Indexator XR 400 User manual

IMPORTANT!

Read through the service manual carefully and

make sure that you understand the content

before starting the service.

Servicemanual

www.indexator.com

ROTATOR

XR 400

1049170

2018-02-16

2

1049170 2018-02-16 © Indexator Rotator Systems AB

GENERAL

This service manual has been produced inhouse Indexator and can show the special tools and equipment

that are used in the production. Alternative equipment can also be used.

Vi are contstantly improving our products and reserve the right to make design changes without introducing

them on products that have already been delivered.The same applies to maintenance and other service

operations.

The service manual contains instructions for repairing and maintaining your product for long life and fault-

less operation. Before starting repair work on the rotator, read through the manual thoroughly in order to

understand its content. Casual or incorrect actions may result in serious or even life-threatening injury.

Servicing work may only be done by personnel familiar with Indexator products.

For major renovation work, trained personnel should be contacted.

SAFETY

In addition to the recommendations in this service manual, every country(nation) has its own safety regula-

tions. If the recommendations in the manual differs from the regulations in your country, you must observe

your national regulations.

Use the necessary safety equipment for the task, for example safety shoes, gloves, safety glasses and

ear protection. Use gloves as protection against oil, grease and other noxious substances.

3

1049170 2018-02-16 © Indexator Rotator Systems AB

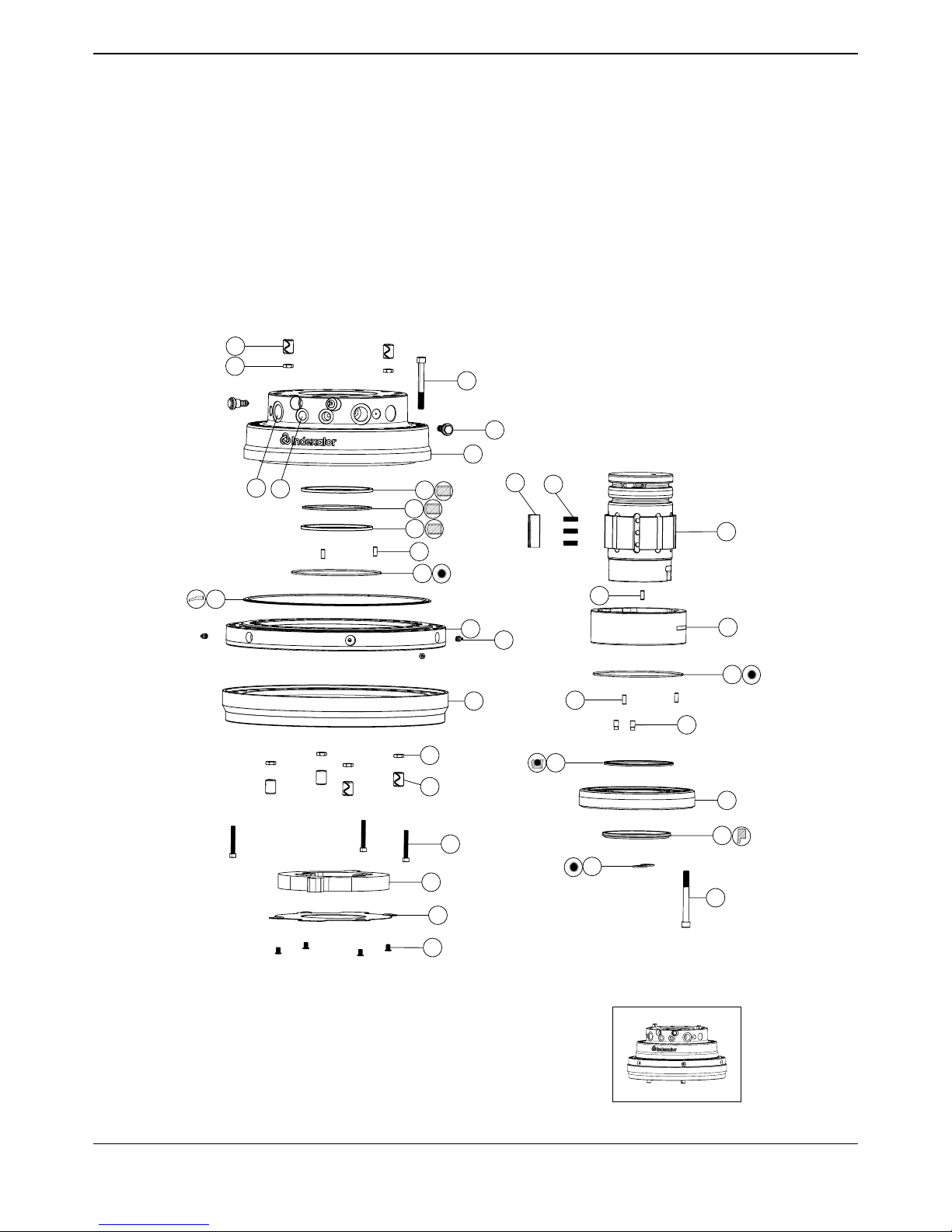

DESCRIPTION

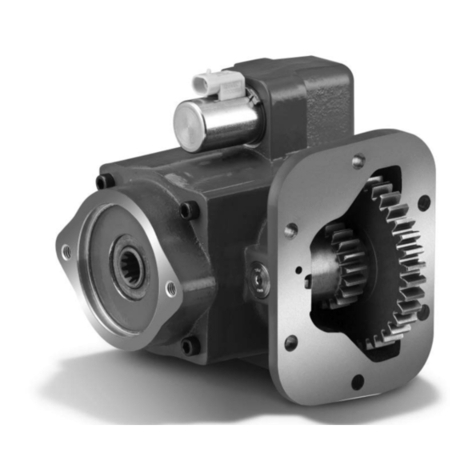

XR is a compact rotator with grapple- and rotation function. C models has an extra function for central grea-

sing. That function is describes as a notification ”only C model” in the servicemanual.

