Induction Solutions Boogie Box NPC-1006 User manual

NPC-1006 Progressive Controller

User Manual

Boogie Box

Induction Solutions

16121 Flight Path Dr

Brooksville, FL 34604

352-593-5900 Phone

352-593-5901 Fax

email: info@inductionsolutions.com

Important—if using the Throttle Position Input for activation refer to

Wiring Diagram #3.

2

Warranty

Inducon Soluons warrants to the original purchaser that the controller shall be free from defects in parts and

workmanship under normal use for 180 days from the date of purchase.

Inducon Soluons obligaon under this warranty is limited to the repair or replacement of any component

found to be defecve when returned postpaid to Inducon Soluons. The Controller must be returned with evidence

of place and date of purchase or warranty will be void. The warranty will not apply if the controller has been installed

incorrectly, repaired, damaged, or tampered with by misuse, negligence or accident.

WhatisIncludedwiththeNPC‐1006kit.

NPC‐1006 Nitrous Controller.

Wiring Harness with sealed automove connectors.

Installaon hardware kit.

User Manual

ImportantInformaon‐Whenusingaconvenonalstyleignioncoil(NotCoilonPlug)youmust

useStacSuppressionIgnionWireswiththisController.

Cauon‐DoNOTsubmergeControllerinliquidordirectlywashunitwithliquidofanytype!(Do

NOTspraywhenwashingvehicle!)

It is the responsibility of the purchaser to follow all guidelines and safety procedures supplied

with this product and any other manufactures product used with this product. It is also the responsi‐

bility of the purchaser to determine compability of this device with the vehicle and other compo‐

nents.

Inducon Soluons assumes no responsibility for damages resulng from accident, improper

installaon, misuse, abuse, improper operaon, lack of reasonable care, or all previously stated rea‐

sons due to incompability with other manufacturer's products.

Inducon Soluons assumes no responsibility or liability for damages incurred from the use of

products manufactured or sold by Inducon Soluons on vehicles used for compeon racing. Induc‐

on Soluons neither recommends nor approves the use of products manufactured or sold by Induc‐

on Soluons on vehicles which may be driven on public highways or roads, and assumes no respon‐

sibility for damages incurred from such use.

It is the purchaser’s responsibility to check the state and local laws pertaining to the use of

Nitrous Oxide for racing applicaons. Inducon Soluons does not recommend nor condone the use

of its products for illegal street racing.

