Independence Evo CROSS 100 User manual

Owner´s manual version 1.1 - 06.06.2012

Rescue system

Evo CROSS 100

Evo CROSS 120

Evo CROSS 160

Fly market GmbH & Co. KG

Am Schönebach 3

D-87637 Eisenberg

Tel.: +49-8364-9833-0

Fax: +49-8364-9833-33

Mail: [email protected]

gliders for real pilots

independence

www.independence-world.com

Inhaltsverzeichnis

1. Technical Data

2. Purpose

3. Conditions of use

4. Necessary documentation

5. Mode of operation

6. Inspection of the parachute

7. Behaviour if damages are noticed

8. Storage

9. Maintenance

10. Cleaning

11. Repairs

12. Nature and environment friendly behaviour

13. Environmentally compatible waste disposal

14. Spare parts / changeable parts

15. Structure of the parachute

16. Packing the parachute

17. Mounting in an outer container

18. Mounting / integration to a harness

19. Specialtities for paraglider´s winch towing

20. Pre-flight check

Warning

It´snotallowedtousethisrescueparachuteforskydiving!

AccordingtoEN12491:Notsuitableforusageatspeedsabove32m/s(115km/h).

The rescue systems of the Evo Cross serie are certified according to EN 12491 (European standard) and LTF 91/09

(Germantypeapproval).

The manufacturer can not be made liable for any possible damages to persons or material damages, which may result

fromthisrescueparachutesinanyway.

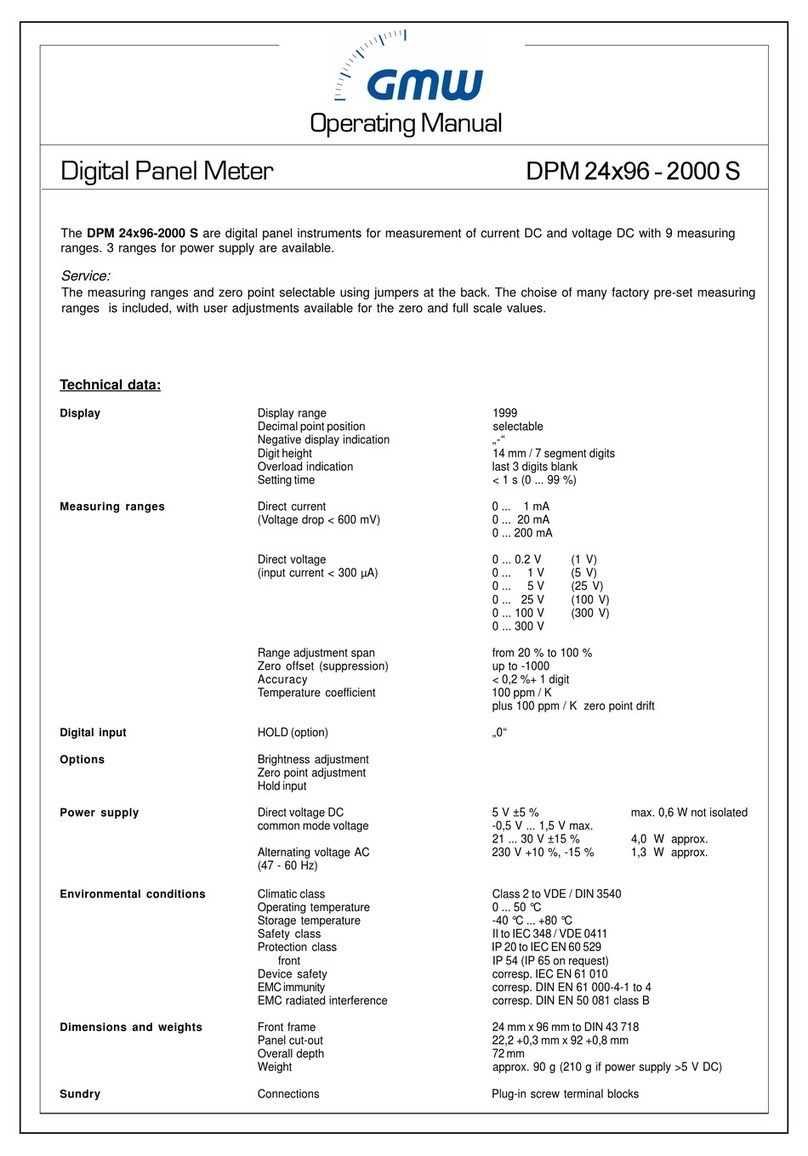

1.TECHNICALDATA

Type: EvoCROSS100,120,160

Manufacturer: FlymarketGmbH&Co.KG

AmSchönebach3

D-87637Eisenberg

Tel.+49-8364-9833-0

Rescueparachute

Weightoftheparachute(kg):

Surface(m²):

Numberoflines/panels:

LengthaccordingtoEN(m)

(Paraglidingversion)

Max.Load(kg)

accordingtoLTF:

Sinkrateatmaxload(LTF)

Max load(kg)

AccordingtoEN(sinkrate5,5m/s)

Volumen(Milliliter)

(Withoutbridle)

Evo Cross

120*

1,9

36,81

8,12

120

4,7 m/s

120

@ sink rate

4,7 m/s

5200

16

Evo Cross

160*

2,4

41,12

8,60

160

5,6 m/s

155

@ sink rate

5,5m/s

5700

20

Evo Cross

100

1,5

25,06

6,92

100

4,9 m/s

100

@ sink rate

4,9 m/s

4500

16

* available as hang gliding version.

