Lateral ram travel ..........................................................403mm

Max height - ram to table.............................................1018mm

Min height - ram to table..................................................58mm

Work table aperture.......................................................100mm

Work table depth ...........................................................206mm

Work table width............................................................630mm

Overall height ..............................................................1796mm

Weight ...............................................................................95kg

Gauge included ...................................................................Yes

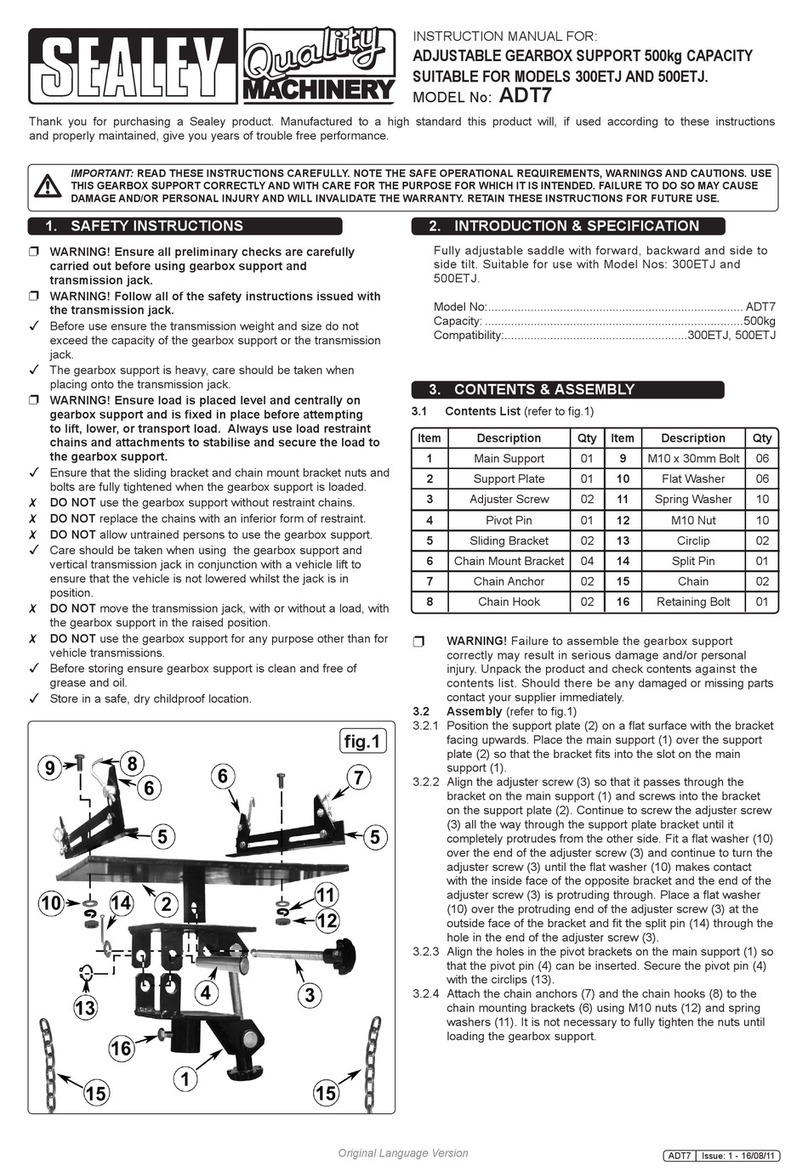

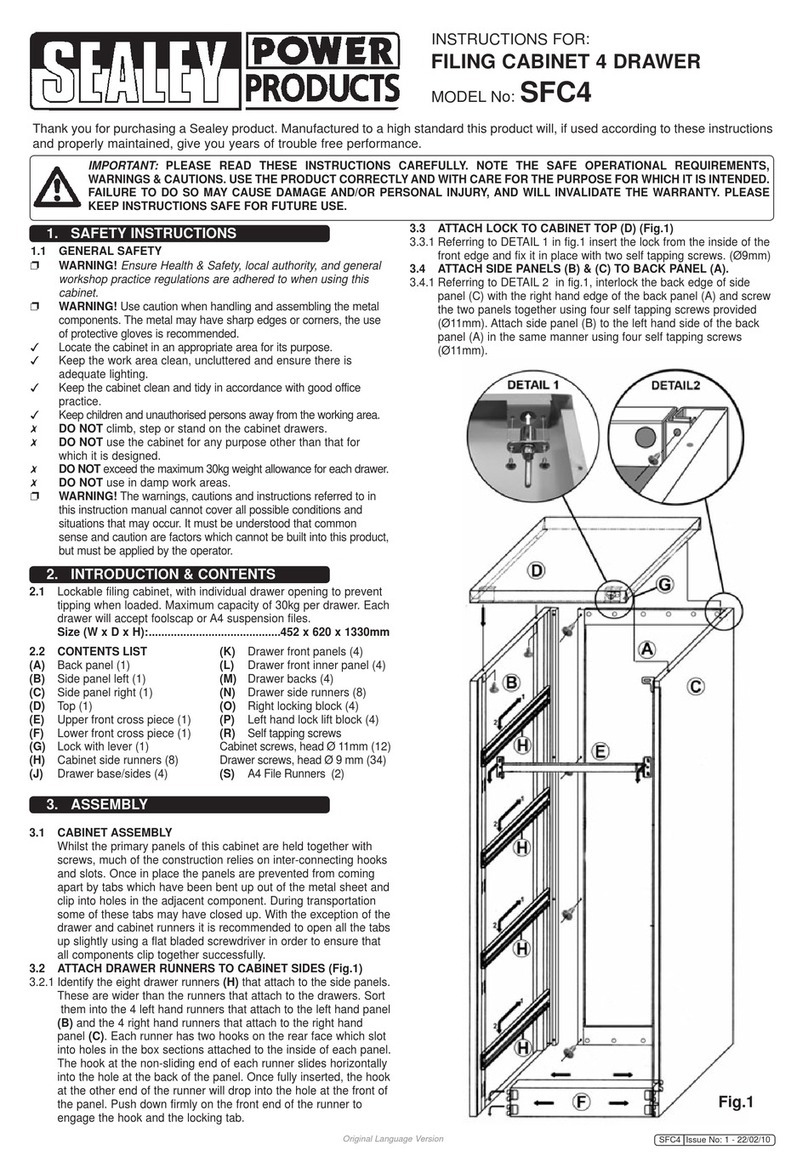

4. ASSEMBLY

REFER TO PARTS LIST

4.1. Unpack the product and check the contents. Should there be any damaged or missing parts, contact your supplier immediately. Take

care to ensure safety when removing main frame from its packing, as the unit is very heavy.

4.2. Use the parts diagram as your guide to assembly. Lay all parts and assemblies out before beginning assembly. The following

procedure is recommended.

4.3. Attach one base section (21) to the left post (20) and lower support (26), using bolts (25), washers (22), spring washers (23) and

nuts (24) to secure, then repeat with the other base section (21), attaching it to the right post (20) and the lower support (26).

4.4. Place the press frame in an upright position, attach one upper cross beam (10) to left and right posts (20) using bolts (9), washers

(13), lock washers (12) and nuts (11).

4.5. Place the other upper cross beam (10) in position and insert the under plate (7) to the two upper cross beams at the same time,

then secure this cross beam to the posts using bolts (9), washers (13), lock washers (12) and nuts (11).

4.6. Screw the upper round nut (6) onto the ram (3), insert the ram into the hole in the under plate (7), then screw the nut (8) onto the ram

and attach the serrated saddle (5) to the ram.

4.7. Join the two press bed frames (18) together by inserting the four bolts (27) through the bushings (28) and the holes in the bed

frames, then secure the four bolts with the washers (14), lock washers (15) and nuts (16).

4.8. Insert the bed frame pins (19) into the holes in the posts, then insert the joined press bed frames (18) into press frame and lower onto

the bed frame pins (19).

4.9. Attach the support plate (31) to the right post, using bolts (25), washers (22), spring washers (23) and nuts (24), then secure the

pump assemblies using the screws (29) and washers (30), insert the handle in the handle bracket.

4.10. Connect the hydraulic hose tting (36) to the connection nut (37) and t the pressure gauge (1) to the pressure gauge connection nut

(38) which is on the top of ram (3).

4.11. Tighten all xings. (nuts, screws and bolts).

5. INSTALLATION

5.1. INSTALLATION.

