Infratek SM201 User manual

USERS MANUAL SM201

SPECTRAL MULTIMETER

Copyright ©2001 by Infratek AG

Infratek AG

Weingartenstrasse 6

CH-8707 Uetikon am See

Phone: +41-1-920 50 05

Fax: +41-1-920 60 34

www.infratek-ag.com

Infratek

CONTENTS

1. SAFETY

1.1. WARNINGS

2. INTRODUCING THE SPECTRAL MULTIMETER

2.1. OPTIONS AND ACESSORIES

2.2. SPECIFICATIONS

3. MATHEMATICAL DEFINITIONS USED BY THE SPECTRAL

MULTIMETER

4. GETTING STARTED

4.1. FRONT PANEL AND REAR PANEL

4.2. ADJUSTING THE OPTIMAL VIEWING ANGLE

4.3. LINE POWER

4.4. TURNING THE SPECTRAL MULTIMETER ON

4.5. USING THE FUNCTION KEYS

4.6. SELECTING A MEASUREMENT RANGE

4.7. TAKING SOME BASIC MEASUREMENTS

5. OPERATING THE SPECTRAL MULTIMETER FROM THE

FRONT PANEL

5.1. INTRODUCTION

5.2. FRONT PANEL OPERATIONS

5.3. CURRENT INPUT SELECTION

5.4. RANGE SELECTION / AUTO RANGE SELECTION

5.5. SELECTING MEASURING MODE

5.6. SELECTING THE MEASUREMENT TIME

5.7. SELECTION OF AC- OR DC+AC-COUPLING

5.8. CHANGING THE DISPLAY CONFIGURATION

5.8.1. CHANGING THE HARMONIC NUMBER

5.9. MAIN MENU SELECTION

5.9.1. DISPLAY HOLD

5.9.2. AUTO RANGE SELECTION

5.9.3. SELECTING THE SIZE OF THE GRAPHIC AREA

5.9.4. SELECTING THE GRAPHIC DATA

5.10. SHORT TIME INTEGRATOR

5.11. ENERGY COMPUTATION

5.11.1. SET-UP FOR ENERGY MEASUREMENT

5.11.2. SET-UP FOR CHARGE MEASUREMENT

5.11.3. STARTING AND STOPPING

5.12. SCALING OF CURRENT- AND VOLTAGE INPUTS

5.13. PRINTING DATA

5.14. THIS IS HOW YOU SAVE YOUR DESIRED INSTRUMENT

SETTINGS

5.14.1. THIS IS HOW THE SM201 STARTS UP IN THE DESIRED

CONFIGURATION

5.15. MEASUREMENT TECHNIQUES USING THE SPECTRAL

MULTIMETER

6. OPERATING THE SPECTRAL MULTIMETER USING THE

COMPUTER INTERFACE

6.1. INTRODUCTION

6.2. LOCAL AND REMOTE OPERATIONS

6.3. COMPUTER INTERFACES

6.4. SETTING INTERFACE PARAMETERS

6.5. CABLING THE SPECTRAL MULTIMETER TO A HOST

6.6. HOW THE SPECTRAL MULTIMETER PROCESSES INPUT

6.6.1. INPUT TERMINATOR

6.6.2. SENDING COMMANDS TO THE SPECTRAL MULTIMETER

6.6.3. HOW THE SPECTRAL MULTIMETER PROCESSES OUTPUT

6.6.4. OPTIMIZING SPEED FOR DATA TRANSFER

6.7. SERVICE REQUESTS AND STATUS REGISTER

6.8. COMPUTER INTERFACE COMMAND SET

7.1. INSTALLING THE OPTION ASSEMBLY

7.2. OUTPUT CONNECTORS

7.3. ANALOG INPUTS

7.4. FOUR ANALOG OUTPUTS

7.5. CURRENT SENSOR MODULES

7.6. PRINTER OUTPUT

7.7. EXTERNAL SYNCHRONISATION

7.8. DISTURBANCE PREVENTION

8. CALIBRATION PROCEDURE

8.1. CALIBRATION CYCLE

8.2. EQUIPMENT NEEDED

8.3. PREPARING FOR CALIBRATION

8.4. OFFSET ADJUSTMENT AND CALIBRATION

8.4.1. AMPLIFIER OFFSET ADJUSTMENT

8.4.2. CURRENT AMPLIFIER CALIBRATION

8.4.3. VOLTAGE CALIBRATION

8.4.4. SHUNT INPUT CALIBRATION

8.4.5. POWER CALIBRATION

1-1 1-2

1. SAFETY

Before using the Spectral Multimeter, read the following safety information carefully. In this

manual „WARNING“ is reserved for conditions that pose hazards to the user; „CAUTION“ is

reserved for conditions that may damage your instrument.

• Avoid working alone.

• Follow all safety procedures for equipment being tested.

• Inspect the test leads for damaged insulation.

• Be sure the Spectral Multimeter is in good operating condition.

• To avoid electrical shock, use caution when working above 30V dc or rms.

• Disconnect the live test leads before disconnecting the common test leads.

• When making a current- or power measurement, turn the circuit power off before connecting

the Spectral Multimeter in the circuit.

• Switching on inductive loads means large inrush currents. Take precautions to avoid

overloading the current channel by shorting the start-up currents accross the current input.

• Switching off inductive loads or switching on rotating loads means large voltages or extremely

fast changing voltages on the Spectral Multimeter input terminals. Such conditions may

damage the instrument and are potentially hazardous.

• To comply with EN50081-1 the current- and voltage test leads must form 4 windings through

ferrite torroid Philips Type 4322 020 9720 or equivalent. Interface inputs/outputs must be

shielded.

• 1kV burst test: use shielded input- and output cables.

• The Spectral Multimeter complies with the safety standards IEC 1010-1, EN 61010-1.

1.1. WARNINGS

• Before reading the manual or before using this instrument read carefully the warnings below

and make sure you understand them.

• WARNING: Line Power

To avoid shock hazard, connect the instrument power cord to a power receptacle with earth

ground.

• WARNING

The maximum floating voltage above earth ground on the current input terminals and the

voltage Lo-input terminals is 600V. Exceeding these limits poses a hazard to the meter and

operator.

• WARNING

This instrument must be operated by qualified personnel.

• WARNING

Refer all servicing of this instrument to qualified personnel. Before opening case disconnect

all leads connected to the instrument and finally disconnect the power line cord.

• WARNING

The specifications given in this manual solely describe the technical properties of the

instrument. They do not imply any other properties unless it is explicitly said so.

• WARNING

Use of this instrument in life support systems and in systems for people transportation must be

expressly authorized.

The authorization must be signed by the manufacturer of this instrument.

2-1 2-2

2. INTRODUCING THE SPECTRAL MULTIMETER

WARNING

Read the „Spectral Multimeter Safety“ in section 1 of this manual before using the instrument.

This instrument is designed for bench-top, field service, and system application.

Some features provided by the Spectral Multimeter are:

• Large, blue LCD monitor, 120 x 64mm (240x128 pixels).

• Fully menu controlled operation with only 11 membrane keys.

• Meter mode and graphics mode.

• Measures and computes all electrical quantities of current, voltage, power, energy and

harmonics of current, voltage, and power simultaneously.

• Frequency measurement 0.1Hz-100kHz.

• AC, and AC+DC for individual quantities.

• Built-in integrator.

• Harmonic Analysis of current, voltage and power, including IEC555-2.

• Bar graph and wave form display.

• Wide voltage- and current range (15mA-40A).

• High common mode rejection ratio.

• Flicker measurement, SM201 complies with IEC868.

• Measures current- and voltage bursts.

2.1. OPTIONS AND ACCESSORIES

Six option packages are available. Options 01 through 03 can be installed at the factory or by the

customer on site. Option 04 and 08 must be installed at the factory.