Inhaltsverzeichnis

1. Technical Data

2. Purpose

3. Conditions of use

4. Necessary documentation

5. Mode of operation

6. Inspection of the parachute

7. Behaviour if damages are noticed

8. Storage

9. Maintenance

10. Cleaning

11. Repairs

12. Nature and environment friendly behaviour

13. Environmentally compatible waste disposal

14. Spare parts / changeable parts

15. Structure of the parachute

16. Packing the parachute

17. Mounting in an outer container

18. Mounting / integration to a harness

19. Specialtities for paraglider´s winch towing

20. Pre-flight check

Warning

It´snotallowedtousethisrescueparachuteforskydiving!

AccordingtoEN12491:Notsuitableforusageatspeedsabove32m/s(115km/h).

The rescue systems of the Evo Cross serie are certified according to EN 12491 (European standard) and LTF 91/09

(Germantypeapproval).

The manufacturer can not be made liable for any possible damages to persons or material damages, which may result

fromthisrescueparachutesinanyway.

1.TECHNICALDATA

Type: EvoCROSS100,120,160

Manufacturer: FlymarketGmbH&Co.KG

AmSchönebach3

D-87637Eisenberg

Tel.+49-8364-9833-0

Rescueparachute

Weightoftheparachute(kg):

Surface(m²):

Numberoflines/panels:

LengthaccordingtoEN(m)

(Paraglidingversion)

Max.Load(kg)

accordingtoLTF:

Sinkrateatmaxload(LTF)

Max load(kg)

AccordingtoEN(sinkrate5,5m/s)

Volumen(Milliliter)

(Withoutbridle)

Evo Cross

120*

1,9

36,81

8,12

120

4,7 m/s

120

@ sink rate

4,7 m/s

5200

16

Evo Cross

160*

2,4

41,12

8,60

160

5,6 m/s

155

@ sink rate

5,5m/s

5700

20

Evo Cross

100

1,5

25,06

6,92

100

4,9 m/s

100

@ sink rate

4,9 m/s

4500

16

* available as hang gliding version.

2.Purpose

The emergency parachutes are manually-released parachutes for paraglider / hangglider pilots in an emergency situation

whileflying.

3.Conditionsofuse

Maximumspeedforusage:115km/h(32m/s)

Intervalforrepacking:12month,thentherescueparachutehastoberepackedandthisrepackinghastoberecordedinthe

“Repackandinspectionlogbook”.

Interval of inspection: 24 month, then a complete inspection of the rescue parachute is necessary. The inspection have to

berecordedinthe“Repackandinspectionlogbook”.

Operational lifespan of parachute: 10 years. The lifespan can be extended for 2 more years if the rescue parachute is

inspectedyearlyduringthislasttwoyears.Sothetotalmax.possiblelifespanis12years.

4.Necessarydocumentation

a)Owner´smanual

b)Repackandinspectionlogbook

5.Modeofoperation

During an emergency situation while flying the pilot pulls at the release handle with a firm tug. Thereby the outer container

opensandthedeploymentbagisreleased.Afterthattherescueparachutepackage(whichisstillpackedinit´sdeployment

bag)havetobethrownwithadynamicmoveintothefreeair-space.Thatmeansthereleasehandlehavetobethrownaway

togetherwiththedeploymentbag!!!

Thedeploymentbagandtheconnectionbridle,aredesignedinawaywhichreleasesthelinesandcanopyoftheparachute

notbeforetheparachutepackageisthrownaway.

This prevents an unintentional or too early opening of the rescue parachute. This is minimizing the danger of tangling up

with the paraglider, the pilot or the reason which maybe causal for the emergency case (e.g. collision with another

paraglider).

Moreover the maximum throwing speed of the deployment bag should be reached when the deployment bag leaves the

pilothand.

Ingeneral:Thefastertherescueparachutepackageisthrownaway,thequickertheparachutewillopen.

After the throw the depolyment bag opens and releases lines and canopy. The powerful throw and/or the airstream

stretchesthelinesandcanopynowtherescueparachutesopens.

Aftertherescueparachuteisopenedcompletely,youfirsthavetocheckthealtitudeaboveground.

If you have still enough height you should ty to make the paraglider unable to fly according to the doctrine, to avoid an V-

positionoftheparagliderandtherescueparachute.

Ifyoudonothaveenoughheightanymore,justfocusonthegroundandprepareyourselfforthelandingfall.

6.Inspectionoftheparachute

Aparachutemustbe controlledby aregisteredpacker beforeit ispacked.Afteranemergencyopeningthe parachutemust

be inspected by the manufacturer or a workshop which is authorized by the manufacturer. After a re-pack the rescue

parachuteshouldundergoareleasetest.Thisverifiesthattheopeningforceoftheharnesscontaineroroutsidecontaineris

in between2daNand7daN.

Acompatibility test must be performed by an authorized person if the rescue system and harness (with integrated rescue

container)ismountedthefirsttimeinthiscombination.Thecompatibilitymustberecordedintheparachutelogbook.