COMPONENTS

1

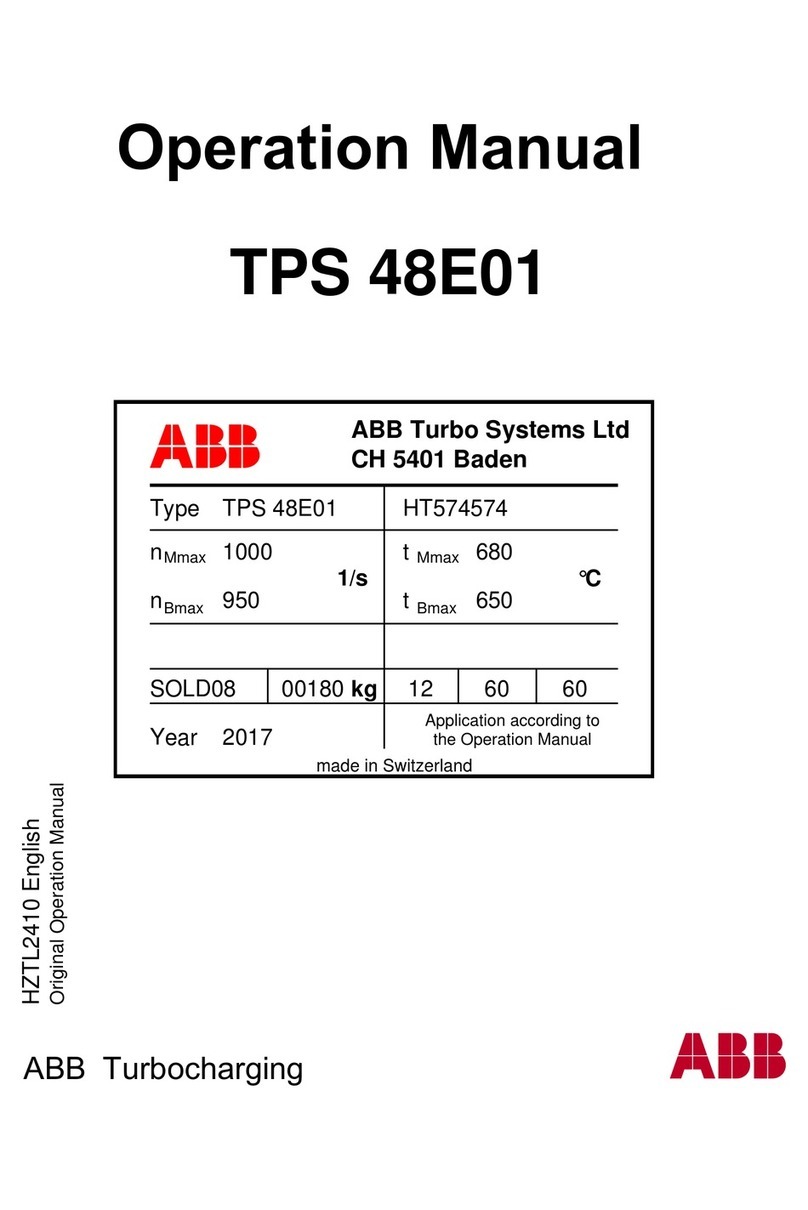

RESERVDELAR 8400003 XR 400

SPARE PARTS

2018 04 09

1049428

Indexator Rotator Systems AB

Box 11, S-922 21 Vindeln, Sweden

Tel +46 933148 00, Fax + 46 933 148 99

E-mail: rotator@indexator.com, www.indexator.com

3

20

4

20

14

19

8

5

18

17

6

7

25

20

9

2

12

11

10

23 24

20

20

12

13

20

22

16

15

17

18

1

21

26

20

4

1049170 2018-02-16 © Indexator Rotator Systems AB

2

RESERVDELAR 8400003 XR 400

SPARE PARTS

2018 04 09 1049428

Indexator Rotator Systems AB

Box 11, S-922 21 Vindeln, Sweden

Tel +46 933148 00, Fax + 46 933 148 99

E-mail: rotator@indexator.com, www.indexator.com

Pos Detalj nr Ant Beskrivning Description Anm Åtdragn mom

8400 003 Rotator XR 400 Rotator XR 400

1 6002 763R 1 Stator övre Stator plate upper Incl pos. 19, 23, 24