• Option 01 contains the RS-232 serial interface and the Centronics printer output.

• Option 02 contains the RS-232 serial interface, the Centronics printer output, and the IEEE-

488 interface. The IEEE-488 interface complies with the 488.1 and the 488.2 (1987) standard.

• Option 03 contains the RS-232 serial interface, the Centronics printer output, the IEEE-488

interface, four programmable ±5V analog outputs, and eight analog inputs.

• Option 04 contains a current sensor module supplied by the SM201. Current ranges are: 0-

25A up to 0-1000A.

• Option 07 contains an operating software under Windows.

• Option 08 contains an external TTL-input for synchronization.

Available accessories are described below.

ACS1A: Current clamp with connector to the shunt input of the Spectral Multimeter; range 0-

400A, DC-1kHz, 2 % accuracy.

ACS1B: Current clamp 0-20A and 0-200A, 1 %, DC-10kHz.

ACS2: Portable printer (106 x 180 x 88mm) with Centronics interface.

ACS3: Soft carrying case provides protection for the instrument. Ideally suited for service

applications.

ACS4: Set of test leads, max. 32A, 1.5m; 2 red, 2 black.

ACS5: Shunt input connector.

ACS6: Service Manual.

ACS7: Rack Mounting Kit.

2.2. SPECIFICATIONS

This section defines the performance of the Spectral Multimeter SM201. The user must be aware

that exposure of the SM201 inputs to their maximum value for a prolonged time will result in

additional measurement errors. These errors add to those given in the specification table.

5A input: (I2x 0.004 %/A2) for t >1 minute per 10 minutes

30A input: (I2x 0.0002 %/A2) for t >1 minute per 10 minutes

voltage input: (U2x 0.0000003 %/V2) for t >1 minute per 10 minutes.

Operating the 5A input at elevated currents (>4A) will also affect the 30A input, and visa versa.

Operating temperature range:15°C - 30°C

2-3 2-4

SPECIFICATIONS

Voltage Ranges, 8 ranges 2-6-20-sequence; 0.6 V, 2V, 6V, 20V, 60V, 200V, 600V, 2000V.

Frequency range DC, 2Hz-300kHz

Crest Factor 4:1 at 50 % full scale (fs) Common Mode 50Hz/100kHz 155dB/95dB

Input Impedance >2.3MΩ

Standard accuracy 23°±

3°K; rms, mean, rectified mean; for 0.6V range typical. improved accuracy, 1Hz-400Hz

1Hz-1kHz ±(0.1 % rdg + 0.1 % range) ±(0.05 % rdg + 0.07 % range)

DC, 1kHz-10kHz ±(0.2 % rdg + 0.2 % range + 0.04 %/kHzrdg), DC typical

10kHz-100kHz, ±(0.3 % range + 0.04 %/kHzrdg)

100kHz-300kHz ±(0.3 % range + 0.04 %/kHzrdg), typical

Current Ranges, 12 ranges 1-3-10-sequence; 15mA, 50mA, 150mA, 500mA, 1.5, 5, 15A, 1, 3, 10, 30, 100A.

Frequency range DC, 2Hz-300kHz

Crest Factor 4:1 at 50 % full scale (fs) Common Mode 50Hz/100kHz 160dB/120dB

Standard accuracy 23°±

3°K 5A-/Shunt input130A input1improved accuracy 1Hz-400Hz

1Hz-1kHz ±(0.1 % rdg + 0.1 % range) ±(0.1 % rdg + 0.1 % range) ±(0.05 % rdg + 0.07 % range)

DC, 1kHz-10kHz ±(0.2 % rdg + 0.2 % range) ±(0.9 % rdg + 0.2 % range) DC typical

10kHz-100kHz ±(0.3 % range + 0.04 %/kHzrdg) ±(0.3 % range + 0.5 %/kHzrdg) 1For 2 lowest ranges, input

100kHz-300kHz ±(0.3 % range + 0.04 %/kHzrdg), typical >50 % fs

Power 80 ranges corresponding to the products V x A .

Frequency range of fundamental frequency 20Hz-1kHz

Accuracy 23°±

3°K

20Hz-100Hz 0.3 % rdg + (0.3 % + 1 % sinϕ) range -80°< ϕ<80°

100Hz-200Hz 0.5 % rdg + (0.5 % + 2 % sinϕ) range -80°< ϕ<80°

200Hz-1kHz 0.5 % rdg + (0.5 % + 0.2 %/100Hz) range, typical PF=1

Frequency 2Hz-100kHz, A or V triggered; Accuracy ±0.1 %. 100 % full scale

Computed Values Accuracy; Reactive Power, Var = ±(VA2- W2)1/2; Apparent Power: VA = Arms Vrms; Power Factor: Add accuracy percentage figures

PF = W/VA; Crest Factor: CF = Ap/Arms, Vp/Vrms; Form Factor: FF = At/Arms, Vt/Vrms; of values involved in comput-

Impedance: Z = Vrms/Arms; Total Harm Dist: THD = (Irms2- IFund2)1/2/Irms, Flicker, Pst, Plt ation.

Integrator Energy, Accuracy 50Hz Wh, VAh, Varh; Basic accuracy of integrated quantity. >1s measurement time.

Harmonic Frequency range of fundamental 5Hz-60kHz

Analysis Range of harmonic 1-63

Accuracy, Harmonic current and voltage Computed values:

5Hz-1kHz ±(0.2 % rdg + 0.1 % range) Harmonic power, Harmonic

1kHz-10kHz ±(0.5 % rdg + 0.5 % range) phase angle (power factor),

10kHz-60kHz ±(0.7 % range + 0.1 %/kHzrdg), typical Harmonic impedance

Burst Measures current- or voltage burst of an intermittent signal. Minimum burst duration 1ms.

Flicker Determines short time flicker Pst and long time flicker Plt. Use 0.5 sec. measurement time.

Display Blue liquid crystal graphic display with FL back light 64 x 120mm; 128 x 240 pixels

Power AC, 50-400Hz; Fuse: Power 18W. 85V-240V; 2AF/20VA

Dielectric Strength Inputs to case or power supply 2.5kV/50Hz/1 minute

Line input to case 1.5kV/50Hz/1 minute

Dimension H x W x D; Weight 150 x 235 x 320mm; 4kg

Options IEEE-488-2, RS232,Centronics printer output

4 Analog outputs, Output impedance 100Ω; accuracy 0.2 % 0 - ±5V

4 Analog inputs, low range, input impedance 200kΩ; accuracy 0.4 % typical 0 - ±1V

4 Analog inputs, high range, input impedance 200kΩ; accuracy 0.4 % typical 0 - ±10V

Rack mounting kit; Humidity: KYG according to DIN 40040, max. 85 % RH non-condensing.

Shunt Input οopen circuit Ranges in mV: 60, 60√10, 600, 600√10, 6000, 6000√10

Hi οο Lo Accuracy: Same as 5A-input

Input impedance: 200k; input of 60mV corresponds to 1.0000A display.

3. MATHEMATICAL DEFINITIONS USED BY THE

SPECTRAL MULTIMETER

3-1 4-1

RMS-value (1/T

i

o

T

∫2dt)1/2

Rectified mean 1/T |i |dt

o

T

∫

Mean value 1/T

i dt

o

T

∫

Maximum max. (i) in averaging interval

Minimum min. (i) in averaging interval

Peak-to-peak max. (i) - min. (i) in averaging interval

Average Power P 1/T u i dt

o

T

∫

Apparent Power S RMS current x RMS voltage

Reactive Power Q ±(S2- P2)1/2 for every harmonic

Crest Factor Maximum / RMS-value

Form Factor RMS-value / Rectified mean value

Frequency Number of zero crossings of current or voltage.

