Infratek 108B User manual

USERS MANUAL 108B

SINGLE- TO FOUR PHASE

INFRATEK POWER ANALYZER

page 2

TABLE OF CONTENTS

1. Power Analyzer Features, Quick Overview, Safety 5

1.1 Standard Measure Mode ................................................................................................... 6

1.2 Logging Measure Mode ..................................................................................................... 7

1.3 Transient Measure Mode ................................................................................................... 7

1.4 Power-Speed Measure Mode (Option) ............................................................................... 8

1.5 Power Analyzer Rear Panel ............................................................................................... 9

1.6 Summary of 108B Power Analyzer Features ................................................................... 10

1.7 Safety Instructions ........................................................................................................... 11

2. Connection to Circuits 12

2.1 Measurement in 3-Phase mains Circuit ........................................................................... 12

2.1.1 Three Wattmeter Connection ............................................................................. 12

2.1.2 Aron Connection ................................................................................................. 13

3. 108B Mathematical Definitions and Specifications 14

3.1 Mathematical Definitions .................................................................................................. 14

3.2 Specifications .................................................................................................................. 18

4. Operating The Power Analyzer from the Front Panel 22

4.1 Operations in Standard Measure Mode ........................................................................... 23

4.1.1 Selecting Measure Mode .................................................................................... 23

4.1.2 Selecting Current Inputs using same Inputs for all Phases ................................ 24

4.1.3 Selecting individual current inputs per phase ..................................................... 24

4.1.4 Selecting Current Range using same range for all phases ................................. 25

4.1.5 Selecting Voltage Range using same range for all phases ................................ 25

4.1.6 Selecting Measurement Synchronization (Synchronization for all phases) ........ 26

4.1.7 Selecting Averaging Time ................................................................................... 26

4.1.8 Selecting Display Pages ..................................................................................... 26

4.1.9 Selecting Wave Forms (Graph) .......................................................................... 27

4.1.11 Selecting FFT Table and FFT Bar Graph ........................................................... 27

4.1.12 Selecting AC or DC+AC-Coupling ...................................................................... 27

4.1.13 Selecting Display RUN and Display HOLD ......................................................... 28

4.1.14 Resetting Energy ................................................................................................ 28

4.1.15 Selecting Display Quantities ............................................................................... 28

4.1.17 Selecting SETUP ................................................................................................ 31

4.2 Operations in Logging Measure Mode ............................................................................. 34

4.2.1 Valid Synchronization ......................................................................................... 34

4.2.2 Selecting CYCLES ............................................................................................. 34

4.2.3 What has to be observed when using Logging? ................................................. 35

page 3

4.3 Operations in Transient Measure Mode ........................................................................... 36

4.3.1 What is measured in Transient Measure Mode? ................................................ 36

4.3.2 Two Ways To Use Transient Measure Mode ..................................................... 36

4.4 Basics Of Power-Speed Measure Mode (Option) ............................................................ 38

4.4.1 What Is Measured In Power-Speed Measure Mode ........................................... 38

4.4.2 Operations in Power-Speed Measure Mode ....................................................... 38

5. Operating The Power Analyzer Using A Computer Interface 41

5.1 What Has To Be Observed When Using An Interface ...................................................... 41

5.2 What Has To Be Observed When Using The Interface Command Set ............................. 41

5.3 Computer Interface Command Set .................................................................................. 44

5.4 Composite Commands .................................................................................................... 44

5.5 Reading voltages, reading and writing voltage scale factors ............................................ 45

5.6 Reading currents, reading and writing current scale factor ............................................... 46

5.7 Reading power, apparent power, and reactive power ...................................................... 47

5.8 Reading energy, charge, and time ................................................................................... 47

5.9 Reading frequency, impedance, and phase angle. .......................................................... 48

5.10 Reading/writing range of harmonics, number phases for output, and cycle for Logging ... 48

5.11 Read and write display, RS232 Baud Rate, IEEE-488 address........................................ 49

5.12 Read and write common control commands. ................................................................... 49

6. Computer Operating Software 51

6.1 Installing Computer Operating Software .......................................................................... 51

6.2 108A Data Window (Computer Software) ........................................................................ 52

6.2.1 Select Interface .................................................................................................. 52

6.2.2 Select instrument mode ...................................................................................... 53

6.2.3 Select software mode ......................................................................................... 54

6.2.4 Operate the computer software .......................................................................... 54

6.2.5 Input, Ranges, Synchronization, Aperture selection ........................................... 55

6.2.6 Phase Slider for selecting individual settings per phase ..................................... 55

6.2.7 Curve .................................................................................................................. 55

6.2.8 FFT Numerics (Harmonics) ................................................................................ 56

6.2.9 FFT Bar Graph (Harmonics) ............................................................................... 56

6.2.10 Vector Graph (Phase Angle) .............................................................................. 56

6.2.11 IEC Data Window ............................................................................................... 57

6.2.12 Control / Setting Window .................................................................................... 59

6.2.13 Logging-, Transient-, Power Speed Measure Mode ........................................... 61

7. Analog Input and -Output 62

7.1 Analog Input And Output Specification ............................................................................. 63

page 4

7.2 Programming The Analog Outputs ................................................................................... 63

7.3 Using Inputs for Motor Testing (See also 4.1 Motor Testing) ........................................... 64

7.4 Using Low Current Shunt for Standby Power Measurement ............................................ 65

8. Data Management 66

8.1 Operating the Power Analyzer using the USB Interface ................................................... 66

8.2 Operating the Power Analyzer using the Ethernet Interface ............................................. 66

8.3 Measurement Data from the Power Analyzer (USB) to Computer .................................... 67

9. Calibration via 108B Front Panel 68

9.1 Equipment Needed .......................................................................................................... 68

9.2. Calibration Procedure ...................................................................................................... 68

9.2.1 Voltage Calibration At 60Hz ............................................................................... 68

9.2.2 Current Calibration At 60Hz, Shunt Input Calibration ......................................... 69

9.2.3 Storing The Calibration Constants ...................................................................... 70

9.3. A Few Practical Hints ....................................................................................................... 70

9.4. 108B Calibration using Windows Operating Software (LabView) ..................................... 71

9.4.1 Equipment Needed ............................................................................................. 71

9.4.2 Calibration Procedure ......................................................................................... 71

9.4.3 Voltage Calibration At 60Hz ............................................................................... 71

9.4.4 Current Calibration At 60Hz (IN 5A) ................................................................... 72

9.4.5 Current Calibration At 60Hz (IN 1A) ................................................................... 73

9.4.6 Current Calibration At 60Hz (IN 30A) ................................................................. 74

9.4.7 Current Calibration At 60Hz (SHUNT) ................................................................ 74

9.4.8 Storing The Calibration Constants ...................................................................... 75

9.4.9 A Few Practical Hints ......................................................................................... 75

page 5

1. POWER ANALYZER FEATURES, QUICK OVERVIEW, SAFETY

The Infratek 108B High Precision Power Analyzer is available in 1-, 3- and 4- phase versions.

All voltage inputs (ranges 0.3V up to 1500Vpeak) and all current inputs (1.5mA up to 1A;

15mA up to 5A; 1A up to 40A; and current shunt inputs 60mV up to 6V) are potential free and

exhibit

Excellent low noise

Common mode suppression

DC-stability

Wide frequency range (2MHz)

Very low self-heating on current inputs.

There is no need to fiddle with dc-compensation, or changing current plug-ins. All is built into

the input sections of the Power Analyzer, ready to be used.

Your intuition will guide you to operate the Power Analyzer touch screen correctly. With basic

knowledge of power measurement, you will be able to change the settings to your needs. Al-

most all setting changes are accomplished with two touches on the display screen or two

clicks with the mouse.