3

Contents

UserInterface

MainScreenandUserInterfaceOverview Page5

DropDownMenuOverview Page6

Slider Bar, Value Adjust Overview Page 6

Solenoid Output Graph Setup Overview Page 7

UsingtheIntegratedHelp Page8

ViewingHelpText Page8

SetupMenu

CurrentSetup Page9

Hold&Wait Page9

MainTimer Page9

TachPulseCount Page10

Trans Brake Input Delay Page 10

RPMWindowEnable Page10

MinimumRPM Page11

MaximumRPM Page11

TPS (Throle PosionSensor)InputSetup

TPSAcvaonEnable Page11

AcvaonPercent Page11

ProgramTPSVoltage Page12

TPS Closed Voltage (Manually adjust voltage) Page 12

TPS WOT Voltage (Manually adjust voltage) Page 12

HelpTextEnable/Disable Page13

FactoryReset Page13

Output1Menu

Output1 Ramp Setup

Graph View‐Setup Page13

CopySetuptoOutput2 Page13

NumberofRamps Page14

StartPercent Page14

Ramp(x)Time Page14

Ramp(x)EndPercent Page14

Output1Delay Page15

Output1Frequency Page15

Output1ResumePercent Page15

Output1ResumePercentPerPulse Page15

Output2Menu

Output2Setup Page15

4

TimerMenu

Timer1Setup Page16

Timer1Sync Page16

AcvaoninputEnable Page16

Trans Brake input Enable Page 17

DelayTimerEnable Page17

TimerOnDelay Page17

Timer OffDelay Page17

RPMControlEnable Page17

OnRPM Page18

OffRPM Page18

Timer2Setup Page18

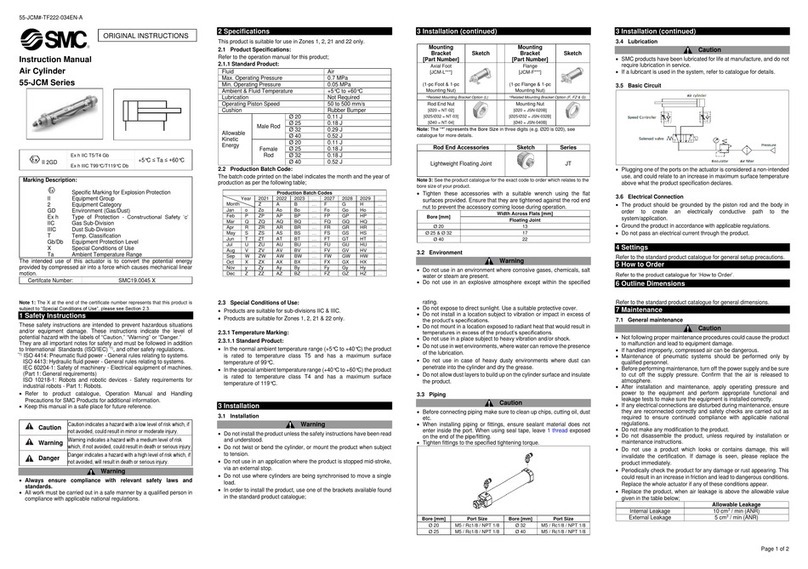

ControllerInstallaon

WiringDiagrams Page19,20

TransmissionBrake/ClutchInputWiring Page21

RPM/TachometerInputWiring Page21

Timer1+12VoltOutputWiring Page22

Timer2+12VoltOutputWiring Page22

Throle PosionSensor Page22

ElectricalSpecificaons

Normal Operang Voltage: 10 to 16 volts.

Solenoid Output Maximum Current: 35 amps maximum.

Timer Output Maximum Current: 1 amp with .015 amp pulldown to ground when off.

Acvaon Input: 8 to 16 volts @ .04 to .08 amps respecvely.

Throle Posion/Analog Input: 0 to 5 volts normal operang range, maximum 20 volt tolerant.

Tach/RPM Input: 5 to 16 volts square wave signal.

5

MainScreenandUserInterfaceOverview

Setup Button

Global options

Timer Button

Timer Setup

Output2 Button

Output2 Setup

Output1 Button

Output1 Setup

Selected Setup

RPM

TPS Percent

Tran Brake Input

Activation Input

Main Timer

Output1 Percent Output2 Percent

Output1Percent—Readout that displays current Output1 duty cycle percentage.

Output2Percent—Readout that displays current Output2 duty cycle percentage.

MainTimer—Main mer count, this mer starts when the controller is acvated.

AcvaonInput—Acvaon input status, background and text colors invert when input is On.

TransBrakeInput—Transmission brake / Clutch switch input status, background and text colors invert when input is

On.

SelectedSetup—Readout that displays the selected setup.

RPM—Engine rpm, use to verify correct rpm input sengs.

TPSPercent—Throle posion sensor percentage. Will only be acve if the TPS is setup correctly.

Output1Buon—Open the Output1 setup menu.

Output2Buon—Open the Output2 setup menu.

TimerBuon—Open the Timer setup menu.

SetupBuon—Open the Setup menu, all sengs in this menu are global and are not changed when a new Setup is se‐

lected.

6

DropDownMenuNavigaon

Menu Title

Current Selection Scroll Position

Up Button

Selection Up

Down Button

Selection Down

Back Button

Exit Menu

Enter Button

Menu Item Select

BackBuon—use this buon to go back or exit to previous screen.

UpBuon—use this buon to move the highlighted menu item up.

DownBuon—use this buon to move the highlighted menu item down.

EnterBuon—use this buon to select the highlighted menu item.

SliderBar,ValueAdjustOverview

Decrease Button

Adjust Value Down

Increase Button

Adjust Value Up

Escape Button

Exit Without Save

Save Button

Save New Value

Maximum ValueMinimum Value

Value Description New Value

Current Value

EscapeBuon—use this buon to exit without saving.

DecreaseBuon—use this buon to decrease value.