7.Behaviourifdamagesarenoticed

If you notice any damage at the rescue parachute, which may affect the airworthy condition of the rescue parachute, you

have to send the rescue parachute for inspection/repair to the manufacturer.Also, if you are not sure about the airworthy

conditioninanyway,youhavetosendtheparachutetothemanufacturer.

Attention:Chemicals,detergents,insects,mouldstainsor thelikecanhavethe samenegativeeffectstothestrengthofthe

partsasmechanicalinfluences.

8.Storage

Oil, grease, acid and paint should not be stored near the parachute. The storage space should be dry. Parachutes which

havenotbeenusedforalongperiodoftimeshouldbeopenedandthecanopylooselyrolledandstoredinabag.

Avoidunnecessaryhightemperature(e.ginaparkingcar)!

9.Maintenance

Thelifespanandconditiondepends mainlyuponhow carefullyyou handleandmaintain yourparachute.Out ofthisreason

werecommendtocontroltheparachuteregularly,atthelatestifitisrepacked,ifthereareanywearsordamages.

Duringnormaluseyouhavetotakecareofthefollowingpoints:

If the parachute got wet, you have to open it and dry it at a well-ventilated place as soon as possible (but avoid direct

sunlight!)Thefastdryingisimportanttoavoidmouldstains.Aftertheparachuteiscompletedryitcanberepacked.

Iftheparachuteisstrainedmorethannormal(forexample:acardroveovertheharnessinwhichtheparachuteisplaced,or

itmaybeisdamagedbyasharpobject,oranyotherpossibledamage),youhavetosendtheparachutetothemanufacturer

tocheckit.

Avoidcontactwithsaltwater,acidsorotheraggressivesubstances!

Alsoavoidunnecessaryexposuretosunlight,causetheUVraysmaydamagethemolecularstructureofthematerial.

10.Cleaning

Adirtycanopyandcontainercanbecarefullycleanedwithclearwaterandasoftsponge.

Attention: Never use detergents, chemicals, brushes or hard sponges to clean the parachute! Also a cleaning in the

washingmaschineisnotallowed.

If the rescue parachute gets in contact with salt water, you have to wash it with fresh water. A cleaning accelerates the

ageingofthesystem.

11.Repairs

Repairjobshavetobeperformedonlybythemanufactureroraworkshopwhichiscertifiedbythemanufacturer.

12.Natureandenvironmentfriendlybehaviour

Pleasedoournature-nearsportinawaywhichdonotstressnatureandenvironment!Donotwalkbesidethemarkedways,

don´tleaveyour litter,don´tmake unnecessaryloud noisesand respectthe sensitivebalance inthe mountains.Especially

atthetake-offwehavetotakecareforthenature!

13.Environmentallycompatiblewastedisposal

Thematerialsof whicha rescueparachute ismade requiresa special wastedisposal. Soplease senddisused parachutes

backtous.Wewillcareaboutanprofessionalwastedisposal.

14.Spareparts/changeableparts

Excepttherubberbands ofthe innercontainerandsealingthreadnosparepartisnecessaryat theEvoCrossseries.Only

approved rubber bands with the size 30x3x1 mm or 25x3x1 mm should be used! An inexpensive purchase is possible

throughus.

The deployment bag is except for the use of an under point 18.4. described the deployment bag part of the rescue system

and may not be exchanged for an other one. If another deployment bag as described is used you will loose the type

approval.

2.Purpose

The emergency parachutes are manually-released parachutes for paraglider / hangglider pilots in an emergency situation

whileflying.

3.Conditionsofuse

Maximumspeedforusage:115km/h(32m/s)

Intervalforrepacking:12month,thentherescueparachutehastoberepackedandthisrepackinghastoberecordedinthe

“Repackandinspectionlogbook”.

Interval of inspection: 24 month, then a complete inspection of the rescue parachute is necessary. The inspection have to

berecordedinthe“Repackandinspectionlogbook”.

Operational lifespan of parachute: 10 years. The lifespan can be extended for 2 more years if the rescue parachute is

inspectedyearlyduringthislasttwoyears.Sothetotalmax.possiblelifespanis12years.

4.Necessarydocumentation

a)Owner´smanual

b)Repackandinspectionlogbook

5.Modeofoperation

During an emergency situation while flying the pilot pulls at the release handle with a firm tug. Thereby the outer container

opensandthedeploymentbagisreleased.Afterthattherescueparachutepackage(whichisstillpackedinit´sdeployment

bag)havetobethrownwithadynamicmoveintothefreeair-space.Thatmeansthereleasehandlehavetobethrownaway

togetherwiththedeploymentbag!!!

Thedeploymentbagandtheconnectionbridle,aredesignedinawaywhichreleasesthelinesandcanopyoftheparachute

notbeforetheparachutepackageisthrownaway.

This prevents an unintentional or too early opening of the rescue parachute. This is minimizing the danger of tangling up

with the paraglider, the pilot or the reason which maybe causal for the emergency case (e.g. collision with another

paraglider).

Moreover the maximum throwing speed of the deployment bag should be reached when the deployment bag leaves the

pilothand.

Ingeneral:Thefastertherescueparachutepackageisthrownaway,thequickertheparachutewillopen.

After the throw the depolyment bag opens and releases lines and canopy. The powerful throw and/or the airstream

stretchesthelinesandcanopynowtherescueparachutesopens.

