Incuvers IRIS User manual

!

USER MANUAL

V1.3.2

1!

!

Index

1 | DELIVERY! 2!

1.1 COMPONENTS! 2!

2 | DEVICE INSTALLATION! 2!

2.1 PLACEMENT! 2!

2.2 TRANSPORT! 3!

2.3 STACKING! 3!

3 | DESCRIPTION OF THE DEVICE! 3!

3.1 INCUBATOR ATMOSPHERE! 3!

3.2 SUPPLY CONNECTIONS! 4!

3.3 INTERNAL WORKING AREA! 5!

4 | GETTING STARTED! 6!

4.1 PREPARING THE INCUBATOR CHAMBER FOR USE: DECONTAMINATION! 6!

4.2 GAS CONNECTION! 7!

! 8!

4.3 POWER SUPPLY CONNECTION! 8!

4.4 SETTING UP IRIS! 9!

4.5 !WORK WITH KNOB AND DISPLAY! 9!

5 | TROUBLESHOOTING!12!

6 | SHUT DOWN!13!

6.1 SHUTTING DOWN THE DEVICE!13!

7 | PARTS AND ACCESSORIES!13!

8 | TECHNICAL DATA!15!

9 | APPENDIX!17!

9.1 ICON LEGEND!17!

9.2 HOW CAN I CUSTOMIZE MY IRIS?!18!

!

2!

!

1 | Delivery

1.1 COMPONENTS

Components delivered

Quantity

Incubator system

1

Shelving parts

2

Water bath tray

1

Power cable

1

User Manual

1

1.2 INSPECTION

Once you have received your device, inspect that all contents are present and

undamaged.

*If damages are detected or any components missing, please contact us

immediately.

2 | Device Installation

2.1 PLACEMENT

To ensure proper functioning and long-term use of the device, it must only be

operated in ambient working conditions including:

● Dry location;

● A level, solid surface capable of sustaining the weight of the device;

An ambient temperature-regulated room with a range of 18 °C to 35°C;

● Maximum relative humidity of 80%;

● Avoid direct exposure to sunlight;

● Devices that produce excessive heat or cooling should not be used near the

IRIS.

It is important to note that this product can consistently release N2, Air, and CO2 to

maintain proper cell culture conditions. As such, do not install this incubator in a room

without proper ventilation as required by the ZH 1/119 (Guidelines for laboratories).

3!

!

2.2 TRANSPORT

*IMPORTANT: Do not lift the device using the door or any external component (e.g.

hose connectors or LCD display) attached to the device

To transport, lift from underneath in an upright position and avoid abrupt shaking.

2.3 STACKING

The IRIS system is fully self-stackable. It is not recommended that you stack more

than 2 IRIS systems at a time. Additionally, the movement or disruption of one could

interfere with the image capture process of the other. During image acquisition, the

incubator should not be disturbed.

3 | DESCRIPTION OF THE DEVICE

3.1 INCUBATOR ATMOSPHERE

The working area within the incubator replicates the physiological conditions needed

for the preparation and cultivation of cells and tissue culture. This atmosphere is

regulated by three factors:

● Temperature;

● Humidity;

● CO2 concentration;

● O2 concentration.

Temperature: To ensure a sustained operating condition, ambient temperature within

the room must be at least 18°C and below the desired temperature of incubation.

Humidity: The water tray for the incubator chamber holds up to 2L of diH2O or dH2O

processed water. The heating of the working area within the incubator causes

evaporation of the water, creating constant humidity within the incubator. Under

working conditions of 37°C, a constant relative humidity of 95% can be achieved. The

water bath tray should be checked every week to ensure the presence of water.

*IMPORTANT: DO NOT USE regular tap or bottled water to refill the water tray

For humidification of the incubator, the following water quality is required:

● dH2O - Distilled water and autoclaved for sterilization

● diH2O- Deionized water and autoclaved for sterilization

4!

!

CO2concentration: The CO2 of the working atmosphere within the incubator can be

regulated between 0-20%. The CO2 gas supply must be of 99.5% purity or medical

grade.

O2Concentration: The O2 of the working atmosphere within the incubator can be

regulated between 0.5-21%. The N2 gas supply must be of 99.5% purity or medical

grade.

*IMPORTANT: When connecting the CO2 / N2 tubing to the supply valve, ensure that

the pressure does not exceed 10 psi or inner component pressure may burst.

