PSL IPC-480V-200A User manual

page 1

Industrial Power Corruptor Manual Rev 1.00

PSLPSL

PSLPSL

PSL

Power Standards Lab

1201 Marina Village Parkway #101

Alameda, California 94501 U.S.A.

TEL ++1-510-522-4400

FAX ++1-510-522-4455

www.PowerStandards.com

IPC-480V-200A

IPC-480V-100A

IPC-480V-50A

IPC-240V-25A

Manual Revision 1.00

User’s Manual

Industrial Power Corruptor

R

absolute-emc.com

Phone:703-774-7505

Sales Partner:

page 2

Industrial Power Corruptor Manual Rev 1.00

WARNING: Death, serious injury, or fire hazard could result

from improper connection or operation of this instrument.

Carefully read and understand manual before connecting this

instrument.

AVERTISSEMENT: Si l'instrument est mal connecté, la mort,

des blessures graves, ou un danger d'incendie peuvent s'en

suivre. Lisez attentivement le manuel avant de connecter

l'instrument.

WARNUNG: Der falsche Anschluß dieses Gerätes kann Tod,

schwere Verletzungen oder Feuer verursachen. Bevor Sie

dieses Instrument anschließen, müssen Sie die Anleitung lesen

und verstanden haben.

ADVERTENCIA: Una conexión incorrecta de este instrumento

puede producir la muerte, lesiones graves y riesgo de incendio.

Lea y entienda el manual antes de conectar.

© 2005 Power Standards Lab. All rights reserved. No parts of this document may be copied, reproduced, or translated to

another language without the prior written consent of Power Standards Laboratory. “Industrial Power Corruptor” is a regis-

tered trademark of Power Standards Lab. “Windows” is a registered trademark of Microsoft.

The information contained in this document is subject to change without notice.

PSL MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

USE.

PSL shall not be liable for errors contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

Printed in the United States of America.

First Printing: June 2003

absolute-emc.com

Phone:703-774-7505

page 3

Industrial Power Corruptor Manual Rev 1.00

Symbol Meaning

Caution. Risk of electric shock.

Caution. Refer to this manual.

Fuse. Replace only with indicated rating

and type.

Alternating current

Protective conductor terminal (earth)

Heavy. Risk of injury. Do not attempt to lift

by yourself.

Heavy. Use cart to transport.

Heavy. Lift with a partner.

SYMBOL TABLE

absolute-emc.com

Phone:703-774-7505

page 4

Industrial Power Corruptor Manual Rev 1.00

Table of Contents

1. Overview .......................................................................................................................................................................... 6

1.1 What is an Industrial Power Corruptor? ................................................................................................................. 6

1.2 What is a voltage sag? ............................................................................................................................................ 6

1.3 What is a voltage swell? ......................................................................................................................................... 7

1.4 Why generate sags and swells? ............................................................................................................................. 7

1.5 Why use a multi-channel data acquisition system? ............................................................................................... 7

1.6 Useful technical features of your IPC ..................................................................................................................... 7

1.7 Safety features of your IPC ..................................................................................................................................... 8

2. Testing ............................................................................................................................................................................. 9

2.1 Testing equipment with your Industrial Power Corruptor ........................................................................................ 9

2.2 Pre-test preparation ................................................................................................................................................. 9

2.2.1 Preparing the equipment to be tested ................................................................................................... 9

2.2.2 Safety ..................................................................................................................................................... 9

2.2.3 Unpacking your Industrial Power Corruptor ......................................................................................... 11

2.2.4 Connecting instrument power ............................................................................................................... 11

2.2.5 Connecting to your computer ............................................................................................................... 11

2.2.6 Connecting test power ......................................................................................................................... 12

2.2.6.1 Single-phase power connections ....................................................................................... 13

2.2.6.2 Three-phase delta power connections ............................................................................... 15

2.2.6.2 Three-Phase wye (star) power connections ....................................................................... 17

2.3 Types of testing ..................................................................................................................................................... 19

2.3.1 Choosing the type of test ..................................................................................................................... 19

2.3.2 International standards - a brief introduction ...................................................................................... 19

2.3.3 Voltage sag (dip) / swell immunity testing ........................................................................................... 19

2.3.4 Inrush current testing ........................................................................................................................... 19

2.3.5 Power consumption and harmonic testing .......................................................................................... 20

2.4 Reporting your results ............................................................................................................................. 20

3. Technical Description of your Industrial Power Corruptor ...................................................................................... 21

3.1 General description ............................................................................................................................................... 21

3.1.1 Theory of Operation ............................................................................................................................. 21

3.1.2 Major modules ..................................................................................................................................... 22

