

(b) notifying the retailer of the equipment to refund the price for the equipment paid by you.

1.7 Notwithstanding anything else in this manual, in no event will C-Dax be liable, whether in

contract, tort (including negligence) or otherwise:

(a) where you have altered or modified the equipment, misused or misapplied the equipment,

or the equipment has been subjected to any unusual, excessive or non-recommended use,

service or handling (including as set out in this manual);

(b) where the equipment is not transported, stored, handled or used in accordance with any

directions given by C-Dax (or the retailer) to you (including as set out in this manual);

(c) where the equipment:

(i) has been subject to neglect, accident or hireage, or the damage arises from fair wear

and tear, battery damage or chemical attack;

(ii) has been built to a customer’s specifications; or

(iii) has been dismantled, repaired or serviced other than by an authorised service agent

of C-Dax;

(d) for loss or damage caused by any factors beyond C-Dax’s control; or

(e) for any loss of profit or revenue, or for any special, indirect, incidental or consequential

damage, loss or injury of any kind suffered by you.

1.8 Where C-Dax elects to repair or replace the equipment it will use reasonable endeavours to do so

as soon as practicable but will not be liable for any delay in doing so.

1.9 You agree that the transactions entered into between you and the retailer (and C-Dax) are for the

purposes of trade and that, having regard to all relevant circumstances of the transactions, it is

fair and reasonable that the provisions of the Consumer Guarantees Act 1993 (NZ) do not apply to

those transactions to the fullest extent permitted by law.

5

INSTALLATION

For transport purposes, units are sent partially disassembled –hence some assembly by the user is required. The

following parts are included with each unit:

GardenMate 20

- Handle Assembly - Battery

- Wheel (x2) - Tank, Frame & Hose

- Spray gun Lance - Owner’s Manual

- Battery Cable - 2 x Washers

- 2 x R-Clips - 1 x M5x25 Screw

- 1 x M5x30 Bolt

NOTE

Exploded parts diagrams of the unit can be found at the end of this manual.

GardenMate models are supplied with 12V batteries. If the unit you have purchased is supplied with a battery,

please read the following section carefully.

INSTALLING THE BATTERY

The standard battery fitted is a sealed lead-acid type rated at 12 Volts 10 Ampere-Hours. The battery is shipped in

a charged state. For maximum life the battery must be serviced in accordance with the following instructions.

Failure to comply with these instructions will result in premature failure of the battery.

Charging:

Charge the battery with a current as described in the table below. If using a manual charger the charger must be

monitored during the charging process. The battery charger should be disconnected when the charging has been

completed. Spray switch must be in the ON position in order for the charging circuit to be completed.

Place the battery in the recess or bracket on the unit. Using the supplied battery cable, connect the black wire to

the negative (-) terminal on the battery. Connect the red wire to the positive (+) terminal on the battery. Join the

female 2-pin connector from the switch to the male connector on the pump.

7

THEORY OF OPERATION

Spray fluid is prepared and placed in the tank via the lid opening and strainer basket. Foreign matter is trapped in

the strainer mesh for disposal after the tank has been filled.

When the pump is switched on power is applied to the pump motor from the battery. When the pump operates,

fluid is drawn through the filtered suction line into the pump head.

With each rotation of the pump motor, fluid is forced via valves into a high-pressure chamber in the pump head.

Fluid exits from the chamber and passes through the delivery hose to the handgun.

OPERATING INSTRUCTIONS

Place fluid in the tank through the strainer basket. Turn the switch on. The pump will run. Place the end of the

spray gun in the tank and press the trigger until all of the air has been expelled from the hose. The pump will stop

running when the trigger is released.

Operate the spray gun and adjust the tip until the pump runs smoothly and the desired spray pattern is obtained.

OPERATING HINTS

Pump

If a slight leak develops from between the pumphead components, gently tighten the pumphead screws. If

however, the leak persists or if a leak is observed from between the pumphead and the motor itself, cease

operation immediately and have the pump serviced.

CAUTION

Do not run the pump dry unnecessarily

Spray Gun

Turn the switch on. The pump should build up pressure then automatically switch off. If the pump switches on and

off repeatedly when the spray gun is NOT being used, a leak has occurred either in the delivery housing or the

pump. Repair the problem immediately.

