Infratek 23 User manual

CONTENTS

SECTION PAGE

1. Safety, Working with Batteries can be dangerous 1-1

2. Introducing the Infratek 23 DC-Source Tester 1-2

3. Features of the Infratek 23 DC-Source Tester

3.1. Specifications 1-4

4. Available Test Methods 1-4

5. Getting Started, Instrument Battery Replacement 1-5

6. Basic Measurements 1-6

7. Menu Selection 1-7

7.1. Operating Mode Selection 1-7

7.2. Saving Instrument Settings 1-8

8. Operating Mode „MAN“ 1-8

9. Operating Mode „AUT“ 1-8

10. Operating Mode „RD“ 1-8

11. Operating Mode „CMP“ 1-9

12. Operating Mode „LDT“ 1-9

13. Infratek 23 DC-Source Tester equipped with Label Printer 1-10

14. Efficient and reliable Battery testing using the windows

software 1-10

14.1. BatHandler 1-11

14.2. BatAnalyze 1-11

14.3. BatAlarm 1-11

15. Installation and description of windows software 1-12

15.1. Installation and Overview 1-12

15.2. BatHandler Program 1-13

15.3. BatAnalyze Program 1-15

15.4. BatAlarm Program 1-16

16. Basics of Battery Measurement 1-17

16.1. General Rules 1-17

16.2. Measure the Stationary Battery and not the Power Supply 1-18

16.3. Traction Batteries 1-19

16.4. Car Batteries 1-19

17. Servicing and Calibrating the Infratek 23 DC-Source Tester 1-20

17.1. Servicing 1-20

17.2. Calibration 1-20

-1-

1. SAFETY, WORKING WITH BATTERIES CAN BE

DANGEROUS

Before using the Infratek 23 DC-Source Tester carefully read and understand the

following safety information. This information is meant to be in addition to the safety

practices required by your employer.

•Wear safety glasses.

•Wear protective gloves; batteries can produce high electrical potential.

•Do not place metallic parts on top of batteries; a battery is a powerful DC-

Source that delivers very large short circuit currents.

•For battery testing use safety clamps or safety probes only.

•The Infratek 23 DC-Source Tester is reverse voltage protected up to 200V.

The Infratek 23 DC-Source Tester is designed for maximum user safety. It is safe to

measure batteries on high potential with the printer or a notebook connected to the RS-232

interface of the tester. The interface isolates the high battery potential to protect users

from hazardous shock.

1-3

3. FEATURES OF THE INFRATEK 23 DC-SOURCE TESTER

The Infratek 23 DC-Source Tester characterizes electrical sources (batteries or DC-power

supplies) by their unloaded DC-voltage, and their internal source resistance Ri.

•Simple to use, hand held, and lightweight.

•Designed for battery testing 0.5Ah to 2000Ah.

•Designed for DC power supply testing up to 100V.

•Designed for maximum user safety.

•Designed for efficient handling of maintenance data.

•Tester comes with isolated RS-232, printer, and Windows software.

•Tester for stationary batteries, traction batteries, and car batteries.

•Four test methods for stationary batteries.

•One test method for traction batteries.

•One test method for car batteries.

•Stores up to 500 individual reference values. Uses compare mode.

•Tests single cells (min. 1.65V), battery blocks, and battery strings up to 100V.

•Wide Ri-range 050µΩ (2000Ah) to 8Ω.

•Wide voltage measurement range 0-30V / 0-200V.

•Turn on and measure, no zeroing, no adjusting, no range setting.

•Simple menu programmable functions.

•Stores up to 500 battery measurements (voltage and Ri).

•Operation with 3 keys only.

•Reverse voltage protected up to 200V.

•Five different tester versions are available:

FULL: Tester with RS-232 interface, label printer, Windows software,

Carrying case.

MED: Tester with RS-232 and Windows software

GEN: Tester only, no RS-232.

CAR: Tester with 30A battery load.

CAR FULL: Tester with 30A battery load, RS-232 interface, and label

printer.

•Low cost battery monitors on request.

1-4

3.1. SPECIFICATIONS

Size of Batteries Tests batteries 0.5Ah-2000Ah and

voltages up to 120V sealed, non-sealed; lead acid

and other

Voltage UBRanges 2; 0-30V, 0-200V

Resolution; 10mV, 0.1V

Accuracy; 1 % ±1 digit

200Vdc maximum

Display; 3 digits

23°±3°K

Source

Resistance Ri Ranges 3; 0-20, 0-400mΩ, 0-8Ω

Resolution; 1µΩ, 10µΩ, 0.1mΩ

Measurement repetition; ±1 digit

Accuracy: 1 % ±2 digit; Ri>1mΩ

UB: 1.6V-120V

Display 3 digits

S/N >20dB; Ri>2mΩ

S/N >20dB

Display 6.5mm, 16 character LCD V, mΩ, Mode

Interface RS-232, isolated from batteries 300V CAT II

Operation / Time Via menu, 3 controls 0.6s measurement time

Data Storage 500 complete sets UB, RiN=1 to N=500

Supply 9V battery or accumulator for 6-8h operation

Size / Weight 155 x 90 x 35mm; 400 gr.

