Industrial Vacuum Equipment HURRICANE 500 User manual

HURRICANE

500

OPERATOR’S MANUAL

INDUSTRIAL VACUUM EQUIPMENT CORP.

N8150 MAPLE STREET, IXONIA WI 53036

800-331-4832

Rev 2017-12 1Hurricane 500/600 Tier 4

OPERATOR’S MANUAL

HURRICANE 500 & 600

Tier 4 Diesel

UINTRODUCTION

The Hurricane is designed for rugged, reliable operation featuring powerful vacuuming capability

with a very minimum daily maintenance. The Hurricane will pneumatically convey material from

distances in excess of 1000 feet. Any material that is flowable, whether liquid, slurry or solid, or able

to move through a 4”, 5” or 6” diameter hose, can be handled with this equipment.

This equipment is self-contained and powered by an electronically controlled diesel engine. It will

provide excellent service if properly maintained. There are no unique or complicated parts that require

sophisticated maintenance procedures under normal operation. The diesel engine is equipped with

automatic shutdowns for low oil pressure and high temperature.

The engine enclosure of the Hurricane has locking latches and a locking cap on the fuel tank.

The tandem axle trailer is equipped with electric brakes. The Hurricane can easily be towed and

maneuvered with a one ton, or larger, truck having dual rear wheels.

Because of its ease of set-up and maneuverability, the Hurricane is a very flexible and effective

piece of industrial vacuum cleaning equipment. You will only be limited by your imagination.

DANGER

THE

HURRICANE

SHALL NOT BE USED TO VACUUM/CONVEY

FLAMMABLE OR COMBUSTIBLE HYDROCARBON LIQUIDS.

THE

HURRICANE

SHOULD NEVER BE USED OR MOVED WITHOUT

REFERENCE TO THE SAFETY PROCEDURES NOTED BELOW.