5.1.1. Securely attach the press to a flat, firm, level surface taking into account clearance for working pieces.

5.1.2. Before operating the press, purge the hydraulic system in order to eliminate any air that may have built up during transit. Open the

release valve and pump the handle several times. Should the system malfunction at any time, repeating this process may resolve

the problem.

6. OPERATION

▲DANGER! This model is purpose designed to withstand greater loads than the hydraulic units can develop. For safety reasons, always

ensure the workpiece and press tools are secured on the table and will not flex or suddenly “give way” causing danger to operator or the

component.

6.1. Position the working table at the required operating height by inserting the support pins into the appropriate holes in the main frame.

6.2. Place the arbor plate (17) on the press bed frame (18), then place workpiece onto the arbor plate and align beneath the ram as

required. NOTE: care must be taken to ensure an arbor does not fall from the press work table. If necessary hold the configuration in

position with clamps.

6.3. Close the release valve by turning it clockwise until it is firmly closed.

6.4. Pump the handle slowly until the ram is in close proximity to, or just touching the workpiece. Before applying any pressure to the

workpiece, recheck the alignment with the ram and ensure that the workpiece and press tools are supported in such a way that they

cannot flex.

6.5. Pump the handle to apply load to workpiece.

6.6. When work is complete, stop pumping the handle. Slowly and carefully free the load from the workpiece by turning the release valve

anti-clockwise in small increments.

6.7. Once the ram has fully retracted, remove the workpiece from the bed frame.

NOTE: Always keep the piston retracted after use to avoid ram corrosion.

7. MAINTENANCE

NOTE: Maintenance and repair must only be carried out by qualified person. Contact your Sealey stockist for details.

7.1. When the press is not in use, the hydraulic unit ram must be fully retracted to minimise corrosion. Remove the handle to inactivate the

press.

7.2. Lubricate all moving parts at regular intervals.

7.3. Always keep the press clean, dry, and protected from harsh conditions.

7.4. To check hydraulic oil level, remove the oil filler nut (34) from the pump. If it needs filling, use only Sealey hydraulic jack oil, contact

your local Sealey stockist for details. DO NOT use brake fluid. Replace oil filler nut and purge system of air (see 5.1.2.).

7.5. Should you need to replace the oil, ensure the hydraulic unit ram is fully retracted. An excess of oil will render the press inoperative.

7.6. Use only appropriate Sealey hydraulic jack oil (Sealey Part Number: HJO500MLS/HJO5LS). DO NOT use brake fluid.

7.7. If press efficiency begins to drop, purge the system to eliminate any air from the hydraulic system (see 5.1.2.).

7.8. Check your model parts information for spares.

Original Language Version

© Jack Sealey Limited YK20F.V3 Issue 2 (H, F, 1, 4, 5, 6, 7) 30/11/18