Temperature Operating: 0-30°K; storage: -10 -40°K

Limits on Ri

measurement 1 measurement / minute

2 measurement / minute

3 measurement / minute

UB = 70-100V

UB = 40-69V

UB = 20-39V

4. AVAILABLE TEST METHODS

This section gives an overview of the test methods available using the Infratek 23 DC-

Source Tester. Reference values (voltage, Ri) for every battery or cell are established at

date x when you start your battery maintenance program or when you have a new battery

system in operation for 2 to 6 months. Maintenance measurements are taken once or twice

a year. All later measurements are compared to the individual reference values of every

battery and when, for example, Ri has increased by 40 % the battery must be serviced or

replaced. Individual reference values are used because every battery has its own reference

values. Ri may vary ±50 % even on batteries from the same type and production batch.

Test Method 1: The tester is used together with the label printer. First time

measurements are printed. This label is stuck to the battery and is used as reference label.

Labels from later measurements are put on a label stack next to the reference label and

may be visually compared to the reference values.

1-5

Test Method 2: Number all batteries (cells/blocks) from N=1 ... 500 in the sequence

you would make the measurements. The maintenance measurements are made off-line

(not connected to the notebook) and are stored in memory corresponding to the battery

number N. When you have taken all the measurements load the data to your notebook

using the BatHandler program. Compare the data with the reference values using the

BatAnalyze program. First time measurements can be used as reference values.

Test Method 3: Test method 3 is similar to test method 2 except that testing is on-

line with your notebook, using the BatAlarm program. Measurement by measurement is

transferred to the notebook and directly compared to the reference values. Large warning

signs are flashed when limits are exceeded.

Test Method 4: Test method 4 uses the DC-Source Tester only, no printer nor

software are required.

Number all batteries N=1, 2, 3 .... 500. First time measurements are stored at memory

location corresponding to the battery number N.

Later maintenance measurements are taken using the CMP (compare) operating mode.

The measurements can instantly be compared with the individual reference values stored

in your tester.

5. GETTING STARTED, INSTRUMENT BATTERY

REPLACEMENT

Connect the BLACK two-pole measuring clip to the BLACK input terminals of the tester

and the RED two-pole measuring clip to the RED input terminals. Press the ON-key to

turn the tester on. At start -up the internal instrument battery is checked and its condition

is displayed with the following sequence:

BATTERY TEST →

→→

→8.82V BAT O.K or 5.40V BAT LOW

If the battery voltage is below 5.2V the above sequence will not be executed. A new 9V

battery must be installed as follows: remove battery door at bottom of tester. (See also

Section 2). Use an M2 flat tip screw driver to loosen the two M2 screws. Replace the old

battery with a new one and reinstall the battery door.

1-6

6. BASIC MEASUREMENTS

Connect the BLACK Kelvin measuring clip to the negative pole on your source and the

RED Kelvin clip to the positive pole. The poles can be of any metal including stainless

steel. The source can be a 2.2V cell, a block, or a battery string of up to 100V, or a power

supply of up to 100V.

As soon as the clips are connected to the source the source’s DC voltage is displayed (DC

average reading). Press the Ri key to start a measurement of the source resistance.

The source voltage must be in the range 1.6V to 100V, and the source resistance range

0.05mΩto 8Ω. Also, the source must be able to deliver a 1A peak current. The DC-

Source Tester is protected against reverse polarity of up to 200V.

1-7

7. MENU SELECTION

Press the MENU key to view the available menus. Once you select a menu mode, the

center key becomes the SET key (to alter settings) and the left key becomes the EXIT key

to leave the menu mode.

•

••

•MODE SELECT>

>>

>SET Select operating modes (MAN, AUT, RD, CMP, LDT)

•

••

•INCR 10

•

••

•INCR 1

•

••

•DECR 10

•

••

•DECR 1

Increment memory location by 10

Increment memory location by 1

Decrement memory location by 10

Decrement memory location by 1

•

••

•SET MONTH *

•

••

•SET YEAR * Set month in non-volatile memory to be printed

Set year in non-volatile memory to be printed.

*The tester does not use a real time clock. When you are using the printer update month

and year as required with the SET MONTH and SET YEAR menus.

7.1. OPERATING MODE SELECTION

In the menu “MODE SELECT>

>>

>SET”, five different operating modes can be chosen.

•MAN

manuall Voltage is continuously measured. Press the Ri key to start Ri

measurement. Press the STORE key to store or print the displayed data.

N is incremented by 1.

•AUT

automatic Connect measuring clips to battery. Ri measurement is started

automatically. Data are stored, printed, and displayed. N is incremented

by 1. Measurement is displayed.

•RD

read

memory

Press the READ key to read stored measurements from memory. N is

decremented by 1.