Aftertherescueparachuteisopenedcompletely,youfirsthavetocheckthealtitudeaboveground.

If you have still enough height you should ty to make the paraglider unable to fly according to the doctrine, to avoid an V-

positionoftheparagliderandtherescueparachute.

Ifyoudonothaveenoughheightanymore,justfocusonthegroundandprepareyourselfforthelandingfall.

6.Inspectionoftheparachute

Aparachutemustbe controlledby aregisteredpacker beforeit ispacked.Afteranemergencyopeningthe parachutemust

be inspected by the manufacturer or a workshop which is authorized by the manufacturer. After a re-pack the rescue

parachuteshouldundergoareleasetest.Thisverifiesthattheopeningforceoftheharnesscontaineroroutsidecontaineris

in between2daNand7daN.

Acompatibility test must be performed by an authorized person if the rescue system and harness (with integrated rescue

container)ismountedthefirsttimeinthiscombination.Thecompatibilitymustberecordedintheparachutelogbook.

7.Behaviourifdamagesarenoticed

If you notice any damage at the rescue parachute, which may affect the airworthy condition of the rescue parachute, you

have to send the rescue parachute for inspection/repair to the manufacturer.Also, if you are not sure about the airworthy

conditioninanyway,youhavetosendtheparachutetothemanufacturer.

Attention:Chemicals,detergents,insects,mouldstainsor thelikecanhavethe samenegativeeffectstothestrengthofthe

partsasmechanicalinfluences.

8.Storage

Oil, grease, acid and paint should not be stored near the parachute. The storage space should be dry. Parachutes which

havenotbeenusedforalongperiodoftimeshouldbeopenedandthecanopylooselyrolledandstoredinabag.

Avoidunnecessaryhightemperature(e.ginaparkingcar)!

9.Maintenance

Thelifespanandconditiondepends mainlyuponhow carefullyyou handleandmaintain yourparachute.Out ofthisreason

werecommendtocontroltheparachuteregularly,atthelatestifitisrepacked,ifthereareanywearsordamages.

Duringnormaluseyouhavetotakecareofthefollowingpoints:

If the parachute got wet, you have to open it and dry it at a well-ventilated place as soon as possible (but avoid direct

sunlight!)Thefastdryingisimportanttoavoidmouldstains.Aftertheparachuteiscompletedryitcanberepacked.

Iftheparachuteisstrainedmorethannormal(forexample:acardroveovertheharnessinwhichtheparachuteisplaced,or

itmaybeisdamagedbyasharpobject,oranyotherpossibledamage),youhavetosendtheparachutetothemanufacturer

tocheckit.

Avoidcontactwithsaltwater,acidsorotheraggressivesubstances!

Alsoavoidunnecessaryexposuretosunlight,causetheUVraysmaydamagethemolecularstructureofthematerial.

10.Cleaning

Adirtycanopyandcontainercanbecarefullycleanedwithclearwaterandasoftsponge.

Attention: Never use detergents, chemicals, brushes or hard sponges to clean the parachute! Also a cleaning in the

washingmaschineisnotallowed.

If the rescue parachute gets in contact with salt water, you have to wash it with fresh water. A cleaning accelerates the

ageingofthesystem.

11.Repairs

Repairjobshavetobeperformedonlybythemanufactureroraworkshopwhichiscertifiedbythemanufacturer.

12.Natureandenvironmentfriendlybehaviour

Pleasedoournature-nearsportinawaywhichdonotstressnatureandenvironment!Donotwalkbesidethemarkedways,

don´tleaveyour litter,don´tmake unnecessaryloud noisesand respectthe sensitivebalance inthe mountains.Especially

atthetake-offwehavetotakecareforthenature!

13.Environmentallycompatiblewastedisposal

Thematerialsof whicha rescueparachute ismade requiresa special wastedisposal. Soplease senddisused parachutes

backtous.Wewillcareaboutanprofessionalwastedisposal.

14.Spareparts/changeableparts

Excepttherubberbands ofthe innercontainerandsealingthreadnosparepartisnecessaryat theEvoCrossseries.Only

approved rubber bands with the size 30x3x1 mm or 25x3x1 mm should be used! An inexpensive purchase is possible

throughus.

The deployment bag is except for the use of an under point 18.4. described the deployment bag part of the rescue system

and may not be exchanged for an other one. If another deployment bag as described is used you will loose the type

approval.

15.Structureoftheparachute

Theparachutestructureissquareandhas,dependingonthemodel16or20gores(see“technicaldatas”)

Thecanopyismadeoftearrestistant,highstrenghtnylonfabric.Themainseamsareflatfellseamsandarereinforcedby

a band. The lines are sewn to the canopy and reinforced with V-tapes at the canopy. The crown is pulled down by the

centerlines.Alllinesandcenterlinesareconnectedtothebridle.

The bridle has a strength of more than 2400 daN. Hang gliding models only differ from paragliding models by a longer

bridle.

Standarddeploymentbag:

The deployment bag is made of nylon fabric and gets closed

atthreepoints.

Ontheflatside ofthedeployment bagarefourloops.Atone oftheseloopstherelease-handle oftheoutercontaineror the

harnessistobeattached.

Theoutercontainerismadeofrobust,water-repellentnylonfabric.Itconsistsof2lateralflaps,theupperandlowerflap,the

release-handlewith2pins,whichclosethecontainer.