2 8000 811R 1 Statorring Stator frame

3 6002 903 1 Rotor Rotator shaft from s/n 1605754-

6002 573 1 ER Rotor ER Rotator shaft s/n 1514713 - 1605753

4 6005 165R 1 Stator nedre Stator lower from s/n 1605754 -

8100 111 1 ER Stator nedre ER Stator lower s/n 1514713 - 1605753

5 6002 663R 1 Fästplatta Lower link

6 8100 118 1 Transmission Transmission

7 8100 119 1 Bottenplåt Bottom plate

8 8100 165R 1 Svängkranslager Slewing bearing Incl pos. 22, 26

9 5011 107 2 Käglor Restrictors

10 5011 160 9 Vinge Vane

11 5006 030 27 Fjäder Spring

12 1019 900 4 Spännstift Pin 8x20

13 1010 677 15 Skruv Screw M12x110 120 Nm

14 1079 094 30 Skruv Screw M12x100 120 Nm

15 1070 564 3 Skruv Screw M8x60 33 Nm

16 1070 556 4 Skruv Screw M8x12 33 Nm

17 1066 851 6 Pinne Tubular pin 22x30

18 1074 574 6 Mutter Nut M12

19 6002 565 2 Tryckbegr ventil Relief valve 28 MPa (R, R) 40 Nm

20 6003 706 1 Tätningssats Seal kit XR400

21 1300 234 1 Tätning avstrykare Wiper seal from s/n 1605754 -

1078 922 1 ER Tätning avstrykare ER Wiper seal s/n 1514713 - 1605753

22 1018 258 6 Smörjnippel Grease nipple M8x1

23 1078 021 2 Propp Plug ED G1

24 5001 384 2 Propp Plug ED G1/2

25 1070 408 1 Pinne Pin FRP 8x20

26 6005 146 1 Tätningsats lager Seal kit bearing

5

1049170 2018-02-16 © Indexator Rotator Systems AB

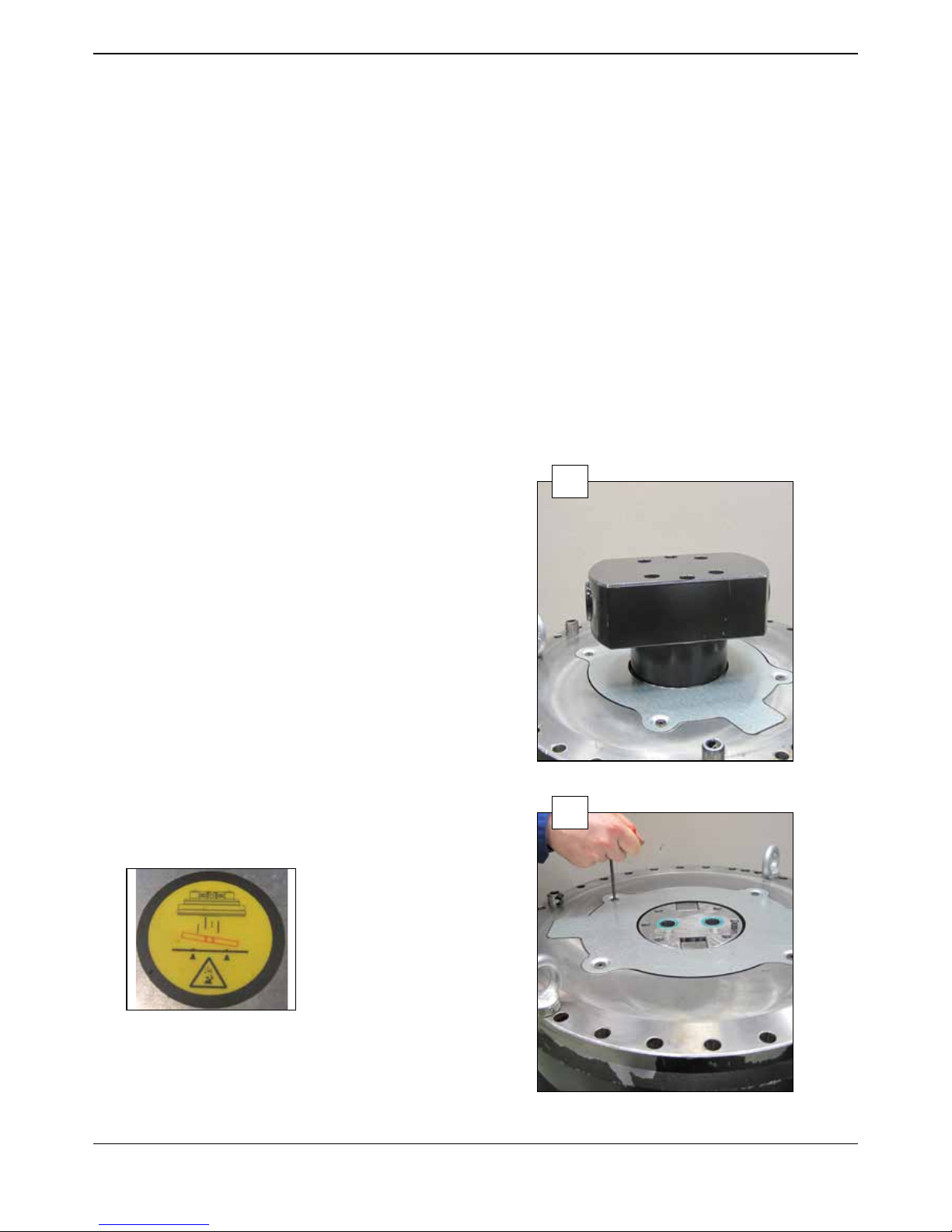

RECOMMENDED TOOLS

PART. NO DESCRIPTION QTY

1077 106 Glide seal remover 1 st

8000 581 Vane compressor 1 st

4000 828 Assembly tool motor 1 st

3122 155 Tool motor 1 st

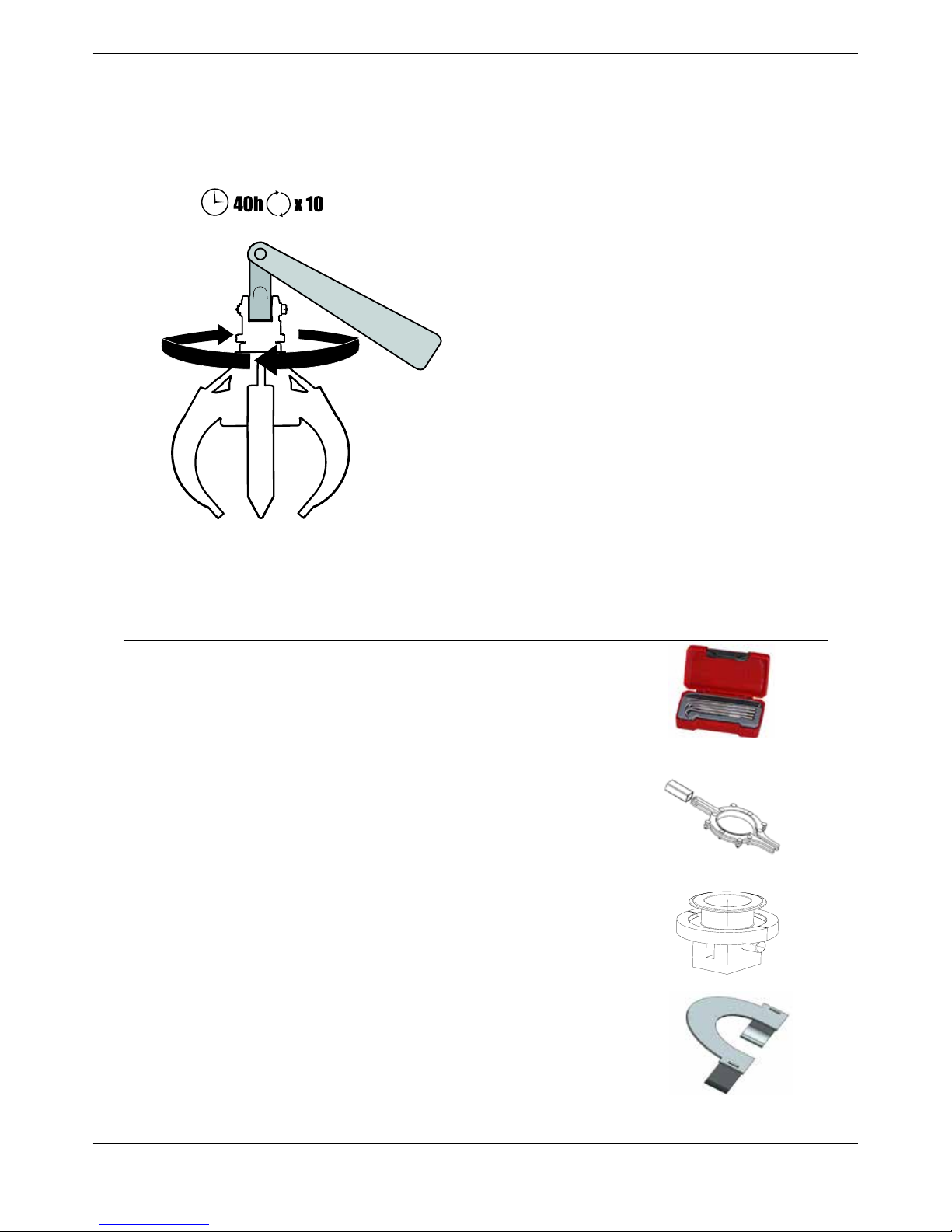

TO PROLONG THE LIFE TIME:

Every 40 hours rotate 10 rounds.