•CMP

compare to

reference

The displayed measurement can be compared to the individual reference

values stored in your tester. Each new measurement increases the

reference location N by 1.

•LDT

load test For car battery testing there is a 30A load available. Press the

LOADTEST key to start the load test sequence. After six seconds the

results are displayed and printed.

1-8

7.2. SAVING INSTRUMENT SETTINGS

Before turning off the tester you can save the settings and have the tester start up in the

same configuration as you left it. The operating mode and the memory storage location N

are saved.

To save the setting:

Press MENU key. Now press the EXIT key twice quickly. Turn tester off.

8. OPERATING MODE “MAN”

The Infratek 23 DC-Source Tester starts up in the Manual operating mode - MAN (unless

you had saved the instrument setting). The source voltage is continuously measured and

displayed. Pressing the Rikey initiates an Rimeasurement.

The measurement can be stored by pressing the STORE key. When a printer is connected

to the tester the measurement data are stored and printed.

When the tester is connected to a notebook computer and you are using the BatAlarm

software, the data are stored in the tester and are transferred to the computer and there

they are instantly compared to the reference file. If voltage and/or Rilimits are exceeded a

warning is displayed on the screen.

9. OPERATING MODE “AUT”

AUT is the Automatic measuring mode for Ri, data storage, and data hold. When a valid

voltage of >1.7V appears at the measuring clips the Rimeasurement starts automatically,

measurement data are stored and either are printed when a printer is connected, or are

transmitted to a notebook computer. The memory location N is incremented by 1. The

display goes into Hold and displays the voltage and Rireading until you connect the

measuring clips to the next cell or battery.

10. OPERATING MODE “RD”

RD is the Read memory. RD is used to display stored measurements at memory location

N=1 up to N=500. Press the READ key to display the stored values and the associated

memory location. N is decremented by 1.

1-9

11. OPERATING MODE “CMP”

CMP is the Compare displayed measurement to your individual voltage- and Ri-

reference values. Illustrative Example: It is your job to service 50 traction batteries. You

want to detect long-term capacity deterioration. This is how you can make use of the

COMPARE MODE:

Step 1: Start your maintenance plan by numbering the batteries N=400 to 449 (these are

also the memory locations in your tester).

Step 2: Establish reference values for every battery by first fully charging it. Wait 1

hour before taking the measurement for the reference value. Read the number on

the battery, e.g. N=410. Store the measured reference value in the tester memory

at memory location equal to the battery number.

Step 3: For battery servicing use the reference values to make your decisions. For

example: the battery needs to be charged, or the battery needs to be replaced

when in charged condition Rihas increased more than 40 % to 60 %.

12. OPERATING MODE “LDT”

LDT is the Load test for car batteries. This operating mode is designed for car battery

testing. Car battery testers are equipped with a 30A battery load.

Firmly connect the two black measuring clips to the minus pole of the battery and the two

red clips to the plus pole. The clips may not touch each other, otherwise the high current

flow will falsify the measurement. For this test the battery does not have to be

disconnected from car electronics. Press the LOADTEST key to start the following

sequence:

1. Riand battery voltage are measured at no load condition.

2. The 30A load is switched to the battery for 5 seconds. The change of Riand battery

voltage is recorded and is used for the final grading.

3. As the test proceeds the measurements are displayed and printed when a printer is

connected. Finally, the car battery is graded as follows:

CHARGE: When the no load battery voltage is low.

GOOD: When the battery under load has successfully past.

FAIR: When the battery under load is marginal.

FAIL: When the battery under load performs unsatisfactorily.

The printed label can be used as customer proof.

1-10

13. INFRATEK 23 DC-SOURCE TESTER EQUIPPED WITH

LABEL PRINTER

Before testing make sure the RS-232 connector is connected to the DC-Source Tester.

Hang the carrying case with the printer and tester around your neck, turn on the tester and

turn on the printer. At start-up the tester is in MAN (manual) operating mode. Connect the

test clips to the first battery and press the key Rito obtain the Rireading. Pressing the

STORE key stores the data and prints a label. Stick the label on the battery you tested and

visually compare with the reference label. If the prescribed limits of Rior of the battery

voltage are exceeded the battery must be serviced or replaced.

The label contains the following information: Type of tester used, The date (month and

year), The battery number N=1 through 500, The battery voltage, and The battery

resistance Ri.

In the AUT (automatic) operating mode the Rimeasurement is started, stored, and printed

automatically - the whole sequence takes approximately 3 seconds.

Caution: Turn off the printer and the tester when finished.

Printer Batteries

The high speed thermal printer requires two 12V/1.1Ah batteries which contain sufficient

energy to print more than 1000 labels. When you expect long standby periods turn the

printer off. Charge single batteries using a charger or a DC power supply with current

limited to 300mA or charge both batteries in series using a 24V power supply with

300mA current limiting.

