Indexator LINKSYS MPB1-80/45 KPL User manual

www.indexat or.com

LINKSET

| 3447 |2015-02-10

Dual Swingdamper MPB1-80/45 KPL

Dual Swingdamper MPB1-100/45 KPL

Dual Swingdamper MPB2-100/45 KPL

Dual Swingdamper MPB2-100/45C KPL

Dual Swingdamper MPB2-CRH KPL

Dual Swingdamper MPB2-CRH C KPL

1048 826

5002806 en

User User

Usermanual

2

1. Description

This product is designed for the supen-

sion of a freely hanging load.

Adapted for use in combination with

Indexator’s H-rotators. The products

brake unit is designed to reduce the

oscillating action. The disc should be

kept free of grease and oil to ensure

the best braking effect.

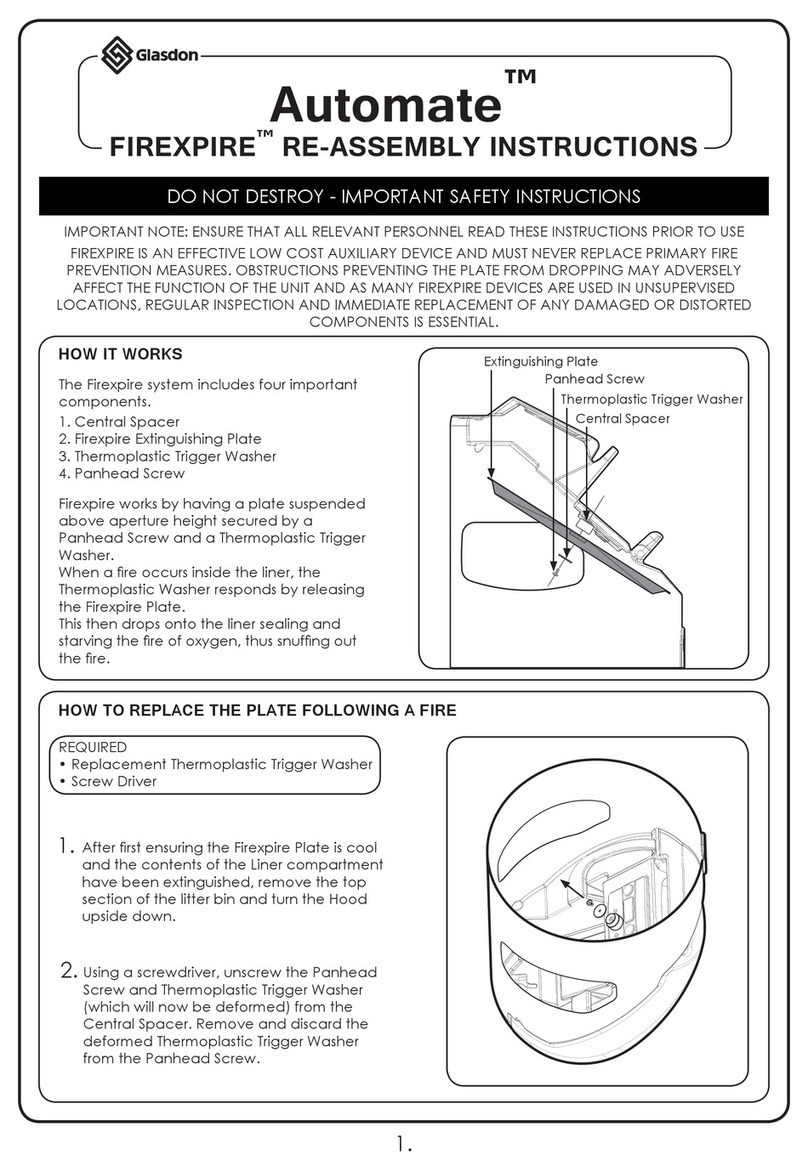

1.1 Warning

The locking rings are a safety feature,

preventing parts from being ejected from

the spring-action brake assembly in the

event of bolt fracture. It is therefore

essential that the locking ring is always in

place when adjusting/tightening. The

locking rings may only be removed when

the brake springs are not compressed

(loosely adjusted), eg, when replacing

the brake lining.

2. Safety instructions

2.1 Check that

2.1.1 the locking rings B are mounted, see also

4.1.2.

Check every 250 hours of operating.

2.2 Thelink’sworkingareamustbesuf

ciently large to allow handling of free

vertically suspended loads. The link

must not come into contact with the

oscillation stop in the crane nose.

2.3 Avoid oscillating the rotator to the stop

positions of the link.

Max. angle of oscillation +90°.

2.1.1 - Locking rings (B)

3

3. Safety sticker

3.1 The sticker should be positioned so that

it is easily visible to the driver without

hindering the view.

3.2 The sticker is self-adhesive. The surface

to which the sticker is attached must be

thoroughly cleaned.

4. Assembly instructions for the lower

brake

4.1 For rotator and swing damper

4.1.1 Check that the bushings are correctly

attached and that the required number of

lubrication holes are present.

4.1.2 Fit the pins Aso that the stop is turned

downwards. Fit the locking rings Band

secure them with clamping rings C

(with the groove turned outwards).