3.2 Front panel features .............................................................................................................................................. 24

3.2.1 Instrument power switch ...................................................................................................................... 24

3.2.2 PC port ................................................................................................................................................. 24

3.2.3 Circuit breaker control ......................................................................................................................... 24

3.2.4 Sag / Swell - Impulse switch ................................................................................................................ 25

3.2.5 Amplitude dial / display ........................................................................................................................ 25

3.2.6 Duration dial / display .......................................................................................................................... 25

3.2.7 Angle dial / display ............................................................................................................................... 25

3.2.8 Power Standard dial / display .............................................................................................................. 25

3.2.9 Step dial / display ................................................................................................................................. 26

3.2.10 Test Margin button ............................................................................................................................. 26

3.2.11 Phase dial / display ............................................................................................................................ 26

3.2.12 Arm and Fire switches - single sequence .......................................................................................... 26

3.2.13 Test Phases dial / display .................................................................................................................. 27

3.2.14 Arm / Stop and Fire switches - Auto sequence .................................................................................. 27

3.2.15 Meters ................................................................................................................................................ 27

3.2.16 High Voltage Input Channels ............................................................................................................. 28

3.2.17 Low Voltage Input Channels .............................................................................................................. 28

3.3 Rear panel connections ......................................................................................................................................... 29

3.3.1 Instrument power ................................................................................................................................. 29

3.3.2 Source and load connections .............................................................................................................. 29

3.3.3 Main circuit breaker ............................................................................................................................. 29

3.3.4 Triggers in/out BNC connectors (panic, arm, and sag) ....................................................................... 30

absolute-emc.com

Phone:703-774-7505

page 5

Industrial Power Corruptor Manual Rev 1.00

3.3.5 RJ-45 rear panel communications ports ............................................................................................. 30

3.3.6 Analog outputs ..................................................................................................................................... 30

3.3.7 Motor drive for circuit breaker (optional) ............................................................................................. 31

3.3.7 Impulse generator connectors (optional) ............................................................................................. 31

3.5 Software ................................................................................................................................................................ 32

3.5.1 Brief description ................................................................................................................................... 32

3.5.2 System Requirements .......................................................................................................................... 32

3.5.3 Installation ............................................................................................................................................ 34

3.5.4 Planning your test ................................................................................................................................ 35

3.5.4.1 Starting the IPC software ................................................................................................... 35

3.5.4.2 If you can't connect ............................................................................................................ 35

3.5.4.3 Setting up your testing session .......................................................................................... 36

3.5.5 On-screen meter .................................................................................................................................. 37

3.5.6 Triggering, selecting channels, and downloading ............................................................................... 38

3.5.7 Power flow analysis option .................................................................................................................. 40

3.5.7.1 Power flow meters .............................................................................................................. 41

3.5.7.2 Oscilloscope / spectrum analyzer ...................................................................................... 43

3.5.7.4 Vector scope ...................................................................................................................... 45

3.5.7.5 Power flow recorder ............................................................................................................ 46

3.5.8 ChannelScope II ................................................................................................................................. 47

3.5.9 FlowScope ........................................................................................................................................... 50

Appendix A - Status messages ....................................................................................................................................... 51

Appendix B - Specifications - general ............................................................................................................................ 54

Appendix C - Specifications - Maximum allowable current ........................................................................................ 56

Appendix D - Theory of Operation .................................................................................................................................. 58

absolute-emc.com

Phone:703-774-7505

page 6

Industrial Power Corruptor Manual Rev 1.00

1. Overview

1.1 What is an Industrial Power Corruptor?

An Industrial Power Corruptor produces bad quality electric

power, reliably and repeatedly.

Power from a clean source, such as your electric company, passes

through your IPC. Your IPC then adds disturbances - sags, swells,

interruptions, etc. - that reproduce disturbances that occur in the

real world. You use this disturbed power to test your equipment, to

verify that your equipment is rugged enough to tolerate power

disturbances.

Because all power for your equipment passes through your IPC,

you can use its optional Power Flow Analysis package to measure

and record all of your electric power parameters, including inrush

current, kWh, power factor, etc.

Your IPC includes many tools that make it easier to diagnose

power disturbance problems, including a 31-channel digital

oscilloscope, many pre-connected meters, and a waveform display

program that zooms, converts to true-RMS, and has graphs that you

can copy and paste into reports.

The optional Power Flow Analysis package adds a real-time

spectrum analyzer, harmonics meters, power flow meters, and a

superb power flow recorder for analyzing energy consumption of

your load.