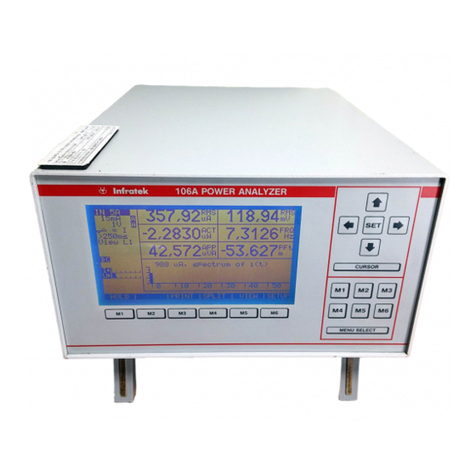

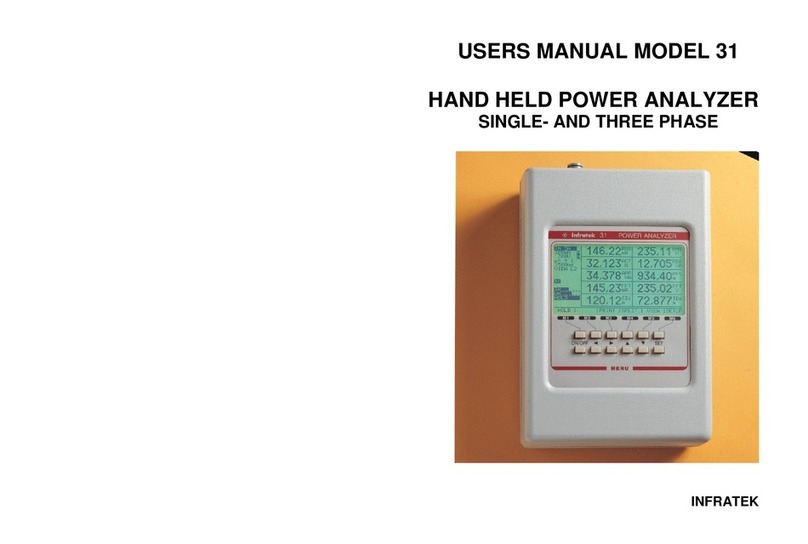

Figure 1.1 Shows the display of a 4-phase instrument in “Standard Mode”.

Figure 1.1 shows the display of a 4-phase instrument in “Standard Mode”. To change the cur-

rent range from 15mA to 500mA touch the button “AUTO A”. A pop-up window is presented

from which you select “500mA”. Now the Power Analyzer is in 500mA current range (manual

ranging).

page 6

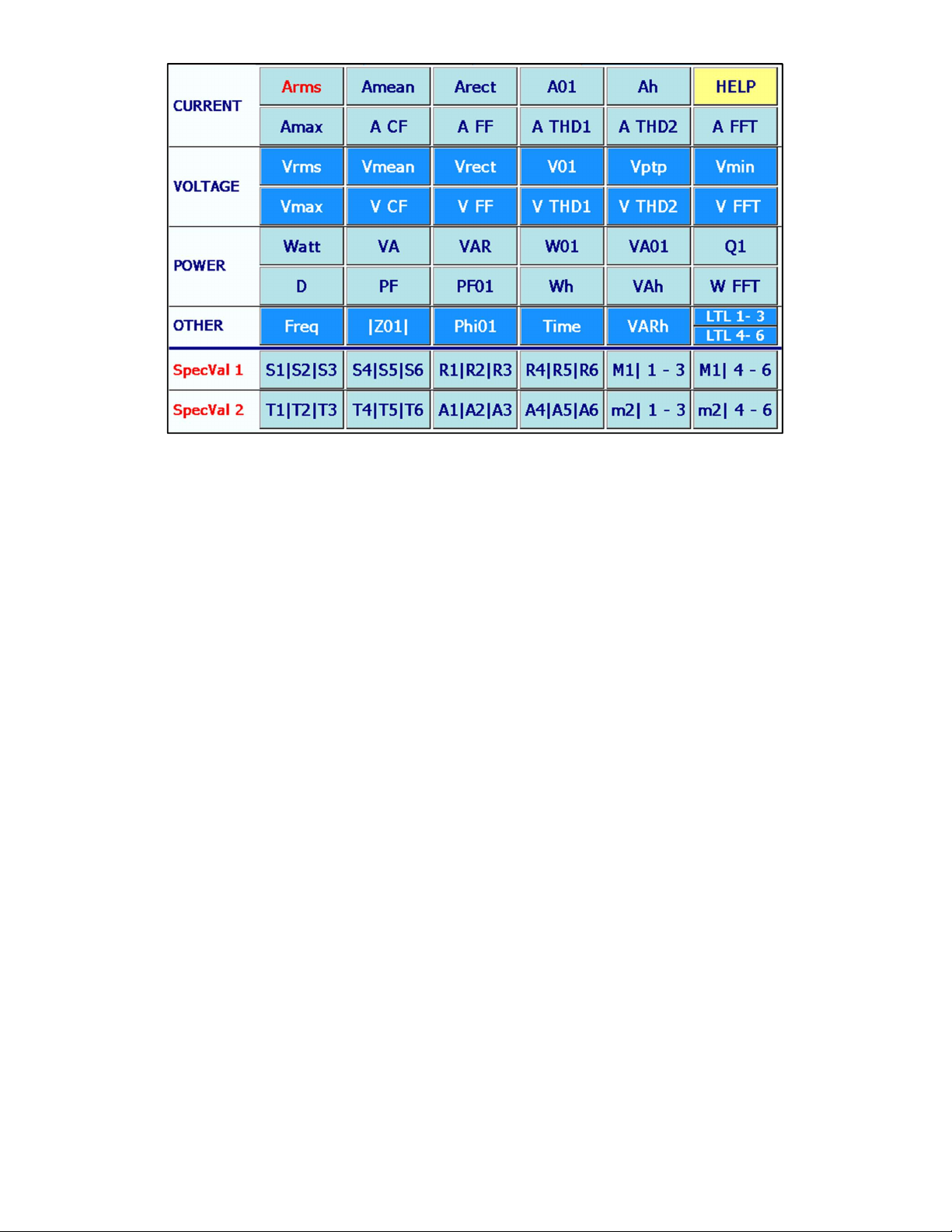

Figure 1.2 108B Value Selection Table

Just as simple is to change the quantity at the bottom line “Freq” to Arectified mean (Arect).

Touch “Freq” at the left side of the display. This will present you a value selection table as

shown in Figure 1.2. Now touch “Arect” which brings you back to Figure 1.1 with the bottom

line quantity changed to “Arect”.

Four different measure modes enhance the 108B Power Analyzer capabilities. These are:

standard measure mode, logging measure mode, transient measure mode, and power-speed

measure mode.

1.1 S

TANDARD

M

EASURE

M

ODE

In the Standard Measure Mode 280 quantities per phase are continuously measured

(no gaps) and are updated. Values can be displayed on four display pages, can be saved in

internal memory, or on a memory stick, or can be transferred via Interface to a computer.

Touching “WAVE” will display a sub-menu which lets you select the current-, voltage-, and

power wave forms of any phase.

Select “OFF” (Wave OFF). Now you have access to the buttons “FFT Table”. Touching

“FFT Table” selects “FFT L1”. On five pages you can now view the harmonics of current, volt-

age, power, and phase angle (harmonics 1 to 40 for current and voltage, harmonic 1-21 for

power and phase angle).

Similarly, selecting “FFT Bar” the bar graph of the harmonics will be displayed in percent of

the fundamental (1. harmonic).

Touching “FFT L1” will toggle to “FFT L2”, “FFT L3”, and so on.

page 7

1.2 L

OGGING

M

EASURE

M

ODE

The basic operation is as follows: Select the number of cycles for which you desire a periodic

data output to the RS232- / USB-interface. If you perform measurements on the 50Hz power

line and you select cycles = 1 you obtain new data every 20ms; if you select cycles = 30000

you obtain new data every 10 minutes.

Before starting the measurement, a valid synchronization signal 5Hz to 2kHz must be applied

to all installed phases of your Power Analyzer. Select Sync A, Sync V, or S_Ext V. Touch the

START-button to start the measurement, touch the STOP-button to stop it. DC signals can

also be measured (e.g. DC-motors). For DC you must apply an external synchronization sig-

nal in the frequency range 5Hz – 2kHz (select EXT synchronization).

Furthermore, the frequency of the synchronization can be varied up and down as much as

10% per second.

From every phase you obtain 8 values: frequency, RMS current, RMS voltage, power, power

factor, apparent power, energy Wh, and apparent energy VAh.

If you select the baud rate of 463.2 kBaud (in SETUP) a 4-phase Power Analyzer transmits

8 x 4 = 32 values in less than 20ms. This can be used to analyze the start-up behaviour of

power systems.

1.3 T

RANSIENT

M

EASURE

M

ODE

The transient measure mode can be used in two ways: You can catch current-, voltage-, and

power wave forms in a start-up on all phases simultaneously or you can view all wave forms

at a critical operating point in Standard Measure Mode (up to maximum 4 phases).