8

CHEMICAL APPLICATION

CAUTION

The Turf and Garden range of 12V sprayers are not high volume sprayers nor ultra low volume. As a general rule

for most spotting applications, label rates under the heading “knapsack rates” would apply.

As no control can be exercised over the use of the equipment or over weather, plant or soil conditions, or over the

storage, handling, mixing, use or application of sprays or chemicals, In-Ex will not accept any liability for loss or

damage (consequential or otherwise) arising directly or indirectly from the use of this equipment.

Chemical Advice

In-Ex or their agents cannot make recommendations or give advice as to the use of chemicals and cannot accept

responsibility for any damage, injury or other consequence for disregarding this warning notice. Contact your

chemical supplier for advice.

WARNING

Mixing chemicals is a most dangerous activity as it involves handling the concentrated material. For toxic

compounds, use protective clothing such as overalls, hat, gloves, boots and respirator.

When using diluted sprays, wear at least a hat, long-sleeved cotton overalls, and boots. If you use pesticides

regularly, it is a good idea to always wear a respirator to avoid accumulation of toxins in the body. Other protection

may be required. Check the label for specific directions for the particular chemical.

Purchasers must ensure that operators of these machines are fully aware of the dangers of spraying chemicals.

MAINTENANCE

Keep the sprayer in good condition. Cleanliness and maintenance are essential for safe and trouble free

operation.

Cleaning

Flush the unit out after each use with a mild detergent solution. Leave fresh water in the pump system for storage.

Filters

Check the filters regularly and clean/replace if necessary.

9

Pressure Switch Adjustments

The pump pressure switch is factory set to 60PSI. Adjustment should not be necessary under normal operating

conditions. Increasing the pressure setting will not increase pump flow but may reduce pump life. To adjust the

switch, rotate the adjustment screw with an Allen key.

TROUBLESHOOTING

In-Ex and their distributors have a comprehensive parts inventory and capable service staff.

Repairs should only be undertaken by In-Ex, or an authorised In-Ex service centre.

Switch on but pump does not

operate

1. Blown fuse

Check wiring and replace

15A fuse

2. Pressure switch operated

Operate spray gun trigger

3. Pressure switch failed

Replace pressure switch

4. On/Off switch failed

Replace switch

Pump runs but does not stop.

1. Spray gun trigger open

Close trigger

2. Air lock in pump

Operate spray gun trigger

until all air is expelled from

the pump and hose.

3. Suction hose loose

Check and tighten all

suction hose connections

between pump inlet and

tank.

4. Dirt or spray residue in

pump valves

Replace valves.

5. Blocked suction filter mesh

Clean filter mesh.

Pump runs but pulses while

pumping

1. Spraying pressure higher

than the pump shut off

pressure

Reduce spraying pressure

by opening the adjustable

spray tip.

2. Pump shut off pressure too

low

Increase pump shut off

pressure. Refer

maintenance.

Fluid leaks from drain holes in

pump

1. Internal leak within pump

head

Remove pump for

servicing.

