Exlar Curtiss-Wright Tritex TTX Series Installation and maintenance instructions

Information furnished by Exlar Corporation is believed to be accurate and reliable. However, no responsibility is assumed by Exlar Corporation for

its use. Exlar reserves the right to change the design and operation of the equipment described herein and any associated motion products that

may appear in this document. Information in this document pertaining to equipment not furnished by Exlar should be conrmed by that equipment

manufacturer. Exlar assumes no responsibility for changes to information by other manufacturers or errors in that information or the description of that

information. Information in this document is subject to change without notice.

This document does not contain any export-controlled technical data.

Installation & Service Instructions

Rev. D | PN75667 | 8/1/22

Tritex®TTX SERIES actuators

Tritex® TTX Vdc Models

2| Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

CONTENTS

1.0 INTRODUCTION ............................................................... 3

1.1 General Product Description......................................... 3

1.2 Product Features........................................................... 3

1.3 Safety Considerations................................................... 5

2.0 SYSTEM CONFIGURATION ............................................ 6

2.1 Tritex TTX Series Actuator............................................ 6

2.2 Options ......................................................................... 6

2.2.1 Internal Holding Brake.......................................... 6

2.2.2 Anti-Rotation Assembly......................................... 6

2.2.3 External Limit Switch ............................................ 6

3.0 MECHANICAL INSTALLATION ........................................ 6

3.1 Mounting Congurations............................................... 6

3.2 Mounting Considerations .............................................. 8

3.2.1 General Operation...................................................... 8

3.2.2 Actuator Alignment ............................................... 8

3.2.3 Anti-Rotation Assembly ........................................ 9

3.2.4 External Limit Switches.......................................10

3.3 Lubrication................................................................... 11

3.4 Outdoor and Wash Down Installations........................ 11

4.0 ELECTRICAL INSTALLATION........................................ 12

4.1 Introduction ................................................................. 12

4.2 Supplied Connectors .................................................. 14

4.3 Grounding (PE) Connection........................................ 14

4.3.1 Shielding............................................................. 14

4.3.2 Other Grounding Considerations........................ 15

4.4 DC Input Power........................................................... 15

4.4.1 Input Power Ratings ........................................... 15

4.5 Over Temperature Protection...................................... 15

4.6 I/O Power Supply........................................................ 15

4.6.1 I/O Connector Wiring.......................................... 16

4.7 Digital Inputs............................................................... 18

4.8 Digital Outputs ............................................................ 18

4.9 Actuator Brake Option................................................. 19

4.10 Analog Input.............................................................. 19

4.11 Analog Output ........................................................... 20

4.12 Communications....................................................... 20

4.13 IA4 Option Board Connections ................................. 21

4.14 4-20 mA Input ........................................................... 22

4.14.1 4-20 mA Input Connection................................ 22

4.15 4-20 mA Output......................................................... 22

4.16 Absolute Feedback ................................................... 23

4.17 Battery Life Information............................................. 23

4.17.1 Low Battery Voltage.......................................... 23

4.17.2 Replacing the Battery ....................................... 24

4.18 Ethernet Options, EIP, TCP or PIO........................... 24

4.19 Shielded or Unshielded Cables ................................ 24

5.0 MAIN POWER SUPPLY SELECTION............................... 25

5.1 Unregulated AC/DC Power Supplies .......................... 25

5.2 Regulated AC/DC Power Supplies ............................. 25

5.3 Power and Battery Systems ....................................... 26

5.4 Handling Regen Energy-Internal Shunt...................... 26

5.5 Handling Regen Energy-External Shunt..................... 27

5.6 Logic Power Supply.................................................... 27

5.7 Power Supply Wiring Diagrams.................................. 27

5.8 Grounding................................................................... 28

5.9 Power Supply Connections......................................... 28

6.0 STARTUP .......................................................................... 29

6.1 Considerations for Startup.......................................... 29

6.1.1 Safety Considerations ........................................ 29

6.1.2 Rotary-to-Linear Motion Relationship................. 29

6.2 General Startup Procedure......................................... 29

7.0 MAINTENANCE PROCEDURES...................................... 30

7.1 Lubrication .................................................................. 30

7.2 Seal Maintenance....................................................... 31

7.3 Replacement Faceplate Assembly Kit ........................ 31

8.0 TROUBLESHOOTING PROCEDURE .............................. 32

9.0 CABLE ACCESSORIES.................................................... 33

9.1 TTIOC-xxx I/O Cable .................................................. 33

9.2 CBL-TTIPC-SMI-xxx Power Cable ............................. 33

9.3 TTICO-xxx Communications Cable ............................ 34

10.0 PRODUCT RETURNS .................................................... 35

11.0 CERTIFICATIONS ........................................................... 35

12.0 WARRANTY AND LIMITATION OF LIABILITY................ 36

TTX Series DC Actuator Installation & Maintenance Instructions | 3www.exlar.com | 952.500.6200

1.0 INTRODUCTION

1.1 GENERAL PRODUCT DESCRIPTION

The Tritex TTX Series is Exlar’s latest family of fully integrated

linear actuators. They feature a robust planetary roller screw

mechanism integrated into the rotor of a brushless servomotor

and drive. This unique design combines the high speed and

high load capacity of the roller screw with the high torque-to-

volume ratio of the brushless servomotor. This manual applies

only to the Tritex TTX DC actuators. Other manuals will cover

Tritex TTX AC actuators. All the required power components

and the motion processor are contained in the actuator housing.

Commissioning software and set-up uses the Exlar Expert™

software tools used on all Tritex II integrated actuators

Actuator Mechanical Specications and Ratings

Please refer to the Tritex TTX Standard Product Catalog for

mechanical specications and output force ratings. The catalog

also contains available model options and ordering information

for specic model selection.

Tritex TTX Series actuators feature an Ingress Protection

Rating of IP66S.

