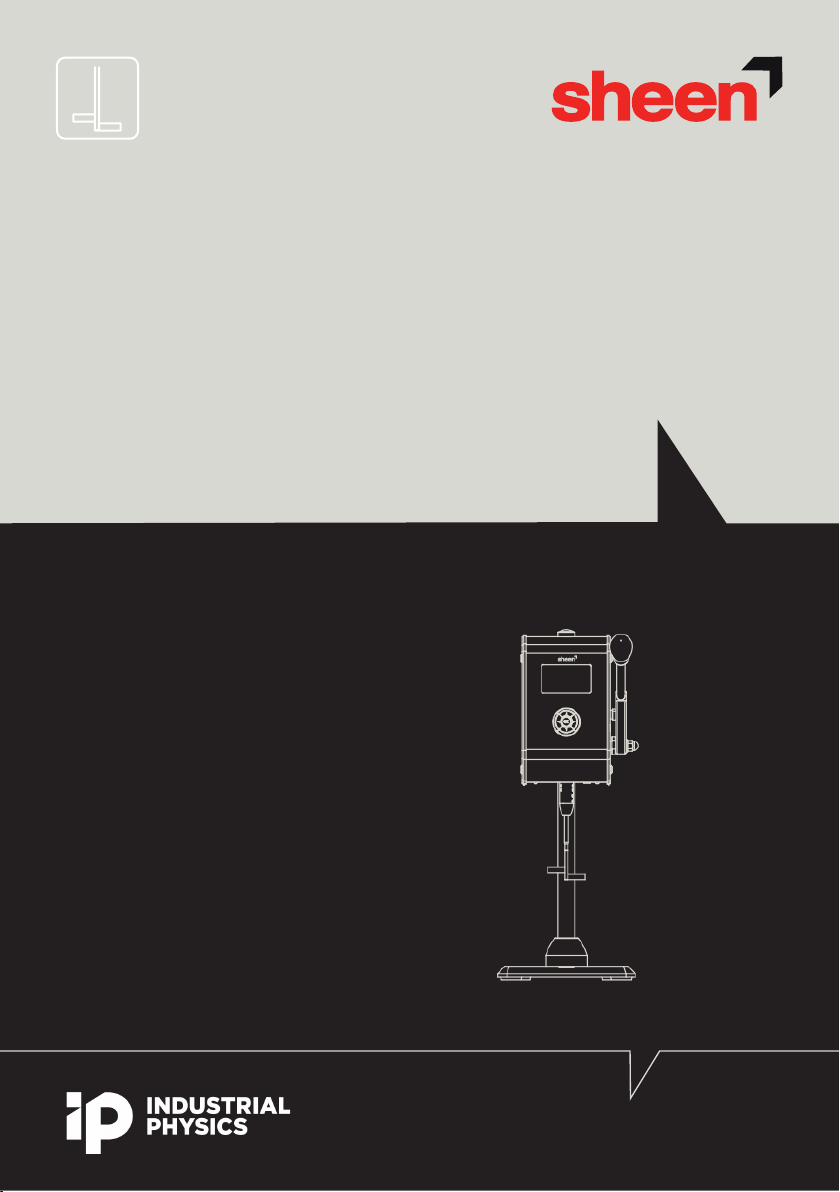

Industrial physics sheen DV2300 User manual

Operating Instructions

(V3.0 072023)

Krebs Viscometer

DV2300

2

Sheen is a brand of Industrial Physics Inc.

www.industrialphysics.com

Manufacturer | COPYRIGHT © 2023 - Sheen

3

Please check the startup screen of

the Krebs viscometer to check if this

manual, written for version 1.0.8.0 is

applicable to you.

