Ricoh A220 User manual

Cardinal Bird

(Machine Code:A220)

Service Manual

–

Insert Version

–

The A220 machine is based on the A175/A176/A177/A191/A192

Copier.

Only the differences from the base copier are described in the

following pages. Therefore, this documentation should be treated

as an insert version of the base copier’s service manual. It should

always be utilized together with the base copier’s service manual.

INSERTION PROCEDURE OF SERVICE MANUAL

1. Replace the book spine tag with the new one.

2. Insert the A220 service manual after the A175/A176/A177/A191/A192

manual.

SECTION 1

OVERALL MACHINE

INFORMATION

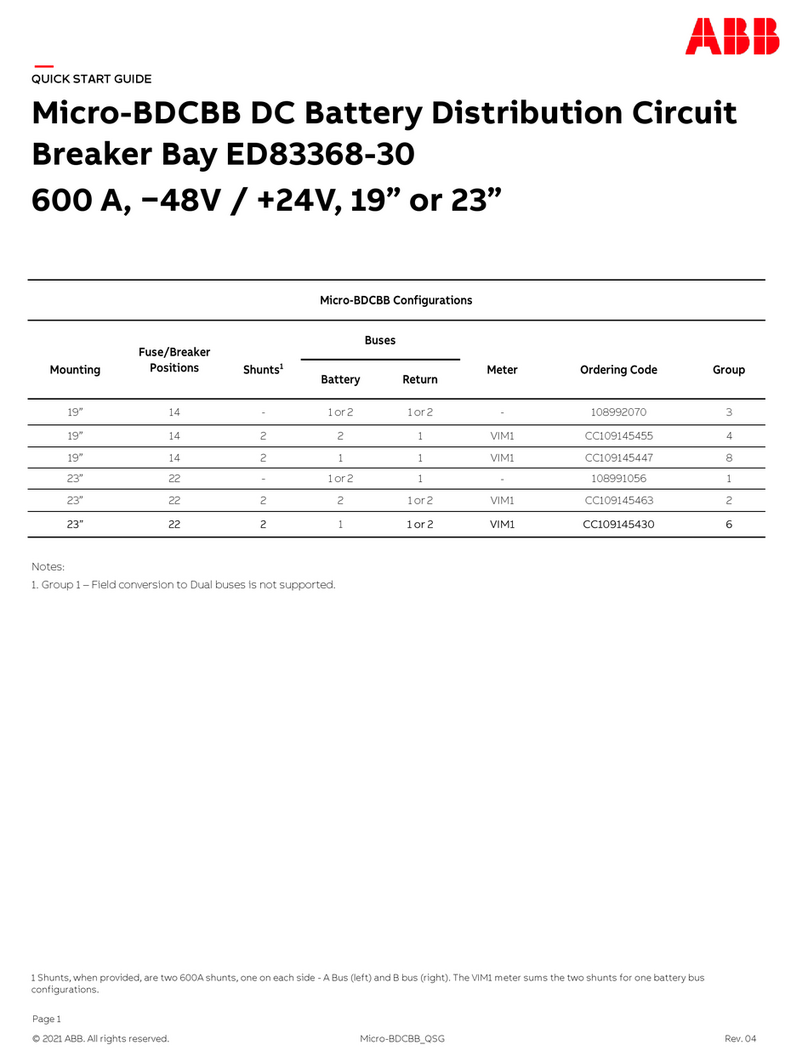

1. SPECIFICATION

Configuration: Console

Copy Process: Dry electrostatic transfer system

Toner Supply Control: Fuzzy Control

Photoconductor: OPC drum

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Original Alignment: Left rear corner

Copy Paper Size: Maximum A3/11" x 17"

Minimum A5/51/2" x 81/2" (Tray)

B5/81/2" x 11" (1.5 k LCT)

A6/51/2" x 81/2" (By-pass)

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/51/2" x 81/2" (sideways)