The duration of the measurement is set by changing in the SETUP menu the Transient-id

from 0 to 7. Sections of the wave forms can be expanded by simply touching one of the 4

“Zoom Sectors” (maximum zoom factor is 256).

For proper operation you must apply signal synchronization to all installed phases of your

Power Analyzer.

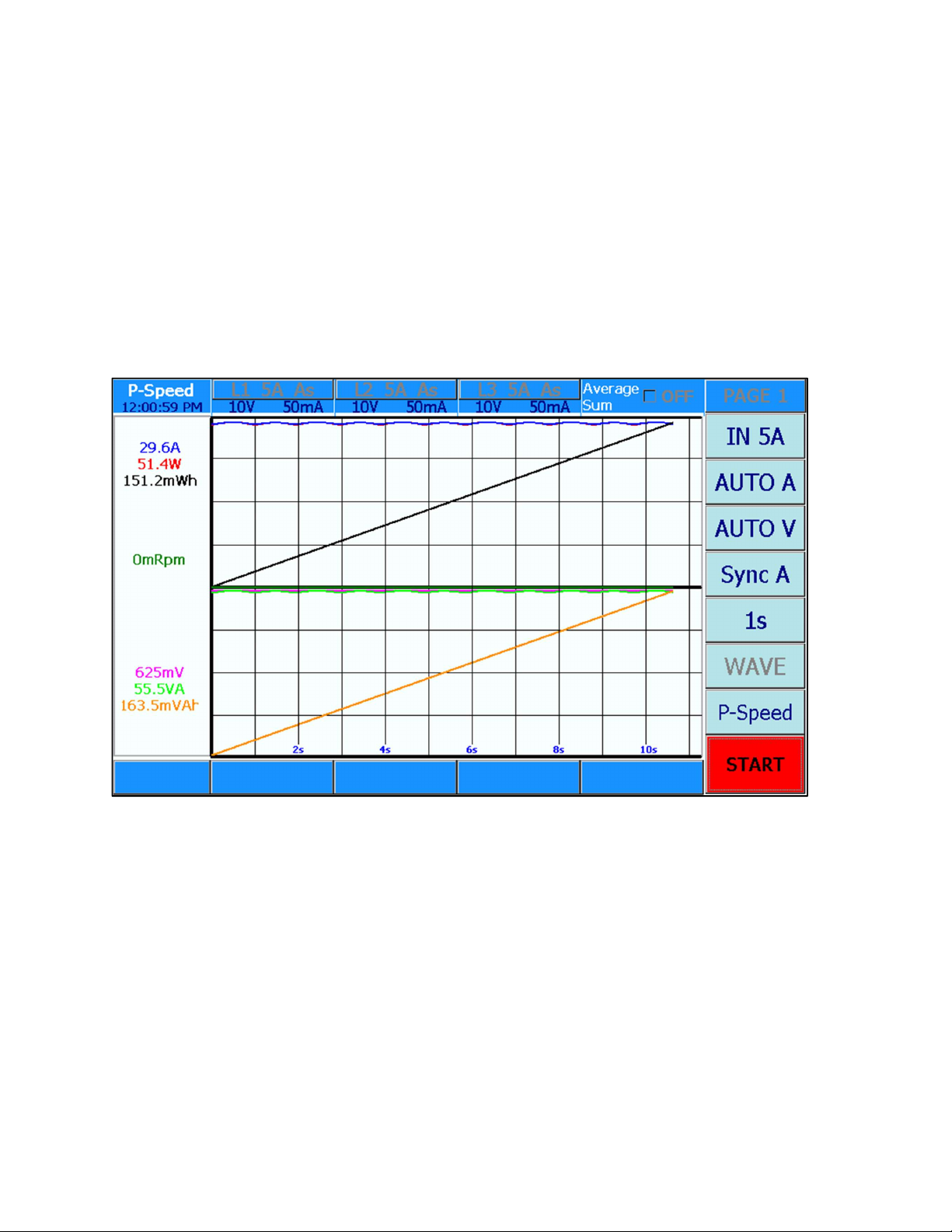

Figure 1.3 108B 3-Phase Power Analyzer Display in Logging Measure Mode

page 8

1.4 P

OWER

-S

PEED

M

EASURE

M

ODE

(O

PTION

)

This measure mode analyzes the performance of electric devices such as electric cars.

In 20ms intervals the following data are stored in internal memory: RMS current, RMS volt-

age, power, apparent power, energy, apparent energy, and speed of an axis or a wheel. Rms

current and –voltage are average values of the number of phases used, power and energy

are the sums of phases used.

Power speed measurements can be performed on DC- as well as AC-drives using either

phase 1, or phase 1 and phase 2, or using phase 1, 2, and phase 3 of the Power Analyzer.

At the end of a measurement cycle (maximum 11 seconds) data versus time are plotted, can

be expanded to view details, or can be stored.

Figure 1.4 108B 3-Phase Power Analyzer in Power-Speed Measure Mode

page 9

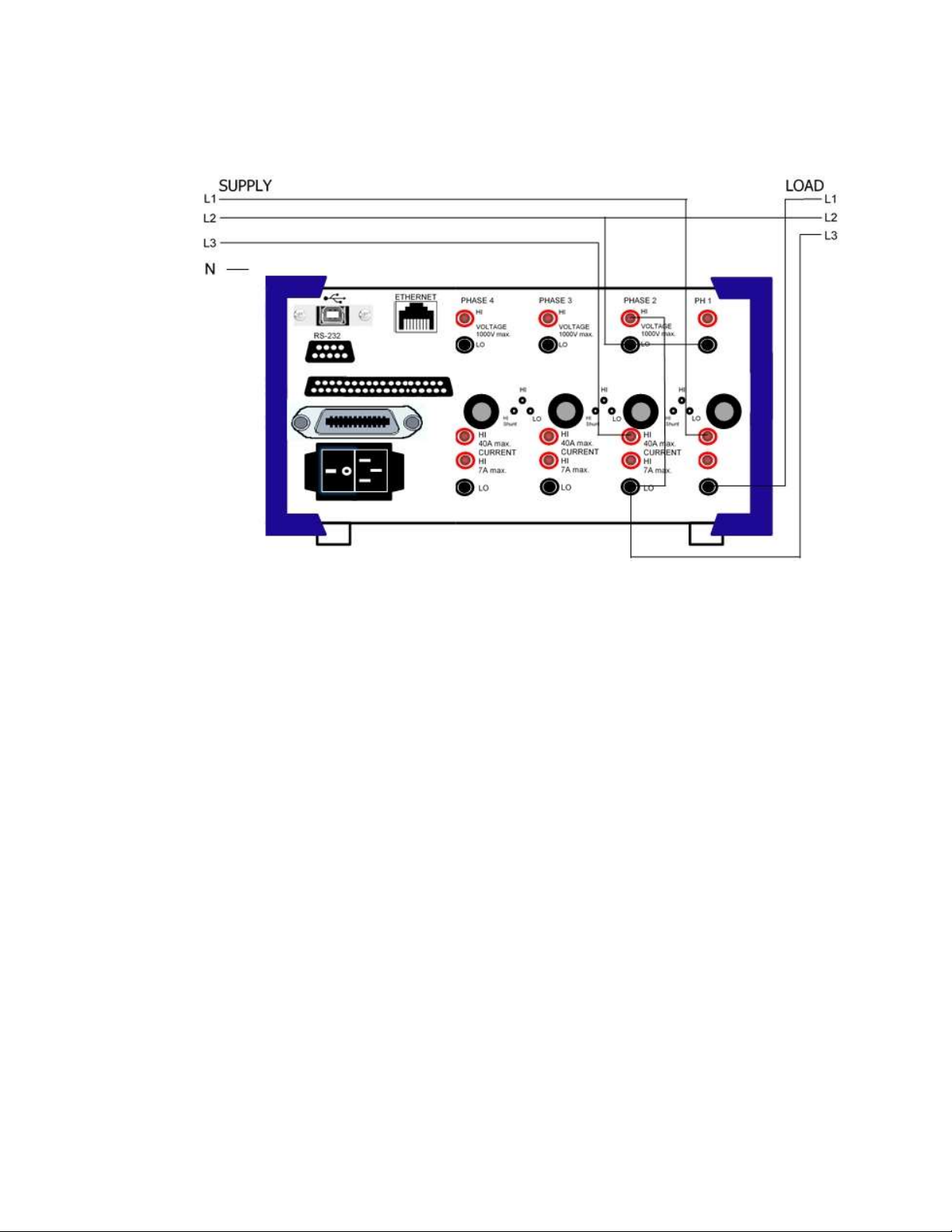

1.5 POWER ANALYZER REAR PANEL

Figure 1.5 shows the 108B rear panel with four phases installed. Every phase consists of a

potential free voltage input along the top side.