NOTE

START - NOTE

4

1 GENERAL 6

1.1 Importance of operating manual 6

1.2 User-responsibility 6

1.3 Responsibility of personnel 6

1.4 Dangers 6

1.5 Designated purpose 6

1.6 Copyright 7

1.7 Manufacturer’s/Supplier’s address 7

2 SAFETY INSTRUCTIONS 7

2.1 Meaning of symbols 7

2.2 Availability of safety information 7

2.3 Training of personnel 8

2.4 Power supply 8

2.5 Special attention 8

2.6 Care, maintenance and repairs 8

2.7 Modications to the equipment 9

2.8 Cleaning of the instrument and disposal of materials 9

3 TRANSPORT AND STORAGE 9

3.1 Packing 9

3.2 User: Check on receipt 9

3.3 Reporting transport damage and documentation 9

3.4 Storage and protective measures when not in use 9

INDEX

5

4 SCOPE OF SUPPLY 10

5 Technical Data DV2300 Sheen Krebs viscometer 11

6 ASSEMBLY 12

7 MENU EXPLANATION 13

7.1 General menu structure 13

7.2 Main menu 14

7.3 Actual measurement 15

7.4 Clean high - low 16

7.5 Setup menus 17

7.5.1 Measurement type 17

7.5.2 Units 19

7.5.3 Calibration 20

7.5.4 Display 20

8. FREQUENTLY ASKED QUESTIONS 21

9. CARE AND MAINTENANCE 22

9.1 Inspection and Maintenance 22

9.2 Customer Service 22

10. DISCLAIMER 23

6

1 GENERAL

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and possible applications

of the instrument. It contains important instructions about how to use the instrument safely and

economically; according to the purpose designated. Following these instructions is not only essential

to avoid risks. It also reduces repair costs and down-time and increases the products reliability and

service life.

Anyone who works with the instrument should follow the instructions in this manual, particularly the

safety related instructions. Additionally local rules and regulations relating to environmental safety

and accident prevention should be observed.

1.2 User-responsibility

The user should

a) Only allow persons to work with the instrument who are familiar with the general instructions

on how to work safely and prevent accidents.

b) Regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument should pay attention to

the general regulations relating to work safety and accident prevention. The safety chapter and the

warnings in this manual should have been read and understood.

1.4 Dangers

This instrument has been designed and constructed in accordance with state-of-the-art

technology and the acknowledged safety regulations. Nevertheless, working with the

instrument may cause danger to the life and health of the operator or to others, or damage to the

instrument or other property. Therefore the instrument should only be used for its

designated purpose, and in a perfect technical condition. Any defect that could have a negative

eect on safety should be attended to immediately.

1.5 Designated purpose

The Krebs viscometer is exclusively designed to be used to measure the viscosity of paint and

products in laboratory and production environments. The design is setup for use with a Sheen

spindle and is carefully calibrated to conform to ASTM D562. Other applications constitute

improper use. Industrial Physics will not be held liable for damage resulting from improper use.

7

Warning

1.6 Copyright

The copyright of this operating manual remains with Industrial Physics.

Its instructions and guidelines may not be duplicated, circulated or otherwise passed on to others,

neither fully, nor partly, without prior permission. Infringement of these restrictions may lead to legal

action to be taken.

1.7 Manufacturer’s/Supplier’s address

Industrial Physics

Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands

T +31(0)10-7900100

2 SAFETY INSTRUCTIONS

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

Symbol Explanation Warning

Possible immediate danger to If this guideline is not noted it can

the life or health of personnel lead to severe danger to health,

up to fatal injury

A dangerous situation could Non observance of this guideline

be caused can lead to injury or to

damage to equipment

NOTE Special tips and particular Guidelines to make optimal use of

information the instrument

2.2 Availability of safety information

The instruction manual should be kept at the place of the instrument operation.

In addition to the information contained in the instruction manual, general and local regulations for

accident prevention and environmental protection should be kept available and observed.

Always ensure all guidelines in respect of safety and dangers on the instrument are in readable

condition.

In case of danger the instrument has to be switched o.

Danger

8

2.3 Training of personnel

• Anyone who operates the instrument should be trained properly.

• It has to be clear who has which responsibility regarding commissioning,

maintenance and repairs, installation and operation.

• Anyone who hasn’t nished training should be supervised by an experienced person while

working with the instrument.

2.4 Power supply

• Work on the power supply may only be done by qualied personnel.

