Wieland SLC Series User manual

SLC-4 Select Host/Guest

Safety Light Curtains

Operating instructions

Doc. no. BA001133

Release: 04/2017 (Rev. A)

Notes

Wieland Electric GmbH | BA001133 | 04/2017 (Rev. A) 2

Notes

Copyright

This document is copyright-protected. The rights derived from this copyright are reserved for

Wieland Electric. Reproduction of this document or parts of this document is only permissible

within the limits of the statutory provision of the Copyright Act. Any modification or abridg-

ment of the document is prohibited without the express written agreement of Wieland Electric.

samos is a registered trademark of WIELAND Electric GmbH

Allen-Bradley, CompactBlock Guard I/O, CompactLogix, ControlFLASH, ControlLogix, DH+,

FactoryTalk, FLEX, GuardLogix, Kinetix, Logix5000, MicroLogix, PanelBuilder, PanelView, Pha-

seManager, PLC-2, PLC-3, PLC-5, POINT I/O, POINT Guard I/O, Rockwell Automation, Rockwell

Software, RSBizWare, RSFieldbus, RSLinx, RSLogix 5000, RSNetWorx, RSView, SLC, Soft-

Logix, Stratix, Stratix 2000, Stratix 5700, Stratix 6000, Stratix 8000, Stratix 8300, Studio 5000,

Studio 5000 Logix Designer, SynchLink, and Ultra are registered trademarks of Rockwell Auto-

mation, Inc.

ControlNet, DeviceNet, and EtherNet/IP are registered trademarks of ODVA, Inc. TwinCAT is a

registered trademark of Beckhoff Automation GmbH.

EtherCAT is a registered trademark and a patented technology licensed by Beckhoff Automa-

tion GmbH.

Microsoft, Windows 98, Windows NT, Windows 2000, Windows XP, Windows 7, Windows 8,

and .NET Framework are registered trademarks of the Microsoft Corporation.

Any other product or trade names listed in this manual are the trademarks or registered trade-

marks of the respective owners.

Subject to change

Subject to technical changes for reasons of continued development.