Copy Paper Weight: Paper tray: 52 ~ 128 g/m2, 14 ~ 34 lb

Bypass feed table: 52 ~ 157 g/m2, 14 ~ 42 lb

Duplex copying: 64 ~ 104 g/m2, 17 ~ 24 lb

Reproduction Ratios: 4 Enlargement and 6 Reduction

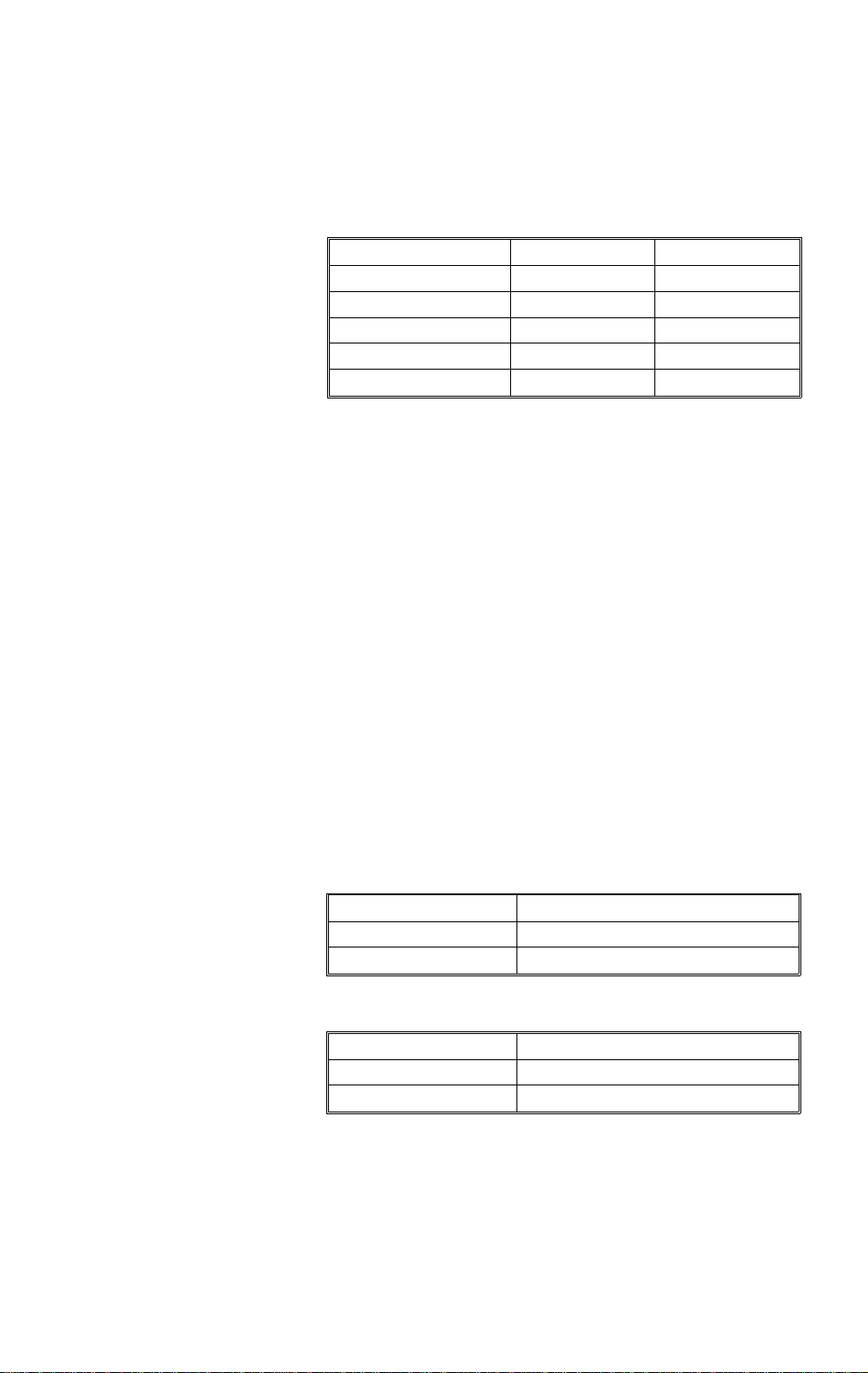

A4/A3 Version LT/LDG Version

Enlargement

200%

141%

122%

115%

200%

155%

129%

121%

Full Size 100% 100%

Reduction

93%

82%

75%

71%

65%

50%

93%

85%

77%

74%

65%

50%

Overall

Information

30 June 1997 SPECIFICATION

1-1

Power Source: 115 V, 60 Hz, more than 20 A (for N.A)

220 ~ 240 V, 50 Hz/60 Hz, more than 10 A (for

Europe and Asia)

Power Consumption: A220 copier

Copier only Full system*1

Warm up 0.90 kVA 0.92 kVA

Stand-by*20.22 kVA 0.24 kVA

Low Power mode*20.19 kVA 0.21 kVA

Copying 1.20 kVA 1.20 kVA

Maximum 1.45 kVA 1.50 kVA

*1Full System:

•Mainframe with dual job feeder, floor type

sorter stapler and 3,500-sheet large capacity

tray

•Mainframe with recirculating document

handler, finisher and 3,500-sheet large

capacity tray

*2When the anti-condensation heaters are off.