Backside of the outercontainer,

with attachment-points

Outercontainer open

Velcro-tapes for attaching

the container to the harness

Release-handle

Attachment points for

release-handle

2. Separate the lines left and right the center lines (marked

yellow) and check that they are not crossed and running

free.

16. Packing the parachute

3. Separate canopy and lines to the left and right that

panels marked with 1 are on top, panels no 9 (Evo Cross

160:10)onthebottom.

4. Hook in packing cord. Bundle the lines, stretch the lines

by fixing the bridle on the other end and put the canopy to

theleftside.

5. Place panel 9 (Evo Cross 160: panel 11) centered to the

the floor and arrange panel 8 (Evo Cross 160: panel 10) to

theside.

6.Arrange the upper part of panel 8 (Evo Cross 160: panel

10)totheside.

Bridle

Suspension

lines

Canopy

Line

attachment

points

Packing loopsPacking loops

Packing loops

in corners

Packing loops

in corners

Attachmen p inst o t

f apex lines

o

1. Slide on the packing loops on a line (packing cord). The

packing loops are colored to find them more easy. At the

corners they are green, yellow on the sides. Slide on 3

yellowpackingloopsinbetweenthegreenones(EvoCross

160:4).

Optionaldeploymentbag:

Thedeploymentbagisavailableas anoptionifa smaller

packing volume is needed. The construction is a hybrid

ofacloverleafandapocketcontainer.

Attachment points for

release-handle

15.Structureoftheparachute

Theparachutestructureissquareandhas,dependingonthemodel16or20gores(see“technicaldatas”)

Thecanopyismadeoftearrestistant,highstrenghtnylonfabric.Themainseamsareflatfellseamsandarereinforcedby

a band. The lines are sewn to the canopy and reinforced with V-tapes at the canopy. The crown is pulled down by the

centerlines.Alllinesandcenterlinesareconnectedtothebridle.

The bridle has a strength of more than 2400 daN. Hang gliding models only differ from paragliding models by a longer

bridle.

Standarddeploymentbag:

The deployment bag is made of nylon fabric and gets closed

atthreepoints.

Ontheflatside ofthedeployment bagarefourloops.Atone oftheseloopstherelease-handle oftheoutercontaineror the

harnessistobeattached.

Theoutercontainerismadeofrobust,water-repellentnylonfabric.Itconsistsof2lateralflaps,theupperandlowerflap,the

release-handlewith2pins,whichclosethecontainer.

Backside of the outercontainer,

with attachment-points

Outercontainer open

Velcro-tapes for attaching

the container to the harness

Release-handle

Attachment points for

release-handle

2. Separate the lines left and right the center lines (marked

yellow) and check that they are not crossed and running

free.

16. Packing the parachute

3. Separate canopy and lines to the left and right that

panels marked with 1 are on top, panels no 9 (Evo Cross

160:10)onthebottom.

4. Hook in packing cord. Bundle the lines, stretch the lines

by fixing the bridle on the other end and put the canopy to

theleftside.

5. Place panel 9 (Evo Cross 160: panel 11) centered to the

the floor and arrange panel 8 (Evo Cross 160: panel 10) to

theside.

6.Arrange the upper part of panel 8 (Evo Cross 160: panel

10)totheside.

Bridle

Suspension

lines

Canopy

Line

attachment

points

Packing loopsPacking loops

Packing loops

in corners

Packing loops

in corners

Attachment points

of apex lines

1. Slide on the packing loops on a line (packing cord). The

packing loops are colored to find them more easy. At the

corners they are green, yellow on the sides. Slide on 3

yellowpackingloopsinbetweenthegreenones(EvoCross

160:4).

Optionaldeploymentbag:

Thedeploymentbagisavailableas anoptionifa smaller

packing volume is needed. The construction is a hybrid

ofacloverleafandapocketcontainer.

Attachment points for

release-handle

7.Arrangepanel7.(EvoCross160:panel9/8) 8. Arrange panel 6 and upper part of panel 5 to the side.

(EvoCross160:panel7,upperpartofpanel6)

9.Arrangepanel5(cornerpanel)(EvoCross160:panel6) 10.Arrangepanel4andupperparttotheside.(EvoCross

160:panel5)

11.Arrangepanel3.(EvoCross160:panel4/3) 12.Arrangepanel2andupperpartofpanel1totheside.

13. Arrange panel 1 (corner panel) and place a packing

weight onto the peripery. 14.Foldtheleftsideontotherightside.

15.Placepanel9(EvoCross160:panel11)centeredtothe

the floor and arrange panel 8 (Evo Cross 160: panel 10) to

theside.

16.Arrange the upper part of panel 8 (Evo Cross 160: panel

10)totheside.

17.Arrangepanel7.(EvoCross160:panel9/8) 18. Arrange panel 6 and upper part of panel 5 to the side.

(EvoCross160:panel7,upperpartofpanel6)

7.Arrangepanel7.(EvoCross160:panel9/8) 8. Arrange panel 6 and upper part of panel 5 to the side.

(EvoCross160:panel7,upperpartofpanel6)

9.Arrangepanel5(cornerpanel)(EvoCross160:panel6) 10.Arrangepanel4andupperparttotheside.(EvoCross

160:panel5)

11.Arrangepanel3.(EvoCross160:panel4/3) 12.Arrangepanel2andupperpartofpanel1totheside.