IncreaseBuon—use this buon to increase value.

SaveBuon—use this buon to save new value and exit.

HelpfulHint—press and hold the decrease or increase buon for large value changes.

7

SolenoidOutputGraphViewNavigaon

Ramp Position

Exit Graph View Select Ramp

Field to Edit

Value Adjust Value Adjust

Selectrampposiontoedit.

1—make sure SELECT buon reads SELECT, if not press the buon unl it reads SELECT.

2—use the leand right arrow keys to move the cursor between the ramp posions. The ramp posion readout will

change and display the current ramp posion.

Adjustrampposionpercentage.

1—press the SELECT buon unl it reads PERCENT.

2—use the lebuon to adjust the percentage down and the right buon to adjust the percentage up.

Adjustrampposionme.

1—press the SELECT buon unl it reads TIME.

2—use the lebuon to decrease ramp posion me and the right buon to increase.

Savingchanges.

1—press the BACK buon.

2—if any changes have been made to the solenoid output ramp you will be prompted to confirm seng save.

8

UsingtheIntegratedHelp

No Button

Do NOT View Help

Off Button

Turn OFF Help

Yes Button

View Help Text

YesBuon—use this buon to view help text associated with the current menu selecon.

NoBuon—use this buon to decline viewing help text.

OffBuon—use this buon to turn Offthis screen for all menu selecons.

Important—the help system may be turned On/Offusing the “SETUP” menu from the main screen.

ViewingHelpText

Up Button

Scroll Text Up

Down Button

Scroll Text Down

Exit Button

Exit Help View

ExitBuon—use this buon to exit the help view screen.

UpBuon—use this buon to scroll the help text up.

DownBuon—use this buon to scroll the help text down.

9

SetupMenu—CurrentSetup

There are 3 Data Setups available. The current sengs will be saved when selecng a New Data Setup from the

list. This way mulple User Setups can be stored and recalled at a later me.

Example ‐you have a Setup that is working well, you decide that you would like to try a few different sengs. You

could then Select and Copy current Setup Data to a New Setup and make changes without loosing the original setup.

1—Press the SETUP buon from the main screen.

2—Highlight the Current Setup menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Highlight the setup you would like to switch to and press the ENTER buon.

4—Choose if you would like to copy the current sengs to the new setup.

5—Press the BACK buon to return to the main screen.

Important—all of the sengs in the Setup menu are global. These sengs are not copied or changed when selecng a

new Setup.

SetupMenu—Hold&Wait

Hold & Wait Opon ‐This seng allows the Progressive system to Hold & Wait when the Acvaon signal is

removed. Example ‐the throle is lied due to wheel spin or ? This allows the Progressive system to resume at the

point where the throle was lied. Hold & Wait is enabled by default from the factory.

Note—If this opon is OFF the Progressive system and All Timers will reset each me the Acvaon is removed. Also

the Resume ramp is disabled for each output.

1—Press the SETUP buon from the main screen.

2—Highlight the Hold & Wait menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Choose YES or NO to enable or disable the opon.

4—Press the BACK buon to return to the main screen.

SetupMenu—MainTimer

Main Timer ‐This seng controls the Main Timer period. This controls the total me elapsed before a System

Timeout occurs. This limits the total amount of me the solenoids can be On if the Acvaon signal is never removed.

This seng also allows the system to be used with Hold & Wait opon and the Progressive Timers will reset aer the

Timeout Period has elapsed and the Acvaon signal is removed. This enables a Reset without powering the unit down.

This seng is in Seconds with a range of 20 to 300 seconds. Factory seng is 20 seconds and a longer meout period

would be used in special cases such as speed records.

1—Press the SETUP buon from the main screen.

2—Highlight the Main Timer menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

4—Press the BACK buon to return to the main screen.

10

SetupMenu—TachPulseCount

Tach Input Pulse Per Revoluon ‐this seng determines the number of Tach Pulses per revoluon of the

cranksha.

Example ‐if the Tach Signal input is connected to a common V8 engine mul‐spark ignion controller a seng of 4

Pulse per Revoluon would be used.