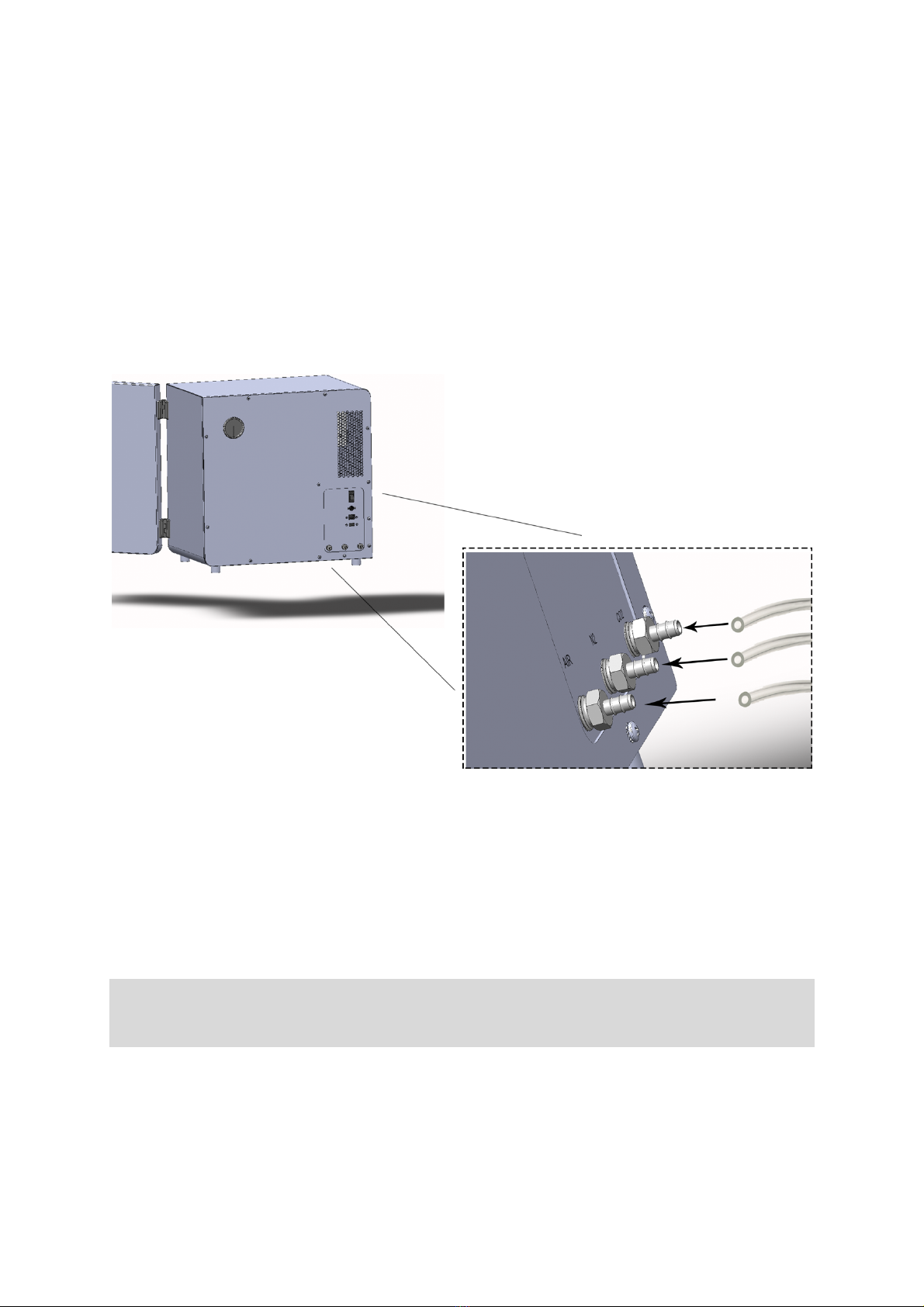

3.2 SUPPLY CONNECTIONS

All supply connections are installed at the rear of the incubator.

Gas connection: The gas supply line between the tank and the incubator is

connected using a ¼’’ NTP connecting valve as shown in Figure 1.

*IMPORTANT: When connecting the N2/CO2/Air tubing to the supply valve, ensure

that the pressure does not exceed 10 psi or inner component pressure may burst.

Electrical Connection: The incubator is powered by a 12v, 10A power supply that

connects into the power jack shown in Figure 1.

Figure 1. The rear of the incubator, where the power jack and power switch are

located at the bottom right corner.

5!

!

3.3 INTERNAL WORKING AREA

The inner chamber of the incubator is a fully enclosed stainless-steel body.