Below the voltage inputs are the 40A input, and the 5A input (7A max.) with common Lo

socket. Above the 40A socket is the 3 pole Amphenol socket for the 1A input and shunt input.

It is normally covered with the shunt short circuit cap.

Figure 1.5 Rear panel of a 4 Phase 108B Power Analyzer

All four current inputs are referenced to the black Lo socket and are potential free.

Figure 1.6 3 pole Amphenol Socket for 1A current input and shunt input

For use of 1A input remove the shunt short circuit cap and insert the 1A adapter. The 1A

adapter is the Hi input, and the black current socket is the 1A Lo.

Caution: When 1A adapter is removed the shunt short circuit cap must be inserted.

1A Input Hi, Lo at black 4mm

socket

Short circuit when clamp not used.

Shunt Hi

Shunt

Lo

page 10

1.6 SUMMARY OF 108B POWER ANALYZER FEATURES

Available as 1-, 3- and 4-phase instrument.

Highest precision available: 0.02 % reading + 0.02 % range.

18bit measurement resolution. High accuracy at 10 % full scale.

Wide angle, touchscreen TFT color display (800 x 480 pixels).

Simple to operate, most settings in 2 steps (2 touches).

Settings per phase for V- A-ranges, current inputs, and synchronization.

Standard-, Logging-, Transient-, Power-Speed measurement functions.

Standard: calculates all quantities of power electronics, including motor- and

transformer values, harmonics, energies, analog inputs, and speed.

Fast data transfer; up to 3400 values per second.

High DC precision for solar applications.

Includes 4 current inputs: 1mA - 1A, 15mA - 5A, 1A - 40A, shunt.

Voltage Ranges: 0.3V to 1000V.

USB memory stick >4GByte

USB interface for downloading measurement data

Optional interfaces: RS232, USB, Ethernet, IEEE-488

Optional: 2 frequency inputs max 150kHz, 6 analog inputs, and 12 analog outputs.

Interface commands for fast data transmission.

Operating software under Windows, LabView Driver

Reasonably priced by virtue of smart design.

Simple servicing, modular concept, pre-calibrated input amplifiers.

Optional high precision, broadband, current sensors.

Upgrading the number of installed phases is possible at any time

page 11

1.7 SAFETY INSTRUCTIONS

The manufacture of this equipment conforms to the safety standards defined in IEC 61010-1.

Protection: The device assigns to protection class and is equipped with a protective

earth stud.

This equipment may be operated only by qualified personnel. A qualified person has complet-

ed training to operate a Power Analyzer.

PROPER USE

Do not exceed maximum currents of the 1A-input, 5A-input, 30A-input, and the shunt input.

Do not exceed maximum voltages on voltage inputs. Do not exceed 1000V on any input ter-

minal with respect to case.

Improper use or modifying any part of the equipment shall void all warranty.

Warranty

The warranty period is 2 years from the date of purchase.

CONNECTING A POWER ANALYZER

Use a power line cable with earth connection

Inspect the connecting cable for faulty connection

Connect the rear panel earth stud to power ground

Make cable connections with the help of a second qualified person

Ensure that connected devices work properly

In case of direct connection to current circuits we recommend to use an external

protection circuit to not exceed the maximum current input in use (1A, 5A, 30A)

Refer Power Analyzer servicing and repair to authorized organizations

Use of this instrument in life support systems and in systems for people transportation

must be expressly authorized by the manufacturer

Use shielded cables for interface connections and keep interface cables away from

parts which can carry large currents and transients.

page 12

2. CONNECTION TO CIRCUITS

Please read section “Safety” of this manual before performing the measurements described

below.

2.1 MEASUREMENT IN 3-PHASE MAINS CIRCUIT

2.1.1 THREE WATTMETER CONNECTION

Power and energy consumed by a load are positive values. This means that current Hi and

Lo, and voltage Hi and Lo must be connected in correct directions (polarity).

Rule 1: All currents flow from supply to load that is into the red current socket and from

current Lo (black socket) to input of load.

Rule 2: Connect current Lo to voltage Hi.

Connect all voltage Lo to power line neutral (3 wattmeter circuit)

Figure 2.1 Power Measurement in 3-phase mains circuit with neutral line using three

Wattmeter configuration. Rule 1 and Rule 2 apply.

Power values of the 3 phases are all positive. You can verify that power of phase 1 becomes

negative by reversing current phase 1.

page 13

2.1.2 ARON CONNECTION

Important! Do not use Aron Connection for unsymmetrical loads.

Figure 2.2 Measurement in 3-phase mains circuit using 2 Wattmeter configuration.

Rule 1 and Rule 3 apply.

Rule 3: Voltage Lo connects to third wire not used for current measurement

(Figure 2.2). Phase to phase voltages are measured.

The 2 Wattmeter circuit measures 2 currents, and 2 line-to-line voltages and determines total

power of the 3 phase load. One of the displayed power values can become negative due to

phase shifts of inductive loads. This may lead to confusion. Therefore, strictly follow rule 1

and rule 3.

page 14

3. 108B MATHEMATICAL DEFINITIONS AND SPECIFICATIONS

3.1 MATHEMATICAL DEFINITIONS

Tables 3.1 and 3.2 define all quantities measured and computed. The “batch” column shows

the symbol that must be used in the interface batch command of section 6 (setting the quanti-

ties viewed on the display).