Common sengs are,

1 Pulse per Two Revoluons = modern coil on plug systems with white wire connected to single coil wire.

1 Pulse per Revoluon = single cylinder engine and some twin cylinder motorcycle engines.

2 Pulse per Revoluon = 4 cylinder car and motorcycle engines.

3 Pulse per Revoluon = 6 cylinder engines.

4 Pulse per Revoluon = 8 cylinder engines.

1—Press the SETUP buon from the main screen.

2—Highlight the Pulse Per Rev menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Highlight the Pulse per Rev seng desired and press the ENTER buon to save.

4—Press the BACK buon to return to the main screen.

SetupMenu—TransBrakeInputDelay

Trans Brake/Clutch Input Delay Timer ‐this seng controls how long the Trans Brake/Clutch input must be On before

accepng the signal. The clutch input hold delay seng is ignored unl the controller is Acvated. Before the controller

is Acvated the clutch input is recognized in real me with no delay. This seng could be used to ignore shis with a

manual transmission (1 second) or a very low seng would act as noise filter to ignore spurious signals (.005 second).

If a clutch input signal is received and accepted aer the controller is acvated the system will turn offthe progressive

system and mers. This would allow the nitrous to be turned Offduring a shiand resumed when the clutch is re‐

leased.

1—Press the SETUP buon from the main screen.

2—Highlight the Tbrake In Delay menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

4—Press the BACK buon to return to the main screen.

SetupMenu—RPMWindowEnable

Enable RPM control ‐this seng enables a RPM Window funcon for both Outputs.

NOTE ‐If the RPM window feature is enabled and the engine is not running the solenoids can be dry fired for tesng.

Once an RPM signal is present the solenoids will only fire at the desired RPM range.

1—Press the SETUP buon from the main screen.

2—Highlight the RPM Window (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Choose YES or NO to enable or disable the opon.

4—Press the BACK buon to return to the main screen.

11

SetupMenu—MinimumRPM

Minimum RPM ‐this seng controls the minimum engine RPM that must be achieved before Outputs will turn

On. A seng of 0 will disable the Minimum RPM funcon and the Maximum RPM seng will be used to turn offthe

Outputs if the engine RPM exceeds the seng.

1—Press the SETUP buon from the main screen.

2—Highlight the Minimum RPM menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

4—Press the BACK buon to return to the main screen.

SetupMenu—MaximumRPM

Maximum RPM ‐this seng controls the maximum engine RPM that the Outputs remain On. When the engine

RPM exceeds this seng The Outputs will be turned Off. The Maximum RPM must be at least 100 RPM greater than

the Minimum RPM seng.

1—Press the SETUP buon from the main screen.

2—Highlight the Maximum RPM menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

4—Press the BACK buon to return to the main screen.

SetupMenu—TPS(ThrolePosionSensor)InputSetup

TPS Acvaon opon ‐this feature allows the throle posion sensor input to control system acvaon.

Important—The Acvaon Input must also be used even if this opon is selected and use wiring diagram #3.

1—Press the SETUP buon from the main screen.

2—Highlight the TPS Input Setup menu selecon and press the ENTER buon.

3—Highlight the TPS Acvaon is (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

4—Choose YES or NO to enable or disable the opon.

5—If turning this opon On you must program and/or set the TPS closed and wide open voltages before the controller

will acvate.

Note—the TPS voltage must have a minimum span of 2.5 volts between the closed seng and the wide open throle

seng. The voltage can sweep up or down. Once the setup is complete the TPS posion will be calculated and dis‐

played as a percentage with a range of 0 to 100%.

SetupMenu—TPSInputSetup—AcvaonPercent

TPS Acvaon Percent ‐this seng determines the TPS percent at which system acvaon will occur. The

“Acvaon Input” must be ON as well.

Note—recommended seng is 90%.

1—Press the SETUP buon from the main screen.

2—Highlight the TPS Input Setup menu selecon and press the ENTER buon.

3—Highlight the Acvaon % menu selecon and press the ENTER buon. (If Help is on choose opon)

4—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

5—Press the BACK buon to return to the main screen.