1.2 PRODUCT FEATURES

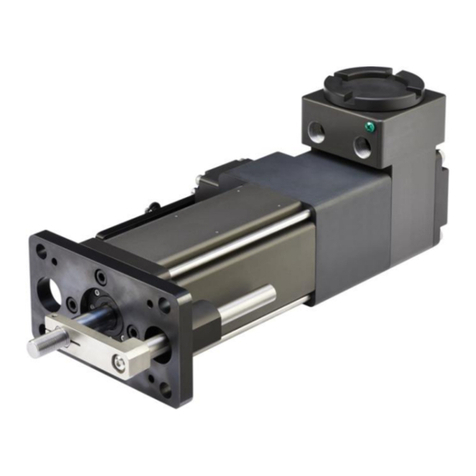

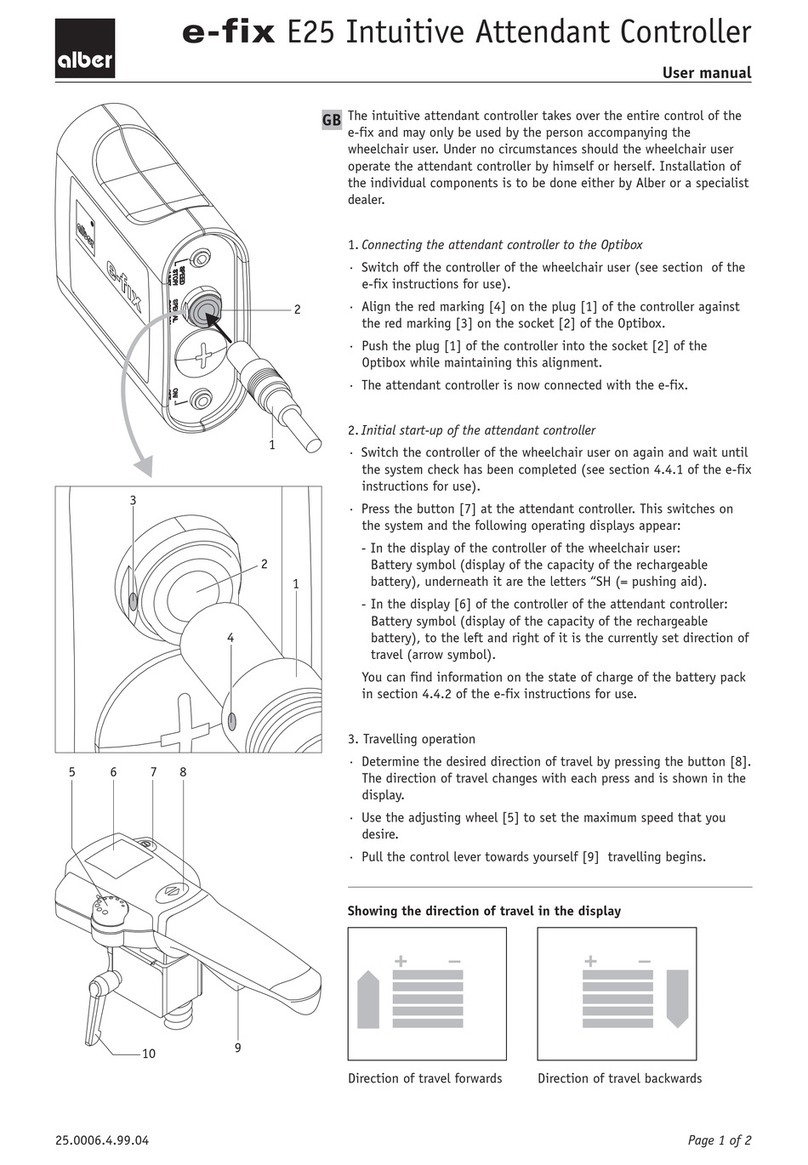

Figure 1 – Tritex TTX060 Series Actuator features

Motor & Roller

Screw Housing

RS485 Port: Modbus RTU

Conguration or Command

Ethernet Port:

EtherNet/IP

PROFINET

Modbus TCP

Actuator Main Rod

Power Connector:

Main and Control Power,

GND (PE)

Electronics Housing

Figure 1 – Tritex TTX080 Series Actuator features

Electronics Housing

Actuator Main Rod

Motor & Roller

Screw Housing

Ethernet Port:

EtherNet/IP

PROFINET

Modbus TCP

RS485 Port: Modbus RTU

Conguration or Command

Power Connector:

Main and Control Power,

GND (PE)

4| Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

DRIVE SPECIFICATIONS FOR ALL TRITEX TTX DC MODELS

Drive Specications

Main Power Input Voltage

Control and Power Input

Voltage (Optional)

Nominal Input Voltage: 12 to 48 Vdc

Tolerance: ±10% of nominal

Note: Control Power is optional.

Optional External I/O

Power Supply

(Required with brake)

24 Vdc ±10% - 0.8 A dc max load

Provides power for Digital Outputs when powering brake and 12 to 30 V when no brake is used

Requires Class 2 source, or protected by 3 A maximum fuse

Digital Inputs 10 to 30 Vdc for ON state

0 to 1 Vdc or 0 to 1mA for OFF state

Common return at “I/O Common” terminal

Programmable functions.

Number of channels varies by I/O option: 4 for 4-20 mA and 8 for all others

Digital Outputs Powered at I/O +24 V terminal

1 V maximum drop from supply voltage

100 mA continuous load per channel

Short circuit and overload protected

Programmable functions

Number of channels varies by I/O option: 3 for 4-20 mA and 4 for all others

Analog Input

(Not available on 4-20 mA

I/O option)

0-10 V or ±10 V dierential input

13-bit resolution, ±0.2% accuracy.

Programmable function – Position, Velocity, or Torque

Analog Output

(Not available on 4-20 mA

option)

0-10 V at up to 10 mA

11-bit resolution; ±0.5% accuracy

Programmable function

4-20 mA Analog Input

(4-20 mA I/O option only)

Externally powered, fully isolated

11.5 V max lift-o at 20 mA

14-bit resolution, ±0.1% of span accuracy

Programmable function – Position, Velocity, or Torque

4-20 mA Analog Output

(4-20 mA I/O option only)

Externally powered, fully isolated

12 V max lift-o at 20 mA

12-bit resolution, ±0.2% accuracy

Serial Interface Optically isolated RS485, Modbus RTU protocol

Selectable bit rate: 38.4 kbaud max

Commutation Sinusoidal, 10kHz pw, space vector voltage

Position Feedback Resolution: 0.001 revolution

Accuracy: ±0.002 revolution

Multi-turn absolute position is standard, but may be disabled and battery back-up removed

Enclosure Rating IP66S with plugs, caps, and cover properly installed and connectors or wiring ports properly sealed

Environmental Operating temperature range: 0 °C to 65 °C

Derate continuous current 1% per 1 °C above 25 °C

Storage Temperature: -40 °C to 85 °C

Operational Altitude: up to 3000 m

Long-term vibration: 1 grms 5 to 500 Hz

Occasional vibration: 2.5 grms 5 to 500 Hz. Shock: 5g peak

TTX Series DC Actuator Installation & Maintenance Instructions | 5www.exlar.com | 952.500.6200

1.3 SAFETY CONSIDERATIONS

Safety is of paramount importance during the installation and

operation of your Tritex TTX Series actuator. Throughout this

manual, content agged with the cautionary symbols shown

below should be read carefully by installers and operators to

help avoid property damage, personal injury or death.

WARNING! Indicates a potentially hazardous situation

which could result in serious injury or death if precautions are

not

CAUTION! Indicates the information following is

necessary for avoiding a risk of damage to the product or other

equipment.

IMPORTANT Identies statements that provide important

information to help ensure safe and trouble-free installation and

operation.

Several general warnings and cautions follow. In addition, refer

to the AGENCY APPROVALS section for Conditions of Use for

additional limits and requirements to ensure safe installation

and operation.

WARNING! General

Failure to follow safe installation guidelines can cause death

or serious injury. Voltages and currents in the product can

cause electric shock or burns and could be lethal. Extreme

care is necessary at all times when working with or adjacent

to the product. The installation must comply with all relevant

safety legislation in the country of use. The forces created by

the actuator could be lethal or cause severe injury if proper

protection is not provided to keep personnel away from moving

components.