Power Factor P/S

Energies, Charge

xdt x=P, S, Q, rect. mean current

0

t

∫

Total harm. Distortion THD (Irms2- Ifund2)1/2/Irms

Impedance Vn/In ⎣phase n=harmonic 1-63

Short time Flicker Pst (10 minutes), PS3 (3 minutes), PS1 (1 minute)

Long time Flicker Plt

NOTE: RMS-, rectified mean-, mean-, maximum-, minimum-, and peak-to-

p

ea

k

value apply to current and voltage.

Energies apply to real-, apparent-, and reactive power. Charge applies to rectified

mean current only.

Total harmonic distortion applies to current and voltage. Flicker applies to voltage

only.

Burst duration B_dur

4. GETTING STARTED

This section explains how to prepare the Spectral Multimeter for operation, discusses general

operating features, and explains some common measurements.

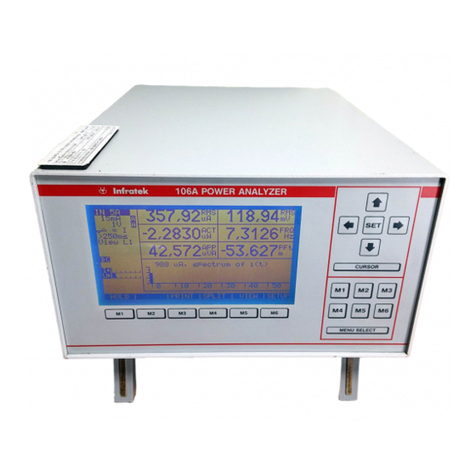

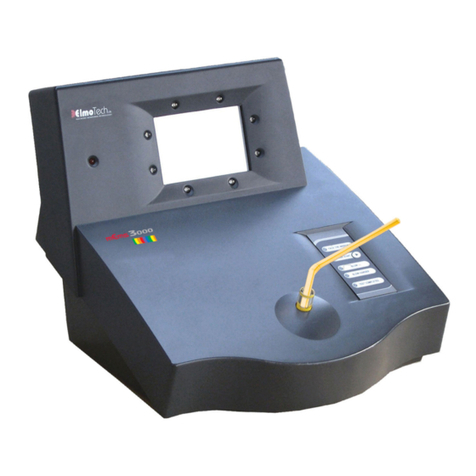

4.1. FRONT PANEL AND REAR PANEL

The front panel in figure 4.1 shows the display monitor in the center and below the display two

rows of control keys. The top row contains the menu control keys and the bottom row contains the

Cursor and SET control keys.

On the left hand side are the input terminals. At the top are the Hi and Lo voltage terminals. At the

bottom are the current Lo, 5A, and 30A input terminals.

Fig. 4.1 Spectral Multimeter Front Panel

RS 232

IEEE-488

Centronics

Analog in-out/Controls

600V

CAT II

0

I

Fuse inside, 2AF/250V

Voltage 90-250V/47-63Hz/30VA

CE

All inputs max. 600V. This

equipment must be earthed.

Do not remove cover. Refer

servicing to qualified personel.

!

Figure 4.2. Spectral Multimeter Rear Panel

The rear panel shown in figure 4.2 contains the shunt input connector. When not in use, the short

circuit connector must be installed.

On the left hand side of the rear panel are, from top to bottom, the RS-232 interface connector, the

IEEE-488 interface connector, the centronics printer connector, and the analog in- and output

connector.

To the far left is the power line cord connector for 50/60Hz line voltages in the range 85V to

265V.

4.2. ADJUSTING THE OPTIMAL VIEWING ANGLE

Operating the Spectral Multimeter on a table you may want to tilt the instrument. This can be done

by rotating forward the stand-offs at the bottom plate.

4-2 4-3

4.3. LINE POWER

WARNING

To avoid shock hazard, connect the Spectral Multimeter line cord to a receptacle with earth

ground.

Plug the line cord into the connector on the rear of the instrument. It will operate on any line

voltage between 85V ac and 265V ac without adjustment, and any frequency between 50 and

400Hz.

4.4. TURNING THE SPECTRAL MULTIMETER ON

To turn the instrument on activate the power line switch located near the power receptacle on the

rear panel.

When the instrument is turned on the display is set to its start-up configuration with all values set

to zero for about 2 seconds while the instrument performs an internal self test. After this self test

the instrument assumes its initial setting. The initial setting is determined by the instrument setting

recall number 00 to 20. It is factory set to recall number 00 which assumes the following state:

The first line of the display number field shows the RMS current and the RMS voltage. The

second line shows power and frequency of current, and the third line shows apparent power and

power factor.

The fourth and fifth lines are graphic area. At start-up the harmonic bar graph of current is

displayed. The horizontal scale is numbered referring to the harmonics of current (N=0 is the DC

component) and the vertical scale gives the magnitudes of the harmonics of mA or A.

4.5 USING THE FUNCTION KEYS

The two key control fields below the display contain 11 keys. The top row is the menu control

field and below is the cursor control field.

The basic use of the two key control fields is as follows:

The cursor key control field is used to move the cursor to the desired position on the display.

Pressing the SET-key means that you want to modify this position; this can be a position to the

very left of the display (annunciator field) such as 5A/30A input selection, or current range- or

voltage range selection, or synchronisation to I or U (current or voltage of phase L1), or selection

of averaging time or selection of measurement mode.

When you move the cursor to the display number field the display can be reconfigured, that is,

you can place at the selected position a different quantity.

The menu-key control field consists of keys M1 through M6 and go with the 6 menus shown

along the bottom of the display. These menus are dynamically changing, depending on the cursor

position and other action you may take.

4-4 4-5

4.6. SELECTING A MEASUREMENT RANGE

When turning on the Spectral Multimeter the range selection is automatic. This is indicated by the

range annunciators on the left hand side of the display, e.g. 1A A/ 300mV A. To select the 5A- or

30A current input proceed as follows: Move the cursor to the „IN 5A“ annunciator and press the

SET-key. A pull down menu gives you 3 choices IN 5A/IN 30A/SHUNT. Now move the cursor

to the 5A- or 30-A input annunciator and press the SET-key. The choice of current input depends

on the maximum current flowing in your circuit to be measured.

The A at the end of the range annunciator indicates autoranging.

To select a current range move the cursor to the current range annunciator and press the SET-key.

A pull-down menu of the possible ranges appears. Move the cursor to the desired range and press

the SET-key. The range annunciator with the new range is now displayed and furthermore, the M

indicates manual ranging for current.

WARNING

Make sure not to overload current inputs, damage may occur to the instrument. Make sure when

wiring the Spectral Multimeter in a circuit that you are wiring the correct current input (5A or

30A) and make sure to select the correct input on the Spectral Multimeter front panel (IN 5A or IN

30A).

4.7. TAKING SOME BASIC MEASUREMENTS

WARNING

Read the Spectral Multimeter safety before operating this instrument.

The following procedures describe the basics of taking common measurements operating the

Spectral Multimeter from the front panel. These procedures are provided for the user who needs to

get started quickly.

WARNING

To avoid electrical shock or damage to the Spectral Multimeter, do not apply more than 850V

peak between any terminal and earth ground.

The user should be well aware of the fact, that switching off inductive loads may generate

extremely fast and high voltage transients exceeding above limits.

To measure voltage, current, power and related quantities in a circuit connect the test leads as

shown in figure 4.3 and described below.

voltage

Lo

5A

30A

max. 30A

max. 5A

N

L1

load

Fig. 4.3 Spectral Multimeter wiring in a single phase system

• Turn off power in the circuit to be measured.

• Break the circuit and connect phase L1 to the voltage input and current input as shown in

figure 4.3.

• Switch on the Spectral Multimeter (it will start-up in automatic ranging and measuring Mode

P). Select the correct current input IN 5A or IN 30A as described in 4.6.