12

SetupMenu—TPSInputSetup—ProgramTPSVoltage

The TPS Input Closed and Wide Open Throle can be set using Live data from the TPS Input or these values can

be set manually. With the key on but the engine off, with your foot offthe throle press the SET MIN buon, apply full

throle and press the SET MAX buon. The actual TPS input voltage will be displayed and this should be used to verify

correct operaon. On some electronic throle vehicles you will not be able to set the Wide Open Throle voltage with

the engine offand the sengs must entered manually.

Important—IfthismodulecausestheECMtosetacodeorcausesanyotherengineoperaonissues,disconnectanddisconnue

theuseofthismoduleImmediately.Althoughthisinterfacehasbeentestedonavarietyofvehiclesitmaynotbecompable

withall.

Important—SomethroleposionsensorsnolongerprovideananalogsignaltotheECM,thesesensorssendadigitaldata

streamtotheECM.ThiscontrollerisNOTcompablewiththistypeofsensor.

1—Press the SETUP buon from the main screen.

2—Highlight the TPS Input Setup menu selecon and press the ENTER buon.

3—Highlight the Program TPS Voltage menu selecon and press the ENTER buon. (If Help is on choose opon)

4—With the throle in the closed posion and engine OFF press the SET CLS buon.

5—With the throle in the wide open posion and the engine OFF press the SET WOT buon.

6—Press the BACK buon to return to the main screen.

SetupMenu—TPSInputSetup—TPSClosedVoltage

TPS Closed Voltage ‐this seng is the TPS voltage with the throle in the closed posion.

1—Press the SETUP buon from the main screen.

2—Highlight the TPS Input Setup menu selecon and press the ENTER buon.

3—Highlight the TPS Closed Voltage menu selecon and press the ENTER buon. (If Help is on choose opon)

4—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

5—Press the BACK buon to return to the main screen.

SetupMenu—TPSInputSetup—TPSWOTVoltage

TPS WOT Voltage ‐this seng is the voltage with the Throle Posion Sensor in the wide open throle posi‐

on.

1—Press the SETUP buon from the main screen.

2—Highlight the TPS Input Setup menu selecon and press the ENTER buon.

3—Highlight the TPS WOT Voltage menu selecon and press the ENTER buon. (If Help is on choose opon)

4—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

5—Press the BACK buon to return to the main screen.

13

SetupMenu—HelpTextEnable/Disable

This seng turns the help text on or off.

1—Press the SETUP buon from the main screen.

2—Highlight the Help is (ON/OFF) menu selecon and press the ENTER buon.

3—Choose YES or NO to enable or disable the opon.

4—Press the BACK buon to return to the main screen.

SetupMenu—FactoryReset

Factory Reset ‐Selecng this opon will return ALL Sengs to the original Factory sengs.

1—Press the SETUP buon from the main screen.

2—Highlight the Factory Reset menu selecon and press the ENTER buon. (If Help is on choose opon)

3—Choose YES, NO or CANCEL to confirm the reset acon desired.

4—Press the BACK buon to return to the main screen.

Output1Menu—Output1RampSetup

This selecon will open the Output1 Ramp menu, this is where the start percentage, build me, and final per‐

centage for the output are set. Each output can have up to five med progressive ramps.

To enter the output ramp setup menu,

1—Press the OUT1 buon from the main screen.

2—Highlight the Output1 Ramp Setup menu selecon and press the ENTER buon.

Output1Menu—GraphView‐Setup

This menu selecon will open a graph view of the solenoid output ramp. This opon may be used to view the

current setup as a graph view and/or edit the output ramp. Individual output ramp sengs can also be adjusted using

the Output1 Ramp menu. Using either the graph view or the menu selecons may be used, both methods are provided

and it is user preference as to which one to use.

1—Highlight the Graph View menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Refer to page 7, Solenoid Output Graph View Navigaon for more informaon.

Output1Menu—Output1RampSetup—CopySetuptoOutput2

Use this funcon to copy this output channel setup to the other output setup. This provides an easy way to

sync both outputs.

Important—only the sengs from the output ramp setup menu will be copied with this opon.

1—Highlight the Copy Setup to Output2 menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Confirm the copy funcon by pressing the YES buon or NO to exit without copying the ramp setup data.