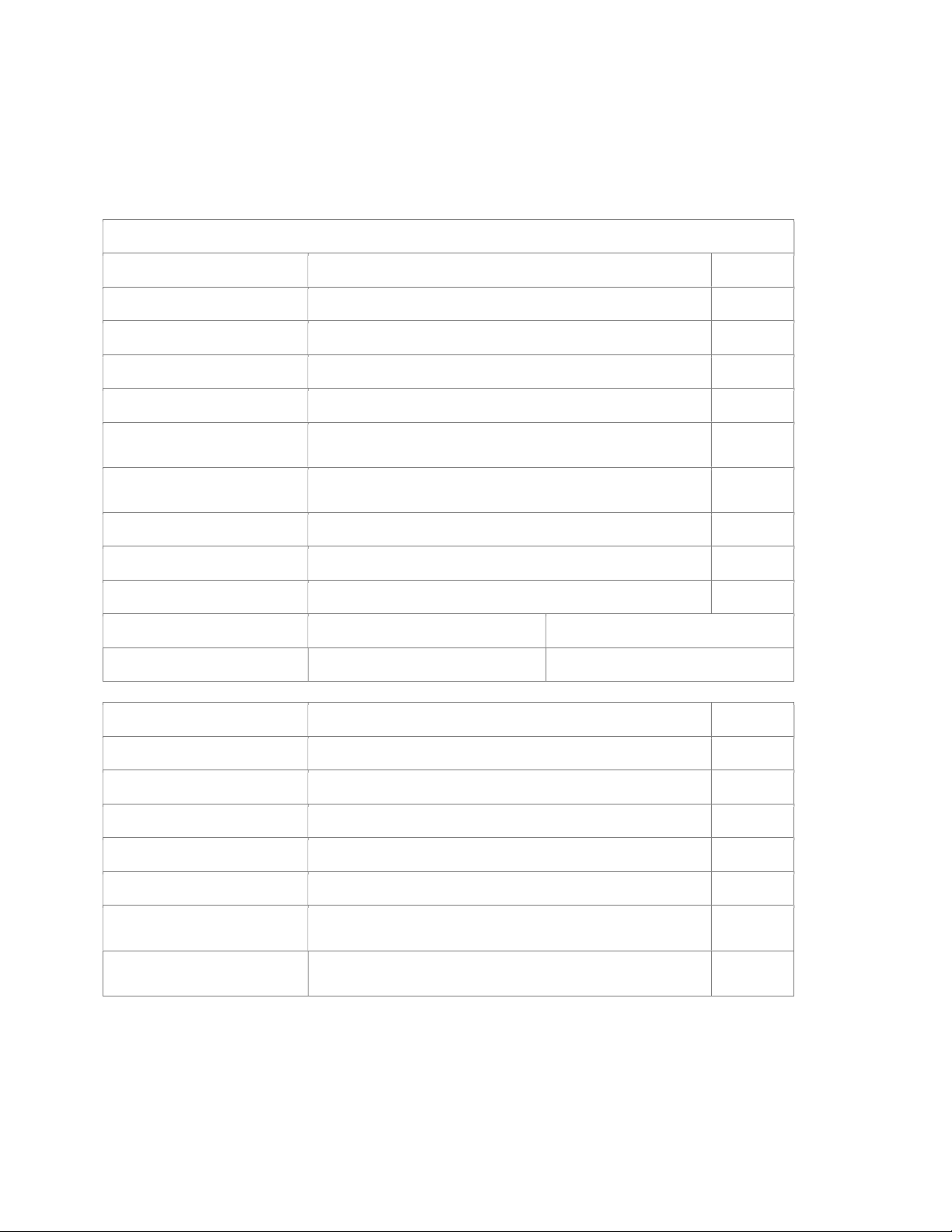

Table 3.1. List of standard values that can be displayed

Description Symbol = Formula, Description Batch

rms current Arms = (1/T T

0 A2 dt)1/2, includes all harmonics A00

mean current Amean = 1/T T

0 Adt, dc-component of current A01

rectified mean current Arect = 1/T T0 lAl dt, rectified mean current A02

peak current Amax = maximum current in time interval A10

current distortion Athd1 = (Arms2 – A012)1/2 / Arms, use for fre-

quency inverter

A23

harmonic current distor-

tion

Athd2 = (

An2)1/2 / Arms, n = 2,3, … 40 A25

current crest factor Acf = Amax / Arms A20

current form factor Aff = Arms / Arect, is 1.1107 for sine wave A22

current fundamental A01 = fundamental current of FFT A35

current 2. to 7. harm A02,A03,A04,A05,A06,A07 A3,A39,A41,A43,A45,A47

current 8. to 13. harm A08,A09,A10,A11,A12,A13 A49,A51,A53,A55,A57,A59

rms voltage Vrms = (1/T T

0 V2 dt)1/2, includes all harmonics A03

mean voltage Vmean = 1/T T

0 Vdt, dc component of voltage A04

rectified mean voltage Vrect = 1/T T

0 IVI dt, rectified mean voltage A05

peak voltage Vmax = maximum voltage in time interval A13

lowest voltage Vmin = lowest voltage in time interval A12

peak to peak voltage Vptp = Vmax – Vmin A11

voltage distortion Vthd1 = (Vrms2 – V012)1/2 / Vrms, use for fre-

quency inverter

A24

harmonic voltage distor-

tion

Vthd2 = (

Vn2)1/2 / Vrms, n = 2,3, …, 40 A26

page 15

Table 3.1: continued. List of standard value that can be displayed

Description Symbol = Formula, Description Batch

voltage crest factor Vcf = Vmax / Vrms A19

voltage form factor Vff = Vrms / Vrect, is 1.1107 for sine wave A21

voltage fundamental V01 = fundamental voltage of FFT A36

voltage 2. to 7. harm V02,V03,V04,V05,V06,V07

A38, A40, A42, A44, A46, A48

voltage 8. to 13. harm V08,V09,V10,V11,V12,V13

A50, A52, A54, A56, A58, A60

active power W = 1/T T0 ui dt, total power in W A06

apparent power VA = Arms Vrms, total apparent power VA A17

reactive power Var = (Papp2 – Pact2)1/2, reactive power Var A18

power factor PF = Pact / Papp, includes all harmonics A27

fundamental power W01 = A01

V01

cos

01,

01 = phase A61

fund apparent power VA01 = A01

V01 A29

fund reactive power Var01 = (VA012 – W012)1/2, magnitude only A30

fund power factor PF01 = W01 / VA01 A28

power 2. to 6. harm W02, W03, W04, W05, W06 A63, A65, A67, A69, A71

power 7. to 10. harm W07, W08, W09, W10 A73, A75, A77, A79

power of distortion D = V01(An2)1/2, n = 2,3, …, 40; D in Watt A31

energy Wh = t

0 Pact

dt, active energy in Wh A14

apparent energy VAh = t0 Papp dt, use it for long term PF A15

reactive energy VAR = t0 Prea dt, can be positive / negative A16

battery charge Ah = t0 Arect dt, is positive only A09

elapsed time time = t0 dt, time in hours since RESET A32

magnitude impedance Mag Z = V01 / A01 fundamental A33

phase of fundamental Phi01 = phase V01, A01 A34

phase 2. to 6. harm phase 2., 3., 4., 5., 6. harmonic A64, A66, A68, A70, A72

phase 7. to 10. harm phase 7., 8., 9., 10. harmonic A74, A76, A78, A80,

frequency Freq = zero crossing of A, V, Ext; SYNCI, U, Ext A07

Note: Harmonic values not contained in table 3.1 can be read via interface:

These are: current A14 to A88 and voltage V14 to V88.