WARNING! System Design and safety for personnel

The actuator is intended as a component for professional

incorporation into complete equipment or a system. If installed

incorrectly, the actuator may present a safety hazard. The

actuator uses high voltages and currents, carries a high level of

stored electrical energy, and is used to control equipment which

can cause injury. Close attention is required to the electrical

installation and the system design to avoid hazards either in

normal operation or in the event of equipment malfunction.

System design, installation, commissioning, and maintenance

must be carried out by personnel who have the necessary

training and experience. They must read this safety information

and this manual carefully.

None of the functions or features of the Tritex TTX actuator may

be used to ensure safety of personnel. They must not be used

for safety-related functions.

For example, the actuators enable / disable, brake, stop/

start and forward/reverse functions are not sucient for use

in safety-critical applications without additional independent

channels of protection. Careful consideration must be given to

the functions of the actuator, which might result in a hazard,

either through their intended behavior or through incorrect

operation due to a fault. In any application where a malfunction

of the actuator or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and

where necessary, further measures taken to reduce the risk- for

example a fail-safe brake in case of loss of actuator braking

power.

WARNING! Hot Surface – Risk of Burn

Exposed surfaces of the actuator may exceed 70 °C under

normal operation and can take a long time to cool, resulting in a

risk of burns when touched.

6| Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

1.4 LABEL INFORMATION

Actuator Type

TTX = Integrated Drive / Motor / Actuator

AAA = Actuator Frame Size

080 = 80 mm (3.15 in)

060 = 60 mm (2.36 in)

BBB = Stroke Length

100 = 100 mm

150 = 150 mm

300 = 300 mm

450 = 450 mm

CC =Screw Lead

01 = 0.10 in (2.54 mm)

02 = 0.20 in (5.08 mm)

05 = 0.50 in (12.7 mm)

D = Winding Voltage

4 = 230 Vac Max

D = 48 Vdc Max

E = Rod End Thread

A = Male Metric

B = Female Metric2

M = Male, English)2

F = Female, English2

F = Internal Holding Brake

N = No Brake

B = Internal Holding Brake, Electrically Released

G = Amplier Voltage

A = 200 Vac Class

D = 48 Vdc Class

HHH = Option Boards

SIO = Standard I/O Interconnect

IA4 = 4-20 mA Analog I/O

EIP = SIO plus EtherNet/IP w/M12 connector

PIO = SIO plus PROFINET IO w/M12 connector

TCP = SIO plus Modbus TCP w/M12 connector

M = Mounting Options

N = None

1 = Front Flange, Metric

3 = Tapped Face, Metric

5 = Rear Clevis, Metric

F = Front Flange, English2

C = Rear Clevis, English2

N = Accessory Options

N = None

A = Anti-Rotate Assembly

L = Limit Switch Housing / Anti-Rotate Assembly1

1Switches sold separately

2 Available option. May add lead time.

Sample Product Number: TTX080-0300-02-D-B-B-D-PIO-1-A

Option Boards

Stroke Length

BBB DG

Winding Voltage

Actuator Type & Frame Size

TTX AAA

Rod End Thread

Screw Lead

CC E FM

Mounting Options

N

Other Options

Internal Holding Brake Amplifier Voltage

HHH

TTX Series DC Actuator Installation & Maintenance Instructions | 7www.exlar.com | 952.500.6200

2.0 SYSTEM CONFIGURATION

2.1 TRITEX TTX SERIES ACTUATOR

Tritex TTX Series actuators provide a robust solution for long-

life, continuous-duty applications even when environmental

contaminants are an issue. In most rotary-to-linear devices,

critical mechanisms are exposed to the environment and must

be frequently inspected, cleaned and lubricated. In contrast,

Tritex TTX Series actuators are designed with all converting

components mounted within sealed motor housings. With a

simple bushing and seal on the smooth extending rod, abrasive

particles or other contaminants are prevented from reaching

the actuator’s critical mechanisms. As a result, actuator life

can exceed that of a ball screw actuator by 15 times, even in

high-speed, high-force applications. In addition, the Tritex TTX

Series has an on-board amplier with control software and

rmware available from Exlar.

2.2 OPTIONS

2.2.1 Internal Holding Brake

Many applications require the addition of a holding brake. The

Exlar internal holding brake is engaged by a permanent magnet.

The mechanical advantage of the roller screw allows the holding

brake to prevent the output rod from back driving the load. The

holding capacity of the brake is sucient to hold the rated force

of the actuator.

2.2.2 Anti-Rotation Assembly

The unique design of Tritex TTX Series actuators helps simplify

actuator setup by allowing the user to rotate the extending

rod and thread it in and out of the actuator for mechanical

attachment or system testing. In most applications, the load

is coupled to linear bearings or some other support device,

preventing rotation during operation. To ensure proper linear

motion in applications in which the rod is free to rotate, an Anti-

Rotate Assembly is required to prevent the rod from rotating.

2.2.3 External Limit Switch

A Tritex TTX Series actuator equipped with the anti-rotate and

limit switch options can accommodate multiple limit switches

for use as end-of-travel limit switches or home position sensors

positioned outside the low-prole extruded channel housing.

3.0 MECHANICAL INSTALLATION

3.1 MOUNTING CONFIGURATIONS

Figure 2 – Mounting congurations

Tritex TTX Series actuators mounting congurations:

• Rear clevis

• Front ange

• Tapped face

• Side mount.

TTX060: 5 mm Hex

TTX080: 6 mm Hex

Torque: 4.6 Nm (3.4 ft-lbs)

Torque: 12.2 Nm (9 ft-lbs)

Figure 3 – Rear clevis mount (NOTE: Dimension drawings can be

found in the Tritex TTX Series catalog or on the Exlar website.)

TTX080 shown as example

TTX080 shown as example

8| Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

Figure 4 – Flange mount

TTX060: 5 mm Hex

TTX080: 6 mm Hex

TTX060: 5 mm Hex

TTX080: 6 mm Hex

18 mm Long

25 mm Long

30 mm Long

40 mm Long

TTX060: Torque 4.6 Nm (3.4 ft-lbs)

TTX080: Torque 12.2 Nm (9 ft-lbs)

Figure 5 – Tapped face mount

TTX060: 5 mm Hex

TTX080: 6 mm Hex

TTX060: 5 mm Hex

TTX080: 6 mm Hex

18 mm Long

25 mm Long

30 mm Long

40 mm Long

TTX060: Torque 4.6 Nm (3.4 ft-lbs)

TTX080: Torque 12.2 Nm (9 ft-lbs)

TTX Series DC Actuator Installation & Maintenance Instructions | 9www.exlar.com | 952.500.6200

3.2 MOUNTING CONSIDERATIONS

3.2.1 General Operation

The Tritex TTX linear actuators function in the same manner as

a brushless servomotor. The servo amplier is used to rotate

the motor at controlled speed and torque, and for controlled

numbers of revolutions and move times. This rotary motion is

translated into linear motion by the internal planetary roller screw

mechanism of the Tritex TTX Series linear actuator.

See sections 2.2.1, 2.2.2 and 2.2.3 regarding the holding brake,

anti-rotate mechanisms, and external limit switches and that can

aect the operation and motion of the actuator.