• Turn on power to the load to be measured.

• The Spectral Multimeter will automatically select the voltage range and displays the following

six electrical quantities (display top to bottom) RMS-current, RMS-voltage, power, frequency,

apparent power, and power factor.

The bar graph of current shows the harmonic content.

• Use the side menu to alter settings.

5-1 5-2

5. OPERATING THE SPECTRAL MULTIMETER FROM

THE FRONT PANEL

This section explains how to operate the instrument from the front panel.

5.1. INTRODUCTION

This Spectral Multimeter is a very advanced measuring system, equipped with features not known

to similar instruments. For example, you can select dc- or ac-coupling for individual quantities,

you can choose those quantities you want to integrate, you can combine meter mode and graphics

mode, you can obtain harmonic analysis while the Spectral Multimeter is running in the meter

mode. You can select from six different measuring modes: Mode P, U, I; Burst U, I; and Flicker.

In Mode P the Spectral Multimeter measures current and voltage simultaneously and also

determines power when the fundamental frequency of the signal is in the range 20Hz-1kHz.

5.2. FRONT PANEL OPERATIONS

The following operations can be performed from the front panel:

• Select manual or automatic ranging.

• Select the 5A-, 30A-, or shunt input.

• Select a current or a voltage range.

• Select the measurement time.

• Select AC- or DC-coupling for individual quantities.

• Select integration for individual quantities.

• Select display configuration.

• Select the measuring mode.

• Select display HOLD.

• Select graphics mode.

• Select current- and voltage scaling.

• Select input- output configuration.

• Save instrument settings and set start-up instrument configuration.

5.3. CURRENT INPUT SELECTION

You have the choice of selecting one of three inputs 5A-, 30A-, and shunt input.

CAUTION

Due to different overload conditions of the current inputs you should, at all times, know which one

of the inputs is in use.

If you are using the 5A input you must select the 5A input indicated by the input annunciator IN

5A or IN 30A. If it is not already selected proceed as follows: move the cursor to the input

annunciator, press the SET-key. A pull-down menu appears for selection of the desired input.

With cursor and SET you select the 5A current input. Now the current ranges are 15mA, 50mA,

150mA, 500mA, 1.5A, 5A, and 15A and the current display is scaled correctly.

Similarly, you select the 30A input with ranges 1A, 3A, 10A, 30A, and 100A.

Finally, selecting the current shunt input will set the input ranges to 60mV, 60mV√10, 600mV,

600mV√10, and 6V with a sensitivity of 1A/60mV. Using the scaling capabilities of the Spectral

Multimeter will give you direct read out in ampere for your shunt or your current clamp (with

voltage output).

For current harmonic measurements according to IEC1000-3-2 we recommend to use the 30A

input. Its internal resistance is 4.7mOhm.

5.4. RANGE SELECTION / AUTO RANGE SELECTION

To select a current range move the cursor to the current range annunciator. Press the SET-key. A

pull-down menu appears with the available ranges. Move now the cursor to the desired range and

press the SET-key again to select that range. The current input is now in manual ranging indicated

by the Min the range annunciator.

In similar manner a voltage range is selected. Once you have selected a current range the current

input of the Spectral Multimeter is in manual ranging. You can bring it back to autoranging as

follows: Move the cursor to the current range annunciator. The menu at the bottom of the display

shows „AUTO“. If you press the menu control key M2 the current range annunciator changes to

A at its very end indicating autoranging.

Similarly you proceed to set the voltage input to autoranging.

5.5. SELECTING MEASURING MODE

The Spectral Multimeter is equipped with a voltage input, two current inputs (0-5A and 0-30A)

and a shunt or current clamp input to cover almost any current range (0-5A and 0-30A) and a

shunt or current clamp input to cover almost any current range (lowest range is 15mA). You are

allowed to simultaneously connect a voltage signal and a current signal to the instrument as long

as the two signals have one common node in the electric circuit. The common node must be

connected to the SM201 Lo-terminals. Move the cursor in the side menu to MODE and press

SET. A pull-down side menu displays the available measuring modes:

5-3 5-4

MODE P

MODE I

MODE U

BURST I

BURST U

FLICKER

Select MODE P if you want complete signal information in your test circuit and if you have both

current and voltage applied to the Spectral Multimeter. This very unique measuring mode can be

used when the fundamental frequency of the applied current is in the range 20Hz to 1kHz. The

SM201 determines all available quantities on current (also IEC555-2) and voltage including

harmonics, impedance, and phase angle between current and voltage of every harmonic. A novel

measuring technique allows the computation of active-, apparent-, and reactive power, power

factor, harmonics of power, and energies (active, apparent, reactive).

Select MODE I if you want signal information on current only. All available quantities pertaining

to current including harmonics and charge (integration of rectified mean current) are available.

Select MODE U if you want signal information on voltage only. All available quantities

pertaining to voltage are determined.

Select BURST I or BURST U if you want to measure the rms-value of a current burst or a voltage

burst. A typical application could be the measurement of a current burst in a welding process. A

minimal burst duration of 1ms is acceptable. At all times you must use manual ranging and you

must select a suitable range. For more information on various measurements refer to the end of

section 5 of this manual. By selecting B_dur from the display selection table the duration of a

burst is displayed (1ms up to 10s).

Select FLICKER if you want to run a precompliance test on your equipment regarding flicker

according to IEC555-3 / IEC1000-3-3 / EN61000-3-3.

The SM201 complies with the IEC report 868 to determine short time flicker PST and long time

Flicker PLT. PST is determined in 10 minute intervals and its value is displayed if you have selected

PST and PLT as one of the display values. PLT is updated every 10 minutes and can run as long as

5300 hours. Always use 0.5 sec measuring time for flicker measurements.

For a quick flicker result you can select PS1 (1 minute) or PS3 (3 minutes) flicker quantities. Only

one short time flicker value must be displayed at a time. Long time flicker is update when a new

short time flicker value is available (1 minute, 3 minutes, or 10 minutes).

Prior to a flicker measurement we recommend to reset PST and PLT to zero. This reset function is

combined with the energy reset. Therefore, you should display an energy value in a number field.

To RESET FLICKER (and energy) move the cursor to the energy value and press the RESET-

key to set PST and PLT to zero.

5.6. SELECTING THE MEASUREMENT TIME

The measurement time sets the minimum time for signal averaging as well as the time for display

update. It can be varied from 100ms, 250ms, 500ms, 1s, 2s, 5s, and IEC555-2. For frequencies

below 10Hz use 1s measurement time.Furthermore, this averaging time is expanded to the end of

the next signal period. This results in stable readings down to 2Hz. To select the measurement

time move the cursor to the measurement time annunciator and press the SET-key.

The pull-down menu gives you seven choices. Select the one you need by moving the cursor to

the desired position. Press the SET-key to select the desired measurement time.

Selecting the measurement time IEC555-2 (measuring Mode I) current harmonics are determined

according to IEC1000-3-2 / EN61000-3-2. Current harmonics are calculated from an FFT over 16

periods.

5.7. SELECTION OF AC- OR DC+AC-COUPLING

Coupling pertains to some, not all, measured quantities. AC-coupling is possible for the rms

values, for active-, apparent-, and reactive power, and for power factor.

Move the cursor to the quantity you want to change the coupling, e.g. rms current. The menu at

the bottom of the display shows AC/DC and an annunciator DC+AC or AC on the left side of the

display indicates the presently set coupling for the selected measurement value. The second menu

key M2 toggles the coupling from DC+AC to AC and vise versa.

Selecting AC means that this measurement value is without a possible dc-component and DC+AC

coupling means it is including the dc-component.