14. EFFICIENT AND RELIABLE BATTERY TESTING USING

THE WINDOWS SOFTWARE

The Infratek 23 DC-Source Tester and the available PC software are designed to handle

large amounts of measurement data. You can organize your maintenance procedures as

you require, either you a) measure single cells, 6V-12V- or 24V blocks, or b) measure up

to a 100V battery string. We strongly recommend you tag every cell or block with a

number in the range N=1 to 500. The cell or block numbers should be in ascending order

from N=1 to 500 and should correspond to the memory location N in your tester. For

example, the measurement data of battery N=102 should be stored in the tester memory

N=102. This is a simple way to keep data in perfect order and to keep your computer files

simple.

The following programs are available: BatHandler, BatAnalyze, BatAlarm.

1-11

14.1. BatHandler

With the BatHandler program you can transfer the measurement data from the tester

memory to your computer; for example, read data from memory location N=50 to 95 (this

takes approximately 4 seconds). When you start your maintenance plan and have taken

first time measurements you can define these data as a reference file for future use. Next

time you take measurements at this battery site you can compare the new data to your

reference file. If you have a notebook computer you can download the data at the site and

run the BatAnalyze program to obtain a battery grading.

14.2. BatAnalyze

With the BatAnalyze program you can compare new measurement data with the reference

file. You can set the allowable tolerances for battery voltage and resistance. For resistance

we recommend you use 40 % tolerance, which is equivalent to a 20-40 % decrease of

battery capacity. We suggest you download the measurements on site to a notebook

computer and run the BatAnalyze program to evaluate battery conditions.

14.3. BatAlarm

The BatAlarm program allows on-line comparison of the maintenance measurements

with the reference values of this particular battery site. First load the BatAlarm program

to your notebook computer, then load the reference file for this particular battery site (the

reference file you created using the BatHandler program). Connect the RS-232 cable

from the notebook computer to the DC-Source Tester. The cable can be up to 15m long.

Let us assume at this particular battery site, batteries N=50 to 80 are installed.

Consequently the reference file numbering also ranges from N=50 to 80. First select

memory location N=050 on your DC-Source Tester using the INCR=10 and INCR=1

menu. Now you are ready for on-line testing. Measure battery N=50 and send the data to

the notebook computer by pressing the STORE key. The new measurement is instantly

compared to the reference value N=050. If voltage and Riare within specified limits (you

set the allowable tolerances yourself), two large green dots will be displayed. If one limit

is violated one large red dot is displayed. If both limits are exceeded two large red dots

will appear. Based on the displayed warnings you can take immediate action. For

example, you may mark a battery for servicing or for replacing. Pressing the STORE key

not only transfers data to the notebook computer it also stores data in the tester and

increments the internal memory counter N by 1. Therefore, after transferring the data of

battery N=50, the tester is ready to measure battery N=51. As described above you

continue up to the last battery N=80. The measurement of a battery parameters and its data

transfer to the notebook computer takes not more than 2 seconds.

1-12

The BatAlarm program offers the most efficient way to test batteries. In addition you

have stored long-term data in your notebook computer. You can print these data to be

used for your ISO9000 / 14000 quality assurance system, or you can perform statistics

using a spreadsheet program such as EXCEL.

15. INSTALLATION AND DESCRIPTION OF WINDOWS

SOFTWARE

15.1. Installation and Overview

I Distribution Kit for Win95/98NT

The software package includes 3 disks. To install the software on your PC or

notebook computer insert the first disk into your drive and double click the setup

icon. Follow the installation instructions.

Copy the file “serpdrv” into the new installed directory.

II Make sure that the number setting of your PC is set to decimal point (not comma!).

You can check it here:

START →Settings →Control Panel →Regional Settings →Numbers →

Decimal Point.

III After installation you find the following executables:

•

••

•BatHandler Reads the data stored in the DC23 memory to your PC.

Triggers a measurement from your PC, or provides a display.

•

••

•BatAnalyze Compares your measurements to the reference files and provides

a fast battery condition overview.

•

••

•BatAlarm Compares current measurements with your reference values.

IV For proper communication between your Infratek 23 DC-Source Tester and your

PC/Notebook computer, use a regular 9-pole D-Sub RS-232 cable (1 to 1

connection, no pins are crossed out). Connect the cable to the tester and the PC and

run the program you wish to use.

1-13

15.2. BatHandler Program

With the BatHandler program you can download measurement data to the PC, trigger a

measurement to read data, or just read the display of the tester.

First set the COM-Port in the mask, choose a command from the menu and press START.

To trigger a measurement for example just select “Trig Measurement” and press the

START button. To read the display values use “Read Display” and press START.

To read out the stored values from the DC 23 Battery Tester choose “Read Memory”, set

your desired battery numbers at the Start/End fields (max. 1 to 500) and press START.

You will be asked then to create a filename for your data If you have taken, for example,

an initial (first time) measurement from your battery system define the file as “reference

file - system XY” or “master file - system XY”.