The relationship between the rotary motion of the motor and

the linear motion of the actuator corresponds to the following

relationships:

English

Linear Distance Traveled (in)=(Motor Revolutions)*

(Roller Screw Lead (in))

Linear Speed (in/sec) = ((Motor RPM) / 60)*

(Roller Screw Lead (in))

Linear Force (lbf) = ((Motor Torque (in-lbf))*(2π)*

(eciency)) / (Roller Screw Lead (in))

Metric

Linear Distance Traveled (mm) = (Motor Revolutions)*

(Roller Screw Lead (mm)

Linear Speed (mm/sec) = ((Motor RPM) / 60)*

(Roller Screw Lead (mm))

Linear Force (N) = ((Motor Torque (N-m))*(2π)*

(eciency)) / (Roller Screw Lead (mm))

All of the above relationships require proper anti-rotation of the

Tritex TTX actuator rod. For more information on sizing and

selection of Tritex TTX actuator and servo ampliers to power

them, consult the sizing and selection section of the Exlar

catalog.

CAUTION! Care should be taken not to exceed the

physical travel limits of Tritex TTX actuators. Doing so will cause

the actuator to end-crash internally. End crashes can physically

damage the roller screw and the internal components of the

actuator. Care should be taken to avoid high-speed impact with

objects of high rigidity that immediately stop the travel of the

actuator with no deceleration or energy absorption. An example

would be a high-speed impact of two solid steel parts. The

resulting impact will create a very short eective deceleration

time. Kinetic energy contained in the rotating inertia of the

actuator and motor can possibly generate extremely high impact

forces that exceed the mechanical capacities of the actuator and

cause physical damage to the actuator. For applications requiring

this type of impact, contact Exlar application engineering to

ensure that the actuator is properly sized or provisions are made

to absorb the induced energy.

3.2.2 Actuator Alignment

IMPORTANT! Aligning the Tritex TTX Series actuator with

respect to the load it is moving is critical. Any misalignment

will decrease the life of the actuator’s components and may

adversely aect application performance.

CAUTION! Excessive side load on the actuator output

rod will dramatically reduce the life of the actuator and should

be avoided. Side load can result from misalignment or loading

that is not in line with the actuator output rod.

Side-mounting notes:

Tritex TTX Series actuators include threaded holes in the

faceplate and endplate. Exlar recommends using hardened

fasteners to mount an actuator to your machine frame with an

engagement depth of two times the screw diameter for tapped

holes.

Stroke length and centering must be carefully considered to

avoid hitting physical travel limits in linear actuators, including

over travel in fast motion proles. Homing to end of travel may

be done at very slow speed and limited force, but homing

manually or to a limit switch, or maintaining continuous Logic

Power or using the absolute position feedback option to avoid

frequent homing should be considered. Apply appropriate

deceleration ramps to end of moves, or velocity and

acceleration limits in positioners to prevent over-travel.

IMPORTANT! Tighten four cap screws to 12.24 Nm

(9.0 ft-lb) max. Failure to properly tighten the screws can aect

normal operation, damage the actuator and/or cause possible

premature actuator failure.

10 | Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

3.2.3 Anti-rotation Assembly

To keep the extending rod from rotating, Exlar oers the Anti-rotation Assembly shown below.

TTX060: 2.5 mm Hex

TTX080: 2.5 mm Hex

Torque 0.6 Nm (0.5 ft-lbs)

Torque 0.6 Nm (0.5 ft-lbs)

TTX060: 4 mm Hex

TTX080: 5 mm Hex

Torque 4.6 Nm (3.4 ft-lbs)

Torque 9.5 Nm (7 ft-lbs)

5 mm Hex

5 mm Hex

TTX060: Torque 4.6 Nm (3.4 ft-lbs)

TTX080: Torque 4.6 Nm (3.4 ft-lbs)

Figure 6 – Anti-rotation Assembly (shown in standard location)

TTX Series DC Actuator Installation & Maintenance Instructions | 11www.exlar.com | 952.500.6200

3.2.4 External Limit Switches

This option allows multiple external switches (sold separately) to be externally mounted to the actuator. Tritex TTX actuators

generally would not use more than one switch for a home marker. These adjustable switches provide travel indication to the

controller. A bracket with inductive proximity switches mounts to the outside low-prole extrusion and senses a traveling magnet

located inside the anti-rotate tube. This option also provides anti-rotation.

Figure 7 – Limit switch mounting

TTX060: 2.5 mm Hex

TTX080: 2.5 mm Hex

TTX060: Torque 0.6 Nm (5 in-lbs)

TTX080: Torque 0.6 Nm (5 in-lbs)

TTX060: 5 mm Hex

TTX080: 5 mm Hex

Torque 4.6 Nm (3.4 ft-lbs)

Torque 9.5 Nm (84 in-lbs)

TTX060: 5 mm Hex

TTX080: 5 mm Hex

Washer Magnet

TTX060: Torque 4.6 Nm (4 ft-lbs)

TTX080: Torque 4.6 Nm (4 ft-lbs)

TTX060: 5 mm Hex

TTX080: 5 mm Hex

TTX060: Torque 4.6 Nm (4 ft-lbs)

TTX080: Torque 4.6 Nm (4 ft-lbs)

Washer

TTX080 shown as example

12 | Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

3.3 LUBRICATION

Tritex TTX linear actuators are shipped from the factory fully

greased and ready for installation. Exlar uses Mobil SHC 220,

a high performance, extreme-pressure grease. The unique

physical properties of the synthetic base oil provide outstanding

protection against wear, rust, corrosion, and high or low-

temperature degradation. See section 6.1 for more information

on lubrication.

3.4 OUTDOOR AND WASH DOWN INSTALLATIONS

CAUTION! Liquid ingress damages Tritex TTX

electronics

Damage due to water or other liquids can be very extensive,

may not show up immediately, and is not generally covered

under warranty.

Tritex TTX ingress ratings: IP66S. Tritex TTX actuators are not

intended for applications where the actuator could possibly

be submerged. Liquid ingress causes serious damage to

electronics over time. A frequent and often overlooked entry

point is through conduit or wireways. When new, the seals are

eective to IP66S or better. However, over time, and depending

on the amount of side load, seals can wear and eventually allow

moisture in. Here are some additional recommendations to

prevent liquid entry:

1. Avoid installations with main rod or shaft facing up if

possible. Otherwise make external provisions to keep water

away from the main rod or shaft.

2. When using the power and I/O connectors verify the cable

end connectors can seal properly and have the desired

IP rating. Be sure to screw the plug all the way on to the

receptacle for proper sealing.

3. Position conduit ttings or

create a drip loop in cable or

exible conduit so water does

not drain towards the conduit

tting as shown.

4. When the wire termination

cover is re-installed, verify the

gasket is in place and the surfaces of the gasket as well

as the cover are free from debris so a good seal can be

achieved.

5. When re-installing the termination cover install all four

screws to within about one turn from contact, then hold the

cover at in position and bring all screws to seat. Then

tighten the screws to about 0.8 Nm (7 lbf-in).

6. The Tritex TTX actuator has conduit hole plugs to cover

unused conduit entries, verify they are all in place and fully

seated.

