Manntek PERC Original operating manual

Other Manntek Industrial Equipment manuals

Manntek

Manntek DDC Original operating manual

Manntek

Manntek DDC Original operating manual

Manntek

Manntek DCC Original operating manual

Manntek

Manntek SBC User manual

Manntek

Manntek DCC Original operating manual

Manntek

Manntek SBC User manual

Manntek

Manntek SBC Original operating manual

Manntek

Manntek DDC Original operating manual

Manntek

Manntek DCC Original operating manual

Manntek

Manntek DAC User manual

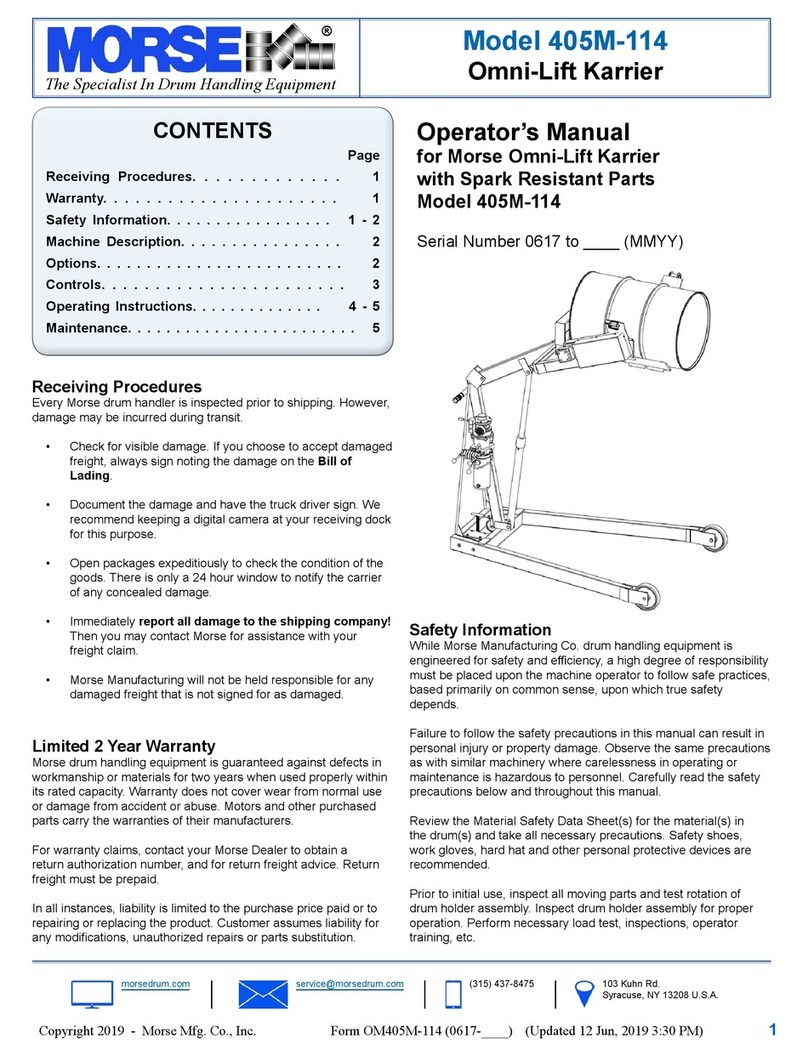

Popular Industrial Equipment manuals by other brands

Senco

Senco Smart Bridge operating instructions

Renova

Renova PWX Series Assembly and maintenance manual

Baldwin Boxall