The next measurement (6 months later for example) can be stored using the same

procedure but name it this time “June 1999” - system XY” or “measurement 1 - system

XY”; which allows you to generate one file for each measurement procedure. Now you

can compare the new measurement file with the reference file using the BatAnalyze

program . A red dot indicates that a battery exceeds voltage- or Rilimits.

BatHandler

The program asks "Choose file to write". Type your filename. The data will be stored in a

spreadsheet compatible mode.

1-14

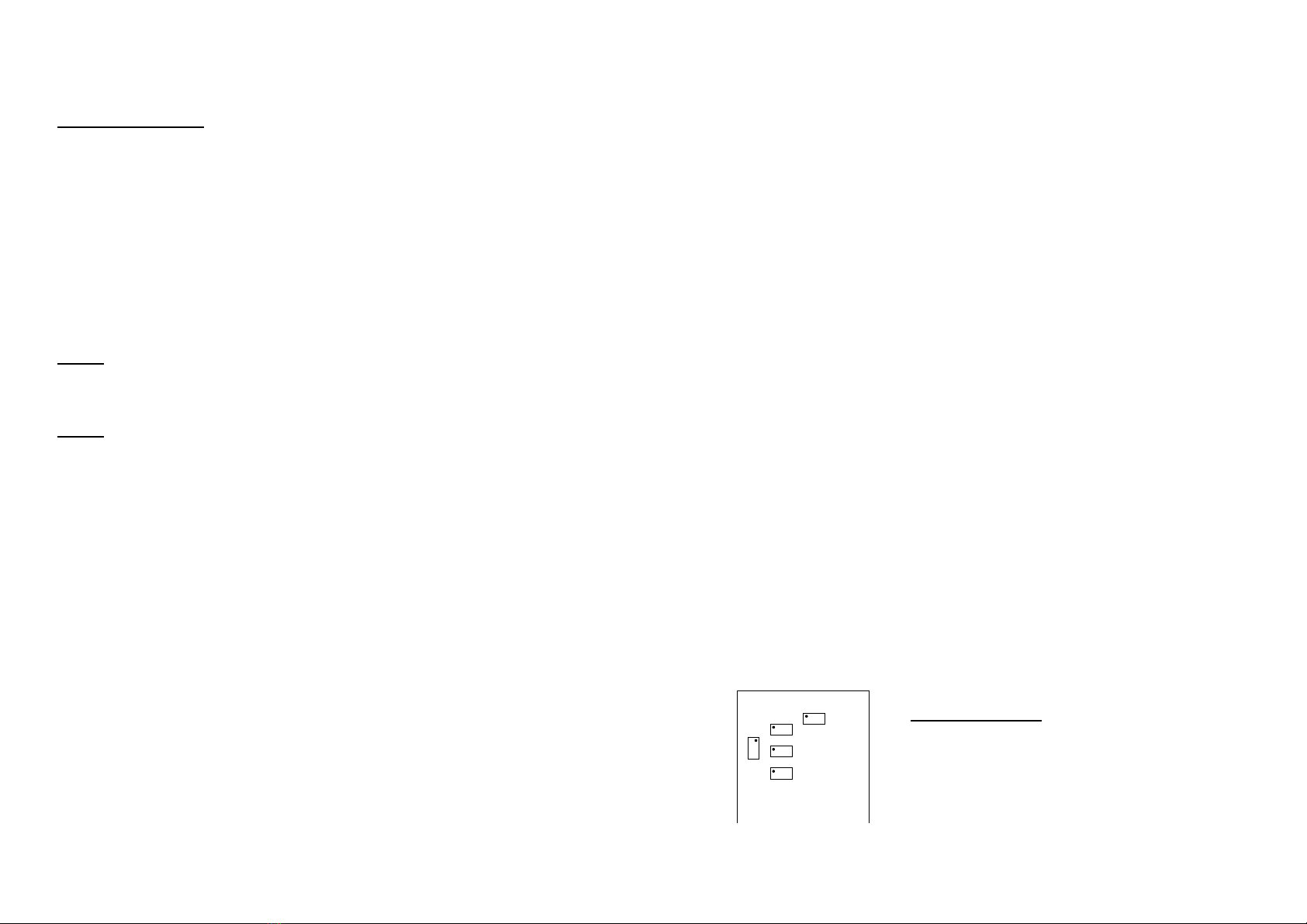

•Menu bar;

•Start/End fields (max. 1 to

500);

•Display field;

•COM-Port number;

•START button;

•STOP button;

•Scheme.

In the display field battery data are

listed in the order you have stored them

in the tester.

To define a Reference-Battery-File

there are two possibilities:

!Make an initial measurement from

your battery system and declare it

as your reference file;

!Use a text editor and write a new

file which is based on a primary

measurement of the battery system.

!When you had to replace a battery

by a new one, measure it after

installation, and edit the existing

reference file with the new

reference value.

1-15

15.3. BatAnalyze Program

1-16

15.4. BatAlarm Program

The BatAlarm program allows on-line battery testing. The notebook computer is

connected to the DC-Source tester. Measurements are directly transferred to the notebook

computer and are instantly compared to the reference values.