Top Mount

Loop

Side Mount

Loop

TTX Series DC Actuator Installation & Maintenance Instructions | 13www.exlar.com | 952.500.6200

4.0 ELECTRICAL INSTALLATION

4.1 INTRODUCTION

All the required power components, motion processor, I/O, and communications ports are contained in the actuator housing. Tritex

TTX DC models do not have an internal 24 Vdc power supply. External I/O Power is required for digital outputs and brake. SRC

+24 terminals are present on termination board but make no internal connection.

The following diagrams show the electrical connections schematically:

24V Power

24VCommon

Output 1

Output 2

Output 3

Input 1

Input 2

Input 3

Input 4

Control Electronics

and Low Voltage

Circuits

DC Input +

DC Input -

I/O Common

RS485+

RS485-

IO +V

SRC +24V

PE PE

4-20mA OUT +

4-20mA IN +

4-20mA IN -

4-20mA OUT -

RS485Common

Shield

GND

Logic Power

PE

IO +V

SRC +24V

Brake +V

Brake

(Optional)

+

-

Power

Supplies

Bus and Motor

Drivers

Jumper-

Figure 8 – Electrical Diagram 4-20 mA

Jumper-

24V Power

24VCommon

Output 1

Output 2

Output 3

Output 4

Input 1

Input 2

Input 3

Input 4

Input 5

Input 8

Control Electronics

and Low Voltage

Circuits

I/O Common

RS485+

RS485-

Input 6

Input 7

IO +V

SRC +24V

Analog Out +

Analog In +

Analog In -

Analog Out Ref

RS485Common

Shield

GND

IO +V

SRC +24V

Brake +V

Ethernet

(Optional)

Ethernet Port

Brake

(Optional)

Bus and Motor

Drivers

DC Input +

DC Input -

PE PE

Logic Power

PE

+

-

Power

Supplies

Figure 9 – Electrical Diagram STD I/O

often used for temporary connection to the Expert™software

conguration tool, but also used for connection to a Modbus

RTU host.

The enclosure cover may be removed for access to I/O and

power terminals and some wiring option jumpers. Removing

the cover also provides access to a battery for multi-turn

absolute feedback. Always replace the cover immediately to

prevent accidental entry of water, wire trimmings, or metal

cuttings from nearby drilling or cutting operations during

installation. See wiring section below.

4.2 SUPPLIED CONNECTORS

All standard models have connectors for external electrical

interface, though the connectors may be removed as needed

for direct wiring to internal terminals or connections.

The connectors are installed in M20x1.5 threaded holes

machined into the rear electronics housing and can be used as

cable entry ports. The power connector is installed in the right

rear port and contains main (motor) power connections. The

I/O connector is installed in the left rear port. The user may

remove or relocate the connectors as needed as long as any

unused holes are properly capped to prevent water or dust

intrusion. Adapters for 1/2 in NPT thread or cable glands may

be used but are not furnished.

4.3 GROUNDING (PE) CONNECTION

There is a protective earth (PE) terminal on the Tritex TTX080

internal power terminal block. On the Tritex TTX060, the PE is

located on the M20 power connector. These connections must

be used to ground the actuator case.

4.3.1 Shielding

In order to meet the European EMC Directive for an installation

to provide immunity from radio frequency (RF) interference and

to minimize RF emissions, the power and I/O wiring or cables

must be shielded. Metallic conduit (solid or exible) can serve

as a shield. Shields must be connected to the enclosure at the

entry / exit point.

Figure 10 – TTX060

Figure 11 – TTX080

A PG 9 threaded hole is machined at the front of the electronic

enclosure. This hole has a connector installed for Ethernet

based communications options: PROFINET, EtherNet/IP, or

Modbus TCP. Otherwise, the hole is plugged but available for

alternate use.

All models have a RS485 connector for Modbus RTU

communications at the front of the electronics enclosure most

PG 9 Port,

shown plugged

w/o Ethernet

Rear M20 ports

for cable entry (2)

Connectors

PG 9 Port,

shown plugged

w/o Ethernet

16 | Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

The connectors and cables supplied by Curtiss-Wright properly

terminate shields. If cable glands are used, make sure the

cable gland has a feature to make contact between the metal

body and shield and that the outer jacket is removed as

recommended by gland manufacturer and installed according to

manufacturer instructions. Example shown in diagram below. A

shield connection such as the one shown does not qualify as a

PE connection.

CAUTION! Avoid Loose Conductive Material

Always apply tape or heat shrink to the end of the shield to

than rated voltage results in proportionally reduced maximum

speed. Refer to Torque/Speed diagrams in catalog for additional

information.

Actuator

Size Input Voltage (Volts DC)

Rated Continuous Input Current

(Amps)

60 mm 12 to 48 ±10% 18.0

80 mm 12 to 48 ±10% 18.0

4.5 OVER TEMPERATURE PROTECTION

UL/CSA approved motor over temperature sensing is not

provided by the actuator. Motor over temperature protection

relies on limiting maximum current to the motor and if time-

averaged motor current exceeds a continuous current setting,

the actuator trips or faults and disables the drive indicating a

Continuous Current fault. The continuous current fault level is

set at the factory and cannot be adjusted. These limits are set

to keep the stator below 130 ⁰C while in a stall condition at

40 ⁰C ambient.

The motor contains a temperature sensor embedded in the

stator windings to provide an actual temperature indication.

The actuator trips or faults when the temperature reaches

130 ⁰C and disables the drive indicating an Actuator Over-

temperature fault.

Additional over temperature protection is provided by a sensor

in the drive electronics which generates a fault when the board

reaches 110 ⁰C.

Though some fault conditions may be congured to take action

other than to disable the actuator immediately, reconguration

of these two faults is not allowed in order to protect the actuator

motor and electronics.

4.6 I/O POWER SUPPLY

An external I/O Power Supply must be used to provide power

for digital inputs, digital outputs, and the optional holding brake,

if present. On DC models of Tritex TTX actuators, logic power

is not associated with I/O power and there is no internal 24 Vdc

supply from main DC (motor) power, making them signicantly

dierent from AC powered models. The I/O power supply must

have the negative side connected to ground and the positive

side fused at 2 A unless internally limited to 3 A or less. The

I/O power supply is typically 24 Vdc nominal, but other nominal

prevent strands of the braided shield from breaking o and

shorting internal electronics or compromising spacing.

Figure 12 – Example of a shielding type cable gland.

An Ethernet cable is not required to be shielded, or if shielded,

does not require that the shield is connected at the actuator

end. Do not use a shielded RJ45 jack for an internal connection

to this actuator.

4.3.2 Other Grounding Considerations

Extra-low voltage DC power supplies for I/O circuits or a holding

brake must be ground referenced on the negative side to

prevent stacking voltages where there is more than one source.

Avoid use of independent “Instrument Ground” connections. All

ground connections must run back to a single point.

It is recommended that driven parts are connected to

stationary parts of the machine with grounding jumpers. Some

applications produce static electric charges in the moving parts

of a machine, for example plastic molding, that produce static

charges or impulses that exceed those in EMC tests.