14

Output1Menu—Output1RampSetup—NumberofRamps

This seng determines the total number of progressive ramps available for this output channel. The number of

ramps is adjustable from 1 to 5.

Note—each output can have a different number of ramps (set points).

1—Highlight the Number of Ramps menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the ramp setup menu.

Output1Menu—Output1RampSetup—StartPercent

This seng determines the output starng percent. This is the output duty cycle when Acvaon starts. If the

output channel has a Delay programmed the output will remain offunl the delay me has expired.

1—Highlight the Start Percent menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the ramp setup menu.

Output1Menu—Output1RampSetup—Ramp(x)Time

This seng determines the me for the progressive ramp to reach the end percent. There is a ramp me for

each Ramp that is enabled using the Number of Ramps seng.

1—Highlight the Ramp(x) Time menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the ramp setup menu.

Output1Menu—Output1RampSetup—Ramp(x)EndPercent

This seng determines the output duty cycle percent at the end of the current ramp. The end percent can be

higher or lower (output percent can go up or down) than the previous end percent if desired.

1—Highlight the Ramp(x) End Percent menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the ramp setup menu.

15

Output1Menu—Output1Delay

This seng controls the delay me in seconds before the output starts aer acvaon.

1—Highlight the Output1 Delay menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to return to the main screen.

Output1Menu—Output1Frequency

The solenoid pulse frequency (or also known as Hertz) is how many mes the solenoids open and close per sec‐

ond when not at 0 or 100 percent operaon. There are many different styles of solenoids available and they will react

differently to changes in the operang frequency. It is up to the user to verify that the solenoids are opening properly

with the sengs used for operaon.

1—Highlight the Output1 Frequency menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to return to the main screen.

Output1Menu—ResumePercent

This seng determines the percent the output resumes at if the user has to lithe throle during Acvaon.

This seng is only valid if the Hold And Wait opon is ON. This seng is used with the Resume Percent per Pulse

seng to build a Resume Ramp. If the Resume Start Percent is greater than the current output percent the resume

ramp is ignored.

1—Highlight the Resume Percent menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to return to the main screen.

Output1Menu—PercentPerPulse

This seng determines the rate at which the output Resumes if the user lis the throle during Acvaon. This

seng is used with the Resume Start Percent to build a Resume Ramp. This allows the user to adjust how quick the out‐

put comes back on if the Acvaon signal is removed.

1—Highlight the Percent Per Pulse menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to return to the main screen.

Output2Menu

Please refer to the Output1 instrucons and apply the operaons to Output2.

16

TimerMenu—Timer1Setup

Stage1 Timer, Timing Retard Control ‐this seng configures the Stage1 Timer, +12V output to be On whenever

Output1 is On (Solenoids funconing).

If this seng is Offthen the Timer1 output can be configured by selecng which control parameters are used to turn

On the mer output. When more than one control parameter has been selected all must meet the condions as config‐

ured before the mer output will funcon.

Example ‐Acvaon Input Enabled and RPM Enabled, RPM On = 2000 and RPM Off= 4000, the Timer1 output will only

be on when the Acvaon Input is acve and the engine rpm is between 2000 and 4000 rpm.

This output supplies +12V when On. This output may be used to drive an external relay with a load of no more than 1

amp.

To enter the mer setup menu,

1—Press the TIMER buon from the main screen.

2—Highlight the Timer1 Setup menu selecon and press the ENTER buon.

TimerMenu—Timer1Setup—Timer1Sync

Timer1 Sync ‐this seng configures Timer1 to be On whenever Output1 is acve. This configuraon can be

used to control ignion retard.

If this seng is Offthen the Timer1 output can be configured by selecng which control parameters are used to turn

On the mer output. When more than one control parameter has been selected all must meet the condions as config‐

ured before the mer output will funcon.

1—Highlight the Timer1 Sync (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Choose YES or NO to enable or disable the opon.

TimerMenu—Timer1Setup—AcvaonEnable

When this seng is On the Timer1 output will be on when the Acvaon Input has +12V applied.

Note—if the TPS input is enabled the Acvaon Input and the TPS Input determine if the output is on.

1—Highlight the Acvaon Enable (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Choose YES or NO to enable or disable the opon.