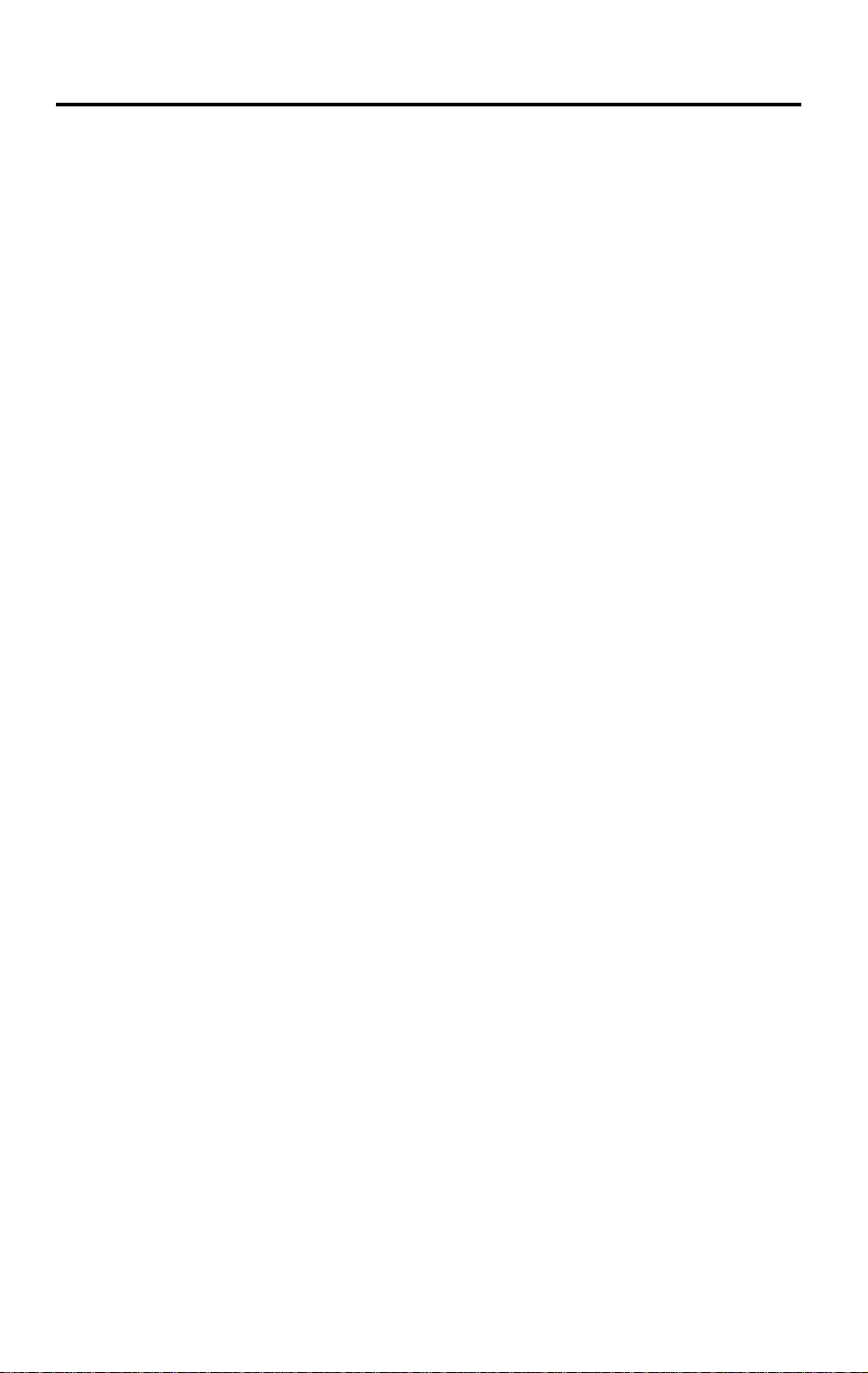

Noise Emission: Sound Pressure Level:

The measurements are made according to

ISO7779

A220 copier

Sound pressure level (The measurements are made according to ISO 7779 at

the operator position.)

Sound power level (The measurements are made according to ISO 7779.)

(average)

Copier only

Stand-by less than 34 dB (A)

Copying less than 57 dB (A)

Copier only

Stand-by less than 48 dB (A)

Copying less than 71 dB (A)

SPECIFICATION 30 June 1997

1-2

Dimensions:

Width Depth Height

Copier only 690 mm

27.2" 690 mm

27.2" 980 mm

38.6"

Copier with dual job feeder, sorter stapler, and

3,500-sheet large capacity tray 1,659 mm

65.4" 690 mm

27.2 mm" 1,116 mm

43.9"

Copier with dual job feeder, sorter stapler with

punch, and 3,500-sheet large capacity tray 1,659 mm

65.4" 690 mm

27.2" 1,113 mm

43.9

Copier with recirculating document handler,

finisher, and 3,500-sheet large capacity tray 1,764 mm

65.9" 690 mm

27.2" 1,112 mm

43.8"

Weight: Copier only:(Without the optional platen cover

= Approximately 2 kg)

Two-Tray version copier: Approximately 152 kg

Three-Tray version copiers: Approximately 162 kg

Zoom: From 50% to 200% in 1% steps

Copying Speed:

Warm-up Time: Less than 5 minutes (20°C)

First Copy Time:

(A4/81/2: x 11" sideways

from the 1st feed station)

3.1 seconds

Copy Number Input: Number keys, 1 to 999 (count up or count down)

Manual Image Density

Selection: 7 steps

Automatic Reset: 1 minute standard setting; can also be set from 1

second to 999 seconds or no auto reset.