Revised 1/2016 Hurricane 500/600 Tier 4

2

HURRICANE 500 & 600 Tier 4

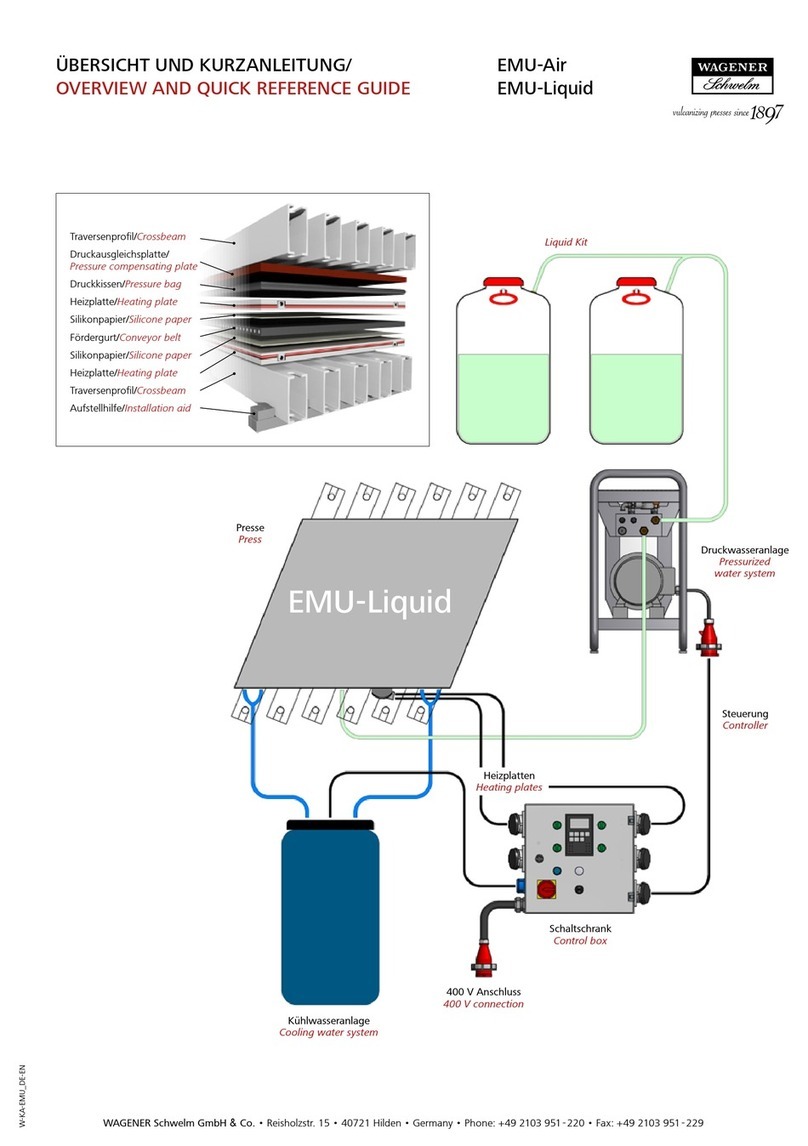

NOTE: Unit purchased may not have features pictured; representational only.

Manual Jack Stand

Hinged Belt Guard

Baghouse Timer Board

Silencers

6” Inlet

Vacuum

Hose

Connection

Pipe

Figure 1

Tier 4 Engine

Revised 1/2016 Hurricane 500/600 Tier 4

3

Figure 2

Figure 3

Microfilter

Housing

Quick Release

Wing Nut

Filter

Microfilter Hold

Down Bracket

Vacuum

Relief

Valve

Revised 1/2016 Hurricane 500/600 Tier 4

4

Vibrator

Oiler

6” Inlet

Vacuum

Pipe

Connection

Twist Lock

Connection

(Female) for Hand

Held E-Stop

Pendant

Dump

Door

Figure 4

10”

Inspection

Manhole

Revised 1/2016 Hurricane 500/600 Tier 4

5

SAFETY PROTOCOL

Failure to follow the safety rules in this manual can result in personal injury, death or property damage.

Please observe the same common sense precautions used with any machine, where carelessness,

inattention or poor maintenance could be hazardous to people or property. Carefully read the safety

precautions below and within this manual.

Towing Safety Instructions

•Due to the Hurricane’s height caution is required for overhead clearance.

•The Hurricane’s height does not permit shipping or transporting via semi-truck trailer. The

Hurricane must be towed using an appropriate motor vehicle. Caution must be used when

towing the Hurricane due to its weight.

•The Hurricane is not engineered to be lifted or lowered by a crane or similar lifting devices.

•Be sure all lights on the trailer are functioning properly before travel.

•Always tow the Hurricane with the safety chains and the emergency brake chain attached to

the towing vehicle.

•Before towing the Hurricane, inspect the tires and the hitch mechanism to be sure they are

road-worthy.

•Always tow the Hurricane with the hopper in the lowered and locked position.

•Always tow the unit with the hopper completely empty and the discharge door secured closed.

Set-up Safety Instructions

•Be sure to block the wheels before detaching the unit from the towing vehicle.

•Always position the unit on solid, stable ground. Locate planks underneath the jack stands to

distribute the weight of the unit evenly.

•Always position the unit so that it is set no more than 5° off level in any direction.

•Never raise the hopper under electrical power wires.

•Always pin the hydraulic safety strut blocks when the hopper is in the raised position.

•Never stand under the raised hopper unless the hydraulic safety strut blocks are pinned and

secured in place.

•Lower and pin Uall four jack stands so that each bears weight before raising the hopper.

Revised 1/2016 6Hurricane 500/600 Tier 4

SAFETY PROTOCOL

Follow Safety Sticker Instructions

•Carefully read all safety stickers on unit. Keep safety stickers in good, readable condition.

Replace missing or damaged safety signs. Be sure new equipment components and repair parts

include the current safety stickers. Replacement safety stickers are available through the

manufacturer.

Handle Fuel Safely

•Handle fuel with care: it is highly flammable. Do not refuel the machine while smoking or near

open flame or spark.

•Always stop engine before refueling machine. Fill fuel tank outdoors.

•Prevent fires by keeping machine clean of accumulated trash, grease and debris.

Prepare For Emergencies

•Be prepared if a fire starts.

•Keep a first aid kit and fire extinguisher handy.

•Keep emergency numbers for doctors, ambulance service, hospital and fire department near

your telephone.

Wear Protective Clothing

•Wear close-fitting clothing and safety equipment appropriate to the job.