• The electrical equipment of the instrument must be checked regularly. Loose connections and

cable damage must be corrected immediately.

• Always make sure the instrument’s power is turned o while adjusting any electrical

component.

2.5 Special attention

The Sheen Digital Krebs viscometer reaches high rotational speeds.

Do not touch moving parts during testing.

Touching a moving spindle may cause injuries.

2.6 Care, maintenance and repairs

• Always make sure the instrument is connected to grounded outlet.

• Always make sure the instrument’s power is turned o and the instrument is not connected to

an outlet while adjusting any electrical component whenever maintenance, inspection or repair

work is done.

• Do not open the instrument. In case of malfunction always consult the manufacturer.

Danger

9

2.7 Modications to the equipment

• Any modications, additions or alterations to the instrument may solely be made with

permission from Industrial Physics.

• All measures involving modications require written conrmation of approval from

Industrial Physics.

• Instruments which are not in fault-free condition must immediately be switched o.

• Only use replacement parts from the original supplier. Parts used from other sources aren’t

guaranteed to meet the safety requirements.

2.8 Cleaning of the instrument and disposal of materials

• When in use it is possible to spill paint on the instrument’s base. Clean immediately before

hardening.

• Try to keep the instrument as clean as possible to prevent malfunctioning.

• Use a suitable solvent to remove remains of paint or ink.

• Wear suitable gloves and don’t spill solvent during cleaning.

• Cleaning materials must always be used and disposed of correctly.

3 TRANSPORT AND STORAGE

3.1 Packing

Please take note of pictorial symbols on the packing and store the packaging for future transport for

e.g. repair or recalibration.

3.2 Check on receipt

Check packing for damage.

After unpacking check complete supply, using the scope of supply on page 10.

3.3 Reporting transport damage and documentation

Any damage should be documented as accurately as possible (possibly photographed) and reported

to the relevant insurers or, in the case of sales “delivered to customers works”, to the supplier.

3.4 Storage and protective measures when not in use

The instrument must be stored in a dry (≈ 40% RH) place at a temperature between 10 - 40°C.

Store instrument in the original packing if possible.

10

4 SCOPE OF SUPPLY

• DV2300 - Sheen Digital Krebs viscometer • One 0,5l can

• Handle • 110 - 250VAC power adapter

• Standard Krebs spindle DV2305

Note: Calibration verication oils have to be ordered separately.

Standard

Krebs spindle

DV2305

11

5 TECHNICAL DATA DV2300 SHEEN KREBS VISCOMETER

Operating voltage 100-240 VAC / 50-60 Hz from a grounded wall outlet

Operating temperature +5 °C - +40 °C / +41 °F – 104 °F

Net weight 8,5 kg / 18,7 lbs

Speed 200 rpm

Range 52 – 5.000 cP, 40 - 1.047 g*, 40 – 142 KU*

(* density 1 g/ml)

Resolution 1 cP

0,1 KU

0,1 g

Accuracy ± 2% of full scale

Repeatability ± 1% of full scale

Sample container 500 ml, 86 x 102 mm and 60 mm opening

Dimensions (w x d x h) 200 x 360 x 550 mm / 7.9 x 14.2 x 21.7 inch

CAN BOTTOM DIMENSIONS

Diameter (mm) Diameter (in)