Tableofcontents

1 About this document............................................. 5

1.1 Used symbols and signal words............................................................. 5

1.2 Checklists............................................................................................... 5

2 Safety.................................................................... 6

2.1 Intended use and foreseeable misuse .................................................... 6

2.1.1 Intended use.................................................................................................... 6

2.1.2 Foreseeable misuse ......................................................................................... 7

2.2 Necessary competencies........................................................................ 7

2.3 Responsibility for safety......................................................................... 8

2.4 Disclaimer .............................................................................................. 8

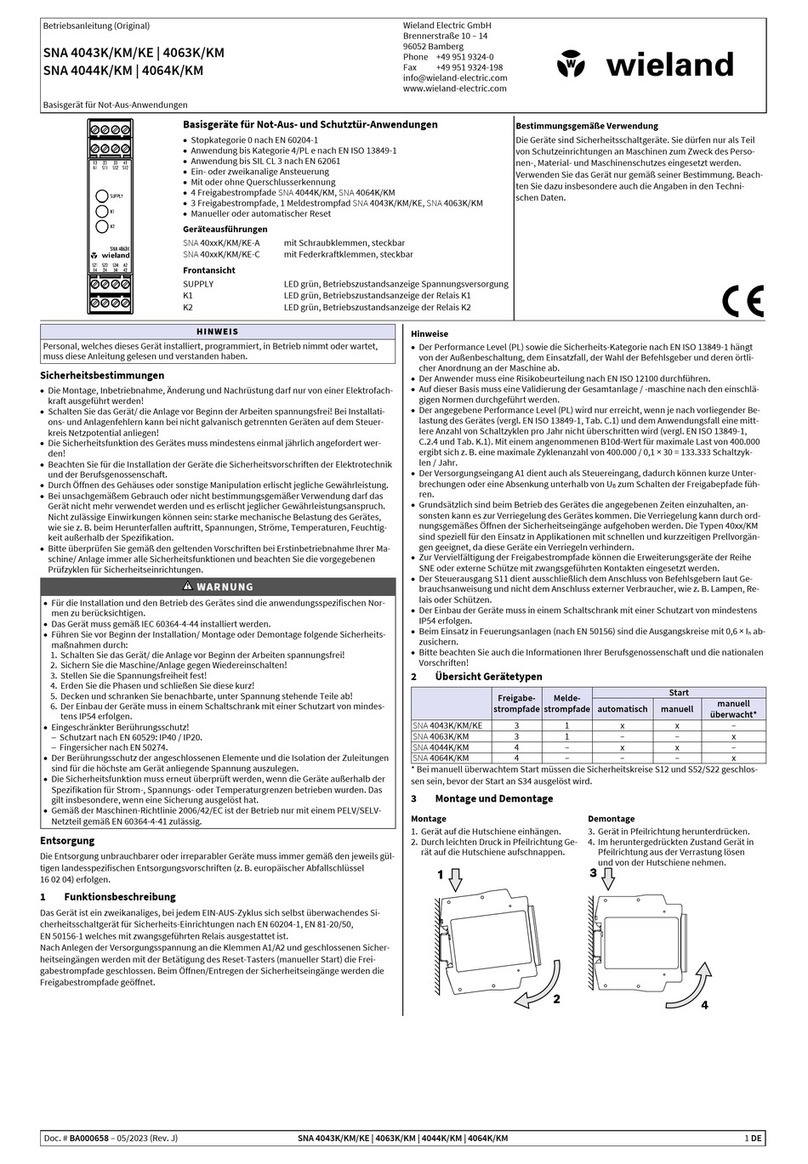

3 Device description................................................. 9

3.1 Device overview of the SLC family......................................................... 9

3.2 Connection technology........................................................................... 11

3.3 Cascading............................................................................................... 11

3.4 Display elements.................................................................................... 13

3.4.1 Operation indicators on the SLC-4TR transmitter............................................ 13

3.4.2 Operation indicators on the SLC-4SL receiver................................................. 14

3.4.3 Alignment display............................................................................................ 15

4 Functions............................................................... 16

4.1 Start/restart interlock RES...................................................................... 16

4.2 EDM contactor monitoring..................................................................... 16

4.3 Transmission channel changeover ......................................................... 17

4.4 Range reduction ..................................................................................... 17

5 Applications .......................................................... 18

5.1 Point of operation guarding.................................................................... 18

5.2 Access guarding..................................................................................... 19

5.3 Danger zone guarding ............................................................................ 19

6 Mounting............................................................... 20

6.1 Arrangement of transmitter and receiver ............................................... 20

6.1.1 Calculation of safety distanceS....................................................................... 20

6.1.2 Calculation of safety distance if protective fields act orthogonally to the

approach direction........................................................................................... 21

6.1.3 Calculation of safety distanceS for parallel approach to the protective field.. 26

6.1.4 Minimum distance to reflective surfaces......................................................... 27

6.1.5 Preventing mutual interference between adjacent devices............................. 28

6.2 Mounting the safety sensor.................................................................... 29

6.2.1 Suitable mounting locations ............................................................................ 29

6.2.2 Definition of directions of movement .............................................................. 30

6.2.3 Fastening via SLX-MO-TNUTM6 sliding blocks............................................... 31

6.2.4 Fastening via swivel mount SLX-MO-RO2....................................................... 31

6.2.5 Fastening via swiveling mounting bracketsSLX-MO-2RO3............................ 32

6.2.6 One-sided mounting on the machine table ..................................................... 33

Table of contents

Wieland Electric GmbH | BA001133 | 04/2017 (Rev. A) 3

6.3 Mounting accessories ............................................................................ 34

6.3.1 SLC-PRO protective screen ............................................................................. 34

7 Electrical connection ............................................. 35

7.1 Pin assignment transmitter and receiver................................................ 35

7.1.1 SLC-4TR transmitter ........................................................................................ 35

7.1.2 SLC-4SL receiver ............................................................................................. 37

8 Starting up the device ........................................... 38

8.1 Switching on .......................................................................................... 38

8.2 Aligning the sensor ................................................................................ 38

8.3 Aligning of deflecting mirrors with the laser alignment aid ................... 39

8.4 Unlocking start/restart interlock............................................................. 39

9 Testing .................................................................. 41

9.1 Before the initial start-up and following modifications .......................... 41

9.1.1 Checklist for integrator – to be performed prior to the initial start-up and

following modifications ................................................................................... 41

9.2 Regularly by qualified persons ............................................................... 43

9.3 Periodically by the operator.................................................................... 43

9.3.1 Checklist – periodically by the operator........................................................... 44

10 Maintenance.......................................................... 45

11 Troubleshooting .................................................... 46

11.1 What to do in case of failure? ................................................................ 46

11.2 Operating indicators of the LEDs............................................................ 46

11.3 Error messages 7-segment display......................................................... 47

12 Disposal................................................................. 50

13 Service and support .............................................. 51

14 Technical data ....................................................... 52

14.1 General specifications ............................................................................ 52

14.2 Dimensions, weight, response time ....................................................... 54

14.3 Dimensional drawings: Accessories....................................................... 58

15 Order guide and accessories ................................. 62

16 EC Declaration of Conformity................................ 69

Table of contents

Wieland Electric GmbH | BA001133 | 04/2017 (Rev. A) 4

About this document

Wieland Electric GmbH | BA001133 | 04/2017 (Rev. A) 5

1 About this document

1.1 Used symbols and signal words

Tab.1.1: Warning symbols and signal words

Symbol indicating dangers to persons

NOTE Signal word for property damage

Indicates dangers that may result in property damage if the measures

for danger avoidance are not followed.

CAUTION Signal word for minor injuries

Indicates dangers that may result in minor injury if the measures for

danger avoidance are not followed.

WARNING Signal word for serious injury

Indicates dangers that may result in severe or fatal injury if the mea-

sures for danger avoidance are not followed.

DANGER Signal word for life-threatening danger

Indicates dangers with which serious or fatal injury is imminent if the

measures for danger avoidance are not followed.

Tab.1.2: Other symbols

Symbol for action steps

Text passages with this symbol instruct you to perform actions.

Symbol for action results

Text passages with this symbol describe the result of the preceding

action.

1.2 Checklists

The checklists (see chapter 9 "Testing") serve as a reference for the machine manufacturer or

supplier. They replace neither testing of the complete machine or system prior to initial com-

missioning nor their periodic testing by a qualified person (see chapter 2.2 "Necessary compe-

tencies"). The checklists contain minimum testing requirements. Depending on the application,

other tests may be necessary.

This manual suits for next models

5

Table of contents

Other Wieland Industrial Equipment manuals