TimerMenu—Timer1Setup—AcvaonEnable

When this seng is On the Timer1 output will be on when the Acvaon Input has +12V applied.

Note—if the TPS input is enabled the Acvaon Input and the TPS Input determine if the output is on.

1—Highlight the Acvaon Enable (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Choose YES or NO to enable or disable the opon.

17

TimerMenu—Timer1Setup—TransBrakeEnable

When this seng is On the Timer1 output will be on when the Trans Brake Input has +12V applied.

1—Highlight the Tbrake Enable (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Choose YES or NO to enable or disable the opon.

TimerMenu—Timer1Setup—DelayTimer

This seng enables a Delay Timer with a programmable On and Offme.

1—Highlight the Delay Timer (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Choose YES or NO to enable or disable the opon.

TimerMenu—Timer1Setup—TimerOnDelay

If the On seng is 0 there will be No delay and the output will remain ON for the amount of me set by the Off

seng.

If the Offseng is 0 the output will remain OFF unl the On Delay seng mes out aer acvaon.

1—Highlight the Timer On Delay (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the Timer1 menu.

TimerMenu—Timer1Setup—TimerOffDelay

If the On seng is 0 there will be No delay and the output will remain ON for the amount of me set by the Off

seng.

If the Offseng is 0 the output will remain OFF unl the On Delay seng mes out aer acvaon.

1—Highlight the Timer OffDelay (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the Timer1 menu.

TimerMenu—Timer1Setup—RPMControl

This seng enables a RPM Window switch for the Timer1 output.

1—Highlight the RPM Control (ON/OFF) menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Choose YES or NO to enable or disable the opon.

18

TimerMenu—Timer1Setup—OnRPM

Engine RPM On, Off‐these sengs control the Timer output based on Engine RPM.

If the On seng is 0 the output will be On unl the engine rpm exceeds the OFF RPM seng. If the OFF RPM seng is 0

the output will remain Offunl the engine rpm exceeds the ON RPM seng.

If neither the ON or the OFF seng is 0 the output will only be On when the engine rpm is within the ON RPM and OFF

RPM range.

1—Highlight the On RPM menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the Timer1 menu.

TimerMenu—Timer1Setup—OffRPM

Engine RPM On, Off‐these sengs control the Timer output based on Engine RPM.

If the On seng is 0 the output will be On unl the engine rpm exceeds the OFF RPM seng. If the OFF RPM seng is 0

the output will remain Offunl the engine rpm exceeds the ON RPM seng.

If neither the ON or the OFF seng is 0 the output will only be On when the engine rpm is within the ON RPM and OFF

RPM range.

1—Highlight the OffRPM menu selecon and press the ENTER buon. (If Help is on choose opon)

2—Adjust the value as desired. (See “Slider Bar, Value Adjust Overview”)

3—Press the BACK buon to exit the Timer1 menu.

TimerMenu—Timer2Setup

Please refer to the Timer1 instrucons and apply the operaons to Timer2.

19

WiringDiagram#1—(CommonPlateSystem)currentdrawlessthan30ampscombined.

WiringDiagram#2—(DirectPortSystem)currentdrawlessthan35ampscombined.

20

WiringDiagram#3—(DirectPortHighAmp)currentdrawmorethan35ampscombined.

WiringDiagram#4—(2‐StageDirectPortHighAmp)currentdrawmorethan35ampscombined.

Table of contents

Other Induction Solutions Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens SIMATIC S5 manual

Mitsubishi Electric

Mitsubishi Electric MELSEC-Q QnPHCPU Programming manual

HP

HP ProCurve MSM765zl installation guide

FUTABA

FUTABA MC601C Multipurpose Edition instruction manual

Siargo

Siargo MFC3000 Series manual

Oracle

Oracle MICROS Kitchen Display Controller 210 Setup guide

iNels

iNels IM2-140M Manual instructions

MICROIDEA

MICROIDEA EPFCB installation manual

Excelitas Technologies

Excelitas Technologies OmniCure LX500 quick start guide

Melink

Melink Intelli-Hood installation manual

Morningstar

Morningstar ProStar PS-30M-PG Operator's manual

Crestron

Crestron QM-RMC Operation guide