Capacity inner Outer Inner Outer

1 l 105 111 4,1 4,4

3/4 l 96 102 3,8 4,0

1/2 l 85 92 3,3 3,6

1/4 l 68 77 2,7 3,0

12

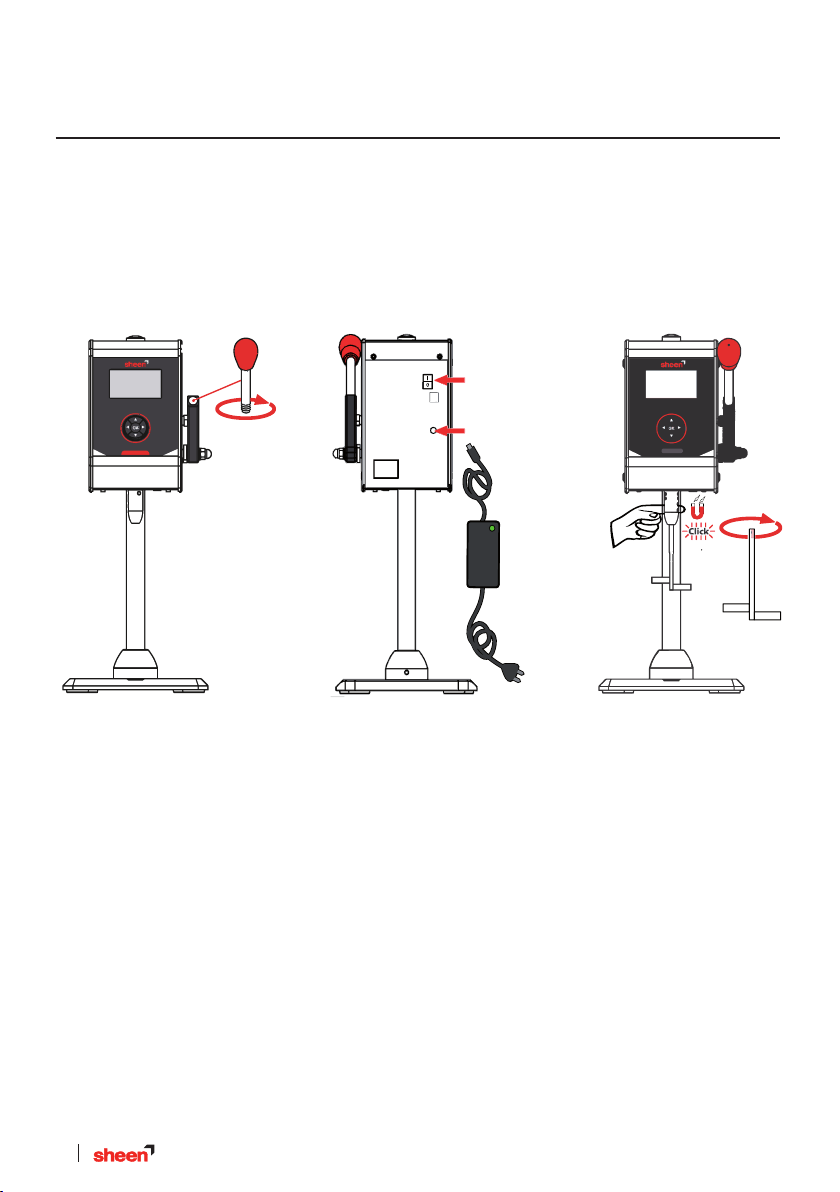

6 ASSEMBLY

1. Install the handle.

2. Install the power supply.

3. Install the Krebs spindle .

- The spindle is keyed and magnetic for easy installation and removal after taking a measurement.

- The base of the instrument can be screwed to the tabletop for extra stability.

Stop the chuck from rotating.

ON/OFF

Power input

13

7 MENU EXPLANATION

This section describes in detail all the menu options the instrument oers.

7.1 General menu structure

Below is a high level overview of the Krebs viscometer menu structure.

The menu is navigated using

the buttons as indicated.

14

7.2 Main menu

7.3 Actual measurement

After switching on the unit, this is the main menu.

The machine will revert to the settings used the

previous time.

Place a can with the uid to be measured on the

base of the instrument making sure it is well

centered and magnetically secured.

Measure and record the uid temperature as

indicated by your local procedures.

Lower the instrument with the handle and with

that the spindle into the uid right up to the level

indicator on the spindle ’s shaft.

This is essential for a proper measurement.

With START highlighted (see section 7.2), pushing

the OK button will start the paddle motor and the

actual measurement.