Although your IPC has many safety features, such as ground

current detection, overtemperature sensors, overvoltage sensors, and

overcurrent breaker trips, testing with electric power is always

dangerous. Do not operate your IPC unless you have the training

and skill to do so. Be careful.

1.2 What is a voltage sag?

A voltage sag, or dip, is a brief reduction in RMS voltage on an

AC power circuit. Typically, a voltage sag duration is between one

cycle and a few seconds; longer events are usually called

“undervoltages”.

Common causes of voltage sags include distant faults, or short

circuits, on a utility power grid; sudden, large increases in current,

typically caused by a motor starting or a large electronic load being

connected; and voltage regulation faults.

Voltage sags can disrupt sensitive electronic equipment in four

different ways. First, there may not be enough energy available during

a voltage sag to continue to operate all, or part of, the equipment.

Second, a circuit within the equipment may detect the voltage sag

and consequently decide to shut down the equipment, whether that

action is appropriate or not. Third, a voltage sag on one phase of a

three-phase system can trip phase unbalance or phase rotation relays.

And fourth, the end of the voltage sag often involves a rapid increase

in line voltage, which can inadvertently trip the equipment’s “power-

on-reset” circuits.

These are difficult problems to diagnose, because they happen at

random times, and they are generally very brief. The symptom is

often simply that the sensitive equipment misbehaves, or malfunctions,

for no apparent reason.

Use your IPC to verify that your sensitive electronic

equipment can tolerate power disturbances.

A typical voltage sag, generated by the IPC. The top

graph shows the voltage waveform. The middle graph

shows the current drawn by the load. The bottom

graph shows the load's internal DC bus, which

collapsed during the sag. All of these graphs were

recorded by the IPC’s internal data acquisition system.

absolute-emc.com

Phone:703-774-7505

page 7

Industrial Power Corruptor Manual Rev 1.00

1.3 What is a voltage swell?

A voltage swell is the opposite of a voltage sag. It is a brief increase

in RMS voltage on the AC power circuit.Although the negative impacts

of small voltage swells are rare, certain types of equipment are highly

susceptible to these fluctuations. As a result, some international

standards also address these types of events.

1.4 Why generate sags and swells?

The simplest way to solve voltage sag and swell problems is to

make your equipment immune to common voltage sag/swell events.

And the simplest way to increase sag/swell immunity is to apply sags

and swells of controlled depth and duration to the equipment, find out

what goes wrong, and fix it.

Your IPC lets you provide poor quality power to your equipment

under test. It can apply sags/swells of controlled depth and duration to

your equipment, and records how your equipment responds.

1.5 Why use a multi-channel data acquisition system?

It isn’t necessary to use a multi-channel data acquisition system

during sag testing, but it helps.

If you simply need to verify that your sensitive equipment can

tolerate a particular range of voltage sags, a data acquisition system is

not necessary. Just apply the sags, and see if your equipment works.

However, if your equipment does misbehave, it is useful to know

exactly what happened. Your IPC contains many channels of high-

speed data acquisition. Some of these channels are permanently

connected to ac power voltages and currents, but many of them are

available for you to use any way you like.

You can use these uncommitted channels to monitor high voltages

and low voltages inside your equipment. Common monitoring points

include power supply outputs, emergency shutdown contacts, reset

lines, and unbalance detection lines.

With the data gathered by your IPC data acquisition system, you

will quickly determine how and why your equipment is misbehaving.

A solution is often easy to design and install, and you can re-test to

verify that you have, in fact, increased your voltage sag immunity.

1.6 Useful technical features of your IPC

Your IPC sag swell generator is unique in that it has been designed

to address a wide variety of testing applications, ranging from a quick

test of a small power supply or relay, to a detailed study of a

sophisticated and complex manufacturing tool.

A patent-pending transformer design enables your IPC to generate

voltage sags, swells, and interruptions, ranging from 0% to 125% of

the nominal voltage.

A patent-pending power switching technology combines the best

features of IGBT switches and electromechanical relays. This design

allows for both gapless switching and long duration events.