Baldwin Boxall VIGIL Eclipse5 Installation details

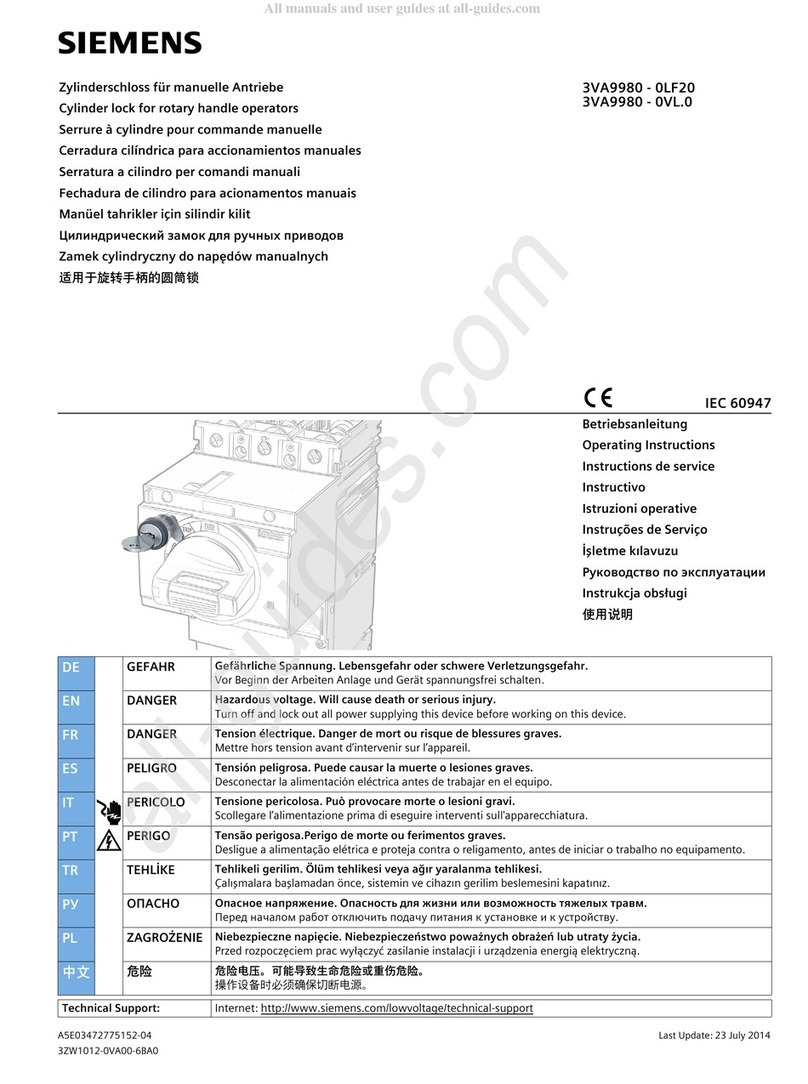

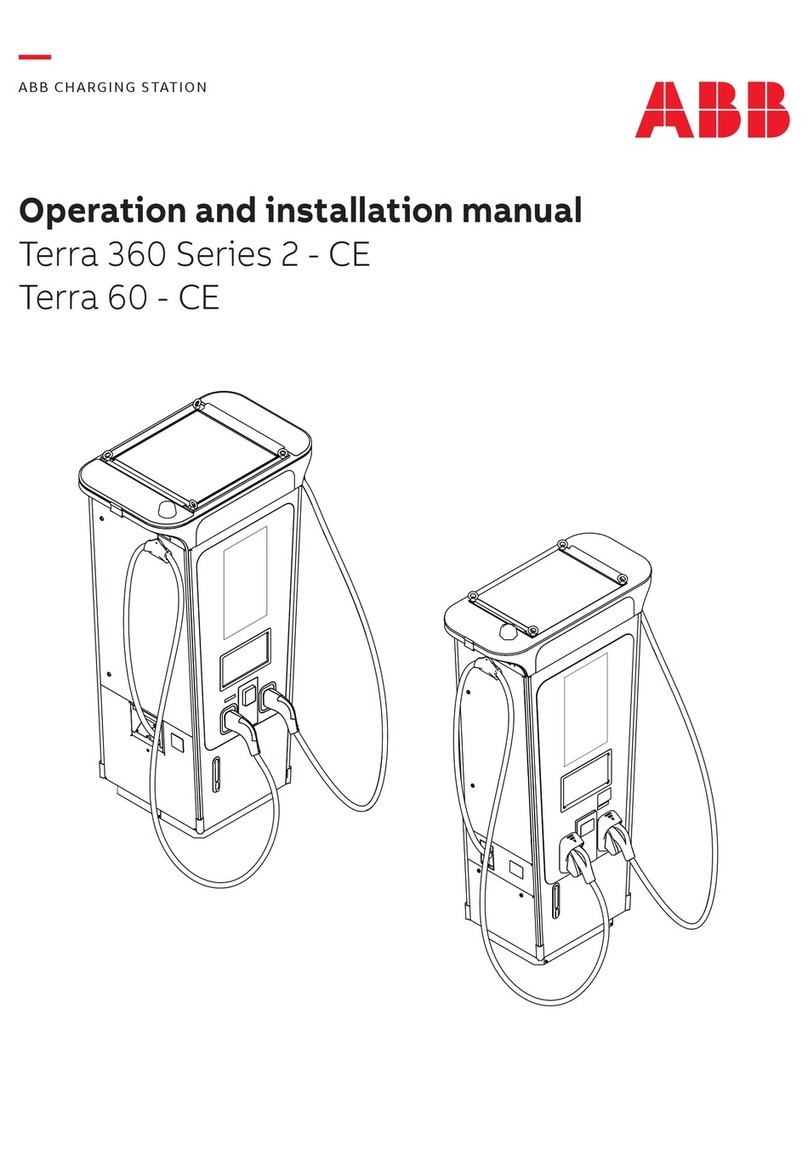

ABB

ABB 2 Series Operation and installation manual

Matsing

Matsing MS-48F90 instruction manual

Zimmer

Zimmer GHK6000 Installation and operating instructions

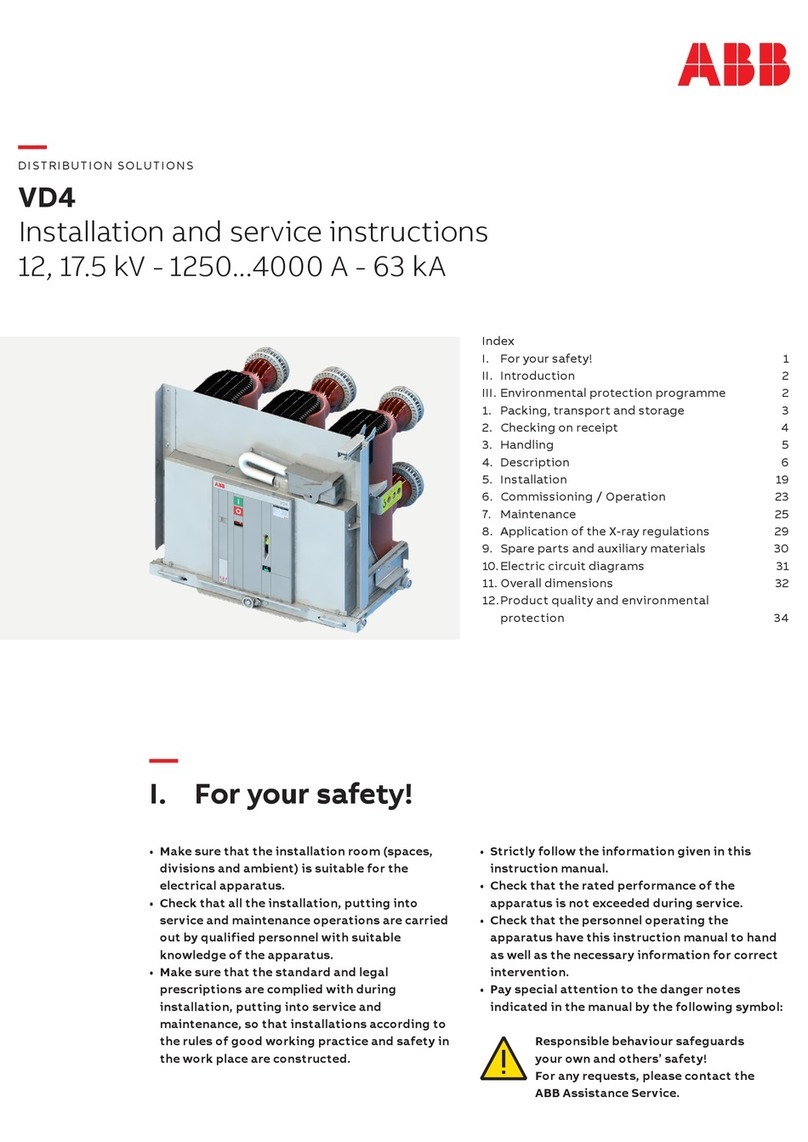

ABB