*IMPORTANT: Certain internal components of the incubator may be sensitive to

strong acids/base. Do not use bleach-based cleaning products with a concentration

above 10%. We recommend cleaning the incubator with 70% ethanol and wiping down

with a paper towel.

Do not spray directly up to the imaging area. Doing so may cause irreversible damage

to the optical components.

Water bath tray: As shown in Figure 2, the water tray is positioned underneath the

lower shelving unit. This water tray should be filled at a maximum of 2L and

periodically checked to ensure water is always present.

Heating system: Heating elements are located at the back of the incubator behind

the protective shield. An internal fan ensures an even and cyclical distribution of

heat and humidity within the inner chamber.

Figure 2: Right-hand side cross-section of the incubator for movable components

positioning!

6!

!

4 | GETTING STARTED

4.1 PREPARING THE INCUBATOR CHAMBER FOR USE: DECONTAMINATION

NOTE!

Certain internal components of the incubator may be sensitive to strong acids/base.

Do not use bleach-based cleaning products with a concentration above 10%. We

recommend cleaning the incubator with 70% ethanol and wiping down with a paper

towel.

Do not spray directly into the imaging area. Doing so may cause irreversible damage

to the optical components.

The incubator is not delivered in a sterile state. Before use, the device must be

decontaminated. Prior to decontaminating the chamber:

● Remove the inner shelving components and the water bath tray from the

incubator. These can be cleaned with 70% ethanol or other non-corrosive

cleaning products.

To clean the inner chamber, perform the wipe/spray disinfection protocol as per

recommended by your surface cleaner. This is carried out in three stages:

● Pre-disinfection;

● Cleaning;

● Final disinfection.

Pre-disinfection:

1. Spray disinfectant onto the surfaces of the working area and of the

accessories located inside the chamber;

2. Allow disinfectant to react as specified by the disinfectant manufacturer.

NOTE!

CO2 / O2 sensor: Do not spray disinfectant directly into the ventilation areas. Doing

so may damage the electronic sensors.

Cleaning:

1. Thoroughly remove any residues and deposits using a solution of tepid water

and dishwashing agents;

2. Wipe surfaces cleaning using a clean cloth;

3. Remove cleaning liquid from water tray and wipe all surfaces of the work area

dry;

4. Wipe accessories dry.

7!

!

Final disinfection

1. Re-install shelving system;

2. Spray the disinfectant onto the surfaces of the working area and the

shelving once more. Wipe down dry;

3. Allow disinfectant to react as specified by the

manufacturer.

4.2 GAS CONNECTION

*IMPORTANT: CO2/N2 gas quality must be of 99.5% purity or medical grade.

*CAUTION

Overpressure: The operating pressure of the gas supplied to IRIS cannot exceed 10

psi. Over-pressurization may result in regulation failure and bursting. It is

recommended to set the gas supply level to 10 psi before connecting any supply to

the device.

Connecting CO2 supply:

The CO2 valve is located at the back of the incubator as shown in Figure 3. Firmly slide

your 1/4” tubing over the barbed valve until all barbed edges are within the tube. Lightly

pull on the tubing to ensure a tight fit. If tubing appears loose, or unsecure, ensure

proper 1/4" PVC sizing and repeat.

Connecting N2 supply:

The N2 valve is located at the back of the incubator as shown in Figure 3. Firmly slide

your 1/4” tubing over the barbed valve until all barbed edges are within the tube. Lightly

pull on the tubing to ensure a tight fit. If tubing appears loose, or unsecure, ensure

proper 1/4" PVC sizing and repeat.

Connecting Air/Additional CO2 supply:

8!

!

The air valve is located at the back of the incubator as shown in Figure 3. Firmly slide

your 1/4” tubing over the barbed valve until all barbed edges are within the tube. Lightly

pull on the tubing to ensure a tight fit. If tubing appears loose, or unsecure, ensure

proper 1/4" PVC sizing and repeat.

4.3 POWER SUPPLY CONNECTION

*CAUTION: Contact with current-carrying components may cause lethal electric

shock. Before connecting IRIS to the power supply, inspect the plug and connection

line for damages. Do not connect or use power supply if damages are found.

Connecting Power supply:

Plug power supply into a voltage appropriate socket. Connect the power jack into the

power socket of IRIS as shown in Figure 1. Turn on the device by flipping the power

switch located at the back.

Figure 3: PVC tubing installation at the back of the incubator; air nozzle from

left to right is for: AIR, N2, and CO2 supply, respectively.!

9!

!

4.4 SETTING UP IRIS

Please refer to

IRIS Quick Start Up Guide

for

detailed installation guide.