10

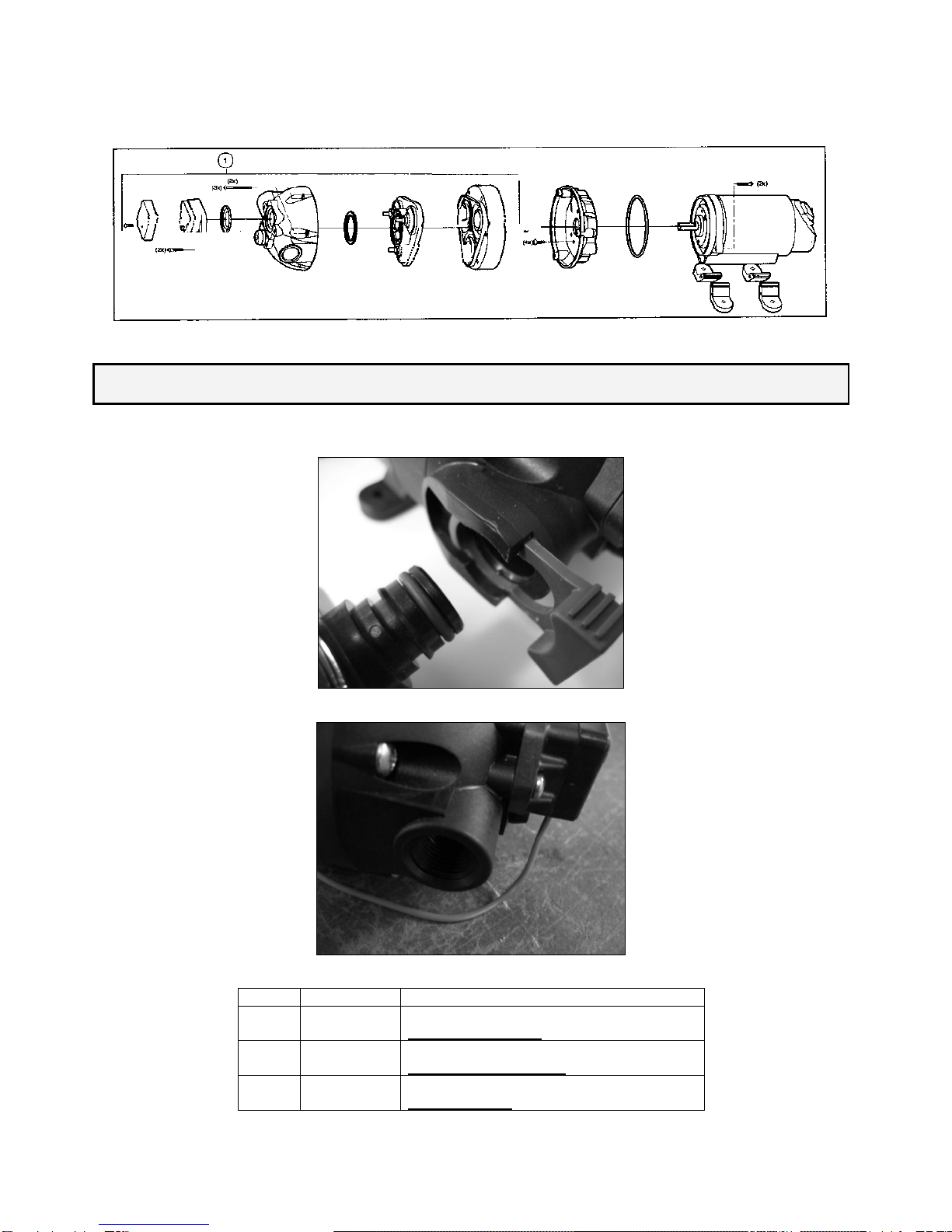

FLOJET SPRAY PUMP RELACEMENT PARTS

The following replacement parts for the 12V Flojet 7.6 L/Min pump are available from any INEX dealer:

NOTE

Please select the correct hose connection type for your pump

Quadport Type:

Screw Type:

ITEM

PART NO.

DESCRIPTION

1

6800-5170

Pumphead Kit (includes pressure switch)

To suit Screw Type

1

6800-5160

Pumphead Kit (includes pressure switch)