Manual MAIN MENU

START CLEAN SETUP

Lower Viscometer

and press START

15

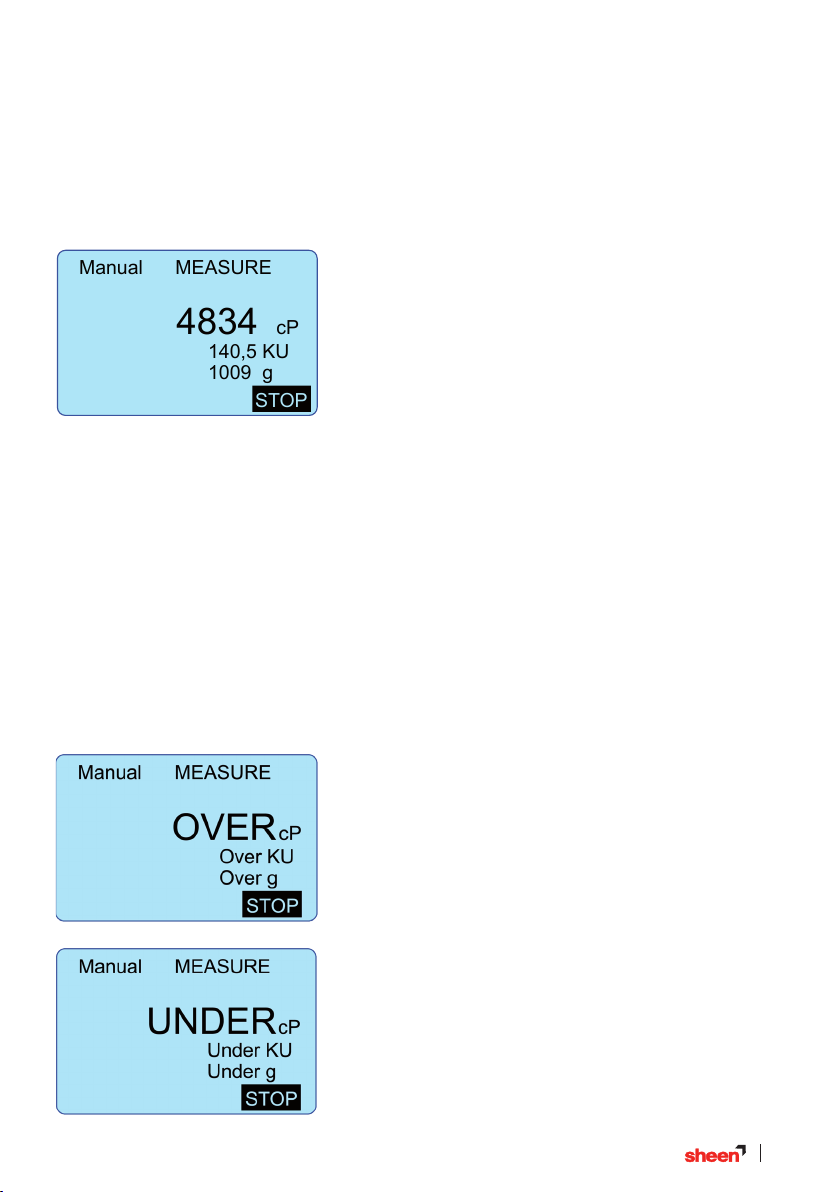

In this example Manual measurement was selected

previously and it’s the operator that has to watch

the duration of the measurement and press the OK

button again to stop the spindle from turning.

(see section 7.5.1 for measurement type selection)

Follow your local instructions for the time to

measure.

In general it is wise to measure for a short time (e.g.

10 s) to prevent a change in temperature of the uid

being measured.

Note: Centipoise (cP) was selected as Unit and is

shown big. The other two units are also valid

measurements, but just shown smaller.

(see section 7.5.2 for unit selection)

After stopping, measure and record the uid

temperature as indicated by your local procedures.

Raise the instrument and its spindle and clean the

spindle with a cloth before removing the can.

Before taking another measurement or leaving the

instrument, it is advised to thoroughly clean the

spindle . See the Clean High - Low section to prevent

contamination.

Possible errors:

The uid being measured is too thick

(viscosity >5.000 cP)

The uid is too thin (<52 cP) or the spindle hasn’t be

lowered into the uid properly.