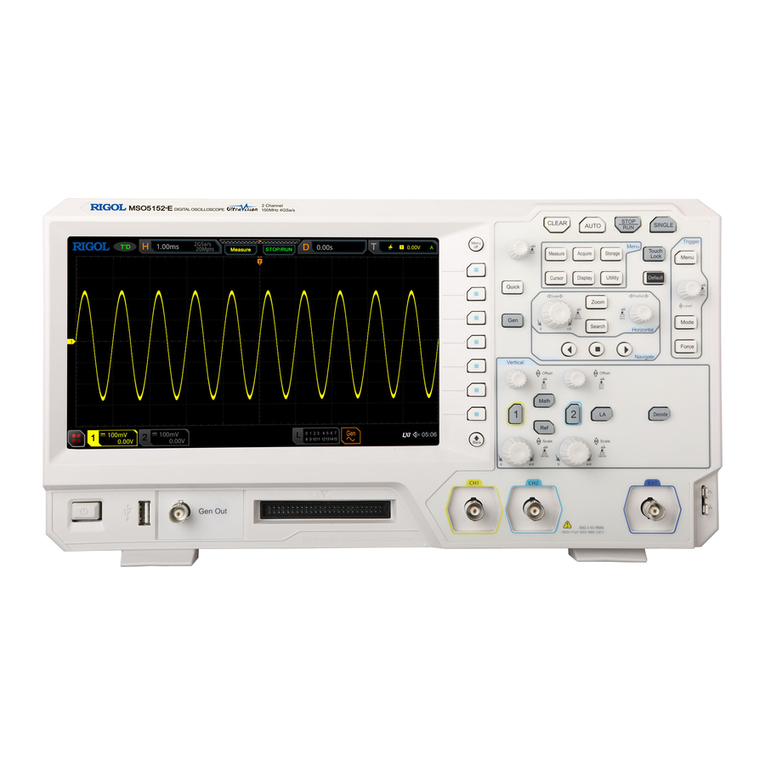

A typical voltage swell, generated by the IPC. The top

graph shows the voltage waveform. The middle graph

shows the current drawn by the load. The bottom

graph shows the response of the load's internal DC

bus.

The IGBT module provides gapless switching during

transitions.

absolute-emc.com

Phone:703-774-7505

page 8

Industrial Power Corruptor Manual Rev 1.00

The IPC main circuit breaker can be manually tripped

using the large red mushroom switch. The trip current

for this breaker can also be set using the Trip Current

dial. For more information, see the Appendix.

True (not simulated) phase-to-phase sags and swells can be

generated.

The front panel of your IPC is packed with an extensive array of

control and monitoring functions. The Disturbance Settings section

on the front panel lets you set depth, duration, angle, and phase

settings for your event. It also allows you to select multiple steps in

a predefined test recipe.

The three sets of front panel meters let you select which of the

30 channels of data you wish to display directly on the IPC. Each set

of meters also includes displays for minimum and maximum reading.

There are 9 external analog input channels on the front panel of

your IPC. Three of these channels are +/- 600V ac or dc, and the

remaining 6 channels are +/- 100V ac or dc. These inputs can be

extremely valuable when you attach them to various locations on

the equipment being tested.

On the rear panel, your IPC has 9 channels of isolated, scaled,

low-voltage outputs that you can connect to external data acquisition

systems, such as strip chart recorders and oscilloscopes. This feature

lets you externally monitor the voltage and current channels internal

to the IPC. An output signal notifies your external system that a sag

is about to begin.

1.7 Safety features of your IPC

Your IPC sag swell generator has many built-in hardware and

firmware safety features:

The internal design and an integrated circuit breaker determines

the maximum current rating or your IPC. You can, however, use the

front panel dial to select a lower current to trip the breaker. This

feature improves safety when testing a low current devices.

You can trip the circuit breaker manually using the large red

mushroom switch on the front panel.

If you have the Motor Operator option installed, you can also

reset the circuit breaker from the button on the front panel, rather

than having to reach back to the high voltage area at the rear of your

unit.

Your IPC continually monitors many internal conditions, both

in standby and event mode. Voltage, current, transformer temperature,

relay temperature, IGBT temperature, and ground current are just

some of the variables that are continually monitored.

Depending on the severity of the fault state, your IPC will respond

by tripping the breaker, halting or preventing an event, or just

notifying you on the front panel display.

absolute-emc.com

Phone:703-774-7505

page 9

Industrial Power Corruptor Manual Rev 1.00

2. Testing

2.1 Testing equipment with your Industrial Power

Corruptor

Use your Industrial Power Corruptor to test equipment that your

have designed or purchased. You can test for immunity to voltage

sags or swells, measure start-up current surges, and - with the IPC's

Power Flow Analysis option - verify power factor, harmonics, and

power consumption.

2.2 Pre-test preparation

2.2.1 Preparing the equipment to be tested

Before you even connect your Industrial Power Corruptor,

you should prepare the equipment that you want to test, which

is commonly referred to as the Equipment Under Test or EUT.

1. Verify that your EUT is working properly. Run it through

a complete operating cycle, and solve any operating

problems.

2. Before doing any testing, write down what you mean by

"Pass" and "Fail". For example, if your EUT misbehaves

during a voltage sag but recovers, does it pass or fail?