13. Arrange panel 1 (corner panel) and place a packing

weight onto the peripery. 14.Foldtheleftsideontotherightside.

15.Placepanel9(EvoCross160:panel11)centeredtothe

the floor and arrange panel 8 (Evo Cross 160: panel 10) to

theside.

16.Arrange the upper part of panel 8 (Evo Cross 160: panel

10)totheside.

17.Arrangepanel7.(EvoCross160:panel9/8) 18. Arrange panel 6 and upper part of panel 5 to the side.

(EvoCross160:panel7,upperpartofpanel6)

19.Arrangepanel5(cornerpanel)(EvoCross160:panel6) 20.Arrangepanel4andupperparttotheside.(EvoCross

160:panel5)

21.Arrangepanel3.(EvoCross160:panel4/3) 22.Arrangepanel2andupperpartofpanel1totheside.

23. Arrange panel 1 (corner panel) and place a packing

weight onto the peripery. 24.FoldrightsideS-shaped.(Step1)

25.FoldleftsideS-shaped.(Step2) 26.Removepackingcord.

27a.Stowtopofthecanopyinthedeploymentbag. 28a.FoldtherestofthecanopyinsmallS-foldsandplaceit

infrontofthedeploymentbag.

29 a. Put the S-folded canopy in the

deploymentbag. 30 a. Bundle the lines in 3x3 “8-

shaped”hanks.Donotbundlethelast

50cmoflines.

Schematic

illustration

S-fold

Schematic

illustration

S-fold

Schematic

illustration

S-fold

Schematic

illustration

S-fold

31 a. Close the deployment bag with

the lines. First in the middle then the

sides.

Attention: You have to use new rubber bands for hanks and deployment

bageverytimetheparachuteispacked.

Versiona)pocketdeploymentbag(standardversion):

19.Arrangepanel5(cornerpanel)(EvoCross160:panel6) 20.Arrangepanel4andupperparttotheside.(EvoCross

160:panel5)

21.Arrangepanel3.(EvoCross160:panel4/3) 22.Arrangepanel2andupperpartofpanel1totheside.

23. Arrange panel 1 (corner panel) and place a packing

weight onto the peripery. 24.FoldrightsideS-shaped.(Step1)

25.FoldleftsideS-shaped.(Step2) 26.Removepackingcord.

27a.Stowtopofthecanopyinthedeploymentbag. 28a.FoldtherestofthecanopyinsmallS-foldsandplaceit

infrontofthedeploymentbag.

29 a. Put the S-folded canopy in the

deploymentbag. 30 a. Bundle the lines in 3x3 “8-

shaped”hanks.Donotbundlethelast

50cmoflines.

Schematic

illustration

S-fold

Schematic

illustration

S-fold

Schematic

illustration

S-fold

Schematic

illustration

S-fold

31 a. Close the deployment bag with

the lines. First in the middle then the

sides.

Attention: You have to use new rubber bands for hanks and deployment

bageverytimetheparachuteispacked.

Versiona)pocketdeploymentbag(standardversion):

17. Mounting in an outercontainer

1. Connect the release handle at the loop in the middle of

the deployment bag. Place the bridle at the side of the

containerwhichyouprefer.

2.Closethe twolateral flaps ofthe outercontainerwithtwo

packing-cords and closed it with the pins of the handle

provisionally.

3.Closetheupperandlower flapwiththepins. Removethe

packingcordsthen! 4. Close the upper flap finally. Notice the packing in the

“repackandinspectionlogbook”.

5. To avoid an unintentional opening, the German type

approval (LTF) prescribe a minimum release-force of 20 N.

Ifthesystemdoesnothavethisminimumrelease-force,itis

necessary to build in a predetermined breaking point

(special thread). This have to define a minimum release

forceof20N.

The special thread which is used as predetermined

breaking point must be put through the hole of the pin and

aroundtheloopasshownonthepicture.

Bothendsofthis specialthreadarefixed withaknotand an

additionalseal.

To secure the pin it is only allowed to use certified material

because if the strength of this material is too high the save

operationoftherescuesystemisnotguaranteed.

This thread is supplied by Fly market GmbH & Co. KG! Do

notuseotherthreadswhichmaylookthesame!

Versionb)hybriddeploymentbag(optional):

27b.Stowtopofthecanopyinthedeploymentbag. 28b.FoldtherestofthecanopyinS-folds(stack-pack).

31b.Closetheleftandrightside.

29 b. Bundle the lines in 3x3 “8-shaped” hanks. Do not

bundlethelast70cmoflines. 30 b. Close the deployment bag with the lines. First the

long side. 1) then 2). No 2) is to be closed with the middle

grommetoftheremainingflapA).

Attention: You have to use new rubber bands for

hanksanddeploymentbageverytimetheparachute

ispacked.

11

22

AA

17. Mounting in an outercontainer

1. Connect the release handle at the loop in the middle of

the deployment bag. Place the bridle at the side of the

containerwhichyouprefer.

2.Closethe twolateral flaps ofthe outercontainerwithtwo

packing-cords and closed it with the pins of the handle

provisionally.