page 16

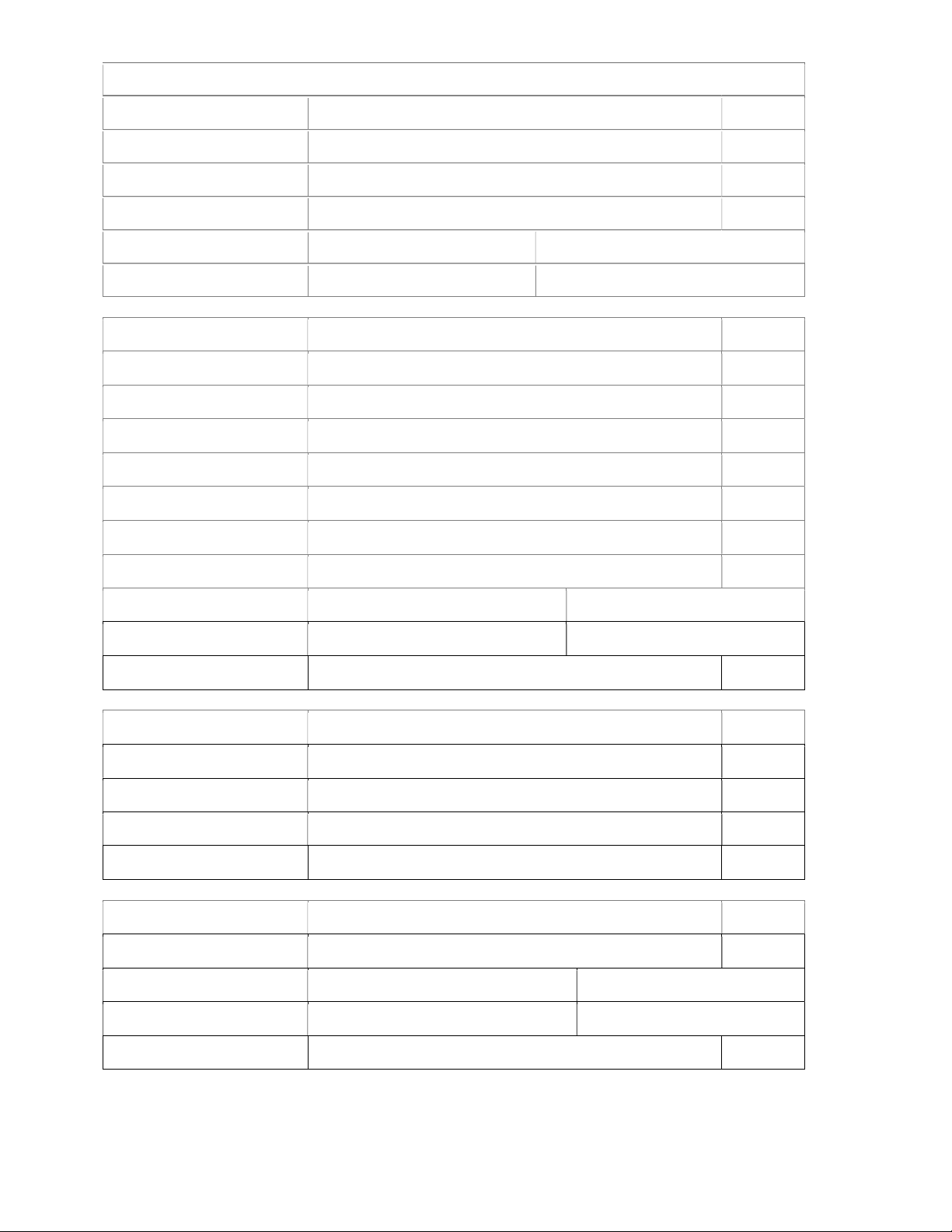

Table 3.2: List of special values that can be displayed

Description Symbol = Formula, Description batch

sum1 of power sum1 = Pact1 + Pact2 + Pact3; Power phase 1+2+3

A81

sum2 of power sum2 = Pact1 + Pact2

sum3 of power sum3 = not used

sum4 of power sum4 = not used

A82

sum5 of power sum5 = not used

sum6 of power sum6 = not used

ratio1 of power ratio1 = Pact4 / Pact1 + Pact2 + Pact3

A83

ratio2 of power ratio2 = Pact3 / Pact1 + Pact2

ratio3 of power ratio3 = Pact2 / Pact1

ratio4 of power ratio4 = not used

A84

ratio5 of power ratio5 = not used

ratio6 of power ratio6 = not used

Motor1 Values from phase 1, phase 2, and phase 3

Mec input power Pin = electric power applied to motor

A85

Mec output power Pout = Pin – Pin at no load in Watt (Loss)

Torque Torque = Pout

poles1 / 4

3.1416

frequency1

Slip Slip = 1 – fout / fin

A86

rotation per minute rpm = 120

frequency1 / poles1

efficiency efficiency = 1 – Pin at no load / Pin

Transformer values from phase 1 and phase 2

Vrect, rms corrected Vcorrected = 1.1107

Vrect

A87

correted power Corr power = Pact 1 / (0.5 + 0.5 Vrms / Vcorrected)

Loss factor Q Q = tan X/R, where Z=R + jX

page 17

Table 3.2: List of special values that can be displayed

Description Symbol = Formula, Description batch

Loss resistance Equivalent loss resistance = Pact1 / Arms2

A88

Loss inductance Equivalent loss reactance = Prea 1 / Arms2

turn ratio turn ratio = N2 / N1 = Vrms2 / Vrms1, no load

analog input1

5V analog input1

A89

analog input2

5V analog input2

analog input3

5V analog input3

analog input4

5V analog input4

A90

analog input5 10V analog input5

analog input6 10V analog input6

V1 line to line V1 ltl = (V1rms + V2rms) 0.86603

A93

V2 line to line V2 ltl = (V2rms + V3rms)

0.86603

V3 line to line V3 ltl = (V3rms + V1rms)

0.86603

V4 line to line not used

A94 V5 line to line not used

V6 line to line not used

Motor2 Values from phase 4, phase 5, phase 6

Mec input power not used

A95

Mec output power not used

Torque not used

Slip not used

A96

rotation per minute not used

efficiency not used

Example:

Assuming you are using a 2-phase Power Analyzer and want to display ratio 3 = Pact2 /

Pact1 at the bottom of the display (Figure 1.1). Touch icon, “Ah” (Fig. 1.1). In the value selec-

tion table touch “R1|R2|R3” (Fig. 1.2).

In Figure 1.1 at the bottom line you have now 3 quantities displayed: ratio1, ratio2, ratio3,

where ratio1 = 0, ratio2 = 0, and ratio3 = Pact2 / Pact1.

page 18

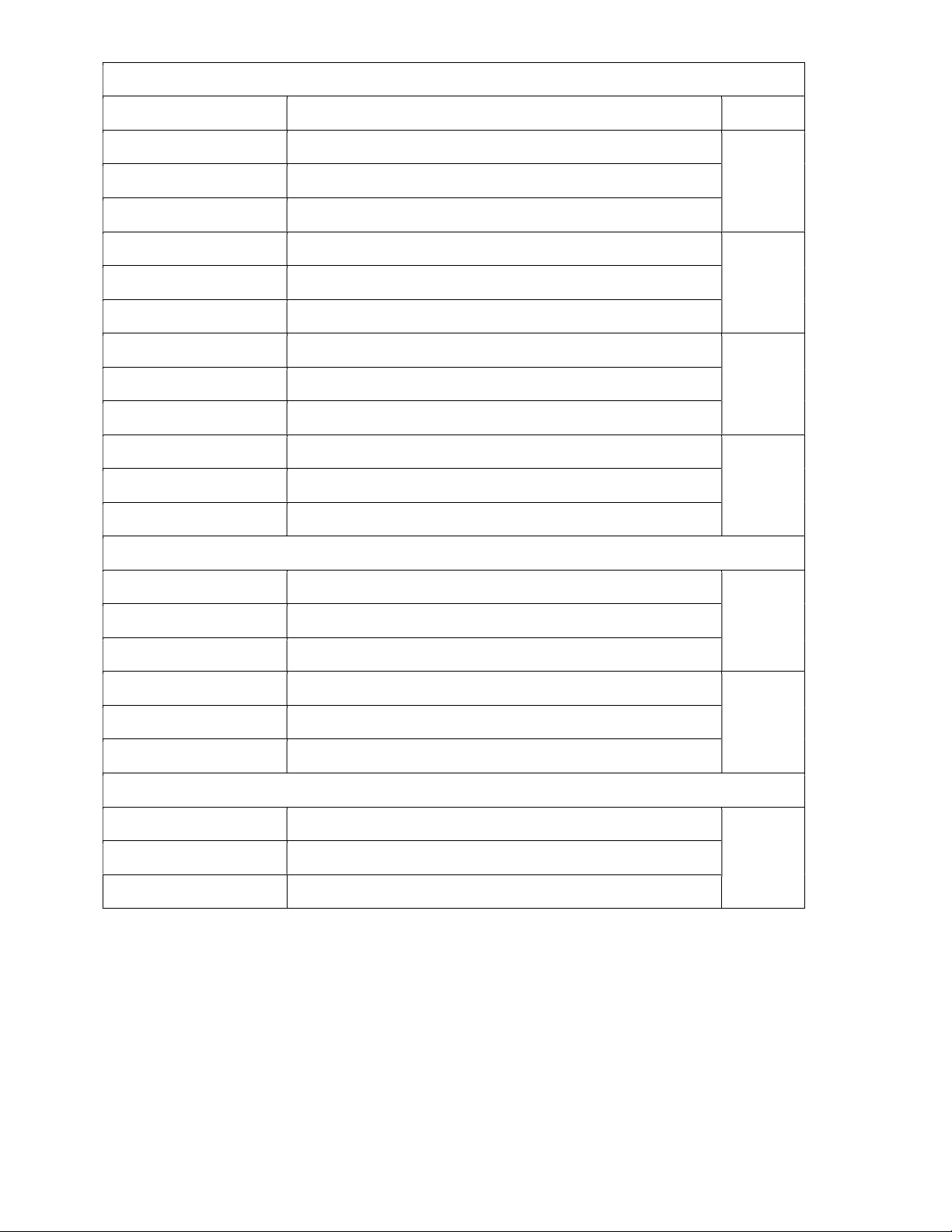

3.2 SPECIFICATIONS

Voltage Measurement

% reading

+ % range

8 me

asuring ranges: 0.3V

1)

–

1V

–

3V

–

10V

–

30V

–

100V

–

300V

–

1000V

Bandwidth DC

-

2MHz

Coupling: AC or AC + DC

Common mode rejection:

100dB at 100kHz

Input impedance: 1M

/ 15pF. Floating input

max. 1000Vrms

Crest Factor 15:1 at 10% fs. Typical accurac

y at 10% is 0.1%

fs = full scale

Temperature coefficient: 0.004% /

C

Standard accuracy 23

C ±1

C. 3V to 600V

45 to 65Hz 0.08 + 0.08

3 to 1000Hz 0.1 + 0.1

1 to 10kHz 0.2 + 0.2

10 to 100kHz (0.2 + 0.2) + (0.2 + 0.2)*log(f/10kHz)

DC1)//100-500kHz1) 0.1 + 0.1// 0.012*f(kHz)

High precision

10V to 600V

0.02 + 0.02

0.03 + 0.03

0.1 + 0.1

(0.2 + 0.2) + (0.2 + 0.2)*log(f/10kHz)

Linearity 100V range:

130 %

100 %

50 %

10 %

5 %

130.01V 100.00V 49.988V 10.000V 5.0014V

Typical linearity at 50/60Hz

Voltage Scalin

g U1

-

U

4

Individual voltage scaling factors of every phase. Use pop

-

up number pad.