Copy Paper Capacity: •By-pass feed table: approximately 50 sheets

•Paper tray: approximately 550 sheets

•Large capacity tray: approximately 1500

sheets

Toner Replenishment: 1,100 g/cartridge

A4/LT (sideways) A3/DLT B4/LG

A220 copier 51 (A4)

50 (LT) 26 32

Overall

Information

30 June 1997 SPECIFICATION

1-3

Optional Equipment: •Platen cover (A528-04)

•Dual job feeder (A610)

•Recirculating document handler (A607)

•20 bin sorter stapler (Floor type) (A606-17:

Ricoh, -22: NRG, -15: Savin)

•Finisher (A608)

•3500-sheet Large capacity tray (A609)

•Receiving Tray (A446-05)

•Key Counter Bracket D (A509-03)

•20 bin sorter stapler (Floor type) with punch

(A606-57, -67: Ricoh, -52, -62: NRG , -55:

Savin)

•Editing sheet (spare part)

SPECIFICATION 30 June 1997

1-4

2. MACHINE CONFIGURATION

2.1 COPIER OVERVIEW

There are two types of mainframe.

A220 - (10, 17, 20, 29:) copiers

Three 550-sheet paper trays

Optional 3,500-sheet large capacity

tray

A220 - (22: china) copier

Two 550-sheet paper trays

storage tray

Optional 3,500-sheet large capacity

tray

550

550

550

(3,500)

A220V500.img

(3,500)

550

550

storage

A220V501.img

Overall

Information

30 June 1997 MACHINE CONFIGURATION

1-5

2.2 SYSTEM OVERVIEW

DJF version

(Mainframe type with dual job feeder and floor type sorter stapler. The

mainframe in the illustration below is the two-tray version.)

RDH version

(The mainframe with recirculating document handler and finisher.

The mainframe in the illustration below is the two-tray version.)

Dual job feeder (A610)

3,500-sheets

large capacity

tray (A609)

Floor type sorter

stapler (A60617,

22, 15) or Floor

type sorter stapler

with punch (A60657,

67, 52, 62, 55)

A220V502.img

3,500-sheets

large capacity

tray (A609)

Recirculating document handler (A607)

Finisher (A608)

A220V503.img

MACHINE CONFIGURATION 30 June 1997

1-6

4. MECHANICAL COMPONENT LAYOUT

5. DRIVE LAYOUT

6. PAPER PATH

As indicated in the machine configuration section, there are neither

1,500-sheet LCT or 4th feed station versions. Refer to the

A175/A176/A177/A191/A192 service manual by ignoring these feed stations.

7. ELECTRICAL COMPONENT DESCRIPTION

There are no 1,500-sheet LCT, 4th tray, tandem tray, 60 CPM, or 70 CPM

versions. Refer to the A175/A176/A177/A191/A192 service manual. You can

find those components, which are not used for the A220 copier because the

notes for the various versions are indicated in the component name column.

The versions except for the A220-22 machine also have the following

components.

Symbol Name Function Index No.

M18 3rd Lift Raises the bottom plate in the 3rd

paper tray. 94

SW8 3rd Tray Set Detects if the 3rd tray is set or not. 84

S38 3rd Paper Near End Informs the CPU when the 3rd

cassette is in near end condition. 79

MECHANICAL COMPONENT LAYOUT

DRIVE LAYOUT

PAPER PATH

ELECTRICAL COMPONENT DESCRIPTION

30 June 1997

Overall

Information

1-7

SECTION 2

DETAILED SECTION

DESCRIPTIONS

4. DEVELOPMENT UNIT

Illustration Correction for the Paddle Roller (service manual page 2-46 and

2-48 of the A175/A176/A177/A191/A192 copiers)

The illustration for the paddle roller on page 2-46 and 2-48 is incorrect.

Please correct your service manuals, as shown below. This correction have

been already issued for the A175/A176/A177/A191/A192 copiers.

Incorrect

Correct

A220D507.wmf

A220D502.wmf A220D503.wmf

A220D504.wmf

A220D505.wmf A220D506.wmf

Detailed

Descriptions

30 June 1997 DEVELOPMENT UNIT

2-1

6. PAPER FEED

6.1 OVERVIEW

This model has two or three drawer tray paper feed stations.