Simply connect the DC23 Battery Tester with a serial interface cable to your notebook

computer, select the COM-Port and select the reference file and you are ready for testing.

There is a large variety of RS-232 cables with different lengths to give sufficient range to

move. (1 to 1 connected)

Caution:Before you make measurements set the tester memory location N to the

first battery number. Also, the numbers N in the reference file must

correspond to the battery number N.

With the BatAnalyze program you

can compare new measurement data

against the reference file. You can

set the allowable tolerances yourself

based on your quality assurance

system.

The result signs show, ordered by

the battery number, GOOD with a

green and FAIL with a red

indicator.

Follow the instructions given at the

bottom of the screen to obtain quick

answers about battery condition.

In the tolerance fields you set your

own battery fail criteria.

An increase of Ri by 40 % at same

charging state roughly corresponds

to a battery capacity decrease by 40

%. This slow aging normally takes

place over a number of years.

Reference File

Actual Measurements

Alarm Display (Bat-Nr., Voltage,

Resistance)

Tolerance Selectors

Actual measurement field;

Tolerance for Voltage (in %);

Tolerance for Resistance (in

%);

Number of Batteries to test (1-

9999);

COM-Port number;

Number of battery being

tested.

Large battery condition

indicators: Red = Fail

Reference file with original

battery data

1-17

Measurement procedure:

1. Switch on the DC23 Battery Tester and load the BatAlarm program on your PC;

2. Connect the DC23 Tester to the PC or notebook computer with a one to one

connected RS-232 interface cable;

3. Set the V_tol and Ri_tol values;

4. Insert the number of batteries to test;

5. Set the COM-Port number;

6. Run the BatAlarm program;

7. Choose the reference file to load and define a file to store the current measurements;

8. Set the tester memory location N to the number of the first battery. This number is

equal to the N of the first reference value.

9. Press the Rikey to start a measurement;

10. Press the STORE key to transfer the data to the notebook computer or PC.

If the DC23 Battery Tester is set to AUTO operating mode you don't have to press any

key - just connect the test clips to the battery. From now on every new battery

measurement is compared with its individual reference value. If limits are exceeded the

alarm button will turn red.

16. BASICS OF BATTERY MEASUREMENT

In addition to the information given in this manual please also consult the booklet

BATTERY MAINTENANCE, USING THE INFRATEK 23 DC-SOURCE TESTER.

16.1. General Rules

•A battery is an electrical source which can be characterized by its voltage and

its internal resistance Ri. Its energy storage capability is based on chemical

processes.

•The cell voltage of a new cell is equal to within 0.1V. Riof new cells on the

other hand varies up to ±50 %. In general, small cells (1Ah) have a large Ri

(150mΩ) and large cells (1000Ah) have a small Ri(0.12mΩ).

•Over years of operation Riincreases due to aging whereas the cell voltage

hardly changes unless a cell is shorted. An increase of Riindicates a decrease

of battery capacity.

1-18

•A long-term maintenance plan can prevent battery break down by comparing

present voltage- and Rivalues to the individual reference values when the

battery was new or when the maintenance plan was started.

•Take measurements always at same charging condition.

- Stationary batteries: at preset float voltage

- Traction batteries: fully charged

- Car batteries: Any charging condition but use 30A battery load for testing.

16.2. Measure the Stationary Battery and not the Power Supply

Illustrative Example: Consider the following battery back-up system which keeps the

four 12V batteries at a preset float voltage of 54V. The batteries supply the Telecom

System in case of line power failure.

Mobile telephone systems use 100Ah batteries with an Riof approximately 20mΩ. Let us

assume all 4 batteries have an Riof 20mΩ.

Wrong Measurement

When you measure across all 4 batteries, which you could do with the Infratek 23 DC-

Source Tester, the measurement is meaningless because Riis determined by the 1mΩ

source resistance of the power supply.

The tester displays 1mΩ

ΩΩ

Ωif the current supplied to the telecom system is constant. If

the current varies irregularly the display will just indicate meaningless numbers for

Ri.

54V Power

Supply

Internal Source

Resistance

Ri=1mOhm

Telecom

System

Battery 4

Battery 3

Battery 2

Battery 1

Current 10-100A

+

-

1-19

Correct Measurement

Measure one battery at a time starting with battery 1. The Rimeasurement of battery 1

will be 15mΩand not 20mΩbecause in this electrical circuit Riof battery 1 is in parallel

with the series resistance of the other 3 batteries (60mΩparallel to 20mΩ= 15mΩ).

The Rimeasurement is determined mainly by the battery we are testing but it is also

influenced by the other batteries in the system. The same holds true for the measurement

of batteries 2, 3, and 4.

These facts also strongly suggest that individual Rimeasurements should be used to

determine reference values.

Furthermore, by measuring across single batteries the irregular current flowing from the

power supply to the telecom system will hardly affect the Rimeasurement. You will

experience stable Rireadings which are replicable.