4.4 DC INPUT POWER

4.4.1 Input Power Ratings

The following table shows rated input voltage and current. The

maximum voltage applied to the Tritex TTX080 terminals must

not exceed 53 Vdc from bus to Common and Common must

be tied to PE near or at the power source. Operation on less

TTX Series DC Actuator Installation & Maintenance Instructions | 17www.exlar.com | 952.500.6200

voltages are possible in some cases. Digital I/O and brake

circuits as a group are optically isolated from main power

circuits to provide some fault isolation and enhance immunity

from transients and electromagnetic interference.

All standard models have a 19 pin M23 connector for I/O and

I/O power connections are positive to pin 6 and 0 V return to

pin 19. Though the connection at pin 19 ultimately goes to the

negative terminal of the external power supply, it is required to

be ground referenced so is described as 0 V or “I/O Common”

and labelled “IOCom” internally. All digital inputs are powered

externally but have a single return through I/O Common. The

connection at pin 6 is described as “IO +24 V” and labelled

“IO+V” internally. If the brake option is present, the voltage

must be 24 V ±10%. If no brake is present, the voltage applied

at I/O +24 V may vary considerably as long as the loads

connected to digital outputs are compatible with the I/O power

supply voltage. 24 V I/O systems are most common, but

12 V systems are supported. If no brake is present and no

digital outputs are used, no connection to IO +24 V is required

at all.

The Tritex TTX080 model has a cover that may be removed to

access the Termination Board with push-button release spring

terminals for connections. Connections could be modied if

needed, or the I/O connector could be removed entirely for

direct wiring using other wiring methods through the M20

threaded port. For the Tritex TTX060 the IO must be accessed

through the M23 19 pin connector because the termination

board is not available on the Tritex TTX060. Details of alternate

wiring are not addressed in this manual at this time as they

would be engineered by the user for a specic application. The

same Termination Board is used on both AC and DC models

and with no internal power supply, the “Src+24” terminals are

not used on DC models. A factory installed jumper will tie the

two “Src+24” terminals to prevent accidental connections to

these terminals. On models with brakes, there is also a jumper

from one “IO+V” terminal to the “Brk+V” terminal to power the

brake from the I/O Power Supply.

I/O Power Supply Wiring and Fusing

Volts Amps Fuse Wire

24 Vdc ±10%. 1 2 A, if power supply

is not limited at 3 A

or less

18 AWG

(0.8mm2)

Fuse

AC Input

2A IO +V

IO Com

24 DC

Regulated Actuator Connection

+

-

Figure 13 –Wiring for External I/O Power Supply

CAUTION! Make sure 24 Vdc power supplies are

connected in the correct polarity. Some reversed connections

will cause damage to the circuits. The I/O Common terminal

must be connected to the negative and grounded side of the

power supply. An external supply should not be connected

directly to the +24 V Source terminals.

4.6.1 I/O Connector Wiring

Standard M23 19 pin Connector Pin Assignment and Wire Color

Code

FUNCTION

Connector

Pins

Wire Color Code for Internal Wiring &

TTIOC Cable

Digital Input 1 1 White/Yellow

Digital Input 2 2 White/Red

Digital Input 3 3 White/Green

Digital Input 4 4 White/Black

*Digital Input 5 5 Red/Black

IO +24 V 6 Red

*Digital Input 6 7 Red/Green

*Digital Input 7 8 Red/Yellow

*Digital Input 8 9 Beige

*ANALOG IN+ 10 Green

*ANALOG IN- 11 White

Shields 12 Gray (internal wire) or Clear (cable)

*Analog Out + 13 Blue

*Analog Ref 14 Orange

*Digital Output 4 15 White/Brown

Digital Output 3 16 White/Orange

Digital Output 2 17 White/Blue

Digital Output 1 18 Light Red (Pink)

IO Common 19 Black

* For the 4-20 mA (-IA4) option:

Inputs 5, 6, 7 & 8 and Output 4 are not available.

The analog voltage input and output are replaced with 4-20 mA

input and output respectively.

18 | Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

Figure 14 –Tritex Input /Output Standard M23 Connector Front

View (19 pins)

Tritex TTX080 Internal Termination Board Terminal Assignments

J3 Pos # Label Function J2 Pos # Label Function J5 Pos # Label Function

1 In 1 Digital Input 1 1 Src+24 Not Used 1 *AI+ *Analog IN+

2 In 2 Digital Input 2 2 Src+24 Nor Used 2 *AI- *Analog IN-

3 In 3 Digital Input 3 3 IOCom I/O Common 3 *AO+ *Analog OUT

4 In 4 Digital Input 4 4 Brk+V Brake + 4 *AO- *Analog REF

5 *In 5 Digital Input 5 5 IO+V I/O +V 5 RS485+ RS485+

6 *In 6 Digital Input 6 6 IO+V I/O +V 6 RS485- RS485-

7 *In 7 Digital Input 7 7 *Out 4 Digital Output 4 7 Com RS485 COM

8 *In 8 Digital Input 8 8 Out 3 Digital Output 3 8 Shld Shield (to PE)

9 Shld Shield (to PE) 9 Out 2 Digital Output 2

10 Shld Shield (to PE) 10 Out 1 Digital Output 1

* For the 4-20 mA (-IA4) option:

Inputs 5, 6, 7 & 8 and Output 4 are not available.

The analog voltage input and output are replaced with 4-20 mA input and output respectively.

Figure 15 – Tritex TTX080 SIO and Ethernet Option

Figure 16 – Tritex TTX080 IA4 Option

1=Digital Input 1

2=Digital Input 2

3=Digital Input 3

4=Digital Input 4

5=Digital Input 5

6=IO + 24

7=Digital Input 6

8=Digital Input 7

9=Digital Input 8

10=Analog IN+

11=Analog IN

12=Shield

13=Analog Out+

14=Analog Ref

15=Digital Output 4

16=Digital Output 3

17=Digital Output 2

18=Digital Output 1

19=IO Common

M23 Connector

Pair

Pair

Shield to Nut

Male End View

TTX Series DC Actuator Installation & Maintenance Instructions | 19www.exlar.com | 952.500.6200

4.7 DIGITAL INPUTS

Tritex TTX digital inputs are single ended positive voltage inputs

with negative side all to I/O Common. Standard I/O (-SIO in

model) and Ethernet options have 8 inputs, and the 4-20 mA

I/O (-IA4 in model) have 4 inputs. Since they require a positive

voltage to turn on, they are directly compatible with sourcing

outputs only. The voltage for each input can be sourced from

any supply with the negative side tied to I/O Common. Typically,

this is an external 24 V supply used for digital outputs. Each

input can be assigned to any of the internal input functions

using Expert software. It is important that the external power

source common is connected to PE.

Figure 17 – Input Wiring with External 24 Vdc Power Supply

Digital Input Specications

Description Specication

Absolute Max Input Voltage* -10-40 Vdc to I/O Common

Operating Input Voltage Range 0-30 Vdc to I/O Common

On state voltage range 10–30 Vdc

O state voltage range 0–1 Vdc

On state current

10 V (min)

24 V (nominal)

30 V (maximum)

3.3 mA

5.0 mA

5.7 mA

Eective Load Resistance

(24 V)

4.8 kΩ

O state current (max) 1.0 mA

Update rate 1 ms (typical)

* Inputs are protected from switching transients. Sustained voltage

outside the Absolute Max range may damage the circuit.