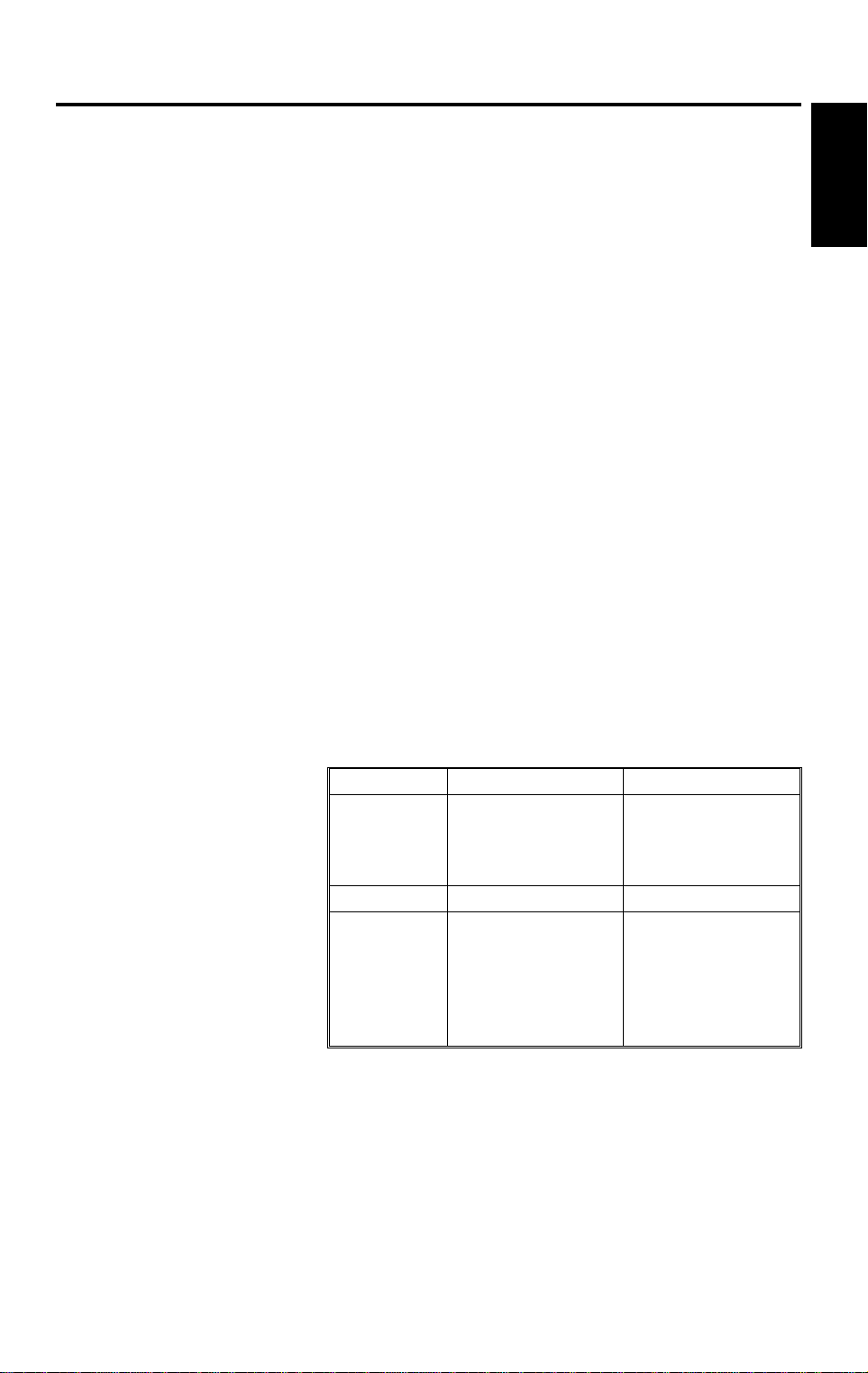

The following table shows the configuration of each feed stations of the

copiers.

Feed station A220 - 10, 17, 20, 29

three tray copiers A220 - 22

two tray copiers

1st 550 sheets tray 550 sheets tray

2nd 550 sheets universal tray 550 sheets universal tray

3rd 550 sheets tray storage tray

Paper can also be fed using the by-pass feed table which has an

independent feed mechanism. The by-pass feed table can hold 50 sheets of

paper.