4.5 WORK WITH KNOB AND DISPLAY

Upon the successful registration of IRIS, the display and knob located at the bottom right

corner of the front can be used for setting up and monitoring experiments locally along with

adjusting the optical parameters.

On the upper left corner of the screen is where the device image is displayed (Figure 4). if no

image has been previously chosen, the default Incuvers image will be present until the user

uploads a new one on the online console (See

How can I customize my IRIS

.) Likewise, users

can also customize the default name of their IRIS (See

How can I customize my IRIS

.)

Figure 4. Incubator UI in Idle State

10!

!

Rotary knob is an efficient way of manually setting condition values (i.e. Co2, O2, and

Temperature). When the rotary knob is turned clockwise or counterclockwise, users shall

notice it promptly responds to their input.

Figure 5. System UI under the

Setting

menu

When rotating the rotary knob, a list of parameters will be shown (Figure 5). Users can

choose to adjust the value by first press the rotary knob. Upon pressing the button, the

dedicated UI for a particular parameter will be shown (Figure 6). Users can then change the

setpoint value by either rotating clockwise or counterclockwise.

11!

!

Figure 6. System UI for setting incubation temperature locally with the knob

Clockwise increments the value and the reverse is true when rotating the knob

counterclockwise. Please note that there are upper and lower constraints in terms of setting

incubation parameters. The value shown on the display will no longer change despite the

rotating knob when the setpoint value met the upper or lower constraint.

*CAUTION: Adjusting the parameter using the rotary knob when an experiment is

taking place will cancel the currently running experiment!

12!

!

5 | TROUBLESHOOTING

In Case

Potential Solution

Device does not power on

● Ensure all cables are connected properly and

there are no obvious signs of cable stress.

● Check obvious cable or incubator enclosure

damage

● Contact [email protected]

Idle state does not appear

● double check to ensure that your device has been

registered or that someone that has access to the

incubator has not performed a factory reset.

The temperature of the inner

chamber has exceeded the

inputted value and cannot be

auto-corrected over time.

● Shut down the system, let cool and restart. If a

problem persists, contact service.

The temperature of the

incubator exterior exceeds

the tolerance range

● Shut down the system, let cool and restart. If a

problem persists, shut down immediately,

disconnect gas lines, and contact service.

The CO2% has exceeded the

imputed value and cannot be

auto-corrected over time.

● Ensure that the flow rate of the tank has not

exceeded 10 psi.

● Shut down the system, let cool and restart. If a

problem persists, contact service.

● Search for a leak in the tubing system.

Device stuck on offline mode

● Most likely cause for the offline status icon to

appear is because there is an issue with your

internet connection in this case please ensure

that your router is configured correctly

● If you’re unsure of your router’s state it may be

best to contact a technician who deals with your

facilities or your residential Wi-Fi.

● If you have ruled out this external issue, please

consider the proximity between the router and the

incubator system.

13!

!

6 | SHUT DOWN

6.1 SHUTTING DOWN THE DEVICE

*CAUTION:

Contamination hazard: The working area of the chamber is contaminated after use,

which may cause bacterial or cellular outgrowth to the surrounding environment of the

device.

We highly recommend decontaminating the area before shutting down.

1. Remove culture containers and all accessories from the working area;

2. Remove the water bath tray;

3. Clean and decontaminate the working area and wipe dry.

- Shut down the device using the power switch located at the back of the incubator;

- Close the gas supply valves;

- Disconnect the gas pressure hose from the barbed valve at the back of the device.

7 | PARTS AND ACCESSORIES

14!

!

When contacting Technical Support for parts and accessories, please have the

following information available:

● Model Number;

● Firmware Version.

*IMPORTANT: Only the use of official Incuvers Inc. components can be used to

repair any damaged incubator. Contact Incuvers Inc. for the replacement of any

components.

*IMPORTANT: Ensure that the PVC tubing is well inserted into the gas nozzles,

failure to do so may result in excessive gas release or inefficient gas supply.

!

15!

!