CAUTION! Each output is rated to continuously drive a

100 mA load and is short protected at 500 mA with automatic

reset after the short fault is removed.

Figure 18 – Wiring of outputs with external 24 V supply for

connection to PLC or any load

Digital Output Specications

Description Specication

Absolute Max Voltage

on Output*

-50 Vdc to 0 V measured to

I/O Power +

Operating voltage range

for I/O Power +

12 to 30 Vdc to I/O Common

(24 V ±10% with brake)

On state maximum

continuous current 100 mA

On state voltage drop

(@ 50 mA) 0.5 V typical

Short circuit protection

(auto reset) 0.5 A

Update rate 1 ms

* Outputs are protected from switching transients, including

kick from ordinary inductive loads. Sustained voltage outside

the Absolute Max range may damage the circuits. Note that an

output should not be driven more positive than I/O Power +.

4.8 DIGITAL OUTPUTS

Tritex TTX digital outputs are the sourcing type with power

from the I/O Power+ (“IO+V”) terminal. SIO and Standard I/O

(-SIO in model) and Ethernet options have 4 outputs, and the

4-20 mA I/O (-IA4 in model) have 3 outputs. The outputs have

a weak pull-down resistor to I/O Common (“IOCom”) terminal

just to prevent leakage current creating a oating voltage on

an output. Typically power comes from an external 24 V supply

used for digital I/O. It is important that the external power

source common is connected to PE. Outputs have short circuit

and thermal protection, and protection against inductive kick

at turn-o. Each output can be assigned to any of the internal

output functions using Expert software.

20 | Tritex® TTX Series DC Actuator Installation & Maintenance Instructions Curtiss-Wright | Rev D | PN75667 | 8/1/22

On Tritex TTX080 models, other modications to standard wiring

can provide other functionality. If a separate interlock is required to

ensure that power is removed from the brake while maintaining logic

and I/O power, the jumper from “Brk+V” to “IO+V” may be removed

and a pin in the I/O Connector may be re-purposed for this.

Figure 19 –Brake Connections with External 24 Vdc Power

Supply

4.10 ANALOG INPUT

An analog input is provided for use as a position, velocity or

current command. It can also be used for a Velocity Override

feature to dynamically moderate velocity during a move. With

the 4-2 0 mA option, the voltage input channel described here

is replaced with a 4-20 mA channel described in a dierent

section.

The analog signal must be wired dierentially with a return

wire to the analog signal reference for best noise rejection.

Dierential input range is -10 V to +10 V. It is not isolated from

DC Input (main power), but has a common mode range of at

least ±5 V, meaning that the ground reference at the analog

signal source and I/O Common at the actuator can vary by up

to 5V positive or negative without aecting the received signal

voltage.

The analog signal must be wired dierentially with a return

wire to the analog signal source for good noise rejection. An

open circuit tends to 0 V, so it is recommended that a 0V signal

produces zero command.

See Expert Software Manual for information on how to

congure the analog input, analog motion, and related

parameters.

4.9 ACTUATOR BRAKE OPTION

The actuators may be ordered with a brake option. This brake

is intended as a “parking brake” and must not be used as a

“stopping brake” while the actuator is in motion in any normal

operation. Brake operation is controlled by internal logic signals,

so power for the brake is normally applied at all times and

the actuator engages and dis-engages the brake. The brake

engages when brake voltage is removed. Brake voltage is

24 V ±10%. Since “Brk+V” and “I/O+V” terminals are jumpered

in standard connectorized actuators, use of a brake places an

additional voltage range limitation and increased load on the I/O

supply. Brake current returns through IO common.

The brake can be released without main AC power applied as

long as an external 24 Vdc supply is connected to I/O

Power + and logic power is applied. It is not possible to directly

release the brake unless the actuator controls are running so it

is able to respond to a command to release the brake through

I/O or communications.

It is worth providing details of internal brake control and how

that aects motion. 24 V is applied to Brake + continuously.

Starting from a disabled status with brake engaged, when the

actuator receives an Enable signal, it enables with a 0 velocity

command which holds the motor position and applies voltage to

the brake. A 0.1 second time delay occurs before starting any

motion to make sure the brake is fully released. Starting from

the enabled state with the brake released or when the drive

is disabled for any reason the drive will immediately apply full

current to decelerate a moving motor to bring it to an abrupt

stop and remove power to the brake. Then after a 0.1 second

delay to allow the brake to engage, the drive will be disabled.

The brake can be released with the actuator disabled by turning

on the Brake Override Input function. See the I/O Assignment

section of the Expert Software Manual.

WARNING! If the brake is released using the Brake

Override function and AC power is o or the drive is not

enabled the load will be free. This may be dangerous in some

applications.