Manual MEASURE

STOP

4834 cP

140,5 KU

1009 g

16

In the main menu, use the control buttons to

highlight CLEAN and press the OK button.

CLEAN is just the spindle turning in an appropriate

solvent, without measurements being made.

Next highlight Low speed or High speed and push

the OK button.

With a can, lled with appropriate solvent securely

installed (see also 7.3) and proper safety measures

taken against spillage or eye or hand contact, lower

the handle to start the cleaning process.

Raising the handle or pressing the OK button will

stop the spindle from turning.

7.4 Clean High - Low

17

7.5 Setup menus

The menus available for setting up the instrument’s behavior are explained in this chapter.

7.5.1 Measurement type

In the main menu, use the control buttons to high-

light SETUP and press the OK button.

The Measurement type selection will allow the user

to select either Manual, Max hold or Timed measure-

ments as shown below.

Press the OK button

Manual measurement is started from the main

window and lasts as long as the operators decides.

Press the OK button to select and then navigate to

BACK and press the OK button to return to the main

window and start a manual measurement.

All three units (cP, KU and g) are shown with the

selected unit (see chapter 7.5.2) in a large font.

BACK

Measurement type

Units

Calibration

Display

SETUP

MEASUREMENT TYPE

BACK

[√] Manual

[] Max hold

[] Timed [0010]s

18

Max hold will show the selected unit with a large

maximum and smaller current value shown.

Press the OK button to select and then navigate to

BACK and press the OK button to return to the main

window.

Navigate to START and press the OK button to start a

Max hold measurement.

Here it shows cP but it could also have been KU or g,

depending on the unit selected in section 7.5.2.

Timed measurement lets the spindle rotate for the

set amount of time before taking and showing one

reading in a large font.

The time can be set by navigation to the digits

between [ ] and using the up and down buttons to

cycle from 1 to 9 and left and right to select a digit.

Pressing the OK button will stop the measurement

and go back to the main window.

MEASUREMENT TYPE

BACK

[ ] Manual

[√] Max hold

[] Timed [0010]s

MEASUREMENT TYPE

BACK

[ ] Manual

[ ] Max hold

[√] Timed [0010]s

19

7.5.2 Units

In the main SETUP menu, navigate to Units and

press the OK button.

The selection for Krebs (KUJ), centi Poise (cP) or

grams (g) will dene:

The top measurement unit shown in large font for

Manual Measurement and the one measurement

unit shown in Max hold or Timed Measurement.

BACK

Measurement type

Units

Calibration

Display

SETUP

SETUP UNITS

BACK

[√] Krebs (KU)

[ ] centi Poise (cP)

[ ] grams (g)

[√] 0,8760 g/ml

[ ] [1,0000] g/ml

Here is the now xed, timed measurement and

continuous current measurement in the unit

selected.

To perform a new measurement press the OK button.

The Sheen Krebs viscometer allows the user to set a custom value for the density. This density

setting inuences the calculated grams and Krebs using the actually measured centipoise (cP).

(6.10 O +906.6 D)

30

g is in grams, Ois viscosity in cP and Dthe density in g/ml

The Sheen Krebs viscometer allows for accurately setting the density of your product and

getting a more precise measurement of the viscosity in grams and in Krebs.

The grams and Krebs scale are hard linked to each other. This correlation is not the same as

commonly seen when calculating from cP to centistokes (cSt).