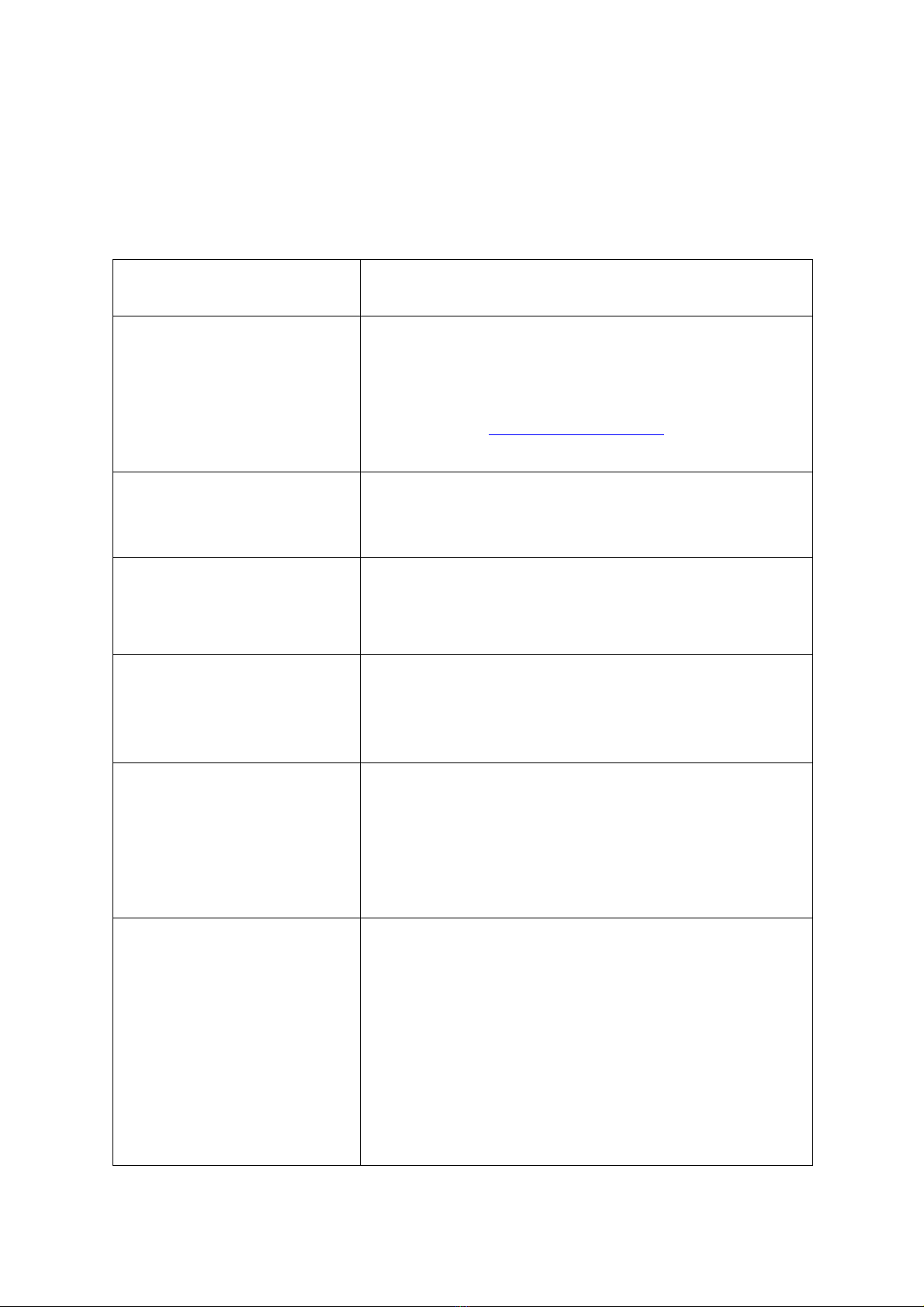

8 | TECHNICAL DATA

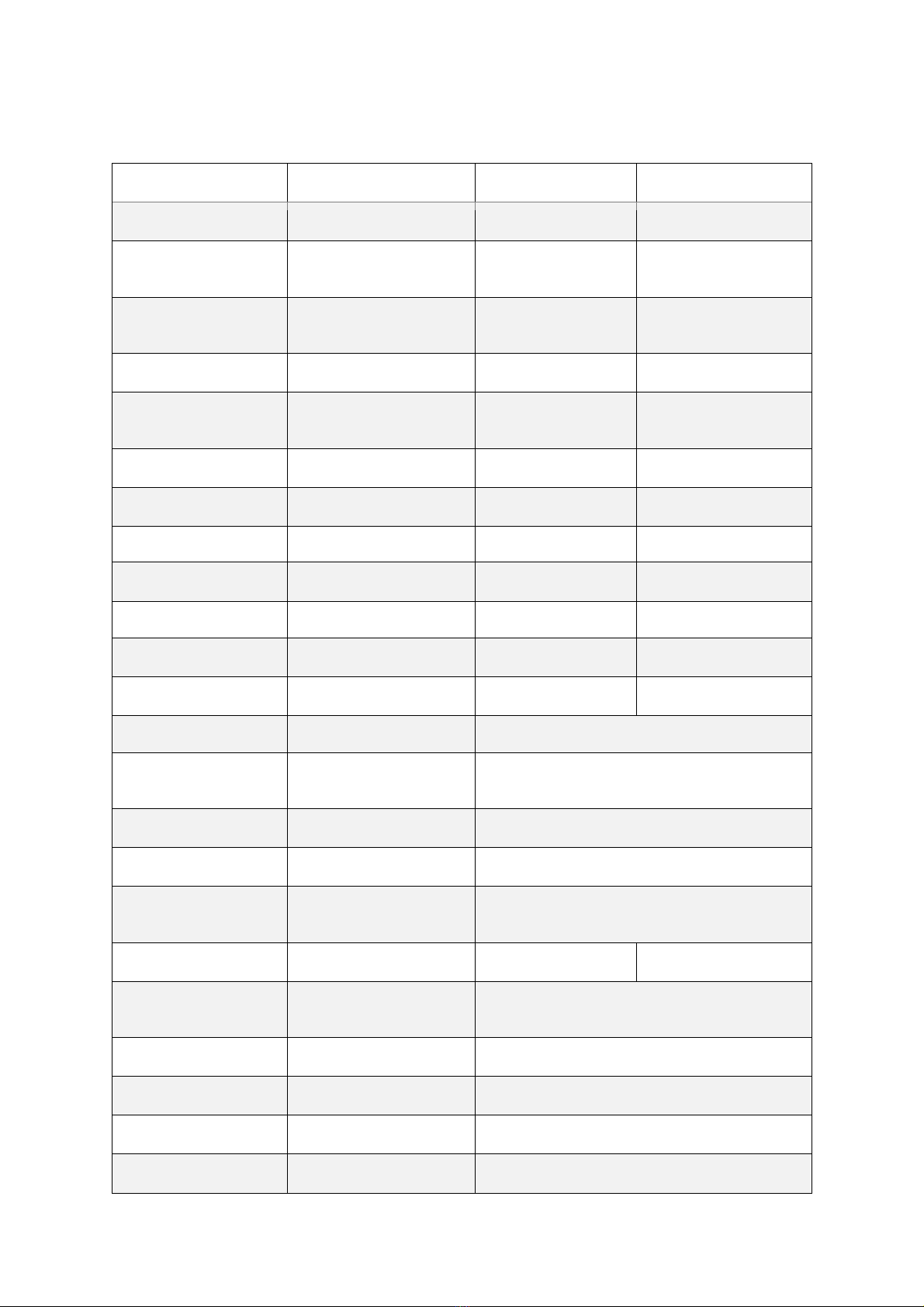

Description

Imperial unit (US)

Metric unit (Int.)

MECHANICAL

External Dimensions

18.5”x14”x19”

47 cm x 35.6 cm x

48.3 cm

Internal Dimensions

10”x11”x16”

25.4 cm x 27.9 cm x

40.6 cm

Chamber Volume

25 L

25 L

Shelving Space

8’ x 11” x 16”

20 cm x 28 cm x

40.6 cm

Weight (w/ shelving)

50 Lbs

22.7 kg

THERMAL

Temperature control

RT – 113 °F

RT – 45 °C

HUMIDITY

Relative Humidity

~90%

~90%

Water Quantity

2 L

2 L

GAS SUPPLY

Gas Purity

Medical grade

Maximum Tank

Pressure

10 psi

Control Deviation

0.1%

Accuracy

±

70 ppm +5% of reading

Measure and Control

Range

CO2 (0.1% - 20%)

O2 (0.1% - 20%)

EXTERNAL POWER

SUPPLY

Source Voltage

110 – 220 V

Rated Frequency

50 - 60 Hz

Rated Current

10 A

Rated Protection

UL, CSA, FCC

Rated Voltage

12 V DC

16!

!

IMAGING

Optimal Arrangement

Inverted

Field of view

Single

Magnification

20 X

Imaging

Phase Contrast

Fluorescence

GFP 488 nm

Local Storage

512 GB

All specifications are assuming NTP conditions and fresh air

!

!

!

17!

!