4.2 Dismantle

4.2.1 Dismantle in the reverse order. Make

sure that the grapple/harvesting head

and rotator are steady. Prize the clam

ping rings loose Cpossibly using a

grooving chisel. Then loosen the locking

rings Band then remove the pins A.

4.3 Assembly of the brake system

4.3.1 Assemble the brake discs Dso that the

feet are turned downwards, towards

the rotator. Worked surface Xturned

towards the brake lining.

4.3.2 Assemble the brake lining Eso that the

feet are turned upwards, away from the

rotator.Incorrectttingwilldamagethe

rotator.

4

4.4.2

4.3.3 The sleeves G, have to be greesed both

in- and outside, and the tube Hgreesed

ourside with copper paste or similar.

4.3.4 Assemble sleeves Gfrom each direction

and then feed into the centre pipe Hto

the centre.

4.3.5 Assemble the adjustment screws F. Re

commended braking moment is achieved

when the adjustment screw Fis tightened

until it stops. Notice that max. tightening

tourque is 60 Nm. If less brake power is

required, the adjustment screw Fcan be

untightened.

4.4 Dismantle

4.4.1 Dismantle in the reverse order.

4.4.2 In order to extend the service life time of

the bearing, after 2000 h the brake disc

has to be disassembled and the bearing

race turned 360 degrees.

5. Assembly instructions for the upper

brake

5.1 Warning

Please notis the warning instruction,

see 1.1.

5.2 Changing and maintaining the brake

lining, screw complete and brake disc

5.2.1 Unscrew the locking nut. Unscrew the

bolted joint.Remove the locking rings,

change or clean the lining.Clean the

brake disc.

Bolted joint

Screw complete

Flanged nut

Locking nut

5

5.2.5

5.2.2 Itisimportantwhenrettingthatthecup

springs are mounted according to Fig. 1.

Remembertotbackthelockingrings

before tightening. Position the locking

rings so that they are easily accessible

for tools/pliers.

5.2.3 It is important that linings are replaced in

time to prevent the steel plate that is

gluedtotheliningfromchang/damaging

the brake disc.

5.2.4 The screw complete must regulary be

inspected and replaced. Changing the

screw when changing the brake lining

is recommended.

5.2.5 For saftey reasons and i order to get

max. effect of the brake the brake disc

ought to be replaced when the thickness

(t) varies more than 1,0 mm, see picture

5.2.5.

5.3 Adjustment

5.3.1 For safety reasons, allow the locking

rings to remain in place. Unscrew

the locking nut before tightening. Hold

theange-nutandtightenthescrew.

Maximum tightening torque for the

bolted joint is 30 Nm.

Greater tightening torque will result in

greater wear and worsen the safety.

Secure the bolted joint with the locking

nut after adjusting.

5.3.2 The pin in the crane nose is assembled

in accordance with the crane

manufacturer’s recommendations.

Indexator recommends:

SurfacenenessRa<1,25µm(50µin)

Surface hardness > 50 HRC

Locking nut

Locking ring

Fig 1 (brake kit 80)

6

6.1 6.2

6.3

6.4

6.5

6.7

6.8

6. Maintenance instructions

6.1 Lubricate the link’s bearings every 50

hours.

6.2 In order to achieve the best operating

purpose possible the sleeves Gshould

be greesed both in- and outside, and the

tube Hgreesed outside with copper

paste or similar every 1000 working

hours. See 4.3.3.

6.3 Adjust the brake when necessary,

see 4.3.5.

6.4 Check that there are no cracks in the

upper or lower attachment of the rotator.

6.5 Check that no abnormal play has arisen

in the link´s bearing. Differences in

excess of 1,0 mm must be corrected.

6.6 If any leakage of hydraulic oil should

occur, it might be necessary to clean the

brake discs. To disassamble and assem

ble, see item 4.3.

If any of the problems in points 6.4, 6.5

are detected, contact your dealer,

for replacement of worn and defective

defective components.

6.7 In order to preserve the function and

a long service life of the swing damper

the brake linings have to be checked

and cleaned every 600 working hours or

every second month.

• Dismount the brake package.

• Remove the grinding dust that piled up

in the cavities of the lining.

• Rotate the inner race of the bearing 360

degrees. See sketch below.

• Reassemble the brake package if the

bearing runs smoothly with no play.

If there is play in the bearing, if it feels

tight, or if the rubber seal is damaged the

bearing should be replaced.

7. Technical data

For futher technical information we refer

to our product data sheets.

Indexator Rotator Systems

Tel + 46 933 148 00

rotator@indexator.com

www.indexator.com

This manual suits for next models

5

Table of contents

Other Indexator Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Caldertech

Caldertech Uniprep 7 operating instructions

Endress+Hauser

Endress+Hauser HART Field Xpert operating instructions

schmersal

schmersal AZM201Z-ST-T-1P2PW-A-2965-1 Instructions for operation

Modine Manufacturing

Modine Manufacturing ECO EG quick guide

S&C

S&C TripSaver II Operation manual

KegLand

KegLand NukaTap KL21760 instruction manual