Format 2000.8.

Measured & Computed Voltage Values

RMS voltage

Vrms = (1/T T

0 V2 dt)1/2, includes all harmonics

Voltage crest factor

Vcf = Vmax / Vrms

Mean voltage

Vmean

= 1/T

T

0

Vdt, dc component of voltage

Voltage form factor

Vff = Vrms / Vrect, is 1.1107 for sine wave

Rectified mean voltage

Vrect = 1/T

T

0

IVI dt, rectified mean voltage

Voltage fundamental

V01 = fundamental voltage of FFT

Peak voltage

Vmax = maximum

voltage in time interval

V1 line to line

V1 ltl = (V1rms + V2rms)

0.86603

Lowest voltage

Vmin = lowest voltage in time

interval

V2 line to line

V2 ltl = (V2rms + V3rms)

0.86603

Peak to peak voltage

Vptp = V

max

–

V

min

V3 line to line

V3 ltl = (V3rms + V1rms)

0.86603

Voltage distortion

Vthd1 = (Vrms

2

–

V01

2

)

1/2

/ Vrms,

2)

Harmonic voltage distortion

Vthd2 = (

Vn

2

)

1/2

/ Vrms, n = 2,3, …, 40

Current Measurement

% reading

+ % range

4 inputs: In30A, In5A, In1A, shunt.

Floating inputs. 1 se

c averaging.

max. 1000Vrms to earth

In1A: 6 ranges 1.5mA

1)

-

5mA

-

15mA

-

50mA

-

150mA

-

500mA

-

1500mA. DC

-

100kHz

max. 2A continuous

In5A: 6 ranges: 15mA

1)

-

50mA

-

150mA

-

500mA

-

1.5A

-

5A

-

15A. DC

-

100kHz

max. 7A continuous

In30A: 4 ranges

: 1A

1)

-

3A

-

10A

-

30A

-

100A.

DC

-

100kHz

max. 40A/30A

cont., 1

-

4phase

Shunt: 60mV - 200mV - 600mV - 2V - 6V. DC-100kHz max. 30V continuous

Coupling: AC or AC + DC

Common mode rejection:

115dB at 100kHz

Crest factor 15:1 at 10% fs. T

ypical accuracy at 10% fs is 0.1%

fs = full scale

Temperature coefficient: 0.004% /

o

C

Standard accuracy 23

o

C ± 1

o

C

Input In1A, In5A, Shunt In30A

45 to 65Hz 0.08 + 0.08 0.08 + 0.08

3 to 1000Hz 0.1 + 0.1 0.2 + 0.2

High precision In1A/In5A

15,50,150,500mA,1A/150,500mA,1.5,5A

0.02 + 0.02

0.03 + 0.03

1 to 10kHz

0.15 + 0.15

0.15 + 0.15

10 to 100kHz

(0.15+0.15)

+

(0.5+0.5)*log(f/10kHz)

(0.15+0.15)

+ (0.5+0.5)*log(f/10kHz)

DC

1)

//100

-

500kHz

1)

0.1 + 0.1// 0.023*f(kHz)

Current

Sensors

0

-

150Ap

eak 0

-

400Apeak 0

-

600Apeak 0

-

700Apeak

45 to 65Hz 0.004 + 0.004 0.004 + 0.004 0.002 + 0.002 0.01 + 0.01

3 to 1000Hz 0.01 + 0.01 0.01 + 0.01 0.01 + 0.01 0.02 + 0.02

Ex

posure of current inputs to

their max. value

will result in additional errors1)

In1A: 0.03% * I2

In5A: 0.003% * I2

In30A: 0.0001% * I2

Input

0

-

100A

precision current sensor

(Option 04) connected to In1A input

3 to 100Hz 0.05 + 0.05

100 to 1000Hz 0.1 + 0.1

Linearity 500mA

range:

130 %

100 %

50 %

10 %

5 %

650.02mA 500.02mA 250.02mA 49.979mA 24.997mA

Typical linearity at 50/60Hz

Shunt Sensitivity:

60mV/A. For an external shunt with 1mV/A scale by 60.0

Current Scaling I1

-

I

4

Individual current scaling factors of every phase. Use pop

-

up number pad.

For

mat 2000.8.

Measured & Computed Current Values

RMS current

Arms = (1/T T

0 A2 dt)1/2, includes all harmonics

Current distortion

Athd1 = (Arms

2

–

A01

2

)

1/2

/ Arms,

2)

Mean

current

Amean = 1/T T

0 Adt, dc-component of current

Harmonic current distortion

Athd2 = (

An2)1/2 / Arms, n = 2,3, … 40

Rectified mean current

Arect = 1/T T

0 lAl dt, rectified mean current

Current crest factor

Acf = Amax / Arms

Peak current

Amax = maxi

mum current in time interval

Current form factor

Aff = Arms / Arect, is 1.1107 fo

r sine wave

Current fundamental

A01 = fundamental current of FFT

1) Typical max. Error2) Used for frequency inverter

page 19

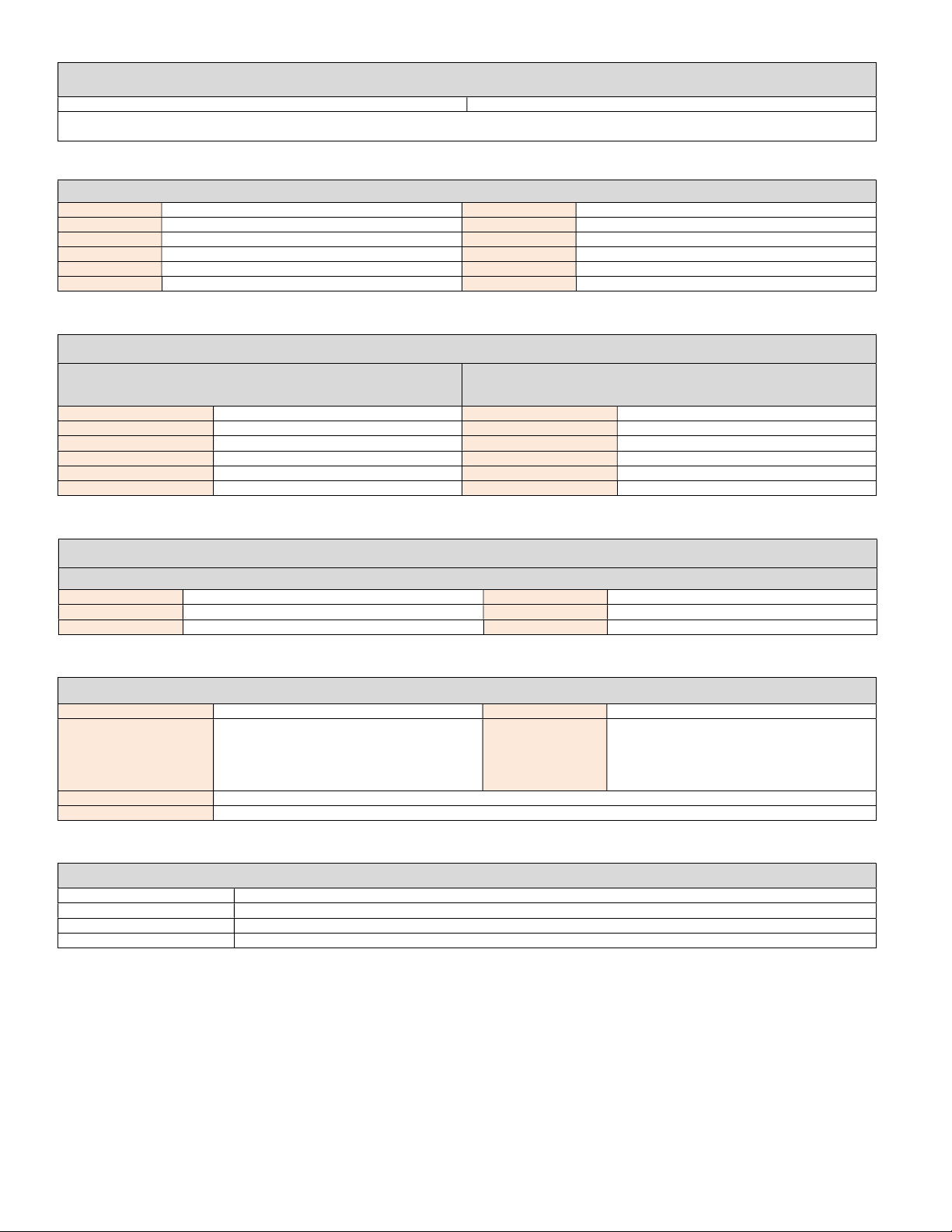

Power Measurement

% reading

+% range

W range =

voltage range times current range

112 power ranges

Standard accuracy 23

o

C ± 1

o

C

Input PF In1A, In5A, Shunt

45 to 65Hz 0-1 0.16 + 0.16

45 to 65Hz 0-0.05

3 to 1000Hz 0-1 0.2 + 0.2

High precision

In1A, In5A, Shunt

0.04 + 0.04

0.01 + 0.01

0.1 + 0.1

1

to 20kHz

0

-

1

0.2

+

(0.2 + 0.2*log (f/100Hz) + 0.08*k1*log (f/100Hz))