What if it shuts down, but can be re-started just by pushing

a button? What if it continues to operate, but goes slightly

out of spec? How far out of spec must it go to be a failure?

3. Gather all the details about the EUT: model number, serial

number, nominal power requirements, etc. You will need

this information for the setup form in the IPC software.

4. Gather all the information about the test participants.

Again, you will need this information for the setup form.

5. Although it is unlikely, it is possible for the EUT (or

materials being processed by the EUT) to be damaged

during testing. Make sure that all participants understand

the risks.

6. Determine how to shut power off for the EUT. Find a

back-up method of shutting power off.

7. Prepare a way of inserting the IPC between the power

source and the EUT. This may be as simple as an extension

cord, cut in the middle, or it may be as formal as a carefully-

wired junction box.

8. Designate a single individual who is responsible for safety.

Make sure everyone involved in testing knows who it is.

Follow that individual's instructions.

2.2.2 Safety

You are working with dangerous high voltage and high

current. Follow industry-standard safety precautions. Do

not connect your IPC unless you are qualified to do so.

The advice that follows does not supersede your own

organization's safety standards. Local safety standards, and

industry safety standards, take priority. The advice in this

section is a supplement to industry and local safety standards.

Whether testing high-power industrial equipment, or

low-power benchtop equipment, always follow the

same safety procedures.

The wiring for inserting your IPC can be as simple as

an extension power cord, broken in the middle, or as

sophisticated as a formal junction box such as this

one.

absolute-emc.com

Phone:703-774-7505

page 10

Industrial Power Corruptor Manual Rev 1.00

It is a very good idea to prepare a written check-list. Use

it every time you begin a new test.

Prior to connecting your IPC:

1. Verify exit locations.

2. Locate the nearest fire extinguisher.

3. Find the nearest telephone, and identify the emergency

telephone number. Write down your location, and place

the note near the telephone.

4. Determine what safety equipment is required: insulating

mats, insulating gloves, goggles, hard hats, etc.

5. Determine what dangerous gases, liquids, or chemicals

are present.

6. Determine what physical risks are present: falling objects,

pinch points, etc.

7. Determine what alarms may sound during testing, and

find out what the appropriate reaction is to each alarm.

8. Assign responsibilities to each member of the test team.

Never test alone.

9. Make sure there is unobstructed access to an emergency

power off location, upstream from your IPC location. Verify

that each member of the test team knows where it is, and

how to operate it.

10. Make sure there is unobstructed access to a secondary

emergency power off location, upstream from the

emergency power off location, and that each member of

the test team knows where it is and how to operate it.

11. Verify the current limiting device ratings (circuit breaker

or fuse), including the speed at which it operates.

12. Inspect the IPC. Do not use it if there is any visible

damage, especially to the high voltage terminals. Do not

use it if there are any rattles or loose connections.

13. Turn off and lock out the power source.

14. First verify that your multimeter works, by testing it on a

live circuit. Then verify that there is no voltage between

each pair of power conductors, and between each power

conductor and earth.

15. Inspect each power conductor that will be used during

the test. Is the power conductor cross-section adequate

for the available current? Look for broken, nicked, cracked,

or damaged insulation.

16. Make the power connections. Verify that all connectors

are appropriately tight. Tug on each connection to verify

it is mechanically secure. Mechanically anchor all power

cables so that no physical strain can be placed on the

connections during testing. Block physical access to any

exposed wiring.

17. Have each member of the test team independently verify

that the connections are correct prior to applying power.

The final verification should be made by the individual

responsible for safety.

absolute-emc.com

Phone:703-774-7505

page 11

Industrial Power Corruptor Manual Rev 1.00

2.2.3 Unpacking your Industrial Power Corruptor

Your IPC is a sensitive and calibrated piece of electronic

test equipment. It is also heavy, which can lead to damage if

not handled with extreme care. Your IPC is shipped to you in a

custom wooden crate with supportive packing.

Do not discard the crate and packing material! Always use

the crate, every time your IPC is shipped. If not transported in

this manner, your IPC has no protection from vibration or shock.

To remove your IPC from the crate, orientate the crate with

the lid (with securing bolts) facing up.

Unscrew the wing nuts holding the lid in place.

Remove the lid, and then remove any accessories in the

smaller side compartments. The compartment may be covered

by a lid with a finger hole.

A lifting strap is provided. Loop this through the upper

handle, and lift the IPC from the crate using a forklift or similar

lifting device. Or orient the crate so that you can gently slide

your IPC from the crate onto a flat surface.

If your IPC is to be hand-carried, ensure that two people

lift the unit using the handles on the side of the case.