3.Closetheupperandlower flapwiththepins. Removethe

packingcordsthen! 4. Close the upper flap finally. Notice the packing in the

“repackandinspectionlogbook”.

5. To avoid an unintentional opening, the German type

approval (LTF) prescribe a minimum release-force of 20 N.

Ifthesystemdoesnothavethisminimumrelease-force,itis

necessary to build in a predetermined breaking point

(special thread). This have to define a minimum release

forceof20N.

The special thread which is used as predetermined

breaking point must be put through the hole of the pin and

aroundtheloopasshownonthepicture.

Bothendsofthis specialthreadarefixed withaknotand an

additionalseal.

To secure the pin it is only allowed to use certified material

because if the strength of this material is too high the save

operationoftherescuesystemisnotguaranteed.

This thread is supplied by Fly market GmbH & Co. KG! Do

notuseotherthreadswhichmaylookthesame!

Versionb)hybriddeploymentbag(optional):

27b.Stowtopofthecanopyinthedeploymentbag. 28b.FoldtherestofthecanopyinS-folds(stack-pack).

31b.Closetheleftandrightside.

29 b. Bundle the lines in 3x3 “8-shaped” hanks. Do not

bundlethelast70cmoflines. 30 b. Close the deployment bag with the lines. First the

long side. 1) then 2). No 2) is to be closed with the middle

grommetoftheremainingflapA).

Attention: You have to use new rubber bands for

hanksanddeploymentbageverytimetheparachute

ispacked.

11

22

AA

18.1.harnesseswithoutintegratedrescuesystemcontainer:

If the harness does not have an integrated rescue system container use one of the outercontainer which is shown at point

15.

The outercontainer shown at point 15 has got several loops, eyelets and velcro-tapes on it´s back side to attach it at the

harness.The possibilitiesoftheattachmenttotheharness dependsontheharness.Foracorrect mountingon theharness

pleaserefertotheharnessmanual.

18.2.Usageofafrontcontainer/outercontainerofanothermanufacturer:

The possible usage of a front container or of an outercontainer of an other manufacturer depends on the size and if the

container is certified. If the container is too small or not certified the operating license of the rescue system expires. If it is a

containerofanothermanufactureryouhavetoreadthemanualofthecontainer.

Forattachingthesystemtotheharnesspleaserefertotheharnessmanual.

18.3.harnesseswithintegratedrescuecontainer:

Almostallmodernharnesseshaveanintergratedrescuecontainerinwhicharescuesystemcanbeplaced.Forthecorrect

mountingoftherescuesystem insuchacontainerpleaserefertotheharnessmanual.

18.4.Harnesseswithcombineddeploymentbag/releasehandle

Severalharnessesareequippedwithacompletereleasehandle/deploymentbagsystem,whichisadaptedoptimallytothe

correspondingharness.

Whenusingsuchasystemensurethatthedeploymentbagiscompatibletotherescuesystemused.Pleaseconsider:

1. The permitted volume range of the handle/deployment bag system must cover the volume of the rescue system. The

volumeoftherescuesystemistobefoundunder1.Technicaldatas.

2.Inadditionmakesurethatthedeploymentbagreleasestherescuesystemwithoutanyproblem.

Adeploymentbagwith4ormoreflaps(socalledcloverleafdeploymentbag)isingeneralcompatible.

The use of a deployment bag in the shape of a pocket (so called pocket container - exemplary design see under no 15) is

possible, but must be tested and certified by a LTF test laboratory separately for every rescue system model.The

deploymentbagwhichcomesasstandardwiththeEvoCrossSerieisofcoursecompatible.

Mounting:

Iftheaboveconditionsaremet,therescuesystemistobepackedbyfollowingNo.16(Packingtheparachute)step1to26.

The remaining steps of stowing the rescue system in the harness specific deployment bag is shown in the manual of the

harness.

If the harness manual shows a so called stack-packpacking method, this is also possible! The below imaging shows the

Cloverleaf container Bridle

Lines

Lines hanks

Closure loop cloverleaf deployment bag

Canopy in S-folds

(stack pack)

Basis

Cloverleaf deployment bag

packing with lines bundles on the bottom of the container:

Cloverleaf deployment bag

packing with lines bundles on top of the canopy:

Lines

Bridle

Closure loop cloverleaf deployment bag

Lines hanks

Canopy in S-folds

(stack pack)

Basis

Fangleinenbündel

Bottom of container

Bottom of container

stack-packmethodonlyexemplary!

Attention:

If the parachute is mounted to a harness or a front/outer container you have to check the compatibility. This check is only

allowed to be done by therefore authorizied persons. The compatibility check have to be noticed in the “Repack and

inspectionlogbook”.

Beside some other points you have to take care particularly that the connection length of the release handle to the

innercontainerisminimized.Thereforearethree loopsatthe deploymentbagatwhich thereleasehandlecanbe attached.

Youshouldalwaystrytousetheshortestpossibleconnectiontoensurethattherescueparachutecanbethrownasgoodas

possible. But you also have to take care that the release out of the container is not hinderd in any way. (take care that the

releasepindoesnotblock!!!). Readthemanualoftheharnessinanyway.

19.Specialitiesforparaglider´swinchtowing

Forwinchtowingyouhavetoconsidertheinstructionsoftheharness-,paraglider-andtowingreleasemanufacturer!