6

1049170 2018-02-16 © Indexator Rotator Systems AB

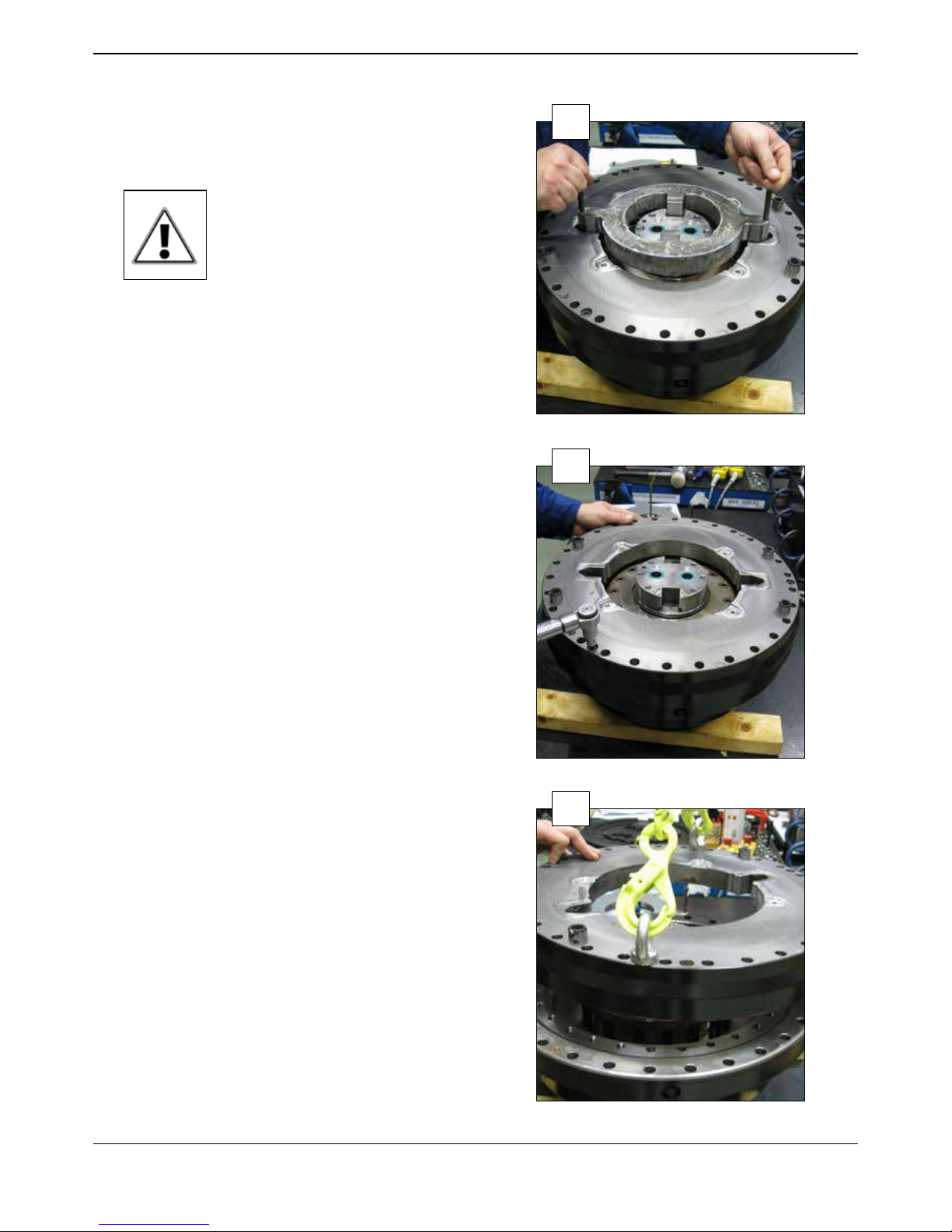

Put the rotator upside down and remove the manifold

block.

1

WARNING! If the rotator is normally positioned the

transmision can fall down if the bottom plate is loosened!

Remove the bottom plate by loosen 4 pcs of

M8x12 screws.

2

CHANGING SEALS

CONTENTS

This service manual describes:

Changing seals................................................................................................................................. page 6-23

Changing seal on slewing bearing.................................................................................................... page 24-27

7

1049170 2018-02-16 © Indexator Rotator Systems AB

Lift up the transmission. Use 2 pcs of M10 screws

to create a good grip and prevent any risk of injury.

NOTE! Risk of injury!