•Operating equipment safely requires the full attention of the operator. Do not wear radio or

music headphones while operating machine.

Protect Against Noise

•Prolonged exposure to loud noise can cause impairment or loss of hearing.

•Wear OSHA approved personal protective equipment to protect against objectionable or

uncomfortable noise.

Handle Chemical Products Safely

•Direct exposure to hazardous chemical can cause serious injury. Potentially hazardous

chemicals used with this unit include such items as lubricants, coolants, paints and adhesives.

•Refer to Material Safety Data Sheet (MSDS) for specific details on chemical products: physical

and health hazards, safety procedures and emergency response information.

•Review each MSDS before you begin using unit.

Revised 1/2016 Hurricane 500/600 Tier 4

7

SAFETY PROTOCOL

Stay Clear of Rotating Components

•Keep rotating shields in place at all times.

•Always operate the machine with access doors closed and locked.

•Shut unit down and be sure all moving parts have stopped rotating before make adjustments or

performing service on machine.

•Keep hands, feet and clothing from power driven parts.

Practice Safe Maintenance

•Understand service procedure before performing work. See specific components service

manual, located in Hurricane’s owner manual for instructions and additional safety

requirements.

•Vacuum creates VERY HIGH SUCTION—EXTREME CAUTION IS REQUIRED when

handling suction inlet locations.

•When vacuuming certain materials static electricity can be generated. PROPER STEPS

SHOULD BE TAKEN TO PROPERLY BOND AND GROUND HOSES, UNIT, ETC.

•Never lubricate, service, or adjust machine while it is operating.

•Maintain all parts in good operating condition. Replace worn or broken parts immediately.

•Disconnect battery ground cable (-) before making adjustment on electrical systems.

•Do not look into the discharge door or the hopper inlet pipe when unit is operating.

•Always wear safety glasses or goggles when performing maintenance on unit.

•Whenever vacuuming sticky materials, such as thick slurry, check the hopper often to verify all

the material is discharging and not building up on the inside. Utilize vibrator often to minimize

material build-up.

Engine Exhaust

•Engine exhaust fumes can cause sickness or death. DO NOT operate engine in an enclosed area

without proper ventilation or exhaust pipe extension to the atmosphere.

Avoid High-Pressure Fluids

•Escaping fluid under pressure can penetrate the skin causing serious injury.

•Avoid the hazard by relieving pressure before disconnecting hydraulic hoses or other lines.

Tighten all connections before applying pressure.

•Refer to MSDS for emergency information.

Revised 1/2016 Hurricane 500/600 Tier 4

8

USAFETY PROTOCOL

Blower Discharge Dust

•DO NOT operate the unit if dust is visible at the blower discharge.

•Shut unit down and contact Industrial Vacuum Equipment Corp. before continuing.

Engine Cooling System

•Explosive release of fluids from pressurized cooling systems can cause serious injury and

burns.

•Shut down engine. Allow sufficient time for coolant to decrease in temperature. Only remove

filler cap when cool enough to touch with bare hands. Slowly loosen cap to relieve pressure

before removing completely.

Dispose of Waste Properly

•Follow OSHA, State and Federal guidelines pertaining to the disposal of waste associated with

vacuum process.

E-Stop Button Instructions

•Each day, before beginning vacuum operations, test the E-Stop button to make sure it is

working properly.

•Whenever the vacuum is in operation, the E-Stop button MUST be within reach of the vacuum

hose operator, or must be attended by another operator.

•Whenever adding/removing hose and/or pipe, the E-Stop button should be used to stop vacuum

suction until all connections are completed.

Button “OUT” - Vacuum ON

Button “IN” - Vacuum OFF

Figure 5

Revised 8/2017 9Hurricane 500 Tier 4

UINSTRUMENTATION

The instrument panel on the Hurricane engine housing contains the following items:

1. Diagnostic Keypad

2. Air Pressure Gauge

3. Ignition Switch –Keyed switch

4. Dump System Timer Board –The dump timer is equipped with an ON TIME or

VACUUM TIME adjustable from 1 to 10 minutes. The OFF TIME or DUMP TIME is

adjustable from 10 to 100 seconds.