5.8. CHANGING THE DISPLAY CONFIGURATION

You have the choice of selecting 8 current values: rms, mean, rectified mean, crest factor,

minimum, maximum, peak-to-peak, and form factor. 8 values four voltage, four power related

quantities, frequency, three energies, charge, and harmonics of current , voltage, and power.

Any one of these measured values you can place at any location on the display. We recommend to

place the most important quantities at the top of the display.

This is how you modify the display, at one place, for example, the quantity at the bottom of the

first column.

Move the cursor to this location and press the SET-key. A table appears in which you can select

the quantity of your choice by moving the cursor to this position in the table. Press the SET-key to

place the new quantity on the display.

5-5

NOTE: The Spectral Multimeter monitors current or voltage transients of less than 1µs duration.

As a consequence, occasional current- or voltage peaks cause undesired range changes

or lead to race conditions. In such cases use manual ranging. 5-6

5.8.1. CHANGING THE HARMONIC NUMBER

When you have a harmonic value (current, voltage, or power) displayed in the display number

field you can change its harmonic number from 1-63 in the following manner: Move the cursor to

the position of the harmonic value. The harmonic annunciator h63 on the left of the display

indicates the harmonic number.

The menus at the bottom of the display give you 4 choices to increment the harmonic number in

steps ±1 and ±10. Together with display HOLD this is a convenient way to step through the

harmonics.

5.9. MAIN MENU SELECTION

Move the cursor to the side menu on the left hand side of the display. The main menu

„HOLD, AUTO, PRINT, SPLIT, VIEW, SETUP“ appears at the bottom of the display.

NOTE: AUTO is displayed only when the cursor is moved downwards to the current- or

voltage range annunciator. AUTO applies to autoranging of current or voltage.

The menus are entered with the control keys M1 through M6.

5.9.1. DISPLAY HOLD

The display update can be stopped by pressing the menu control key M1. The annunciator HOLD

appears. A complete set of data from the latest measurement interval is stored. To resume the

measurement update, press key M1 again.

While the Spectral Multimeter is in HOLD you can inspect every measurement value by altering

the number field, e.g. you can step through every harmonic value of current, voltage, or power;

you can change the graphic area and view the harmonic bar graph of current, voltage, or power; or

you can display the wave form of current or voltage.

It is important to note that the measurement process goes on in the background while the SM201 is

in HOLD. This assures correct integration of energies and charge at all times.

5.9.2. AUTO RANGE SELECTION

The menu AUTO (M2) appears when the cursor in the annunciator field is moved to either the

current- or the voltage range annunciator. To select current autoranging move the cursor to the

current range annunciator and press the menu control key M2.

To select voltage autoranging move the cursor to the voltage range annunciator and press the

menu control key M2.

5.9.3. SELECTING THE SIZE OF THE GRAPHIC AREA

The number field and the graphic area of the Spectral Multimeter can be increased or decreased

using the menu SPLIT (M4). Press the menu control key M4 to enter the menu „ESC, EXP,

RED, , , ,“ which allows you now to alter the graphic area. With EXP (=expand) you can

increase it and with RED (=reduce) you can decrease it. To return to the main menu press M1

(ESC).

5.9.4. SELECTING THE GRAPHIC DATA

The menu VIEW is selected by pressing the menu control key M5. The graphics selection menu

„ESC, FFTi, FFTu, FFTp, i(t), u(t)“ is entered. It allows you to choose graphics data by

pressing the menu control keys M2 through M6. In all bar graphs approximate harmonic peak

values are displayed (not rms values).

Menu FFTi: Pressing the menu control M2 selects the harmonic bar graph of current.

(Note: The size of the graphic area can be changed at any time.) The horizontal axis

shows the harmonic numbers from 0-63, N=zero being the DC-value and N=1 being the

fundamental of the current. The vertical axis shows the magnitude of the harmonic

currents. The top of the scale is given im mA or A written along the top of the graph.

The scaling is done automatically and is dynamically adjusted to give optimum

resolution.

NOTE: If you need more precise values of harmonic currents you can display them in

the display number field and step through the range of harmonics (1 through 63). The

harmonics displayed in the display number fields are rms values.

Menu FFTu: Press the menu control M3 to display the harmonic voltage bar graph. The

horizontal axis shows the harmonic numbers 0-63 and the vertical axis indicates the

magnitude of the voltage harmonic in mV or V. The scaling of the vertical axis is done

automatically and is adjusted for optimum resolution.

Menu FFTp: Press the control M4 to display the harmonic power bar graph. The horizontal

axis is moved to the middle of the graph to allow for positive and negative power

harmonics. A negative power harmonics results, when the phase angle of the

corresponding voltage- and current harmonic is larger than ±90°.

The harmonic numbers 0-63 are indicated at the bottom of the graph.

5-7 5-8

Menu i(t): The wave form display of current can be selected with the control key M5. In the

frequency range 5Hz to 1600Hz the graph shows one cycle and above 1600Hz eight

cycles. The time base is given by the frequency indication in the display number field.

The top of the vertical axis is given in mA or A and is automatically scaled.

Menu u(t): Finally, the wave form display of voltage can be selected by pressing the control

key M6. In the frequency range 5Hz to 1600Hz one cycle is displayed 1600Hz eight

cycles. The time base is given by the frequency indication in the display number field,

e.g. the frequency indication shows 100.0Hz then one cycle corresponds to 10ms. The

vertical axis is automatically scaled and the top of the scale is given in mV or V.

5.10. SHORT TIME INTEGRATOR

The following quantities can be integrated for the duration of the selected measurement time: real-

, apparent-, and reactive power, and rectified mean current. The resulting values are energy in Wh,

apparent energy in VAh, reactive energy in Varh, and charge in Ah. The sign of the quantity to be

integrated is taken into account, that is, the displayed energy can be negative.

This is how you activate the short time integrator for a specific quantity, let’s say, for active

power. Move the cursor to active power display field and press SET.

The third menu along the bottom edge of the display shows σdt indicating that active power is

one of the quantities that can be integrated. When you press now M3 the σannunciator appears

next to the

DC/AC-annunciator or, if it was selected before σ, it disappears. The σannunciator indicates that

power is integrated for the duration of the selected measurement time.

For long time energy computation refer to the section ENERGY COMPUTATION.

5.11.ENERGY COMPUTATION AT 50HZ

The SM201 allows long time energy computation of real-, apparent- and reactive power and

charge computation using rectified mean current. In the HOLD mode the display values are held

and the energy computation is stopped. Range changes during the measurement are allowed and

do not influence the result, accumulation over a period of more than 10 years is possible. The

resolution goes from nWh to MWh. Scaling of current and voltage are correctly taken into

account.

5.11.1. SET-UP FOR ENERGY MEASUREMENT

Let us assume all the energies need to be determined. Move the cursor to the number field where

you want to place active energy. Press SET; the selection table is presented. Move the cursor now

to ENERGY and press the SET-key again. By this time you are back in the number field. The

menu at the bottom of the display shows „HOLD, ACT, APP, REA, RESET, ,“ and gives you

the choice of active-, apparent-, and reactive power. To place active power in this number field

press M2, the annunciator ACT in the annunciator field indicates the type of energy.

Similarly you proceed to place apparent energy in another number field, that is, move the cursor to

this field, press the SET-key and select ENERGY, press SET again to come back to the number

field, and finally press M3 to select apparent energy.

In a similar manner reactive energy is set-up. Note that the accumulated values are indicated by

ACC.

5.11.2. SET-UP FOR CHARGE MEASUREMENT

Charge is determined by integrating the rectified mean value of current. So far we have set up 3

energy values. Let’s put the value of charge to a fourth number field as follows: move the cursor

to this number field. Press the SET-key move the cursor to RECT of current, press the SET-key

again to have the rectified mean current displayed in this number field. The menu at the bottom

shows „HOLD, , σdt, RESET, , ,“. Pressing M3 once you select short time integration, press

M3 again to select the desired longtime charge accumulation. The annunciator shows A, meaning

charge accumulation and the units in the number field are Ah.