20 to 100kHz 1 %error (A+V) %error (A+V)

DC

1)

//100

-

500kHz

1)

1

0.2 + 0.2// add %error (V+A)

Input

PF

In30A

Current Sensor 0

-

100A

45 to 65Hz 0-1 0.16 + 0.16 0.1 + 0.1

3 to 1000Hz

0

-

1

0.2

+

(0.2+0.2 * log(f/3Hz) + 0.1 *k1 * log(

f/3Hz)

DC1) 0.2 + 0.2 0.1 + 0.1

PF 1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

k1 0.5 0.74 0.97 1.18 1.38 1.55 1.70 1.83 1.92 1.98 2.00

k1 = (2

–

PF

4

)

/ (1+PF

2

)

1) Typical max. error

W Linearity

130%

100%

50%

10%

5%

Volt 130.00 100.00 49.985 9.9992 4.9990

Ampere 6.5004 5.0014 2.5020 500.82m 250.40m

Watt PF=1 844.74 500.07 125.05 5.0056 1.2522

Typical linearity of voltage, current

and power

Measured & Computed Power Values

Active power

W = 1/T

T

0

u

i dt, total power in W

Fundamental p

ower

W01 = A01

V01

cos

01,

01 = phase

Apparent power

VA = Arms

Vrms, total apparent power VA

Fundamental apparent power

VA01 = A01

V01

Reactive power

Var =

(Papp2 – Pact2)1/2, reactive power Var

Fundamental reactive power

Var01 = (VA01

2

–

W01

2

)

1/2

, magnitude only

Power Factor

PF = Pact / Papp, includes all harmonics

Power of distortion

D = V01(

An2)1/2, n = 2,3, …, 40; D in Watt

Power Factor of Fundamental

PF01 = W01 / VA01

Frequency Measurement

SyncA:

2Hz

-

5kHz

SyncV: 2Hz-150kHz

S_ExtV: 2Hz-150kHz

S_ExtV is a TTL output for SyncA/V or a TTL input for S_ExtV

Accuracy: 0.05 %

Accuracy: 0.05 %

Accuracy: 0.05 %

Sync for each phase

Measured & Computed Values

Frequency

Freq =

zero crossing of A, V, Ext; SYNC I, SYNC U, Ext; Accuracy 0.05%

Energy Measurement

Wh, VAh, Varh, Ah, integration time. Add accuracy % of values involved.

Reset sets all values to zero. Integration runs uninterrupted, also in the background.

Measured & Computed Values

Energy

Wh =

t

0

Pact

dt, active energy in

Wh

Battery charge

Ah =

t

0

Arect

dt, is positive only

Apparent energy

VAh =

t

0

Papp

dt, use it for long term PF

Elapsed time

time =

t

0

dt, time in hours since RESET

Reactive energy

VAR = t

0 Prea

dt, can be positive / negative

Time

Accuracy: 0.0

5 %

Harmonic Measurement

Frequency range of fundamental 3Hz

–

15kHz

Harmonics: V and A: 1-88; W and phase angle 1-21

Accuracy: Fundamental1), use % figures of V, A, W

FFT averaging:

Set FFT ID = 0, 1, 2, 3, 4 which corresponds to averaging over 4, 16, 64, 256,

or 1024 periods.

H

armonic Display: Select button ‘

FFT Table

’ to view current

-

, voltage

-

, power

-

, impedance

-

, and phase harmonics 1

-

40. A single harmonic can be dis-

played by selecting A FFT, V FFT or W FFT. The whole range of harmonics can be read via interface.

Measured & Computed Values

Magnitude impedance

Mag Z = V01 / A01 fundamental

Phase of fundamental

Phi01 = phase V01, A01

page 20

Additional Computed Values

Accuracy: Add % figures of values involved

65 values per phase

Rectified mean

, VA, Var,

impedance, distortion factor, power factors, motor

-

and transformer values, sums, ratios, analog inputs and

-

outputs, speed

inputs, and more are continuously updated and ready for display or interface output.

1) Typical max. Error

Measured & Computed Values

Sum1 of power

Sum1 = Pact1 + Pact2 + Pact3; Power phase 1+2+3

Ratio1 of power

Ratio1 = Pact4 / Pact1 + Pact2 + Pact3

Sum2 of power

Sum2 = Pact1 + Pact2

Ratio2 of power

Ratio2 = Pact3 / Pact1 + Pact2

Ratio3 of power

Ratio3 = Pact2 /

Pact1

Motor Measurement

Measured & Computed Values from phase

1, phase 2, phase 3

Measured & Computed Values from phase 4,

phase 5, phase 6

Mechanical input power

Pin = electric power applied to motor

Mechanical input power

Not used

Mechani

cal output power

Pout = Pin

–

Pin at no load in Watt (Loss)

Mechanical output power

Not used

Torque

Torque = Pout

poles1 / 4

frequency1

Torque

Not used

Slip

Slip = 1

–

fout / fin

Slip

Not used

Rotation per minute

rpm = 120

frequency1 / poles1

R

otation per minute

Not used

Efficiency

efficiency = 1

–

Pin at no load / Pin

Efficiency

Not used

Transformer Measurement

Measured & Computed Values from phase 1 and phase 2

Vrect, rms corrected

Vcorrected = 1.1107

Vrect

Loss resistance

Equivalent l

oss resistance = Pact1 / Arms

2

Corrected power

Corr power = Pact 1 / (0.5 + 0.5

Vrms / Vcorrected)

Loss inductance

Equivalent loss reactance = Prea 1 / Arms

2

Loss factor Q

Q = tan X/R, where

Z=R + jX

Turn ratio

Turn ratio = N2 / N1 = Vrms2 / Vrms1, no

load

Analog Input / Output

Analog Input

Analog Output

4 Analog inputs (I1

-

I4)

2 analog inputs (I5-I6)

2 TTL auto ranging speed

inputs 20Hz-150kHz

5V, 100k

input impedance, accuracy 0.2%1)

10V, 100k input impedance, accuracy 0.2%1)

Accuracy 0.1%1). Reading rate in Standard-Mode

0.5sec, reading rate in Power Speed-Mode 20ms

Each input can be scaled 0.0001 up to 99999

12 analog outputs

(O1-O12)

5V, 1k

output impedance, accuracy 0.2%1)

Update rate 0.5sec. Arms, Vrms, W, VA, Var, PF,

Frequency, and Wh can be sent to the analog

outputs. In Logging- and Power Speed-Mode

output1 is an actuator to Start/Stop ext. devices.

Scaling An1

-

An6

Individual analog scalin

g. Use pop

-

up number pad.

Format 10.0.

Scaling rpm1

-

rpm2

TTL freq1/rpm1 and freq2/rpm2 scali

ng. Use pop

-

up number pad. Format 2.0. For 180 pulses per turn, scaling = 1.0000

Four Measuring Functions

Standard

1

, 3 and 4

phase, measures all

electrical values at 0.8s updates or 100ms updates.

Logging

Up to

32

values in 20ms, or long time averagi

ng up to 10 minutes.

Transient

Simultaneous V

-

, A

-

, W

-

waves on

4

phases, time 0.25 to 16 seconds.

Power

-

Speed

Measures in 20ms intervals V, A, W, VA

, Wh, VAh, speed of rotating devices.

1) Typical max. Error

Table of contents

Other Infratek Measuring Instrument manuals