9 | Appendix

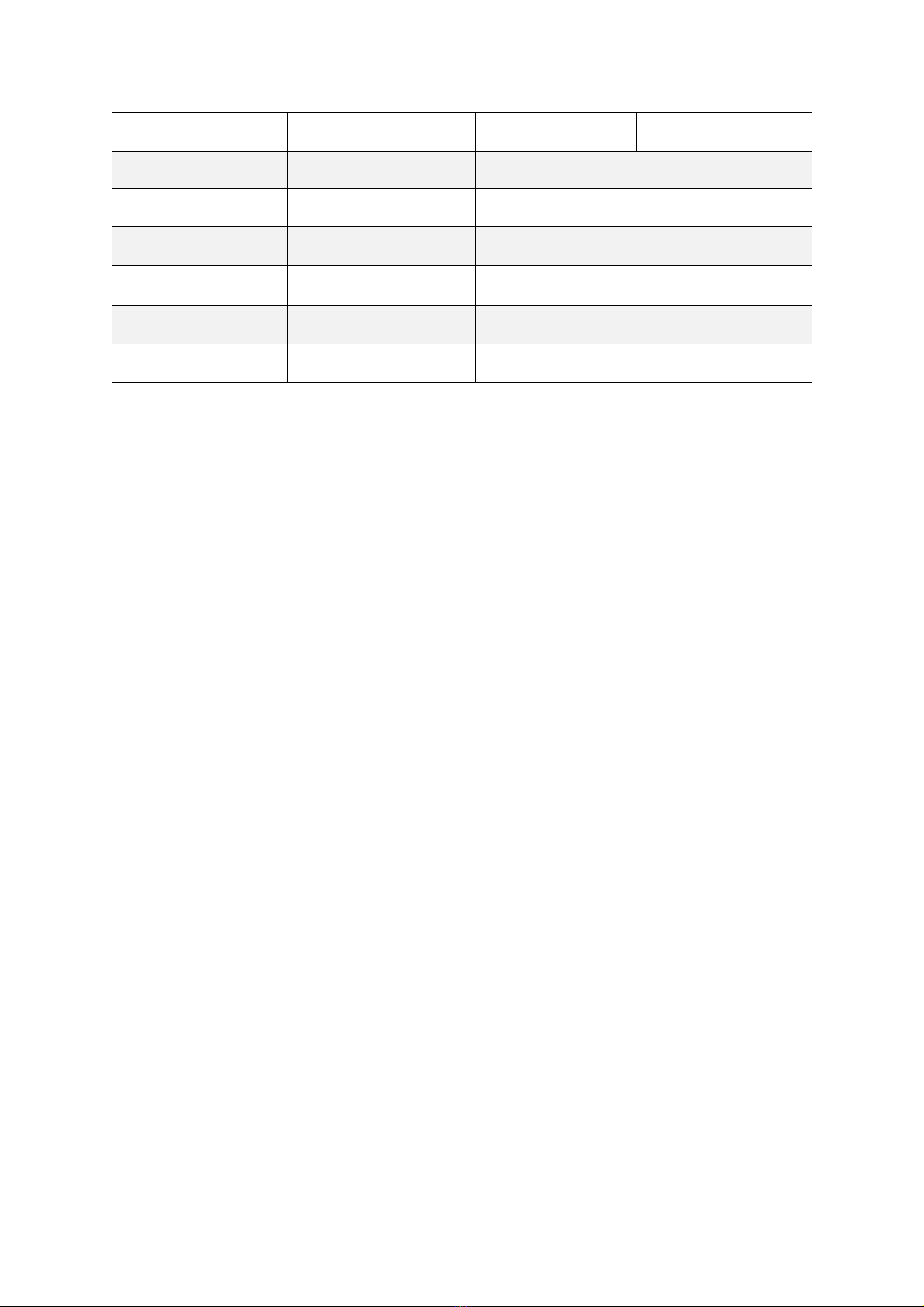

9.1 Icon Legend

Online mode

Online mode icon is displayed when there is a connection to the internet on a registered

device present.

Offline mode

Offline mode icon is displayed when this is no connection to the internet, but the incubator is

still available in offline mode <see here offline mode>

Experiment mode

Experiment mode icon is displayed when there is currently an experiment in progress

Wait icon

The wait icon appears when there is an operation in progress similar to a spinning wheel you

could find in your browser when a page is loading.

!

!

!

!

!

!

!

!

!

!

18!

!