5. Vacuum System ON/OFF Switch –When the switch is in the ON position, the dump timer

will start working and throttle engine to full RPM.

Note: The Emergency Stop Button must be pulled out.

Note: The dump timer always starts its cycle in the dump mode, or OFF time.

6. Baghouse ON/OFF Switch –When the switch is in the ON position, the baghouse timer

will start, pulsing the filters in a factory-set sequence.

7. Vibrator ON/OFF Switch –See Note in “Vacuum Unit Operation” section.

8. Auger Forward/Reverse Switch (optional) –Controls Auger; only operates in dump mode.

Relief Valve

and

Pneumatic

Actuator

Figure 6

Revised 8/2017 10 Hurricane 500 Tier 4

Hurricane Tier 4 Instrumentation

Dump Timer

Keyed

Ignition

Switch

Diagnostic Keypad

Figure 7

Revised 1/2016 11 Hurricane 500 Tier 4

Hurricane 500 & 600 Tier 4

Hopper

Hydraulic

Up/Down

Control

Trailer

Hydraulic

Leveling

Control

Figure 8

Vacuum Gauge

(“Hg)

Revised 7/2015 15 Hurricane 500/600 Tier 4

DAILY MAINTENANCE

ALL MAINTENANCE PROCEDURES SHOULD BE ACCOMPLISHED

WITH UENGINE OFF!

ENGINE

1. Check oil level.

2. Check radiator coolant level.

3. Check or change outer air cleaner cartridge.

4. Check battery connections.

5. Check radiator fins for dirt and obstructions on the fan side.

BLOWER

1. Check oil level at both ends of blower.

2. Check belt tension.

Roots

Blower

Blower Oil level sight glasses –

maintain at half full level

Figure 9

Revised 8/2017 Hurricane 500/600 Tier 4

13

DAILY MAINTENANCE

VIBRATOR

1. Check Vibrator Oiler level.

AIR COMPRESSOR

1. Auxiliary drive air compressor –NO daily maintenance needed.

HYDRAULIC SYSTEM

1. Check oil level (at least 1/2 to 2/3 full).

2. Check for hydraulic leaks on the various hoses and connections.

GENERAL

1. Check fuel level.

2. Make general inspection for leaks and loose bolts.

3. Drain water from all air tanks.

4. Check the inside of the collection hopper to be sure no material is collecting on the walls

of the cone.

5. When the unit is running and the air pressure is up to 90 PSI (minimum), listen for the

bag pulsing sequence.

Revised 8/2017 Hurricane 500/600 Tier 4

14

EXTENDED MAINTENANCE

FIRST 100 HOURS

1. Change engine oil and engine oil filter. Refer to engine manual.

EVERY 200 HOURS

1. Change engine oil and engine oil filter. Refer to engine manual.

2. Check upper deflector plate inside collection hopper for excessive wear.

EVERY 300 HOURS

1. Change blower safety filter.

2. Change filter bags if needed. See maintenance procedures.

3. Rebuild air dryer. Refer to Air Dryer Bulletin.

EVERY 500 HOURS

1. Change engine fuel filter. Refer to engine manual.

2. Change blower oil in both ends. Refer to blower manual. NOTE: Apply pipe joint

compound sealant to blower oil threaded plug before re-installation.

3. Check condition of removable wear plate for excessive wear.

EVERY 1,000 HOURS

1. Remove vent tube on engine and clean it with diesel fuel. Refer to engine manual.

2. Change hydraulic oil. See spec sheet.

3. Check dump door gasket for excessive wear.

4. Replace desiccant in air dryer.

EVERY 5,000 MILES

1. Repack wheel bearings on trailer. Refer to axle manual.

2. Check pressure on trailer tires, 80 PSI.

Revised 8/2017 Hurricane 500/600 Tier 4

15

MAINTENANCE PROCEDURES

Filter Bag Change

1. Disconnect air line that runs from vacuum relief valve to the solenoid.

2. Open all dome hold down clamps. (See Figure 10)

3. Carefully open hinged dome. Remove hinge safety clevis pin prior to opening dome. Re-

install clevis pin after dome is in the open position. (See Figure 11)