To Suit Quadport Type

6800-5000

Replacement Pump

Quadport Type

11

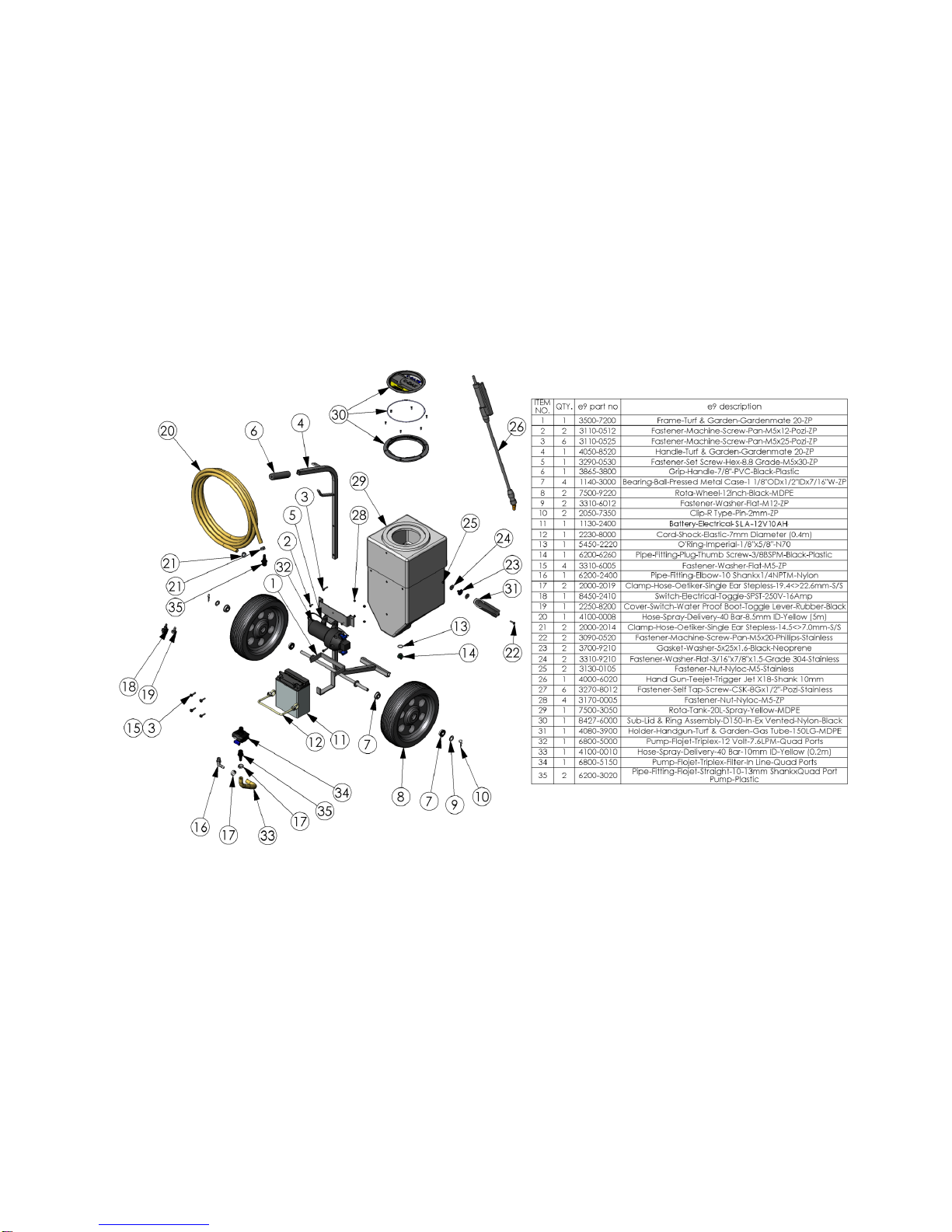

GARDENMATE 20 PARTS DIAGRAM

Table of contents

Other In-Ex Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Nordson

Nordson Trilogy AS product manual

Iwata

Iwata Full Finish G-Series G6 Operating instructions manual