Ifyouuseafrontcontaineryouhavetoensurethattherescueparachutecanbereleasedineverysituation.

20.Pre-flightcheck

Inadditiontoanormalpreflightcheck(seemanualoftheglider/harnessormaybetowingdevice),youhavetocheckbefore

everytakeoffthattherescuecontainerisclosedcorrectlyandthereleasehandleisplacedcorrectly.

Iftherescueparachuteconnectionbridleisremovedaftereveryflight(forexample:whenyouuseafrontcontainer)youalso

18. Mounting / integration to a harness

18.1.harnesseswithoutintegratedrescuesystemcontainer:

If the harness does not have an integrated rescue system container use one of the outercontainer which is shown at point

15.

The outercontainer shown at point 15 has got several loops, eyelets and velcro-tapes on it´s back side to attach it at the

harness.The possibilitiesoftheattachmenttotheharness dependsontheharness.Foracorrect mountingon theharness

pleaserefertotheharnessmanual.

18.2.Usageofafrontcontainer/outercontainerofanothermanufacturer:

The possible usage of a front container or of an outercontainer of an other manufacturer depends on the size and if the

container is certified. If the container is too small or not certified the operating license of the rescue system expires. If it is a

containerofanothermanufactureryouhavetoreadthemanualofthecontainer.

Forattachingthesystemtotheharnesspleaserefertotheharnessmanual.

18.3.harnesseswithintegratedrescuecontainer:

Almostallmodernharnesseshaveanintergratedrescuecontainerinwhicharescuesystemcanbeplaced.Forthecorrect

mountingoftherescuesystem insuchacontainerpleaserefertotheharnessmanual.

18.4.Harnesseswithcombineddeploymentbag/releasehandle

Severalharnessesareequippedwithacompletereleasehandle/deploymentbagsystem,whichisadaptedoptimallytothe

correspondingharness.

Whenusingsuchasystemensurethatthedeploymentbagiscompatibletotherescuesystemused.Pleaseconsider:

1. The permitted volume range of the handle/deployment bag system must cover the volume of the rescue system. The

volumeoftherescuesystemistobefoundunder1.Technicaldatas.

2.Inadditionmakesurethatthedeploymentbagreleasestherescuesystemwithoutanyproblem.

Adeploymentbagwith4ormoreflaps(socalledcloverleafdeploymentbag)isingeneralcompatible.

The use of a deployment bag in the shape of a pocket (so called pocket container - exemplary design see under no 15) is

possible, but must be tested and certified by a LTF test laboratory separately for every rescue system model.The

deploymentbagwhichcomesasstandardwiththeEvoCrossSerieisofcoursecompatible.

Mounting:

Iftheaboveconditionsaremet,therescuesystemistobepackedbyfollowingNo.16(Packingtheparachute)step1to26.

The remaining steps of stowing the rescue system in the harness specific deployment bag is shown in the manual of the

harness.

If the harness manual shows a so called stack-packpacking method, this is also possible! The below imaging shows the

Cloverleaf container Bridle

Lines

Lines hanks

Closure loop cloverleaf deployment bag

Canopy in S-folds

(stack pack)

Basis

Cloverleaf deployment bag

packing with lines bundles on the bottom of the container:

Cloverleaf deployment bag

packing with lines bundles on top of the canopy:

Lines

Bridle

Closure loop cloverleaf deployment bag

Lines hanks

Canopy in S-folds

(stack pack)

Basis

Fangleinenbündel

Bottom of container

Bottom of container

stack-packmethodonlyexemplary!

Attention:

If the parachute is mounted to a harness or a front/outer container you have to check the compatibility. This check is only

allowed to be done by therefore authorizied persons. The compatibility check have to be noticed in the “Repack and

inspectionlogbook”.

Beside some other points you have to take care particularly that the connection length of the release handle to the

innercontainerisminimized.Thereforearethree loopsatthe deploymentbagatwhich thereleasehandlecanbe attached.

Youshouldalwaystrytousetheshortestpossibleconnectiontoensurethattherescueparachutecanbethrownasgoodas

possible. But you also have to take care that the release out of the container is not hinderd in any way. (take care that the

releasepindoesnotblock!!!). Readthemanualoftheharnessinanyway.

19.Specialitiesforparaglider´swinchtowing

Forwinchtowingyouhavetoconsidertheinstructionsoftheharness-,paraglider-andtowingreleasemanufacturer!

Ifyouuseafrontcontaineryouhavetoensurethattherescueparachutecanbereleasedineverysituation.

20.Pre-flightcheck

Inadditiontoanormalpreflightcheck(seemanualoftheglider/harnessormaybetowingdevice),youhavetocheckbefore

everytakeoffthattherescuecontainerisclosedcorrectlyandthereleasehandleisplacedcorrectly.

Iftherescueparachuteconnectionbridleisremovedaftereveryflight(forexample:whenyouuseafrontcontainer)youalso

18. Mounting / integration to a harness

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs F2D0-TI-Ex8.FF Series manual

Seametrics

Seametrics iMAG 4700r quick start guide

Haag-Streit

Haag-Streit AT 900 D Instructions for use

Icon Process Controls

Icon Process Controls truflo TK Series manual

Sedanamedical

Sedanamedical AMG-06 user manual

Advanced Instruments

Advanced Instruments 3300 Service manual