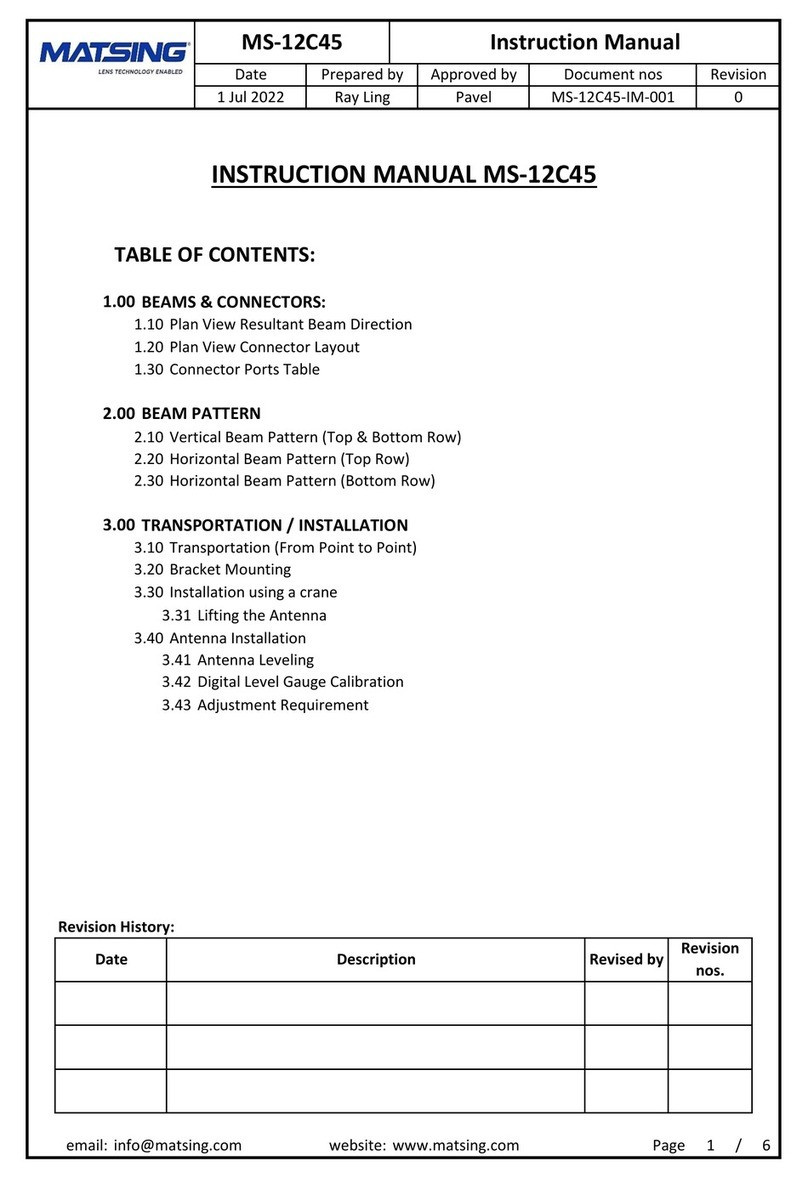

All feed stations use an FRR feed system. Rotation of the pick-up roller [A]

drives the top sheets of paper from each tray to the feed [B] and the

separation [C] rollers. The feed and separation rollers then take over paper

drive. If more than one sheet is fed by the pick-up roller, the separation rollers

rotates in the opposite direction and prevents all but the top sheet from

passing through to the registration rollers.

[A]

[B]

[A] [C]

[B]