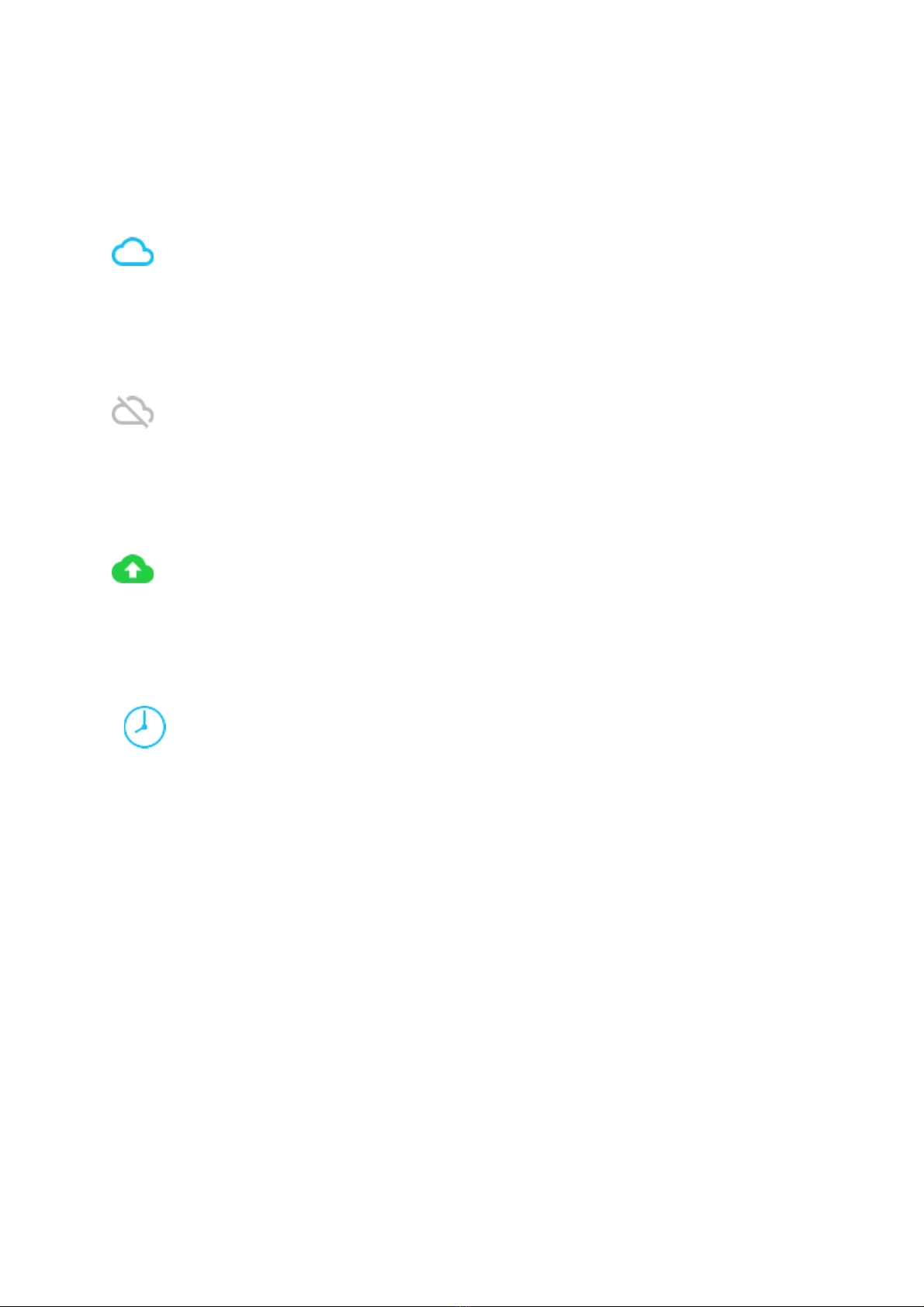

9.2 How can i customize my IRIS?

When you wish to change the device image you need to have access to a device that can

connect to the internet such as your phone or a computer. Please log into your online

console. Now, please click on “details” (Figure i).

Figure i. The UI of online console (

lab.incuvers.com

)

Upon clicking on the details button, a floating window will pop up which allows users to

customize the device image and the device name. To change the device name, update the

text field with “Incubator Name”.

To change the device image, click “select an image” which shall open the file system, upload

the user image from the local file (Figure ii). Upon selecting and resizing the image, it will be

updated automatically.

19!

!

Figure ii. To customize Incubator Name and Avatar (

lab.incuvers.com

)

Table of contents

Popular Accessories manuals by other brands

Avital

Avital 5710 manual

Orno

Orno ENKA DC user manual

Omron

Omron E3X-DA21-S instruction sheet

PCB Piezotronics

PCB Piezotronics IMI SENSORS D643A01 Installation and operating manual

Conrad

Conrad brinno MAS 100 operating instructions

Lippert Components

Lippert Components Solera 795354 Installation and owner's manual