4. Disconnect dinn cable from diaphragm solenoid. (See Figure 12)

5. Disconnect air/draw hose from air cannon. (See Figure 12)

6. Remove nuts from both hold down bolts. (See Figure 12)

7. Remove blast pipe safety clevis pin from bracket. (See Figure 12)

8. Lift hinged blast pipe assembly into vertical position and secure safety pin.

9. Lift cages out of filter bags and set aside.

Hold Down

Clamp

(in locked

position)

Figure 10

Figure 11

Dome hinge,

closed position

Hinge

Safety

Clevis Pin

Revised 8/2017 Hurricane 500/600 Tier 4

16

10. Using a large screwdriver, press in on the top part of the filter and pop it out of place. Let the

filter fall down and through the cone.

11. Remove all filters. Clean all of the dust off filter area.

12. Install filters using the same method, only in reverse.

13. Completed.

Filter Cage

P/N FN8065

Blast Pipe

P/N MC2078

Figure 12

Air Cannon

P/N AR5200

Blast Pipe

Hold Down

Bolt

Tank Drain Hose

Air Cannon–

1½” Integral

Solenoid, 12V

P/N DCP0015-3

Dinn Cable

Connector

P/N AR5208

Safety Clevis Pin

(for securing

blast pipe

assembly in the

vertical position)

P/N MC2008

Revised 1/2016 17 Hurricane 500/600 Tier 4

MAINTENANCE PROCEDURES

ENGINEU

Maintenance instructions on the engine are included with this manual. The engine should be

maintained per the engine manufacturer’s requirements.

UBLOWERU

Maintenance instructions on the blower are included with this manual. This blower is a precision piece

of equipment, and service should not be attempted by other than qualified personnel. The blower needs

little maintenance other than checking oil levels and changing oil as required. If the blower begins to

“knock”, USHUT DOWN THE UNIT IMMEDIATELY AND CONSULT FACTORY.U

U

PTOU

Operating and maintenance instructions are included with this manual. Follow the manufacturer's

instructions as to grease intervals and adjustment procedures. The clutch needs adjustment when there

is little or no effort required to snap it over center. Sometimes this means Uadjusting the clutch every

few daysUfor the first 100 hours of operation. If the clutch slips excessively, it will overheat and cause

damage.

UAIR DRYER

A bulletin on this component is included in this manual.

UBAGHOUSE TIMER AND DUMP CYCLE TIMERU

These components cannot be serviced in the field. All that can be checked are voltage to unit, fuse and

output. If the fuse is good and power is present at the input leads and the unit fails to operate, replace

circuit board.

UVACUUM RELIEF VALVE

This valve is factory set and should not be tampered with. Serious damage may result if unqualified

Personnel improperly adjust valve.

UENGINE AIR CLEANERU

The air cleaner on the diesel engine is a dual element filter. There is a smaller secondary element inside

the primary element. The secondary element needs only to be changed if the primary element is

damaged, or is installed improperly. Operating the engine without proper filtration will VOID THE

ENGINE WARRANTY. Operating the engine without proper air filtering for as little as one hour can

seriously shorten engine life.

Revised 8/2017 Hurricane 500/600 Tier 4

18

FUEL AND LUBRICANT SPECIFICATIONS

FUEL SPECIFICATIONS

1. Use grade No. 2-D Diesel fuel above 32º F.

2. Use grade No. 1-D Diesel fuel below 32º F.

3. Use grade No. 1-D Diesel fuel for all temperatures at elevations above 5,000 feet.

ENGINE LUBRICATING OIL

Use SAE 15W-40, multi-viscosity oil.

Example: Chevron-Delo 400 Multigrade

BLOWER LUBRICATING OIL

The required lubricant for this machine is Amsoil Synthetic R&O, AW Gear & Bearing ISO-220

(RCM).

HYDRAULIC LUBRICATING OIL

Use hydraulic oil AW ISO 32.

VIBRATOR LUBRICATING OIL

General purpose 10 weight oil.

VACUUM RELIEF BUTTERFLY VALVE

Mobil Polyrex EM.

Revised 8/2017 Hurricane 500/600 Tier 4

19

VACUUM UNIT SET-UP

1. Perform daily maintenance procedures.

2. When the trailer is in position, set the wheel chocks to prevent movement when

disconnected from the truck.