Anest Iwata

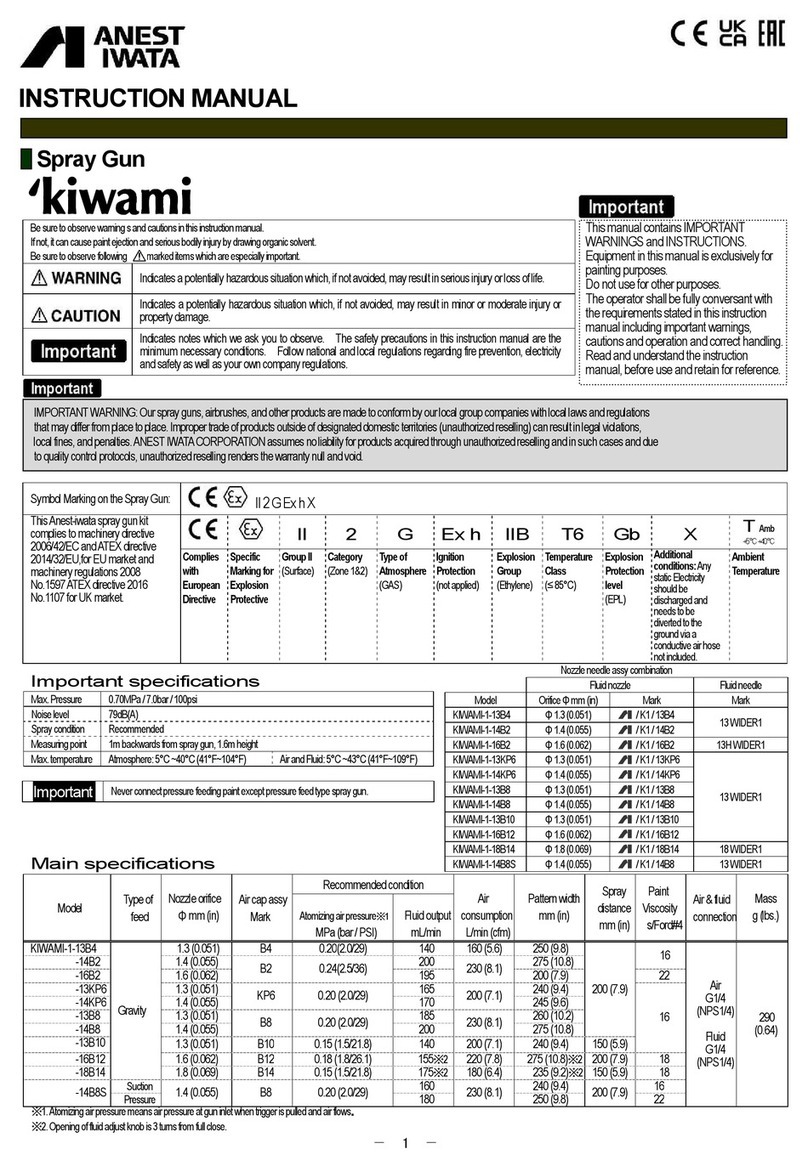

Anest Iwata KIWAMI-1-14B2 instruction manual

Ryobi

Ryobi P2806 Operator's manual

Tornador

Tornador S-100C Operator's safety & operating instruction manual

Carlisle

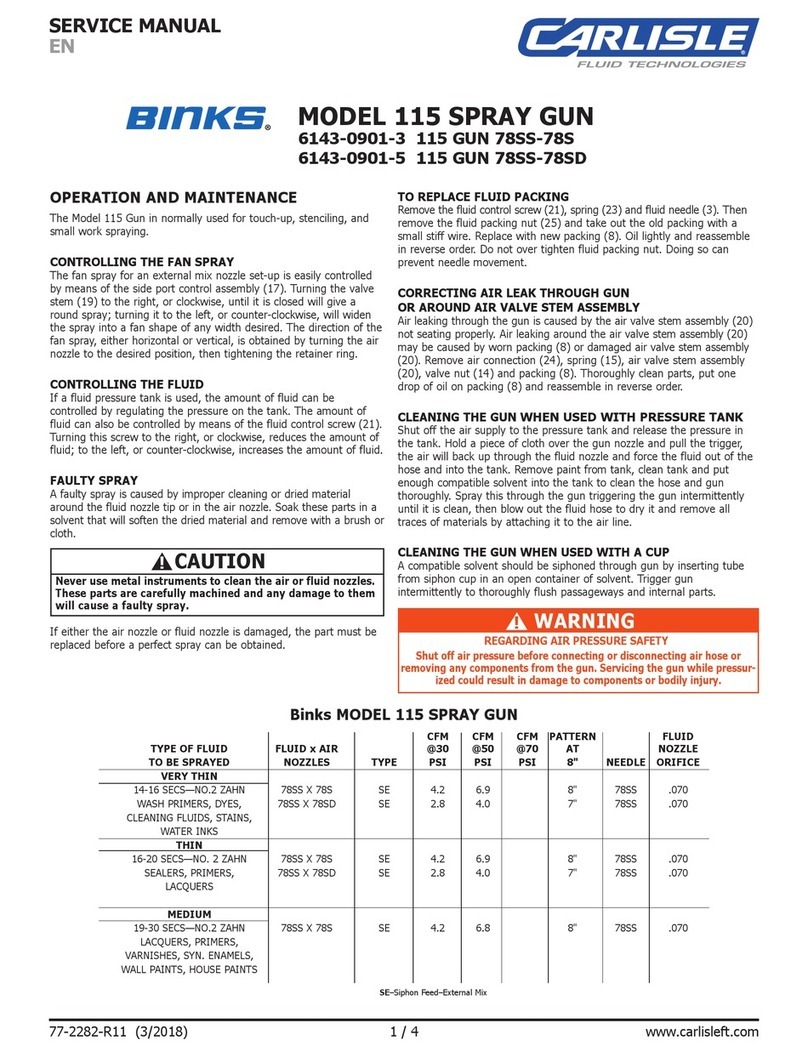

Carlisle BINKS 115 Service manual