This manual suits for next models

2

Table of contents

Other Exlar Controllers manuals

Popular Controllers manuals by other brands

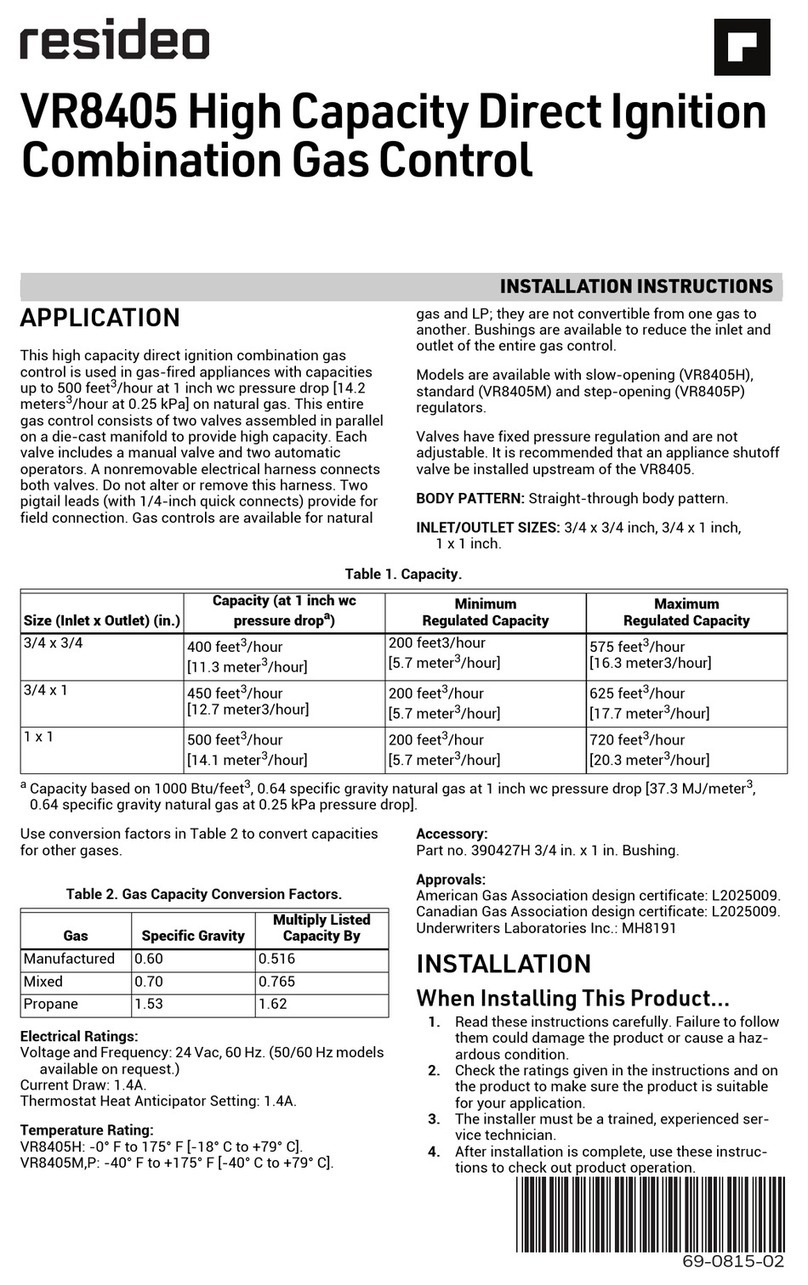

resideo

resideo VR8405 installation instructions

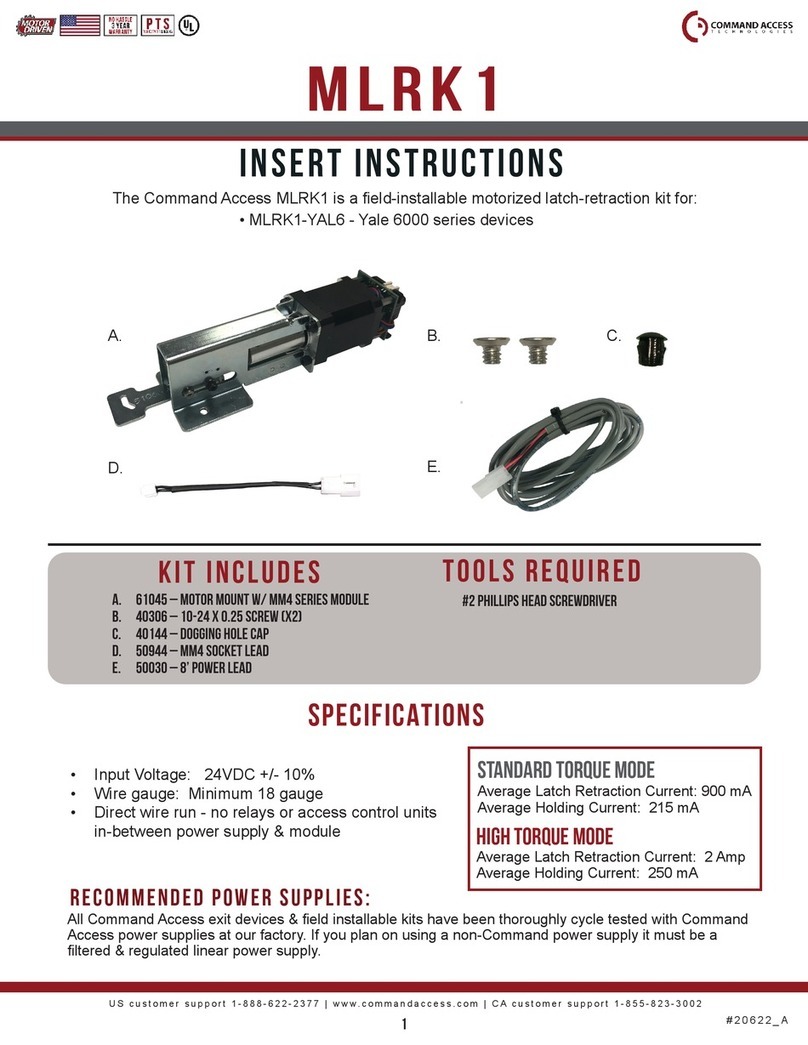

Command access

Command access MLRK1 Series Insert Instructions

Festo

Festo VPPI D Series instructions

Pacific Power Source

Pacific Power Source UPC-32 Operation manual

Mitsubishi Electric

Mitsubishi Electric EZMOTION MR-E Super MR-E-10A-QW003 instruction manual

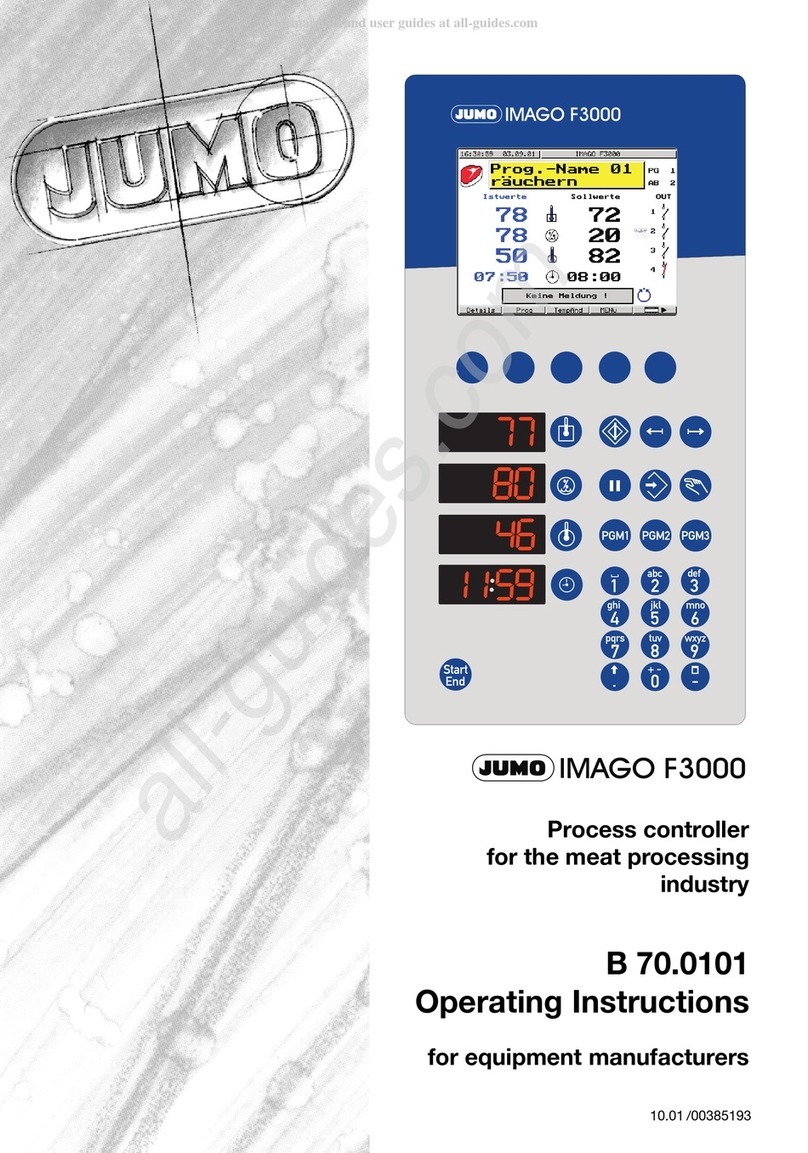

JUMO

JUMO IMAGO F3000 operating instructions