ABB VD4 Series Installation and service instructions

SLI

SLI POLY Operation manual

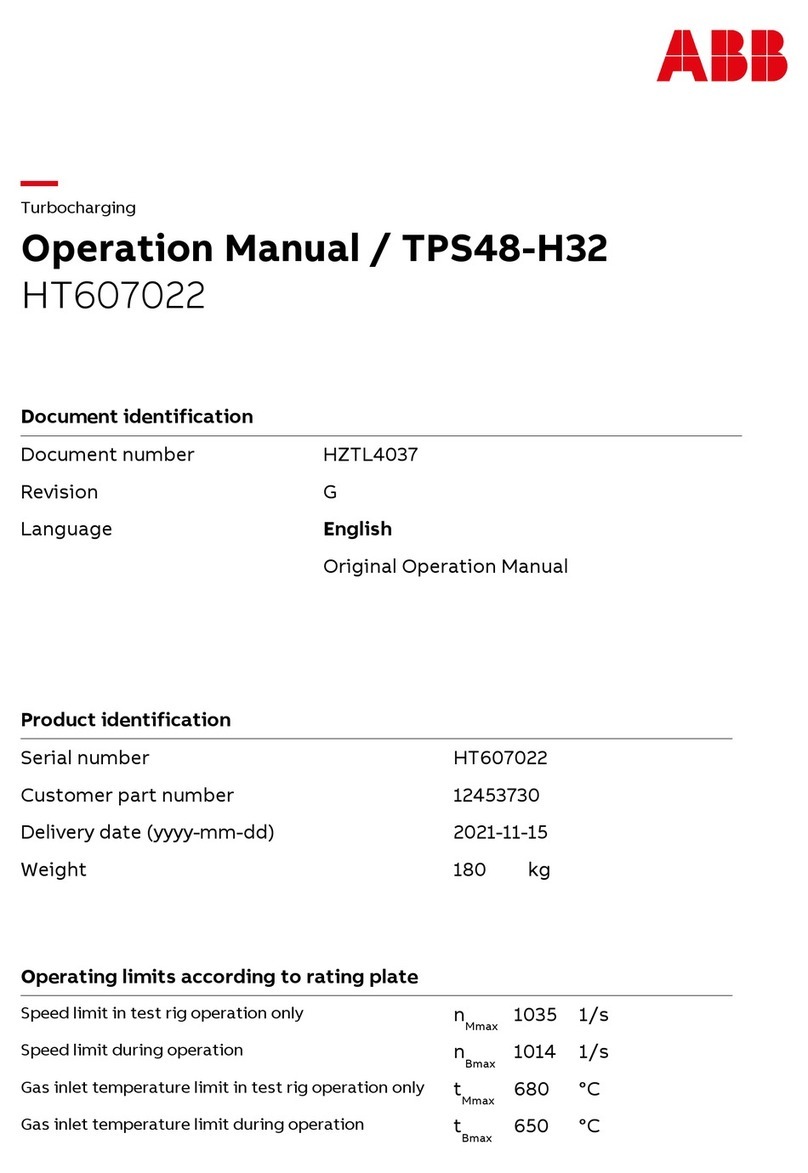

ABB

ABB HT607022 Operation manual

Versum Materials

Versum Materials GASGUARD AP10 Installation, operation & maintenance manual

HEIDENHAIN

HEIDENHAIN ND 1400 QUADRA-CHEK - GUIDE operating instructions

Mankenberg

Mankenberg VV Series Original operating manual