2.2.4 Connecting instrument power

Plug the AC power cord (provided with your IPC) into the

AC inlet, labeled "Instrument power", on the back of your IPC.

Plug the other end into a 100 - 240Vac power source. Turn on

your IPC with the front panel "Instrument Power" switch.

2.2.5 Connecting to your computer

To operate your IPC you must first connect it to a computer

running the IPC software.

If you have not yet loaded the IPC software (contained on

the CD provided with your IPC), read and follow the instructions

in the software section of this manual.

Find the RJ-45 jack, labelled “PC Port”, on the lower left

of the front panel of your IPC.

Use the cable and adapter provided with your IPC to connect

your IPC to the DB-9 serial port on your computer.

If your computer has a USB port, and no 9-pin serial

connection, you will need a USB-Serial adapter. We recommend

using a Belkin model F5U103.

Your IPC weighs 130 lbs. (60kg). You can remove it

from its crate with a forklift, or you can set the crate

on its yellow feet and gently slide your IPC out

horizontally.

Connect one end of the coms cable to the IPC PC Port

on your IPC’

s front panel, near the power switch.

Connect the other end to the serial port on your

computer using the 9-pin adaptor supplied. If your

computer lacks a serial port, use a USB-to-serial

adaptor (use Belkin model F5U103).

absolute-emc.com

Phone:703-774-7505

page 12

Industrial Power Corruptor Manual Rev 1.00

2.2.6 Connecting test power

You will insert your IPC between your main source of power

and the equipment you plan to test.

On the rear of your IPC, find the 10 large gray terminal blocks,

five labelled “from SOURCE” and five labelled “to LOAD”.

Use these terminal blocks to connect the source side power

connections (conductors from your mains panel) and load side power

connections (conductors to the equipment you plan to test).

You can connect single phase, three-phase delta, or three-phase

Y power, depending on what your equipment under test (EUT)

requires for operation. The terminal blocks are labeled for easy

connection.

See following pages for single and 3-phase connection details.

Typical three-phase source-side connections for a

3-phase delta system. The conductors are large

enough to be securely captured by the gray

terminal blocks.

If your conductors are smaller than 2AWG, use the

provided wire size adapters. Insert the stripped

wire (top) into the adapter, making sure that the

set-screw clamps on the conductor, and that the

insulation is fully inside the black insulating

block. Then install the adaptor into the gray

terminal block. Tug firmly on the wire to verify

that it is mechanically secure.

absolute-emc.com

Phone:703-774-7505

page 13

Industrial Power Corruptor Manual Rev 1.00

2.2.6.1 Single-phase power connections

Follow all local safety codes, practices, and

requirements. They take precedence over the instructions

here.

Always disconnect and lock out power before making

or removing connections to your IPC.

Conductors to the source side terminal blocks of your

IPC should be connected to a power source that is equipped

with a disconnect switch, and with an appropriately sized

current-limiting device (fuse or circuit breaker). Avoid

lengthy conductors between this power source and your

IPC; install your IPC as close as practical to this power

source. Do not block access to the disconnect switch.

Always install protective earth conductors to both

source-side and load-side protective earth terminal blocks

with a cross section adequate to carry all available current.

All conductors connected to the IPC must be stranded,

with insulation temperature rating of at least 105°C, a

voltage rating equal to or greater than the voltage supplied,

and of adequate cross-section for the available current.

Make sure that it is impossible for any person to touch

any bare wires or terminal block contacts after you have

made the terminations.

If you are using wire conductors smaller than #2AWG

(34 mm2), insert the conductor in a wire adaptor provided

with your IPC, then insert the wire adaptor in the IPC

Warning: Death, serious injury, or fire hazard could result from improper

connection of this instrument. The rear of the IPC is a high voltage, high

current area. Follow industry standard safety precautions at all times. Do not

make electric power connections unless you are qualified to do so. Do not

operate this instrument until you have received appropriate training and are

familiar with this entire manual.

absolute-emc.com

Phone:703-774-7505

page 14

Industrial Power Corruptor Manual Rev 1.00

terminal block. Failure to use a wire adaptor will result in poor

clamping to the conductor and dangerous access to high voltage

wires/surfaces.

As a standard practice, mount wire adaptors in any terminal

blocks that do not have conductors inserted. This will prevent

finger access to un-used terminal block contacts.

