Unauthorized Copies Prohibited.

6.9 Hardware revisions __________________________________________________________________________________________________________ 51

7 Installation _____________________________________________________________________________________________________________________ 53

7.1 Installing the USB Driver ______________________________________________________________________________________________________ 53

7.1.1 Windows 8 Installation _________________________________________________________________________________________________ 55

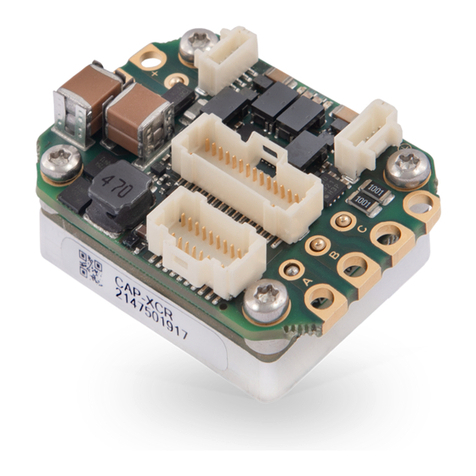

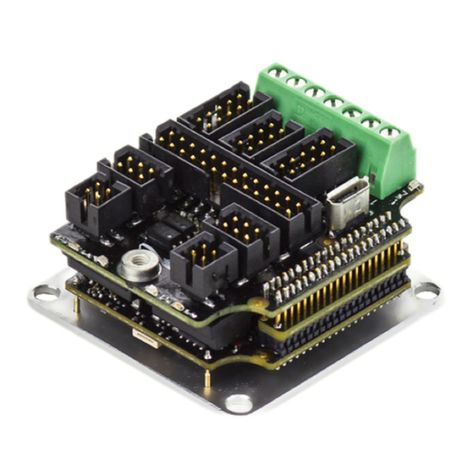

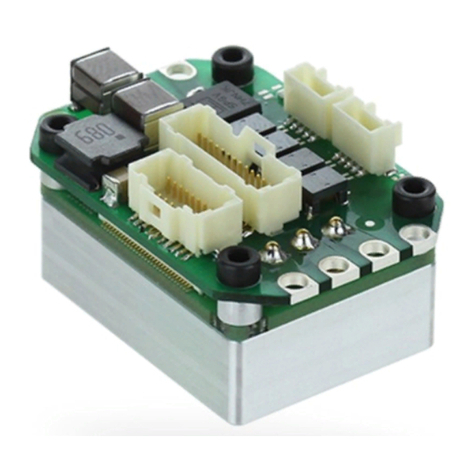

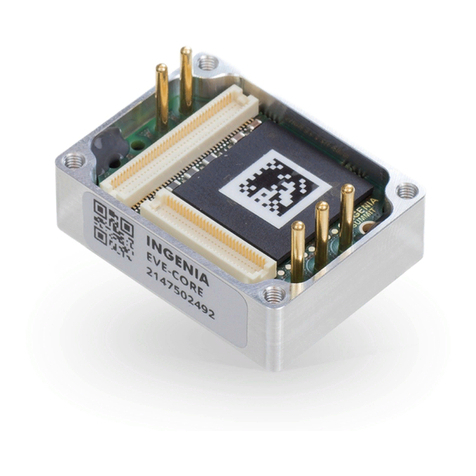

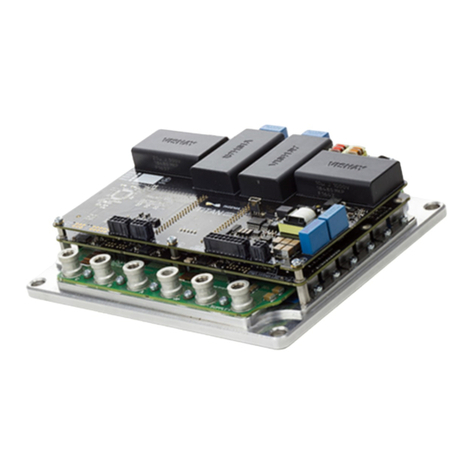

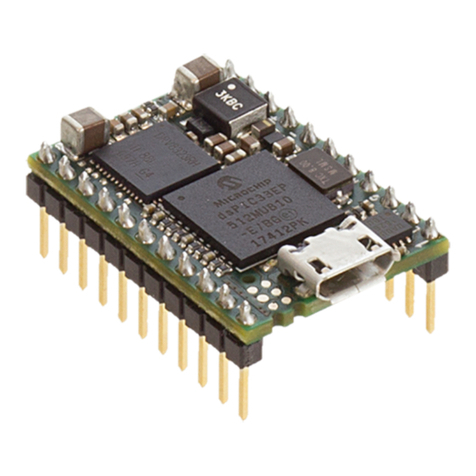

7.2 Connectors position and pinout _________________________________________________________________________________________________ 57

7.2.1 CAN interface connector _______________________________________________________________________________________________ 60

7.2.2 Feedbacks connector __________________________________________________________________________________________________ 61

7.2.3 Absolute encoder connector ____________________________________________________________________________________________ 63

7.2.4 I/O connector ________________________________________________________________________________________________________ 64

7.2.5 RS232 interface connector _____________________________________________________________________________________________ 66

7.2.6 Supply and shunt connector ____________________________________________________________________________________________ 67

7.2.7 Supply, shunt and motor connector _______________________________________________________________________________________ 68

7.2.8 Motor connector ______________________________________________________________________________________________________ 69

7.2.9 STO connector _______________________________________________________________________________________________________ 70

7.2.10 Motor safety connector ________________________________________________________________________________________________ 71

7.2.11 USB connector ______________________________________________________________________________________________________ 71

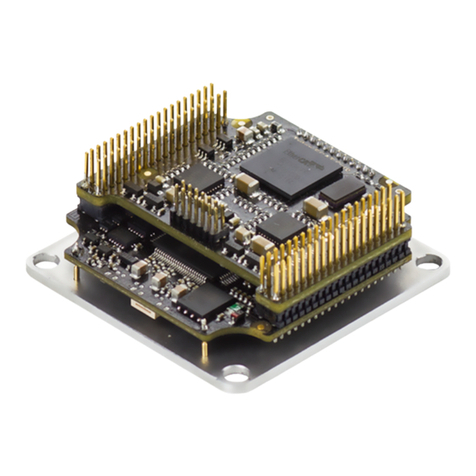

7.2.12 CAN interface connector ______________________________________________________________________________________________ 73

7.2.13 Feedbacks connector _________________________________________________________________________________________________ 74

7.2.14 Absolute encoder connector ___________________________________________________________________________________________ 76

7.2.15 IO connector ________________________________________________________________________________________________________ 77

7.2.16 RS232 interface connector ____________________________________________________________________________________________ 79

7.2.17 Supply and shunt connector ___________________________________________________________________________________________ 80

7.2.18 High current connector ________________________________________________________________________________________________ 81

7.2.19 Motor connector _____________________________________________________________________________________________________ 82

7.2.20 STO connector ______________________________________________________________________________________________________ 82

7.2.21 Motor safety connector ________________________________________________________________________________________________ 83

7.2.22 USB connector ______________________________________________________________________________________________________ 84

7.3 Mating connectors ___________________________________________________________________________________________________________ 85

7.3.1 CAN interface mating connector _________________________________________________________________________________________ 85

7.3.2 Feedbacks mating connectors ___________________________________________________________________________________________ 87