3. Start the diesel engine and idle to build up air pressure and warm up.

4. Attach vacuum suction hose to inlet pipe on collection hopper.

5. Using the adjustable jack on the front of the trailer, raise tongue of Hurricane off pintle

hook to disconnect from truck. Lower front of trailer, then lower and pin rear jack stands

in such a way that trailer will sit level. Make sure the jack stand pads are sitting on a

concrete surface; use heavy planks as required to maintain a stable foundation.

Use the trailer hydraulic leveling control to raise or lower trailer in lieu of manual crank

jack stand.

6. Raise front of trailer so that the rear jack stands are carrying weight, then lower and pin

the front jack stands.

7. When the unit is properly set, it should be level with pressure on all four jack stands.

8. WARNING: Do not proceed or raise collection hopper unless area around and above unit

is inspected and found to be free of electrical power wires or other obstructions.

9. Using hopper hydraulic up/down control lever, located near engine, raise collection

hopper to necessary height to clear the collection box, dump truck, container, etc.

10. When the proper height is reached, reposition safety blocks to the closest hole on the

hydraulic safety struts just above the hydraulic cylinder top, and pin in place. Gradually

lower the hopper until it is resting on the safety strut safety blocks.

11. WARNING: Do not stand under the collection hopper or get between the collection

hopper and the trailer when the cylinder is in the raised position without the hydraulic

safety strut blocks pinned in place.

12. WARNING: Do not leave the collection hopper in the raised position without the

hydraulic safety strut blocks pinned in place.