3

Remove 3 pcs of M8x60 screws in the lower link. 4

Lift off the lower link. 5

8

1049170 2018-02-16 © Indexator Rotator Systems AB

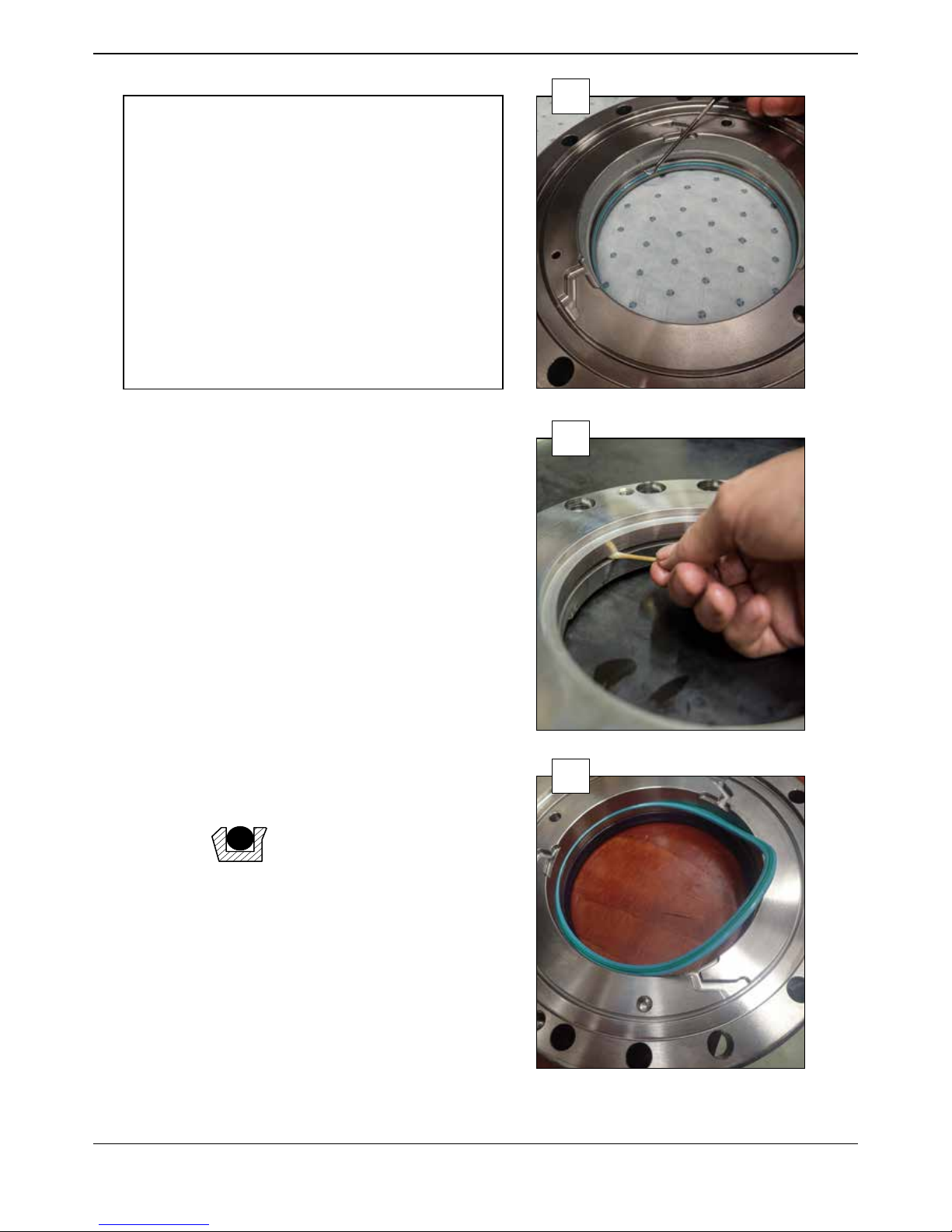

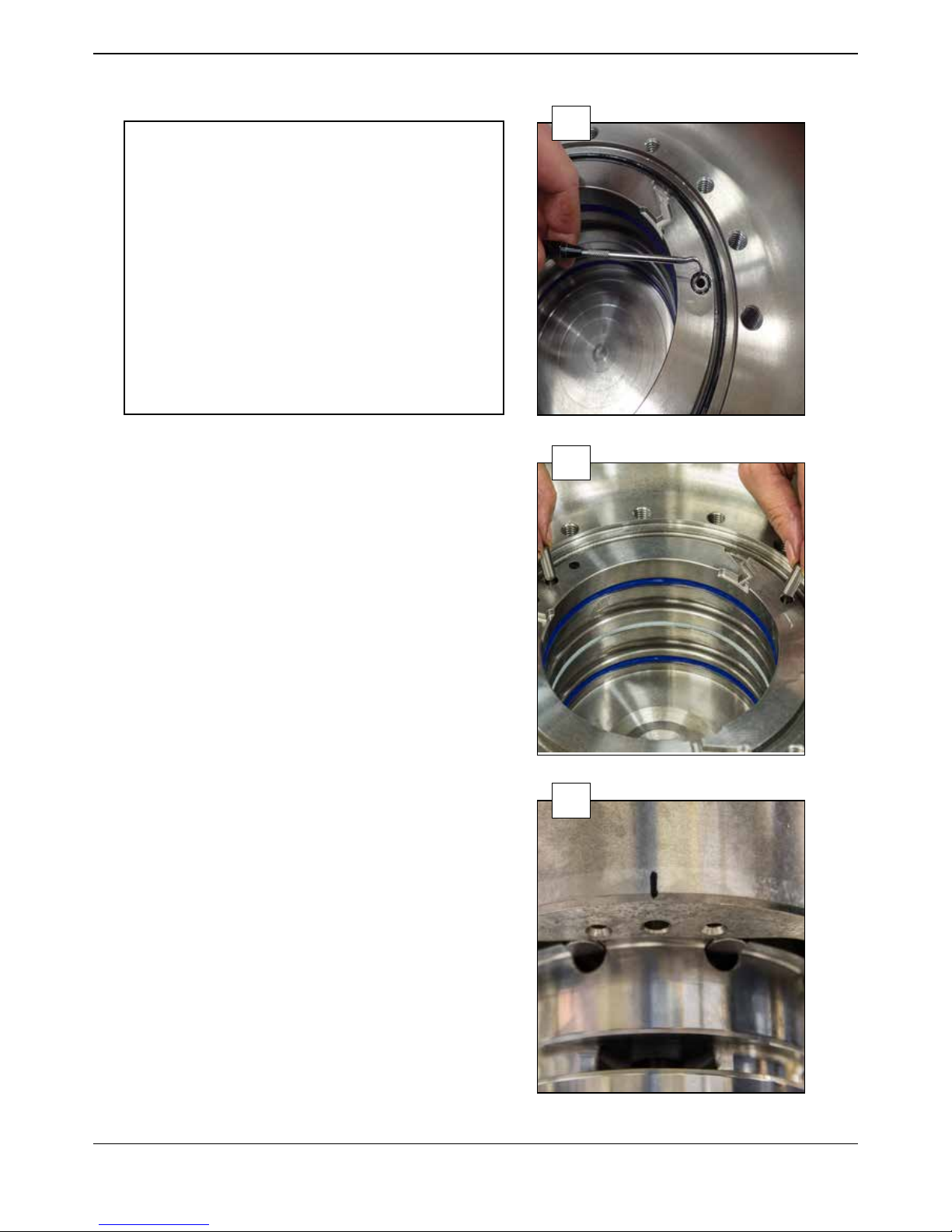

Remove the o-rings from the rotator shaft. 6

Only for C model.

Remove the o-ring for the c-channel on the rotator shaft.

7

Remove wiper seal. 8

9

1049170 2018-02-16 © Indexator Rotator Systems AB

Remove 15 pcs M12x110 screws to loosen the motor

part.

9

Disassemble the stator lower by carefully bending from

two directions.

Note! Important to get it straight up.

10

Remove the seal in stator lower. 11

10

1049170 2018-02-16 © Indexator Rotator Systems AB

Only for C model.

Remove the two seals in stator lower.

12

13

Assemble a new seal in stator lower.

14

Clean the seal seats in stator lower thoroughly, using

cotton buds and oil for example.

11

1049170 2018-02-16 © Indexator Rotator Systems AB

If needed change the wiper seal in stator lower. 15

16

Only for C model.

Assemble a new seal in stator lower.

17

Lubricate the new seals.

12

1049170 2018-02-16 © Indexator Rotator Systems AB

Only for C model.

Assemble a new seal in stator lower.

