Infinity Interlude Series User manual

Other Infinity Speakers manuals

Infinity

Infinity Total Solutions TSS-800 User manual

Infinity

Infinity C205 Infinity Classia User manual

Infinity

Infinity 652M User manual

Infinity

Infinity TSS-Sub1200 User manual

Infinity

Infinity 602M User manual

Infinity

Infinity Sigma User manual

Infinity

Infinity Intermezzo 3.5c User manual

Infinity

Infinity Primus P143 User manual

Infinity

Infinity Kappa Series 42.9i User manual

Infinity

Infinity SAT-750 User manual

Infinity

Infinity IRS Sigma User manual

Infinity

Infinity ERS Series User manual

Infinity

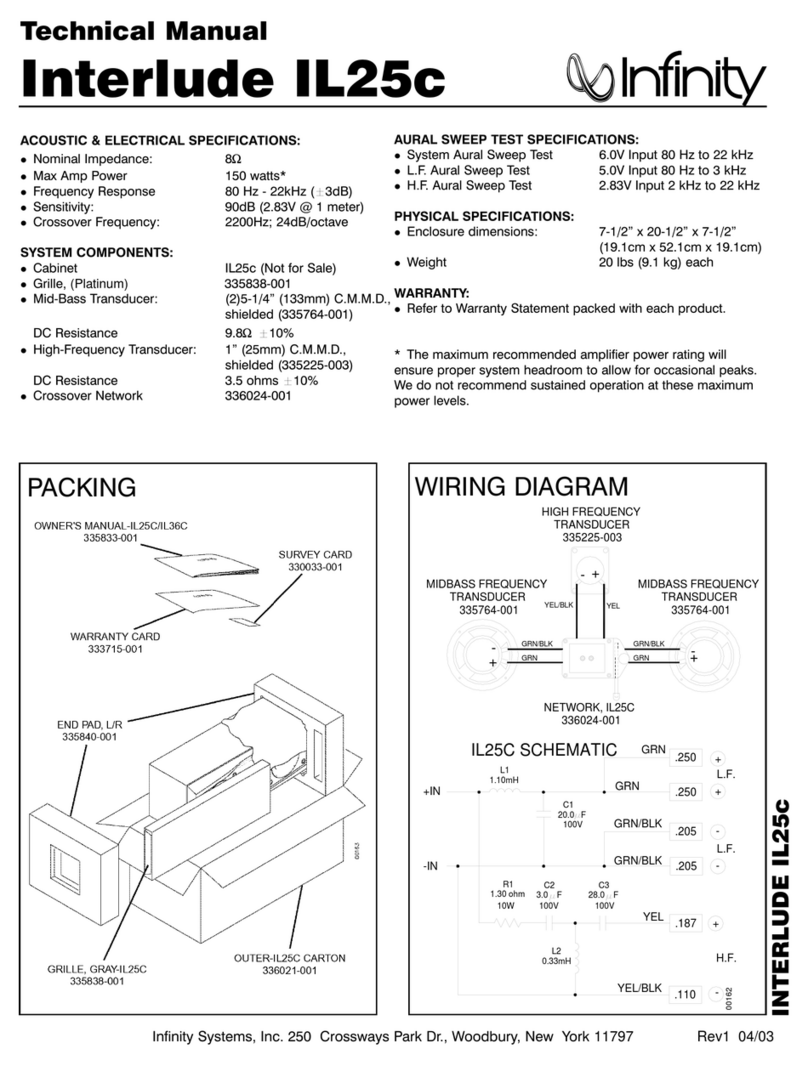

Infinity Interlude IL25c User manual

Infinity

Infinity SAT-750 User manual

Infinity

Infinity SAT-450 OM User manual

Infinity

Infinity OWS-1 User manual

Infinity

Infinity Overture 3 Compositions Series User manual

Infinity

Infinity Omega User manual

Infinity

Infinity Crescendo CS 3006 User manual

Infinity

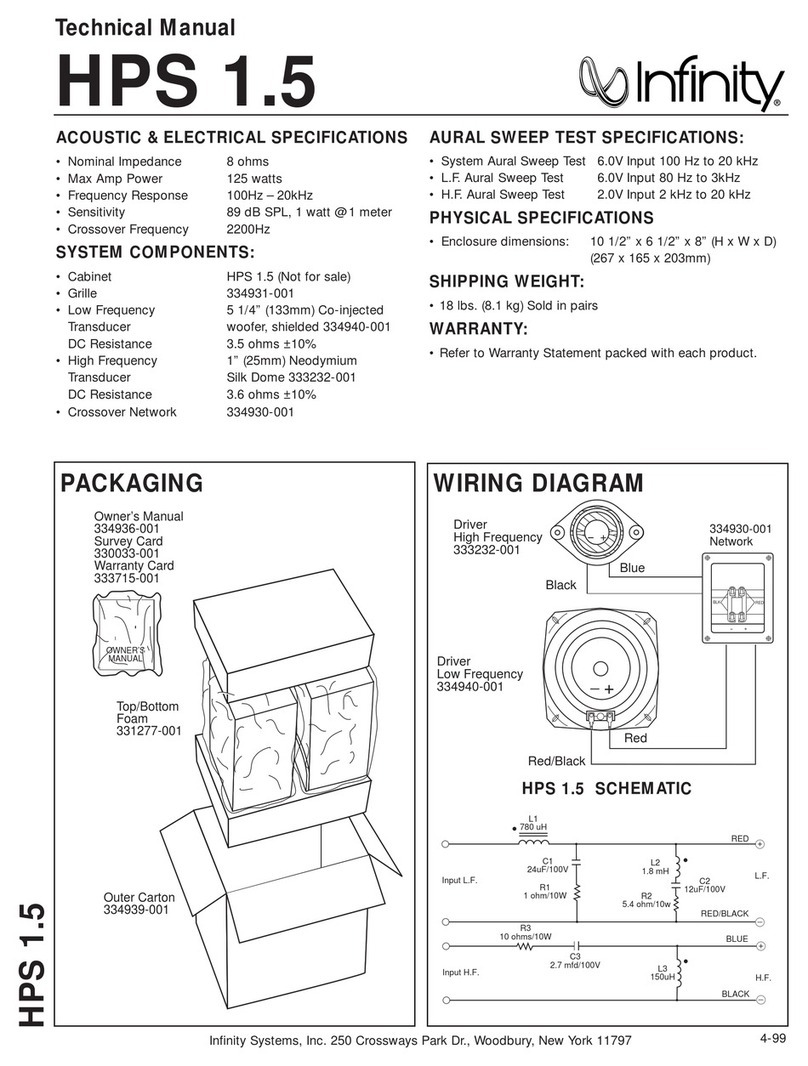

Infinity HPS 1.5 User manual