This manual suits for next models

1

Table of contents

Popular Industrial Equipment manuals by other brands

MIYAWAKI

MIYAWAKI RE1 user manual

Spirax Sarco

Spirax Sarco BPS32 Installation and maintenance instructions

Dadant

Dadant Fill Master M006262 manual

Smart Fibres

Smart Fibres SmartScan SBI product manual

PCB Piezotronics

PCB Piezotronics 393A03/ACS-23 Installation and operating manual

PI

PI L-417 9025E1B Series user manual

Ametek Land

Ametek Land NIR-B installation guide

Manntek

Manntek PERC Service instruction

Siemens

Siemens 3VT9300-4ED30 operating instructions

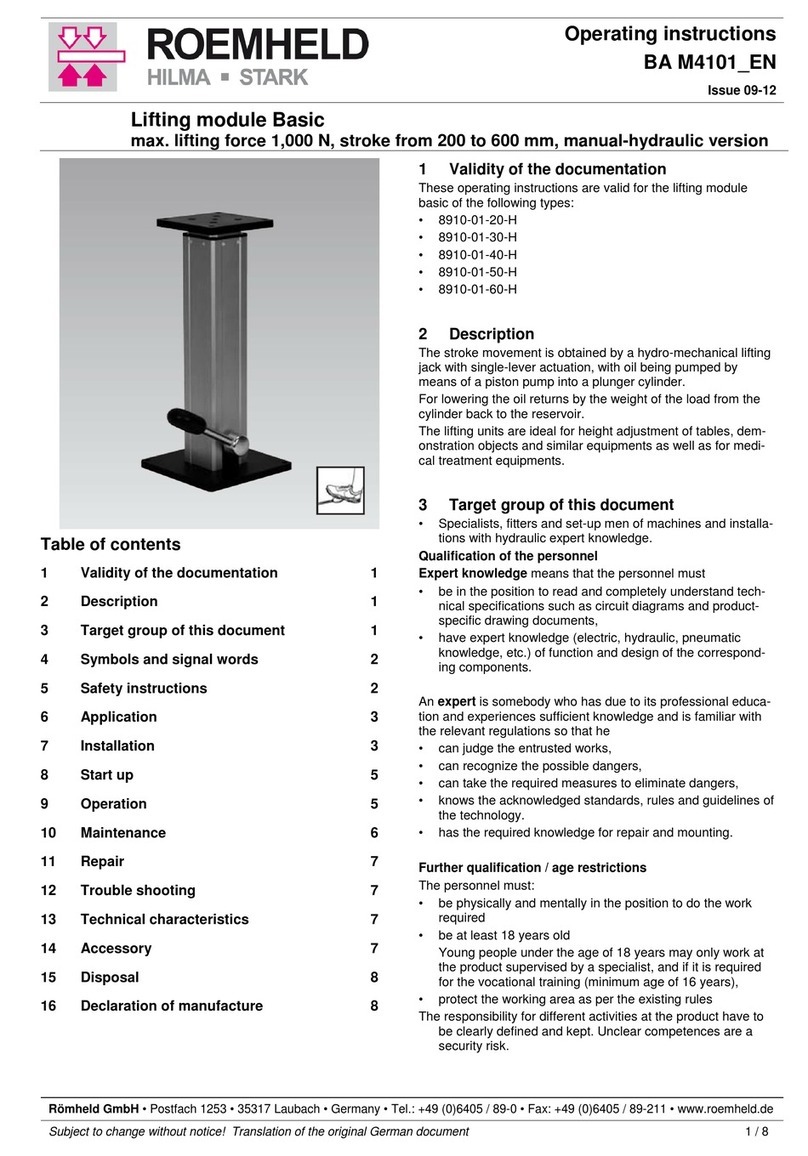

Roemheld

Roemheld 8910-01-20-H operating instructions

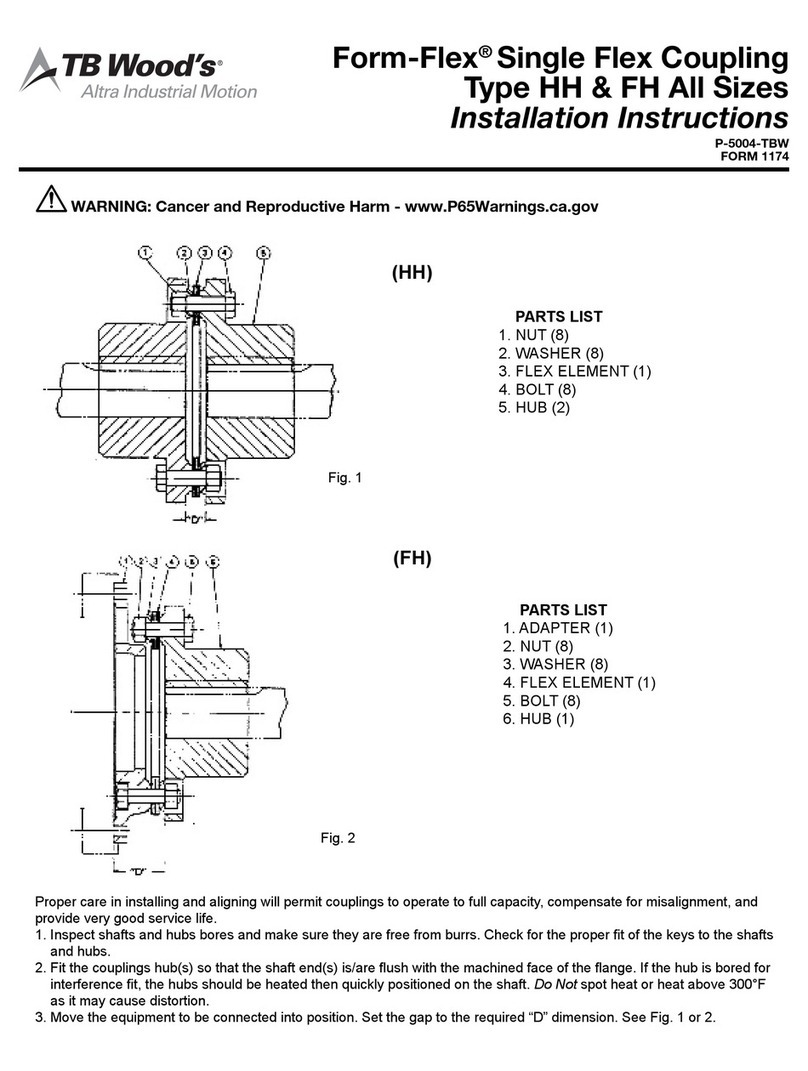

TB Wood's

TB Wood's Form-Flex HH Series installation instructions

Interactive Instruments

Interactive Instruments Jet Stream 500 instruction manual