18

19

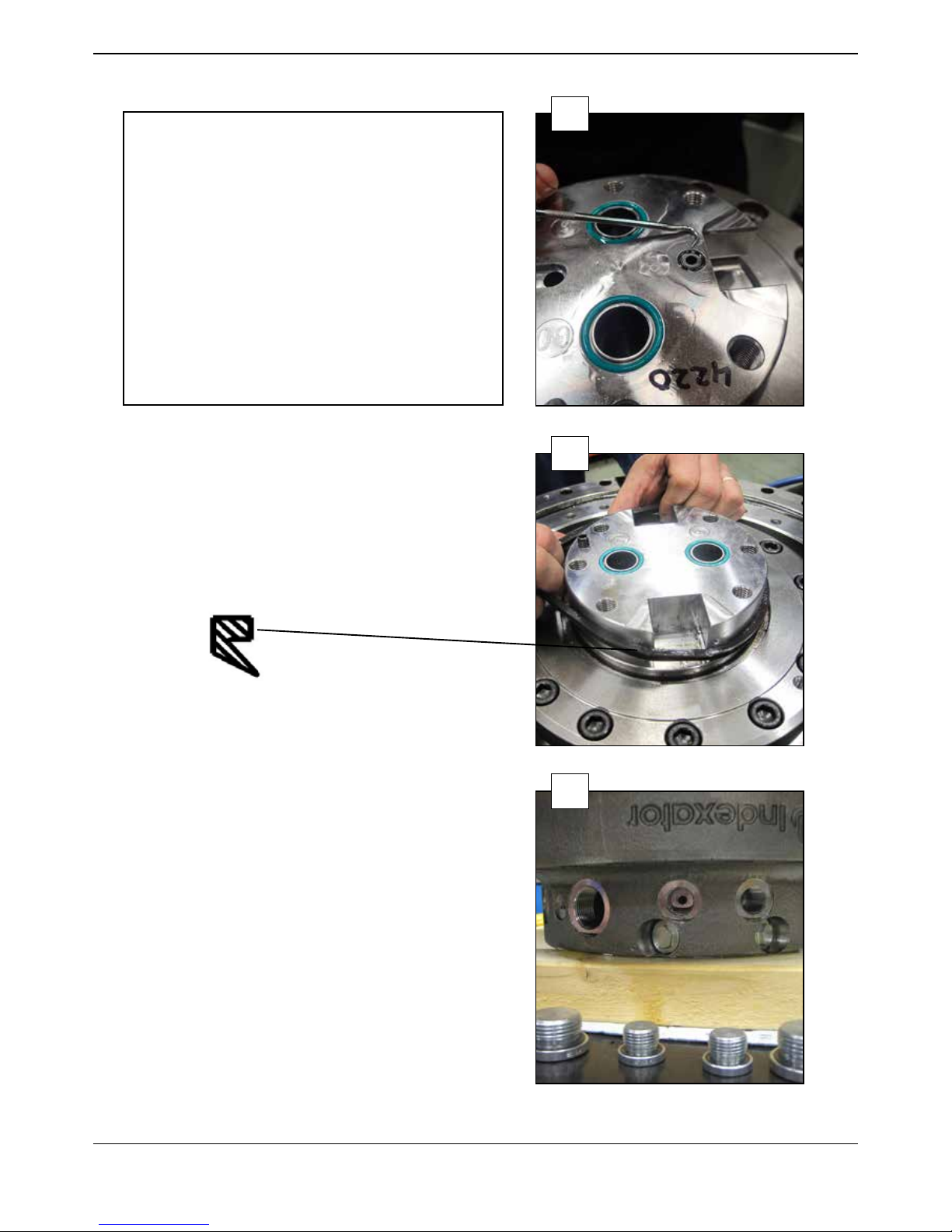

Remove the o-ring from the stator frame.

Clean the seal seat.

Lubricate the new seal and install it.

20

Only for C model.

Lubricate the new seals.

13

1049170 2018-02-16 © Indexator Rotator Systems AB

Only for C model.

Remove the o-ring for the c-channel on the stator frame.

Clean the seal seat.

Lubricate the new seal and install it.

21

Assemble stator lower on the motor part.

Make sure that the holes in stator lower

aligns with the dowel pins in the

stator frame.

Knock - with care - the stator lower the whole way down

with a plastic mallet.

22

Assemble the tool, for holding the motor parts together, on

the motor.

Part no. 3122155

23

14

1049170 2018-02-16 © Indexator Rotator Systems AB

Disassemble the plugs/ttings from the grapple- and

rotation inlets. That will make it easier to lift the motor off.

24

Lift the motor off from stator upper. 25

Remove the o-ring in stator upper. 26

15

1049170 2018-02-16 © Indexator Rotator Systems AB

Remove the three seals in stator upper. 27

Clean the seal seats in stator upper. 28

Lubricate the new seals. 29

16

1049170 2018-02-16 © Indexator Rotator Systems AB

Assemble the three new seals in stator upper in the order:

blue-white-blue.

30

Lubricate the new o-ring. 31

Assemble the new o-ring in stator upper. 32

17

1049170 2018-02-16 © Indexator Rotator Systems AB

Only for C model.

Remove the o-ring for the c-channel in stator upper.

Clean the seal seat.

Lubricate the new seal and install it.

33

Make sure that the dowel pins are assembled. 34

To make the reassembly of the motor easier, make a

mark on the outside of the stator frame where the holes

for the dowel pins are positioned.

35

18

1049170 2018-02-16 © Indexator Rotator Systems AB

Make a mark inside stator upper where the dowel pins

are assembled.

36

Position the motor according to the aligned marks. 37

Assemble the motor by knocking it down carefully with a

plastic mallet.

Important that the dowel pins are in the right positions!

It can be of some help to position the motor if one of the

M12 screws is put in its hole.

38

19

1049170 2018-02-16 © Indexator Rotator Systems AB

Assemble 15 pcs M12x110 screws.

Crosswise tightening.

39

Torque the screws 120 Nm. 40

Assemble new seals on the rotator shaft. 41

20

1049170 2018-02-16 © Indexator Rotator Systems AB

Only for C model.

Clean the seal seat and assemble a new o-ring for

the c-channel on the rotator shaft.

42

Assemble the wiper seal between rotator shaft and stator

lower. For s/n before 1605714.

Lubricate the new seals.

Note! The ”at” side upwards, the ”lip” downwards.

43

Assemble the plugs/ttings for grapple and rotation in

stator upper.

44

Table of contents

Other Indexator Industrial Equipment manuals