The value of 0,8760 as shown is the xed default and backwards compatible with previous

instruments and rmware releases and other commonly available Krebs viscometer brands.

g =

20

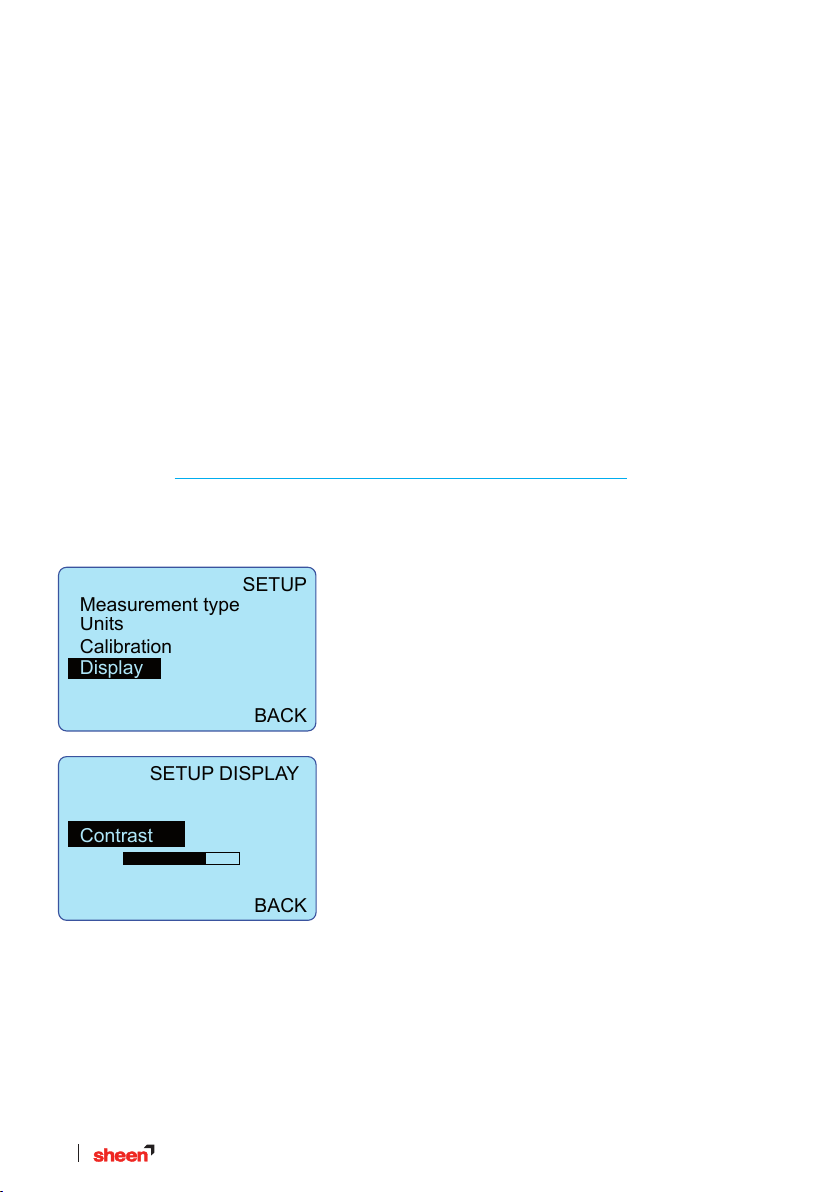

The display setup oers a simple adjustment of

the LCD’s contrast.

Use the Left, Right buttons to decrease or increase

contrast.

Pres the OK button or navigate to BACK and

press the OK button to back go to the Main window.

BACK

Display

SETUP

Units .

Measurement type

Calibration .

BACK

SETUP DISPLAY

.

Contrast .

7.5.3 Calibration

The required knowledge, experience and high quality and well calibrated tools are outside the scope

of a normal user instruction and it is therefore that the calibration of the Krebs unit is no longer part

of the manual.

A separate calibration manual will be made available on request.

Your Krebs viscometer can be recalibrated at the Industrial Physics factory and selected service

centers and distributors.

Using calibration oils with certicates, calibrated thermometers with 0,01 °C reading capability and 0,1

°C accuracy at 25 °C, in a well controlled environment, following ASTM D562 will allow a user to

check the instruments accuracy using the normal measurement functionality.

The Industrial Physics oils suitable for Krebs are: DV2205, DV2206, DV2207, DV2208, DV2209, DV2210.

Please also see: https://industrialphysics.com/product/viscosity-calibration-oils/

7.5.4 Display

Table of contents

Other Industrial physics Measuring Instrument manuals