5.11.3. RESETTING, STARTING, AND STOPPING

This is how you reset the energy values. Move the cursor to a number field displaying energy.

Press RESET (M5). Before starting a measurement energy and charge values are normally reset

to zero. All three energy values can be reset together, charge reset is separate. With the reset of the

energies are also reset the FLICKER values.

This is how you can proceed. Bring the Spectral Multimeter to HOLD and reset energy- and

charge values. Press HOLD to start the measurement and press HOLD again to stop it.

5.12. SCALING OF CURRENT- AND VOLTAGE INPUTS

When the Spectral Multimeter starts up it’s current- and voltage scaling factors are set to 1.0.

When you are using any kind of transducer or current transformer you can scale the inputs to have

actual current-, voltage-, and power values displayed.

To change the scaling factors enter the SETUP menu. Move the cursor to the scaling factor you

want to change. Let’s assume you want to change the current scaling factor to 250. Press SET. At

this point you can modify single digits with the up- and down arrows. Move the cursor to the first

digit and set it to 2, move the cursor one digit to the right and set it to 5, and finally modify the

exponent to 02 and press SET to store the selected factor. The new scaling factor looks like this:

Scale I +2.499999e02

which is very close to 250 for all practical purposes.

5-9 5-10

5.13. PRINTING DATA

In the main menu mode key M3 activates printing of all display values. A printer with Centronics

Interface that does not need any software setting can be used. This way you can print up to 10

different values. Option 01, 02, or 03 must be installed.

5.14. SAVING YOUR PERSONAL INSTRUMENT SETTING

The SM201 lets you store 20 different instrument settings including interface parameters and

allows you to program the desired start-up configuration.

WARNING: Disconnect all inputs and interface connections to the instrument before you

perform the procedures described in sections 5.14.1. and 5.14.2. Failure to do

so may result in erroneous setup data stored in nonvolatile memory. This in

turn may lead to serious start-up problems.

5.14.1. THIS IS HOW YOU SAVE YOUR DESIRED

INSTRUMENT SETTING

First you configure the display area and the graphics area. Select the current input, select the

desired ranges or select auto-ranging, select the measurement time, and the synchronization.

Select the attributes of the displayed quantities such as AC- or DC-coupling, or integration.

Also configure the RS-232-, the IEEE-488 interface, and set the scaling factors. To save the

complete setting under setting number 12 you proceed by selecting the SETUP menu (M6). Move

the cursor to “Setup Save No 00”. Press the SET key to advance the save number. When set to 12

press ESCape (M1). This will store the complete instrument setting under setting number 12.

Valid “Setup Save No” are: 01, 02, .... 19, 20.

5.14.2. THIS IS HOW THE SM201 STARTS UP IN THE DESIRED

CONFIGURATION

The default start up No is 00. To have a start up under No 12 you proceed as follows: Enter the

SETUP menu (M6). Move the cursor to “Setup Recall No 00” and press SET to advance the recall

number to 12. Press ESCape (M1). From now on the SM201 starts up in the saved configuration

12. You can always go back to the default startup by selecting “Startup No 00”. Valid “Setup

Recall No” are 00, 01, ... 19, 20.

Exception: From the four Flicker values PSt, PS1, PS3, and Plt only PSt and Plt

should be used if storage in nonvolatile memory is desired.

5.15. MEASUREMENT TECHNIQUES USING THE SPECTRAL

MULTIMETER

This section gives you an overview how the SM201 can work for you.

6. OPERATING THE SPECTRAL MULTIMETER USING

THE COMPUTER INTERFACE

6.1. INTRODUCTION

The Spectral Multimeter can be operated from a host by sending commands to it through a

computer interface on the rear panel.

Section 6 describes how to set up, configure, and operate the Spectral Multimeter via the RS-232

or the IEEE-488 interface.

With the IEEE-488 interface the instrument is fully programmable for use on the IEEE standard

488.1 interface bus and also complies with the supplemental standard 488.2.

6-1 6-2

7

6.2. LOCAL AND REMOTE OPERATIONS

When the Spectral Multimeter is operated from a host then it is operated „remotely“, when

operated from its front panel the Spectral Multimeter is operated „locally“.

The Spectral Multimeter is no longer controllable from the front panel when via interface the

Local Lockout state has been enabled.

6.3. COMPUTER INTERFACES

Your Spectral Multimeter can be equipped without interface, with RS-232 interface (Option 01),

or with both RS-232 and IEEE-488 interface.

You can check in the SETUP menu which options you have installed. If an interface is not

installed its parameters are marked n/a (not available).

Basically, you can operate both, the RS-232 and the IEEE-488 interface, simultaneously. Due to

limited rear panel space you may have difficulties installing both interface connectors.

6.4. SETTING INTERFACE PARAMETERS

The Spectral Multimeter sets the parameters at startup to the following default values:

Band: 9600

Parity: None

Terminator: CR

Handshake: None

IEEE-address: 1

Above parameters can be changed by entering the SETUP menu via the front panel or by sending

commands through the computer interface. Interface settings can be stored in none-volatile

memory and are selected at start-up if the recall number is selected accordingly (section 5.14.). In

order for the Spectral Multimeter and the host to communicate through the interface the

communication parameters of the Spectral Multimeter must match those of the host.

6.5. CABLING THE SPECTRAL MULTIMETER TO A HOST

Turn Spectral Multimeter off. When cabling is complete turn power on again.

The RS-232 interface on the Spectral Multimeter rear panel uses a DB-9 connector. Its pinout is

given below.

1 DCD Data Carrier Detect

2 RxD Received Data

3 TxD Transmitted Data

4 DTR Data Terminal Ready

5 Grd Signal Ground

6 DSR Data Set Ready

RTS Request to Send

8 CTS Clear To Send

9 RNG Ring

1

5

96

Use a one-to-one connected (TxD and RxD not crossed) RS-232 cable. Its length should be less

than 15m to make sure not to exceed the allowable (2000pF) cable capacitance.

To use the IEEE-488 interface cable the Spectral Multimeter to a host.

The IEEE-488 operation is governed by following limitations: a maximum of 15 devices can be

connected in a single bus system; the maximum length of cable must be less than 20m or 2m times

the number of devices in the system.

6.6. HOW THE SPECTRAL MULTIMETER PROCESSES

INPUT

The Spectral Multimeter processes and executes valid input strings sent by the host. The input

string is followed by an input terminator such as CR/LF (carriage return/line feed).

When the Spectral Multimeter receives input, it stores it in a 32 byte input buffer. As soon as the

input terminators have been recognized the data in the buffer are processed.

The Spectral Multimeter accepts upper and lower case characters. If a command can not be

understood, or it was longer than 32 characters which can not be the case for correct commands,

the command will be ignored and an error will be generated.

For the RS-232 you can select the Xon hand shake modus. Xon signals the host to stop

transmission when the input buffer of the Spectral Multimeter is full. If in this process information

gets lost a device dependent error will be generated.

6-3

For the IEEE-488 the hold-off is set when the input buffer of the Spectral Multimeter is full. This

stops data transmission instantly until space in the input buffer is made available.

6.6.1. INPUT TERMINATOR

An input terminator is a character or command (EO1, IEEE-488.1) sent by the host identifying the

end of a string. Any of these terminators will be recognized as „end of message“.