When you insert larger conductors directly into the terminal

blocks, O-rings or similar protective insulating devices should

be used to ensure that it is impossible to touch bare conductors

or terminal block contacts.

absolute-emc.com

Phone:703-774-7505

page 15

Industrial Power Corruptor Manual Rev 1.00

Warning: Death, serious injury, or fire hazard could result from improper

connection of this instrument. The rear of the IPC is a high voltage, high

current area. Follow industry standard safety precautions at all times. Do not

make electric power connections unless you are qualified to do so. Do not

operate this instrument until you have received appropriate training and are

familiar with this entire manual.

Follow all local safety codes, practices, and

requirements. They take precedence over the instructions

here.

Disconnect and lock out power before making or

removing connections to your IPC.

Conductors to the source side terminal blocks of your

IPC should be connected to a power source that is equipped

with a disconnect switch, and with an appropriately sized

current-limiting device (fuse or circuit breaker). Avoid

lengthy conductors between this power source and your

IPC; install your IPC as close as practical to this power

source.

Always install protective earth conductors to both

source- and load-side protective earth terminal blocks) with

a cross section adequate to carry all available current.

All conductors connected to the IPC must be stranded,

with insulation temperature rating of at least 105°C, a

voltage rating equal to or greater than the voltage supplied,

and of adequate cross-section for the available current.

Make sure that it is impossible for any person to touch

any bare wires or terminal block contacts once the

terminations have been made.

If you are using wire conductors smaller than #2AWG

(34 mm2), insert the conductor in a wire adaptor provided

with your IPC, then insert the wire adaptor in the IPC

terminal block. Failure to use a wire adaptor will result in

poor clamping to the conductor and dangerous access to

high voltage wires/surfaces.

As a standard practice, mount wire adaptors in any

2.2.6.2 Three-phase delta power connections

absolute-emc.com

Phone:703-774-7505

page 16

Industrial Power Corruptor Manual Rev 1.00

terminal blocks that do not have conductors inserted. This will

prevent finger access to potentially high voltage terminal block

contacts.

The sag/swell events will be generated from phase-to-phase.

If you want phase-to-neutral events, connect your IPC for wye

installation (see next page). Do not use the earth conductor as a

neutral.

Three-phase voltage sags/swells and interruptions will cause

phase imbalance as well. Ensure that your equipment is protected

against or can tolerate phase imbalance.

absolute-emc.com

Phone:703-774-7505

page 17

Industrial Power Corruptor Manual Rev 1.00

2.2.6.2 Three-Phase wye (star) power connections

Warning: Death, serious injury, or fire hazard could result from improper

connection of this instrument. The rear of the IPC is a high voltage, high

current area. Follow industry standard safety precautions at all times. Do not

make electric power connections unless you are qualified to do so. Do not

operate this instrument until you have received appropriate training and are

familiar with this entire manual.

Follow all local safety codes, practices, and requirements.

They take precedence over the instructions here.

Disconnect and lock out power before making or removing

connections to your IPC.

Conductors to the source side terminal blocks of your IPC

should be connected to a power source that is equipped with a

disconnect switch, and with an appropriately sized current-

limiting device (fuse or circuit breaker). Avoid lengthy

conductors between this power source and your IPC; install your

IPC as close as practical to this power source.

Always install protective earth conductors to both source-

and load-side protective earth terminal blocks) with a cross

section adequate to carry all available current.

All conductors connected to the IPC must be stranded, with

insulation temperature rating of at least 105°C, a voltage rating

equal to or greater than the voltage supplied, and of adequate

cross-section for the available current.

Make sure that it is impossible for any person to touch any

bare wires or terminal block contacts once the terminations have

been made.

If you are using wire conductors smaller than #2AWG (34

mm2), insert the conductor in a wire adaptor provided with your

IPC, then insert the wire adaptor in the IPC terminal block.

Failure to use a wire adaptor will result in poor clamping to the

conductor and dangerous access to high voltage wires/surfaces.

As a standard practice, mount wire adaptors in any terminal

blocks that do not have conductors inserted. This will prevent

finger access to potentially high voltage terminal block contacts.

absolute-emc.com

Phone:703-774-7505

page 18

Industrial Power Corruptor Manual Rev 1.00

If larger conductors are connected directly into the terminal

blocks, O-rings or similar protective insulating devices should

be used to ensure that it is impossible to touch bare conductors

or terminal block contacts.

The sag/swell events will be generated from phase-to-phase

and phase to neutral.

Three-phase voltage sags/swells and interruptions will cause

phase imbalance as well. Ensure that your equipment is protected

against or can tolerate phase imbalance.

absolute-emc.com

Phone:703-774-7505

page 19

Industrial Power Corruptor Manual Rev 1.00

2.3 Types of testing

2.3.1 Choosing the type of test

Your IPC can perform several different types of electric

power tests: voltage sag and swell immunity, power supply

sustain time after interruptions, unbalance response, inrush

current, and power consumption / harmonics tests.

