Operating manual MELAseal®100

Page 7 Rev.: 0 – 99/0211 BA_1_GB_seal100eco.doc

5. German DIN regulations

5.1.Width of sealed seams and clear space ________________________________________

German Standard DIN 58953 Part 7 requires that

sealed seams in transparent packaging material

should have a width of at least 8 mm. With a width of

10 mm for its sealed seams, the MELAseal® 100 is

considerably better than this minimum requirement.

DIN 58953 Part 7 specifies that a clear space of at

least 30 mm be left below the sealing border

between the sterilisation goods and the seam in

order to ensure a perfect seal without wrinkles. This

applies both for bags and transparent material from

the roll.

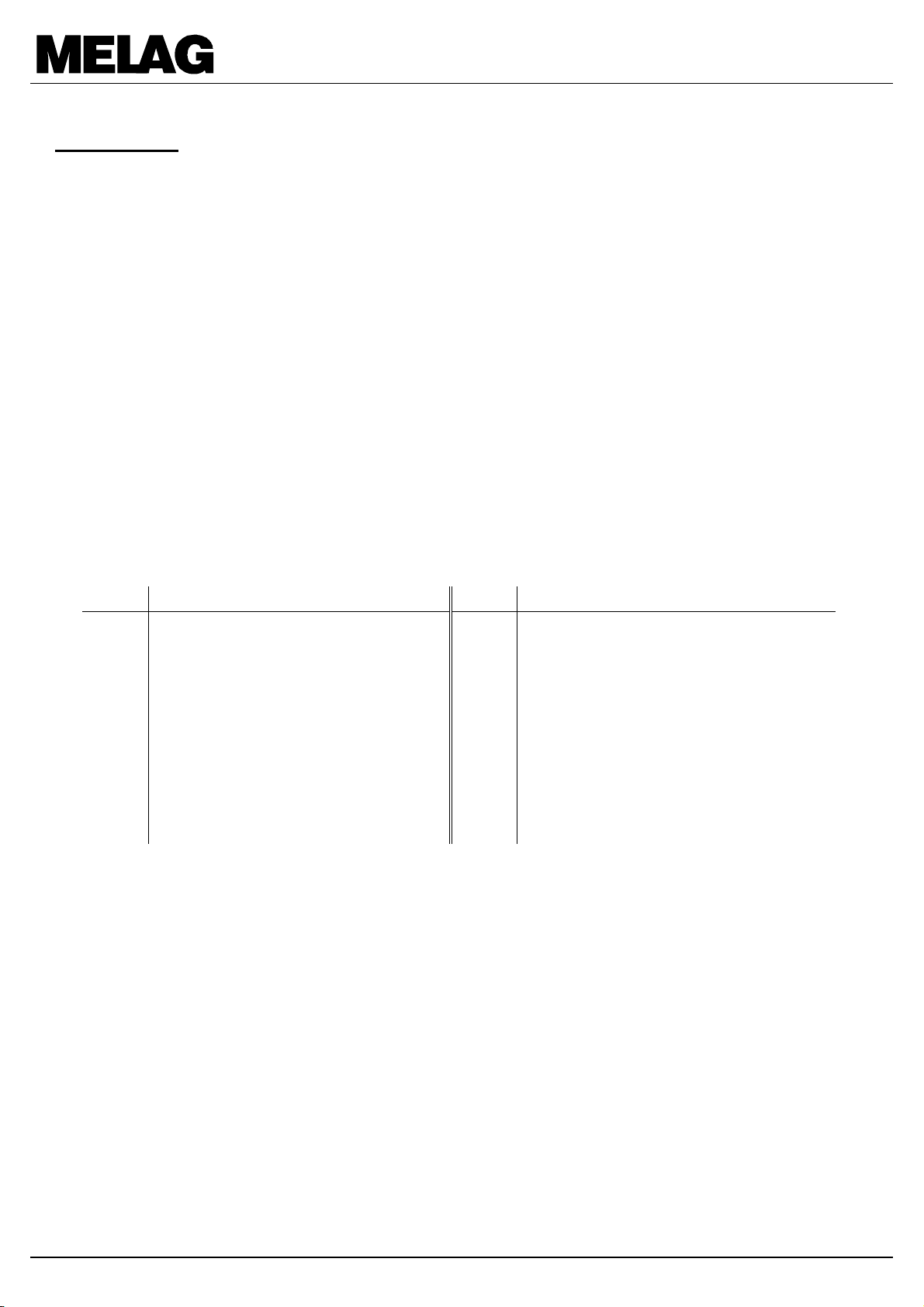

5.2.Storage life ________________________________________________________________

Sterile goods packaging Type of packaging Length of storage

unprotected 1Length of storage

protected 2

Paper bags in accordance

with DIN 58 953 Part 3 Sterile goods single

packaging 24 hours 6 weeks

Transparent sterilization packaging

in accordance with

DIN 58953 Part 4

Two-stage sterile

goods packaging 6 weeks 6 months

Sterile-goods store

packaging 3 years 3,4

1) E.g. on shelves

2) E.g. in cupboards or drawers

3) Before opening sterile-goods store packaging, dust shall be removed from it in accordance with

regulations.

4) The storage life of sterile-goods store packaging which has been opened is not altered if it has been

closed again in accordance with regulations.

A comment on the table in Section 8.2 of the DIN

standard says:

"The information in the table only represents

standard values. These do not mean that longer

storage periods are not possible under particularly

favourable storage conditions, or that a longer

duration of storage necessarily leads to the pack

contents being recontaminated during storage, but

signify that if these periods are observed,

recontamination of the contents when they are

opened and correctly removed is extremely

unlikely."

An additional explanatory note goes into further

detail:

"The risk in storing sterile goods is not that micro-

organisms may penetrate the sterile goods

packaging, provided that dry storage conditions

are ensured and the packaging material has the

required germ-proof qualities, but that when the

sterile goods packaging is opened after storage,

micro-organisms contained in dust particles may

be stirred up and could recontaminate the sterile

objects when these are removed.

"The extent of dust loading depends upon the

dust content of the air and on the duration of

storage. For these reasons the storage period

should be kept as short as possible."

5.3.VDE regulations ____________________________________________________________

In accordance with current VDE regulations, this appliance is not suitable for use in areas at risk of

explosion.

It should only be serviced by the manufacturer or a specially authorised agent (dealer or customer service).