Valid terminators for the RS-232 interface are:

CR (Carriage Retunr), LF (Line Feed)

CRLF (Carriage Return / Line Feed), and

LFCR (Line Feed / Carriage Return)

Valid terminators for the IEEE-488 interface are:

EOI (End or Identify) and any or none of the combinations with CR (Carriage return) and

LF (Line Feed)

6.6.2. SENDING COMMANDS TO THE SPECTRAL

MULTIMETER

Command Action

6-4

VOLT:RMS:AC 1 AC-coupled rms voltage is displayed in display field 1

(fields are: 0 = top left, 1 = top right ... 9). The minimum

required characters (upper case) are used.

voltage:rms:ac:? Query form. To this command the Spectral Multimeter

outputs (in scientific format) an alphanumeric string of the

ac-coupled rms voltage. The maximum allowable

characters in lower case are used.

CURR:SCALE 1.000eo Sets the current scaling factor of the Spectral Multimeter to

1.

CURR:SCALE? Query form. The Spectral Multimeter returns the current

scaling factor in scientific format.

CURR:FFT? Query form. The Spectral Multimeter returns the

harmonics of current in the range specified by the

FORMAT:START/END command.

Commands can be sent in upper or lower case characters. The upper case letters in the command

set table are the minimal string to be sent, the lower case letters are optional.

No space is allowed except for the selector at the end of a command where a space is mandatory.

RULE 1: Every command must be closed by a terminator. The maximum length

must not exceed 32 characters.

You can not pack two commands into one, an error would be generated.

RULE 2: Read Spectral Multimeter’s output only once for each query command.

The output buffer is cleared after it has been read. This prevents previously read data from being

read a second time by mistake. A device dependent error is generated. (Query commands are

identified by the „?“ at its end).

RULE 3: Read query responses before sending an other command string.

If you send a query without removing the old message from the query before the old message gets

lost. A device dependent error is generated.

6.6.3. HOW THE SPECTRAL MULTIMETER PROCESSES

OUTPUT

When the host sends a query command the Spectral Multimeter places an alphanumeric string into

the output buffer. In case of the RS-232 interface, data are transmitted right away and are

terminated with the set terminators (see RS232: terminator command). In case of the IEEE-488

interface the contents of the output buffer is transmitted after the Spectral Multimeter has been

addressed as talker. The string is terminated with CR, LF accompanied with EOI.

The output from the Spectral Multimeter can be measurement data in scientific format. This can

be a single string or, for a range of harmonics, 2 to 99 strings.

Query Examples Explanation

VOLT:RMS? + 1.0238e+01 Measured voltage 10.238V

POW:ACT? - 1.8351e+00 Measured power -1.8351W

CURR:RMS? + 5.8975e-03 Measured current 5.8975mA

FORM:START 1 + 9.0000e+00

FORM:END 5 + 0.0000e+00 Harmonic currents n = 1 to 5.

CURR:FFT? + 3.0000e+00

+0.0000e+00

+1.8000e+00

The output data can also be a scaling factor, an instrument setting, a range indication, or an error

number.

6-5 6-6

6.6.4. OPTIMIZING SPEED FOR DATA TRANSFER

There may be applications where the speed of data transfer to the host becomes an issue. The

speed is increased when you configure the display monitor without graphic area. Avoid

communications of unnecessary status commands. For highest speed focus on sending queries for

data transfer and reading data from the instrument.

6.7. SERVICE REQUESTS AND STATUS REGISTERS

Service requests let the Spectral Multimeter on the IEEE-488 bus get the attention of the host.

Every instrument or the IEEE-bus can set the service request (SRQ) bus line.

The host can determine which instrument made the request by taking a „serial poll“. In this

process the Status Byte Register will be set to 1, identifying it as an instrument that requested

service.

Below the registers are summarized:

STATUS AND EVENT REGISTER DEFINITION

Power ON

User ReQuest (not used)

CoMmand Error

Execution Error

Device Dependant Error

Query Error (not used)

ReQuest Control (not used)

Operation complete

ESR *ESR?

(Event Status Read only

PON URQ CME EXE DDE QYE RQC OPC

7 6 5 4 3 2 1 0

Register)

& & & & & & & & Logical AND

ESE *ESE [0...255]

(Event Status *ESE?

PON URQ CME EXE DDE QYE RQC OPC

7 6 5 4 3 2 1 0

Enable Register) Read and write

Error Status Byte

Message available

RQS

STB ESB MAV *STB?

(Status Byte 7 6 5 4 3 2 1 0 Read only

Register) MSS

& & & & & & & & Logical AND

SRE ESB MAV *SBR

[0...255]

(Service Request 7 6 5 4 3 2 1 0 *SBR?

Enable Register) Read and write

Register Description

STB Status Byte Register Read only. Bit 6 sets SRQ bus line.

Read by Serial Poll.

SRE Service Request Read and write. A bit set to 1

Enable Register in SRE will generate an SRQ when corresponding bit

in STB is also 1.

ESR Event Status Register Read only. Assigns specific events to specific bits.

ESE Event Status Read and wirte. Mask for event generation to set

Enable Register Event Summary Bit.

6-7 6-8

EVENT STATUS REGISTER (ESR)

When , for example, a command Error occurs bit 5 is set to 1. The query *ESR? Returns a decimal

value corresponding to the bit setting.

EVENT STATUS ENABLE REGISTER (ESE)

It is the mask for the Event Status Register. When for the above example the command Error mask

bit 5 is set the command Error would set the Error Status Byte in the Status Byte Register (STB).

STATUS BYTE REGISTER (STB)

The RQS, bit 6, if equal 1 sets the SRQ line true. The status bits 0-5, and 7 determine in

conjunction with the mask in the Service Request Enable Register whether RQS is set or not.

Reading the Status Byte Register with the query *STB? will return a decimal value, for example

„32“. Converting 32 to binary indicates that bit 5 (ESB) is set to 1.

6.8. COMPUTER INTERFACE COMMAND SET

The following table lists the RS-232 and IEEE-488 commands. The RS-232 and IEEE-488

commands are identical, except where indicated. A parameter that must be supplied by the user is

enclosed in angle brackets (<parameter>). Commands can be sent in upper case or lower case.

IEEE-488 Interface Function Subsets:

SH1 Source Handshake, AH1 Acceptor Handshake,

T5 Talker, L4 Listener, SR1 Service Request,

RL1 Remote/Local, DC1 Device Clear.

The following conventions are used:

<F>= Field selector; it is an integer 0 to 9 used to select the display field on which a value

must be displayed. Field 0 is top left, 1 is top right, ... field 9 is bottom right.

<R>= Scientific formated real number, e.g. +1.0e1.

<N>= Signed integer number, e.g. +1024.

Query commands are terminated with „?“ and do not contain a <parameter>.

That part of the command that is written in capital letters is mandatory. The lower case letters are

optional.

COMMAND DESCRIPTION

VOLTage:RMS <F>Query or set field for DC coupled RMS voltage

:AC <F>Query or set field for AC coupled RMS voltage

:RECT <F>Query or set field for rectified mean voltage

:MEAN <F>Query or set field for arithmetic DC voltage

:MIN <F>Query or set field for negative peak voltage

:MAX <F>Query or set field for positive peak voltage

:PEAK <F>Query or set field for peak to peak voltage

:FFT <F>:G Set the field (0,1,...,9) for voltage harmonic previously

selected by the FORMat:START command. Use the G

argument instead of <F>to display FFT(u) in the display

graphic zone.

:FFT? Query all voltage harmonics in the range specified by the

FORMat:STart and FORMat:END commands.

:CREST <F>Query or set field for voltage crest factor

:FORM <F>Query or set field for voltage form factor

:CURVE Display u(t) in the display graphic zone

:SCale <R>Query or set voltage scaling factor

:THD <F>Query or set field for Total Harmonic Distortion

:PST<F>Query crest or set field for short time Flicker (10min.)

:PLT<F>Query crest or set field for long-time Flicker.

CURRent:RMS <F>Query or set field for DC coupled RMS current

:AC <F>Query or set field for AC coupled RMS current

:RECT <F>Query or set field for rectified mean current

:INT <F>Query or set field for average charge (short time

integration).