Often, the most difficult part of testing is connecting your

Equipment Under Test (EUT) and the IPC. Once you have

connected, it makes sense to do as much testing as possible,

even if you don't need all of the data immediately.

2.3.2 International standards - a brief introduction

There are two different approaches to testing your equipment:

you can test your equipment to learn exactly how it performs

(then perhaps improve its performance); or you can test your

equipment to see if it meets or surpasses a standard.

Your IPC has several standard built-in: industry standards,

such as SEMI F47, CBEMA, and ITIC; international standards

such as IEC 61000-4-11; organization standards such as FAA;

and military standards.

If you're not sure what standard to use for voltage sag

immunity, we recommend SEMI F47 as a good general-purpose

standard.

For detailed information about international standards, see

the Appendix or visit www.PowerStandards.com .

2.3.3 Voltage sag (dip) / swell immunity testing

For this type of testing, you use your IPC to create sags and

swells with controlled depths and durations. Use these to verify

that your EUT can tolerate normal sags and swells, or, if it can't,

to figure out why and fix it.

You choose the depth, duration, phase angle, and (for

polyphase systems) conductor pair where the sag or swell will

be applied. Then arm and fire your IPC, and see how your EUT

responds.

Typically, you will connect test leads to the front panel

channels on your IPC, and clip them to power supplies or other

signals inside your EUT. Then when you download the

waveforms from your IPC, you will be able to see exactly how

your power supplies respond during sags.

One typical problem occurs after voltage sags: the EUT

draws large amounts of current, and blows fuses or trips breakers.

Your IPC will automatically record the current waveforms drawn

by your EUT before, during, and after the sag.

2.3.4 Inrush current testing

Many electronic devices draw large amounts of current when

power is first applied. Your IPC can generate 1-phase and 3-

phase interruptions, and can record the current when power is

re-applied.

absolute-emc.com

Phone:703-774-7505

page 20

Industrial Power Corruptor Manual Rev 1.00

Your IPC can also control the phase angle where power is

re-applied. On three-phase systems, this phase angle can be

specified for any voltage conductor pair.

You can specify the duration of the interruption. It should

be long enough to allow the EUT's capacitors to discharge, motors

to slow down, etc.

You may want to manually re-trigger your IPC's data

acquisition system near the end of the interruption; otherwise,

you will have a lot of uninteresting data that simply shows that

there was no power.

Your IPC records the current waveforms; the ChannelScope

II software can convert these waveforms into true RMS, the

usual way of looking at inrush current.

2.3.5 Power consumption and harmonic testing

Your IPC's optional Power Flow Analysis option can be used

to record power consumption and harmonic currents in a variety

of ways.

It is optimized for recording power flow parameters in

industrial processes: kV

A, kW, kWh, kVAR, PF, THD, etc.

Your IPC can also show you real-time oscilloscope screens

and spectrum analyzer screens, which can be connected to any

of the voltage or current channels inside your IPC. Use these

screens to track changing harmonics and verify power system

waveforms.

Use your IPC's VectorScope to visually verify phase rotation,

and voltage and current unbalance.

2.4 Reporting your results

We recommend using Microsoft Word for writing your reports that

explain your results. Your IPC produces graphs and text that can be

copied and pasted into any compatible Windows application.

Most IPC graphs can be optimized for screen or printer. And many

IPC graphs include text details that show exactly when the data was

recorded, on what equipment, by whom. Just use the "Event details"

pull-down option.

Your IPC's Power Flow Analysis option produces power consumption

graphs that paste directly into SEMI E6 reports. These graphs show

exactly how much energy your industrial process consumes while

producing a single unit. They are ideal for optimizing the energy

consumption in your process.

Your IPC is designed to support third-party certification. By filling

out the Setup Test form in your IPC's software package, and carefully

downloading and recording your results after each event, you can

generate a complete set of files that will allow a third-party certification

lab to review and certify your tests. Check with your third-party

certification lab, or with Power Standards Lab at

www.PowerStandards.com , to see how you can meet their requirements.

absolute-emc.com

Phone:703-774-7505

This manual suits for next models

3

Table of contents

Other PSL Test Equipment manuals

Popular Test Equipment manuals by other brands

Performance Tool

Performance Tool W89746 owner's manual

unix Corporation

unix Corporation TTCG - 01B Instrument manual

Major tech

Major tech MT310 instruction manual

Keysight Technologies

Keysight Technologies 8494 Operating and service manual

Mastech

Mastech MS7222 operating instructions

Keysight Technologies

Keysight Technologies 16034E Operation and service manual