A220D500.wmf

PAPER FEED 30 June 1997

2-2

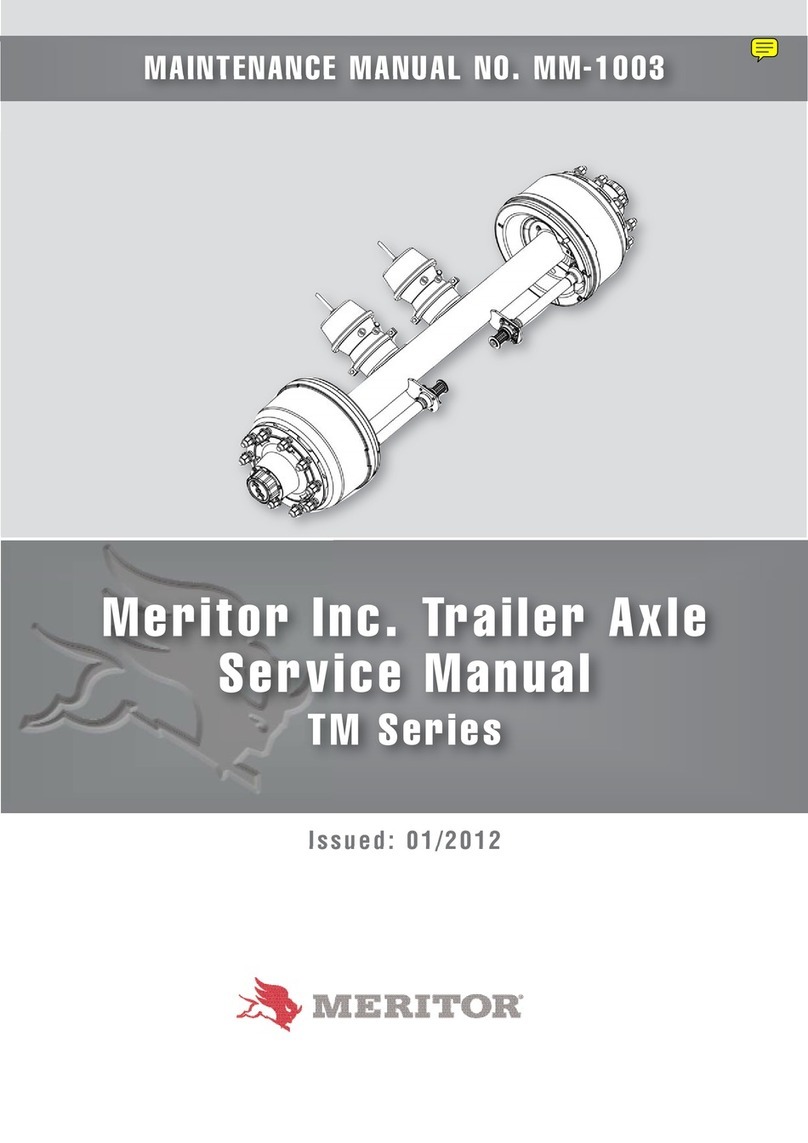

6.8 PAPER LIFT MECHANISM

When the tray is set in the machine, the machine detects this condition by

using several detection methods as shown in the table:

Feed station

1st Tray set switch

2nd Paper size switch

3rd Tray set switch (not used for storage tray version)

When the machine detects that the paper tray is set in the machine, the lift

motor [A] rotates and the coupling gear [B] on the tray lift motor engages the

pin [C] of the lift arm shaft [D], then turns the tray lift arm [E] to lift the tray

bottom plate [F].

[A]

[C]

[B]

[D]

[E]

[F]

A220D501.wmf

Detailed

Descriptions

30 June 1997 PAPER FEED

2-3

9. ENERGY STAR COMPLIANT MACHINES

(North American version only)

The lower power timer and the auto off periods have been revised.

Lower power timer: The copier enters Low Power mode automatically at the

selected time after your job is finished.

The maximum limit of the selectable time has been changed from 120

minutes to 240 minutes.

Auto off timer: To conserve energy, this copier automatically turns off at the

selected time after the last copying job has been completed.

The maximum limit of the selectable time has been changed from 120

minutes to 240 minutes.

Refer to the A175/A176/A177/A191/A192 service manual for the other things.

ENERGY STAR COMPLIANT MACHINES

(North American version only) 30 June 1997

2-4

SECTION 3

INSTALLATION

2. COPIER INSTALLATION

2.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box according to

the following list:

Description Q’ty

1. Sensor Cover ................................................................... 1

2. Flat Head Screw 4 x 6...................................................... 1

3. Leveling Shoes................................................................. 2

Installation

30 June 1997 COPIER INSTALLATION

3-1

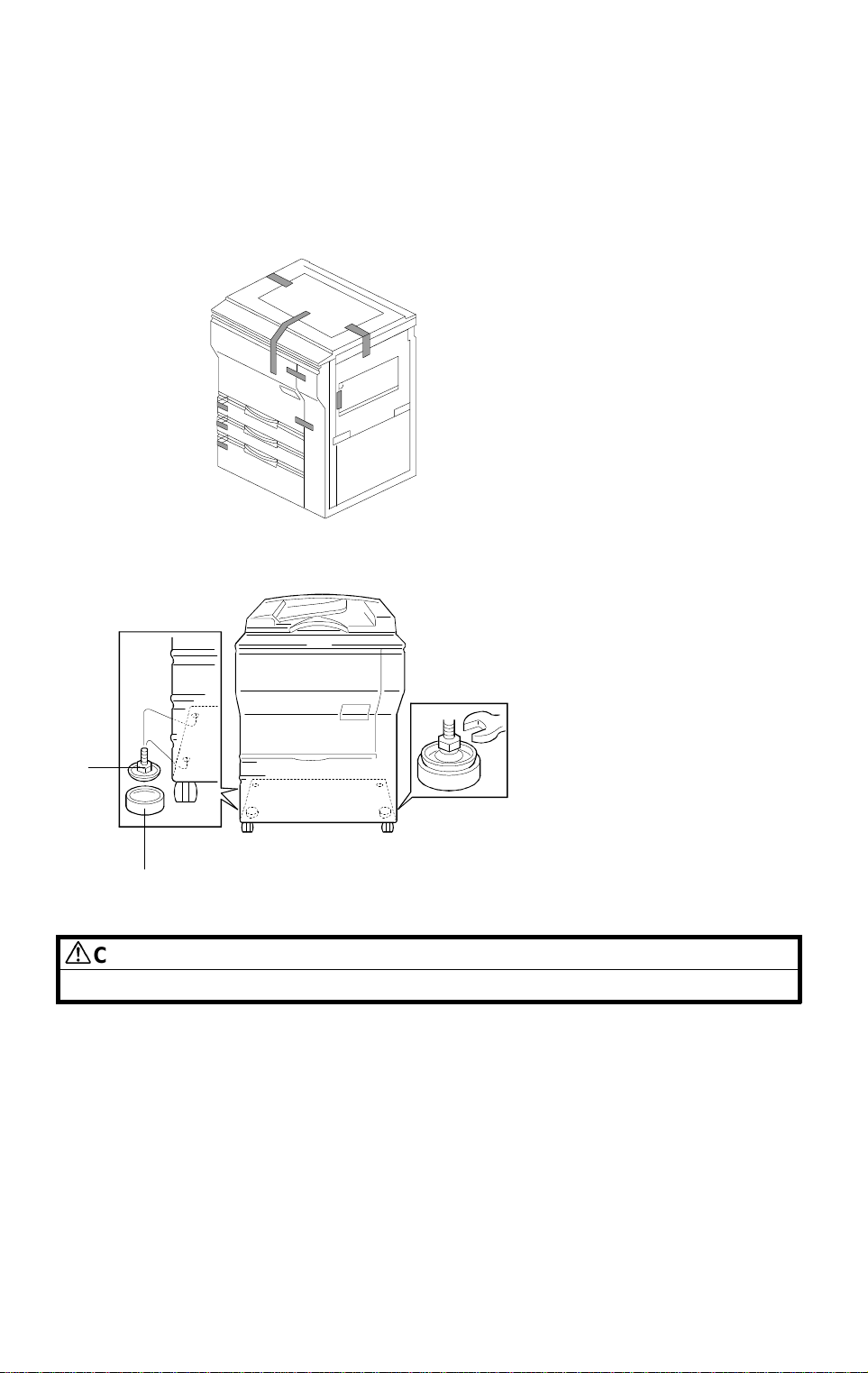

2.2 COPIER INSTALLATION PROCEDURE

NOTE: Since the installation procedure is not packed with the copier as

an accessory, always bring this manual with you.

CAUTION

When installing the copier, make sure that the copier is unplugged.

NOTE: Insert the leveling shoes [A] under the leveling feet [B] for the front

side, and level the machine before starting the installation. (The

leveling feet [B] can be screwed up or down.) Extra leveling shoes

(AH013008) and leveling feet (AH011004) are available as spare

parts.

1. Remove the tape strips.

NOTE: There are neither 1,500-sheet LCT or 4th feed station versions.

Refer to the A175/A176/A177/A191/A192 service manual for

installation.

A220I500.wmf

Note: There are two types of

bottom plate. One has

two leveling feet [B]

installed. The other has

four leveling feet.

[A]

[B]

A220I501.wmf

COPIER INSTALLATION 30 June 1997

3-2

SECTION 4

SERVICE TABLES

1. SERVICE REMARKS

1.11 FUSING UNIT

The following remark is not written in the A175/A176/A177/A191/A192

service manual.

However, this remark has been added as a A175/A176/A177/A191/A192

copiers service remark by RTB.

5. Silicon oil may slightly soak into the surface of the hot roller during

machine storage. The silicon oil may stick to the surface of the pressure

roller when the hot roller was in contact with the pressure roller at

installation. The pressure roller may slip due to the oil because the hot

and pressure rollers are new. Therefore, the smeared image may appear

on the leading edge at about 10 mm on the 1st copy. This is because the

hot roller is rubbing the leading edge of the copy on the pressure roller.

This symptom occurs only at the 1st copy after installation. Make sample

copies and make sure that the symptom does not recur after several

copies.

1.12 OTHERS

1. This machine has re-manufactured parts, which are selected from

dis-assembled machines in the Japanese domestic field. Note that there

are old and new parts in the machine.

Service

Tables

30 June 1997 SERVICE REMARKS

4-1

Other manuals for A220

1

Table of contents

Other Ricoh Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Panasonic

Panasonic EXC18CS quick start guide

EINHELL

EINHELL LE-OFT 800 operating instructions

SMC Networks

SMC Networks MY2 Series manual

Livox

Livox Mid-360 user manual

JohnDow Industries

JohnDow Industries JDI-FST15 Operator's manual

HADEF

HADEF Gentry Crane 800 Installation, operating and maintenance instructions