Rule 1 When a battery string is connected to a charger or to a power

supply measure the string by dividing it in at least 2 equal sections

and take measurements on these sections.

Rule 2 For the best preventive maintenance of a battery string measure the

smallest accessible unit (cell, 6V block, or 12V block).

16.3. Traction Batteries

Traction or motive batteries come in diverse shapes, sizes, and capacities. The Infratek 23

DC-Source Tester can be used in two ways:

1. Determine whether the battery needs charging. It needs charging when the voltage

is 10 % below the reference value and /or Riis twice the reference value.

2. Determine long-term deviations of voltage and Rifrom the reference values of

fully charged batteries. The battery needs to be serviced or replaced when Rihas

increased by 40 % to 60 %.

Reminder: You have the reference values stored in your tester as described in Section

11 Operating Mode “CMP”.

16.4. Car Batteries

For car battery testing a special car battery tester using a battery load is required because

the problem battery is in an unknown charging condition. This tester does not require you

to remove the battery from the car’s electronics. The test is simple and quick.

1-20

The battery values can be printed for record purposes. For more information refer to

Section 12, Operating Mode “LDT”.

17. SERVICING AND CALIBRATING THE INFRATEK 23 DC-

SOURCE TESTER

If you have trouble proceeding, read Section 17.1. In case you want to calibrate the

Infratek DC-Source Tester or you want to check calibration, read Section 17.2.

17.1. Servicing

Perform the following steps; after each step check the results by turning on the tester.

Step 1: Check battery voltage at start-up. If there is no display replace the instrument

battery.

Step 2: Remove the bottom cover and check all connectors. Move the connectors up

and down in case they are corroded.

Step 3: Check all leads going to the input terminals and to the RS-232 output

connector.

Step 4: You may experience display problems, when the left half of the display is

slightly blue with tester turned on. The contrast of the display can be adjusted

with P5.

17.2. Calibration

The tester is designed for long-term stability. Calibrating the tester once a year is more

than sufficient. The following potentiometers are used for calibration.

P5

P3

P1

P4

P2

Voltage Calibration: Use a DC calibrator.

Step 1: Apply 15V at ±VOLTDC input terminals

Adjust P1 for 15.0V display.

Step 2: Apply 1V. Adjust P2 for 1V. Repeat steps 1

and 2 twice. Check 30V and 99V.

1-21

RiCalibration:Use the 200mΩ( 1 %) 4 pole resistor supplied with the tester. A dual

5V DC power supply that can deliver 2A is needed for Ricalibration.