:ACCu <F>Query or set field for charge (long-time integration)

:RESET Reset charge, no query form

:MEAN <F>Query or set field for DC current

:MIN <F>Query or set field for negative peak current

:MAX <F>Query or set field for positive peak current

:PEAK <F>Query or set field for peak to peak current

:FFT <F>:G Set the field (0,1,...,9) for current harmonic previously

selected by the FORMat:START command. Use the G

argument instead of <F>to display the FFT(i) in the

display graphic zone.

:FFT? Query all current harmonics in the range specified by the

FORMat:START and FORMat:END commands.

:CREST <F>Query or set field for current crest factor

:FORM <F>Query or set field for current form factor

:CURVE Display i(t) in the display graphic zone.

:SCale <R>Query or write current scaling factor

:THD <F>Query or set field for Total Harmonic Distortion

POWer:ACTive <F>Query or set field DC coupled power in Watt

:AC <F>Query or set field AC coupled power in Watt

:INT <F>Query or set field DC coupled average energy (short time

integration)

:AC <F>Query or set field AC coupled average energy (short time

integration)

:APParent <F>Query or set field DC coupled apparent power

:AC <F>Query or set field AC coupled apparent power

6-9 6-10

:INT <F>Query or set field DC coupled average apparent energy

(short time integration)

:AC <F>Query or set field AC coupled average apparent energy

(short time integration)

:REActive <F>Query or set field DC coupled reactive power

:AC <F>Query or set field AC coupled reactive power

:INT <F>Query or set field DC coupled average reactive energy

(short time integration)

:AC <F>Query or set field AC coupled average reactive energy

(short time integration)

:FFT <F>:G Set the field (0,1,...,9) for the power harmonic previously

selected by the FORMat:START and FORMat:END

command. Use the G argument instead of <F>to display

FFT(p) in the display graphic zone.

:FFT? Query all power harmonics in the range specified by the

FORMat:STart and FORMat:END commands.

:FACtor <F>Query or set the field for the DC coupled power factor

:AC <F>Query or set the field for the AC coupled power factor

ENergy:ACTive <F>Query or set field of energy (long time integration)

:APParent <F>Query or set field of apparent energy (long time

integration)

:REActive <F>Query or set field or reactive energy (long time integration)

:RESET No query form, resets all energy values

FREQuency <F>Query or set field of current or voltage signal frequency.

Depends on current or voltage synchronisation.

IMPedance:MAGnitude <F>Set the field for harmonic impedance previously selected

by the FORMat:START command.

:MAGnitude? Query all harmonic impedances in the range specified by

the FORMat:START and FORMat:END commands.

:ANGle <F>Set the field for harmonic phase angle previously selected

by the FORMat:START command.

:ANGle? Query all harmonic phase angles in the range specified by

the FORMat:START and FORMat:END commands.

ACQuire:RANge:VOLTage Auto

600M Query or set voltage range

2

6 Examples:

20 ACQ:RAN:VOLT AUTO Voltage in autoranging.

60 ACQ:RAN:VOLT 200 Selects 200V range.

200

600

2000

ACQuire:RANge:CURRent Auto Query or set current input range

15M 1 60M (the valid option column is fixed

50M 3 200M by the active input, IN5, IN30,

150M 10 600M and SHUNT)

500M 30 2

1.5 100 6

5

15

:INput IN5 Query or set the current input or the shunt input.

IN30

SHunt

:MEAsuremo CURRent Query or set instrument measure mode.

VOLTage

POWer

BURSTIi

BURSTUu

FLicker

:APERture 100M Query or set the minimal averaging time

250M

500M Example:

1 ACQ:APER 500m Sets minimal averaging time to

500ms.

2

IEC555-2

:Hold Run Query or set acquisition subsystem.

Stop Display data are held.

:QUality? Query overload and underload of current and voltage

inputs. An integer is returned. The integer indicates the

state during the previous query

(VOLT:,CURR:,POW:,EN:, or FREQ:). For more details

refer to overload and underload register definition.

DISplay:FORMat [0..5]Query or set the number of numeric fields on the panel.

:PRint Print displayed values.

FORMat:START <N> Query or set the range for data array transfer

:END <N> Range of N for harmonic values is 1 to 63

Range of N for analog inputs is 0-7.

If the value specified is out of range or start>end the

correction is done when values are queried using

VOLT:FFT?, CURR:FFT?, POW:FFT?, IMP:FFT?,

IMP:MAG, IMP:ANG, or AINP?.

AINPort <F>Set display field for analog input port previously selected

by the FORMat:START/END command.

AINPort? Query all analog input port values identified by the

FORMat:START/END command. Range of allowed ports

is 0 to 7.

VERsion? Query form only. Returns software version

LOCk Locks the instrument’s front panel controls. The query

form returns YES or NO whether the controls are locked or

not.

UNLock Unlock the instrument front panel controls.

RS232? Query form only, returns all settings. Output format is

BAUD;PARITY;TERM;HAND

RS232:BAUD 2400 Query or set baud rate

4800

9600

19200

38400

57600

115k2

6-11 6-12

:PARITY None Query or set parity mode

Even

Odd

:TERMinator CR Query or set command terminating characters.

LF

CRLf

:HANDshakes None Query or set handshake mode

Xon

GPIB:ADDRess [0..30]Query or set GPIB address

*ESE [0..255]Query or set the Event Status Enable register

*SRE [0...255]Query or set the Service Request Enable register

*STB? Query the STatus Byte register (IEEE-488 only)

*ESR? Query the Event Status Register (IEEE-488 only)

*RST Resets instrument

*OPC Set ISR bit 0 if no printing AND no measurement are pending

(GPIB only).

*OPC? Returns 1 if no printing AND no measurement are pending.

*TST? Performs self test, returns zero if successful

*WAI Suspends command execution until previous commands are complete.

*TRG Forces a running measurement to become pending if in RUN mode.

Forces a measurement if in STOP mode.

*IDN? Returns identification string in form:<Vendor, Model, Serial No,

Firmware version>.

*CLS CLear status (no query form), (IEEE-488 only)

ERRor? Query the last error code

ERROR CODES DEFINITIONS:

102 Syntax Error

The command was not recognized. ESR bit 5 is set (CoMmand Error)

110 Command header error

A command followed by ‘?’ was sent were no query form is available. And conversly: no

‘?’ followed a query form only command. ESR bit 5 is set (CoMmand Error).

111 Header separator error

Attempted to descend the command hierarchy at a place where there wasn’t any

subcommand. ESR bit 5 is set (CoMmand Error).

140 Character data error

A too long and/or sensless command has been sent to the instrument. ESR bit 5 is set

(CoMmand Error).

222 Data Out Of Range

The command argument is not allowed. ESR bit 4 is set (EXecution Error).

2204 Measurement error, Measurement underflow. ESR bit 4 is set (EXec. Err.).

2207 Measurement error, Measurement overflow. ESR bit 4 is set (EXec. Err.)

350 Queue overflow

This occurs if a query command attempts to place a new message onto the instruments

output queue but there was still an old message waiting on the queue. This results in

information loss. The query answer is replaced by ‘350’ and ESR bit 3 is set (Device

Dependant Error).

2200 Input signal over- and underload. One or more current- or voltage inputs were in over- or

underload during the last query (VOLT:,CURR:,POW:,EN:, FREQ:).

ESR bit 4 is set.

Overload and Underload Register Definition

Voltage 1 overrange

6-13

Current 1 overrange

... 11 10 9 8 7 6 5 4 3 2 1 0

Current 1 underrange

Voltage 1 underrange

Bit 15 ... 5 are not defined and are reserved for extension.

Table of contents

Other Infratek Measuring Instrument manuals