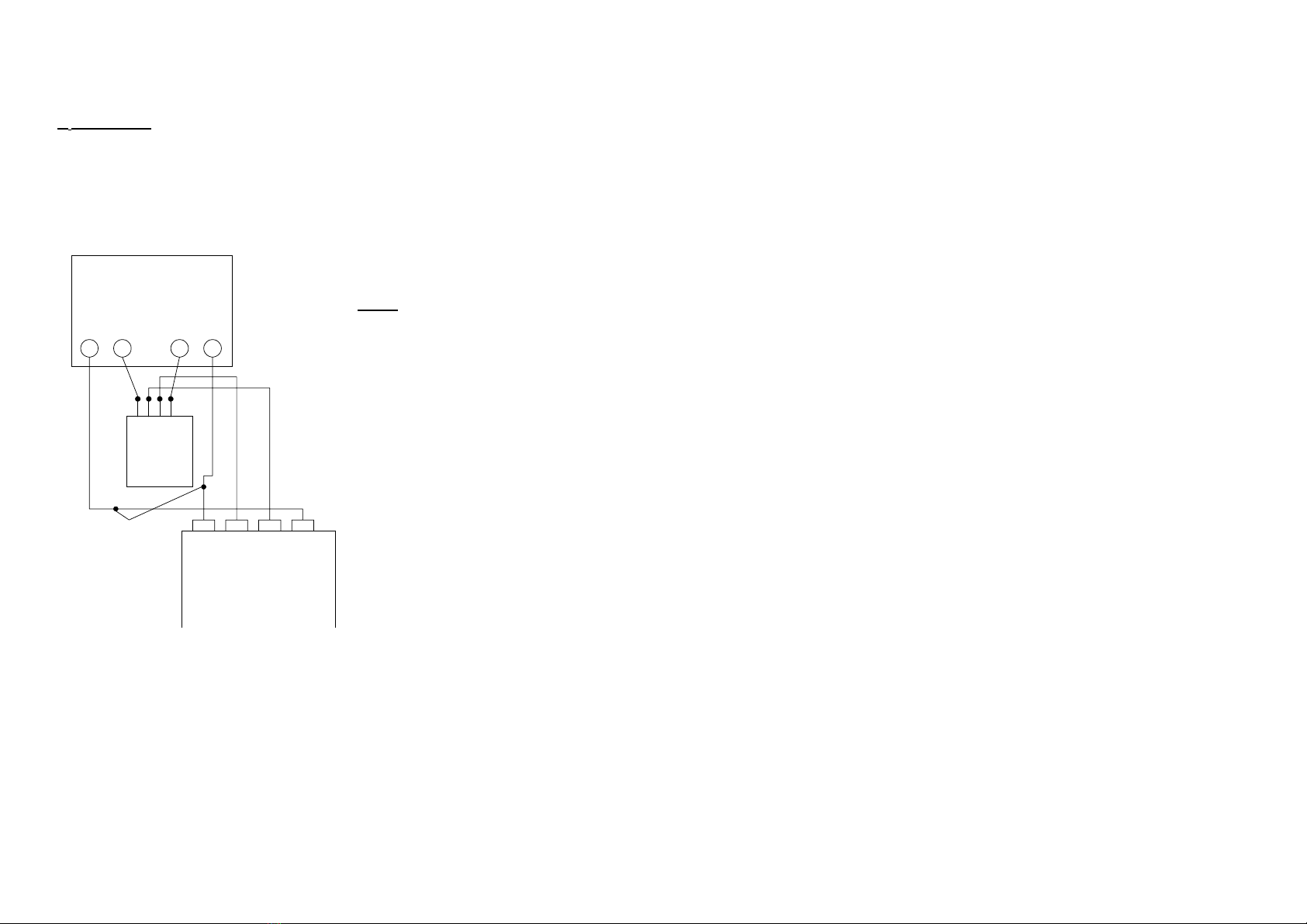

Dual Power Supply

-+

+-

200mOhm

Infratek 23

DC-Source Tester

L=1m

Step 1: Press the Rikey. The tester

measures the 200mΩresistor and

displays the measurement. If the

display is more than 1 digit off adjust

P3. Repeat measurements and adjust

P3 to get a 200mΩreading. All other

ranges are now also within

specification.

This concludes calibration to be

within ±2 %. For better accuracy

determine the precise value of the

1 % 200mΩresistor.

Reinstall the bottom cover.

1-2

2. INTRODUCING THE INFRATEK 23 DC-SOURCE TESTER

4 wire connection to battery or DC power supply

Indicates Operating Mode

MAN: Manual measurement

AUT: Automatic measurement

RD: Read Memory

CMP: Compare Reference

LDT: Load Test

Operating Mode

MAN is the operating mode at

start up.

Starts Ri measurement.

Select MENU

Use SET to increment,

decrement, and select.

Use EXIT to leave menu

selection

Turn tester on

Turn tester off

Battery door at bottom of tester. Remove two M2 screws with screwdriver.

RS-232 Interface connector DB9.

Isolation voltage between tester inputs

and RS-232 output is 1500V.

Connect to label printer or computer.

•Store and print measurement

•Read memory

•Compare against reference value

EU /UE

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DÉCLARATION DE CONFORMITÉ

Wir

We Infratek AG

Nous

__________________________________________________________________________________

(Name des Anbieters) (supplier’s name) (nom du fournisseur)

Weingartenstrasse 6, CH-8707 Uetikon am See

__________________________________________________________________________________

(Anschrift) (address) (adresse)

erklären in alleiniger Verantwortung, dass das Produkt

declare under our sole responsibility that the product

déclarons sous notre seule responsabilité que le produit

INFRATEK 23 DC-SOURCE TESTER

__________________________________________________________________________________

__________________________________________________________________________________

(Bezeichnung Typ oder Modell, Los-, Chargen- oder Seriennummer, möglichst Herkunft und Stückzahl)

(name, type or model, lot, batch or serial number, possibly sources and numbers of items)

(nom, type ou modèle, no de lot, d’échantillon ou de série, éventuellement sources et nombre d’éxemplaires)

auf das sich diese Erklärung bezieht, mit der/den folgenden Norm(en) oder nomativen Dokument(en)

übereinstimmt.

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

auquel se réfère cette déclaration est conforme à la (aux) norme(s) ou autre(s) document(s) normatif(s)

EN 50081-1; EN 50082-2; CEI/IEC 1010-1, Amendment 1/2;

__________________________________________________________________________________

(Titel und/oder Nummer sowie Ausgabedatum der Norm(en) oder der anderen normativen Dokumente)

(title and/or number and date of issue of the standard(s) or other normative document(s))

(titre et/ou no et date de publication de la (des) norme(s) ou autre(s) document(s) normatif(s))

Gemäss den Bestimmungen der Richtlinie(n); following the provisions of Directive(s); conformément aux

dispositions de(s) Directive(s)

(falls zutreffend) (if applicable) (le cas échéant)

89/336/EWG

__________________________________________________________________________________

Uetikon am See, 1.9.1999 Dr. Hans R. Oppliger

__________________________________________________________________________________

(Ort und Datum der Ausstellung) (Name und Unterschrift oder gleichwertige Kennzeichnung des Befugten)

(Place and date of issue) (name and signature or equivalent marking of authorized person)

(Lieu et date) (nom et signature du signataire autorisé) CE-Info/13.01.95/WR

Table of contents