7

Danger

Please utilise extreme caution when performing work within the compressor. Wear appropriate PPE

(Personal Protective Equipment), follow lock out-tag out procedures, and ensure all safety procedures.

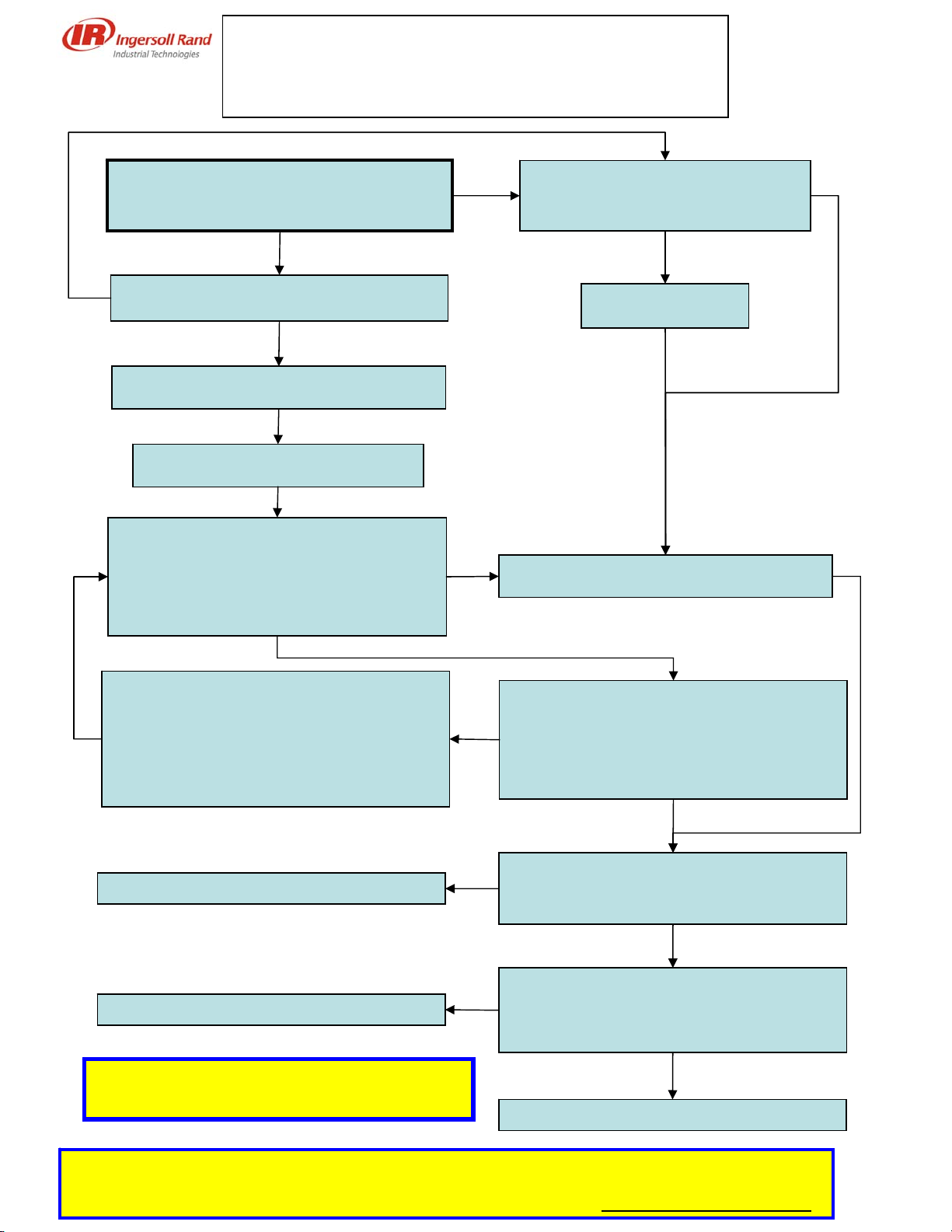

Compressor Trips on “Sec Disable” while

technician on site? – Toggle switch still on

“start” position and E-stop pulled ?

Check connections on E-stop (ESA1

and ESA2) – Connections OK?

No

Do not touch the toggle switch nor the E-stop.

8.09=“enable”? (8.02 must be=“active”)

Yes

Fix connection

No

Problem likely to be linked to: E-Stop / Wiring

or connection issues

No

Yes

Switch the toggle switch to the stop

position

Turn toggle switch to “stop” – Push & pull the

E-stop 10 times – Read 8.09 after each try

8.09 = “Enable” when E-stop pulled

& 8.09 = “Disable” when E-stop pushed ?

(Note : the “sec. disable” will be reset after

the first sequence of push/pull)

Problem may occur only when compressor is

running

Yes

Yes

Disconnect ESA1 & ESA2 so that the E-Stop is

no longer connected to the pins 13 & 14 –

Make contact between these two connectors

8.09 = “Enable” when ESA1 & ESA2 are in

contact

& 8.09 = “Disable” when no contact?

No

E-stop does not work properly – Change E-

Stop and restart the procedure

(with a multimeter, you can check the

resistance between ESA1& ESA2 Must read 0

ohm when the E-stop is pulled and OL ohm

when the E-stop is pushed)

Yes

Remove drive cover and check connections

(especially pins 13 & 14) – Connections loose

or misconnected cables?

No

Tighten the cables and re-conduct procedure -

Problem solved? (8.09 = “Enable” when E-stop

pulled out

& 8.09 = “Disable” when E-stop pulled in)

Yes

Contact IR customer’s service

No

Contact IR customer’s service No

Problem was due to misconnected cables Yes

“SECURE DISABLE” FAULT TREE

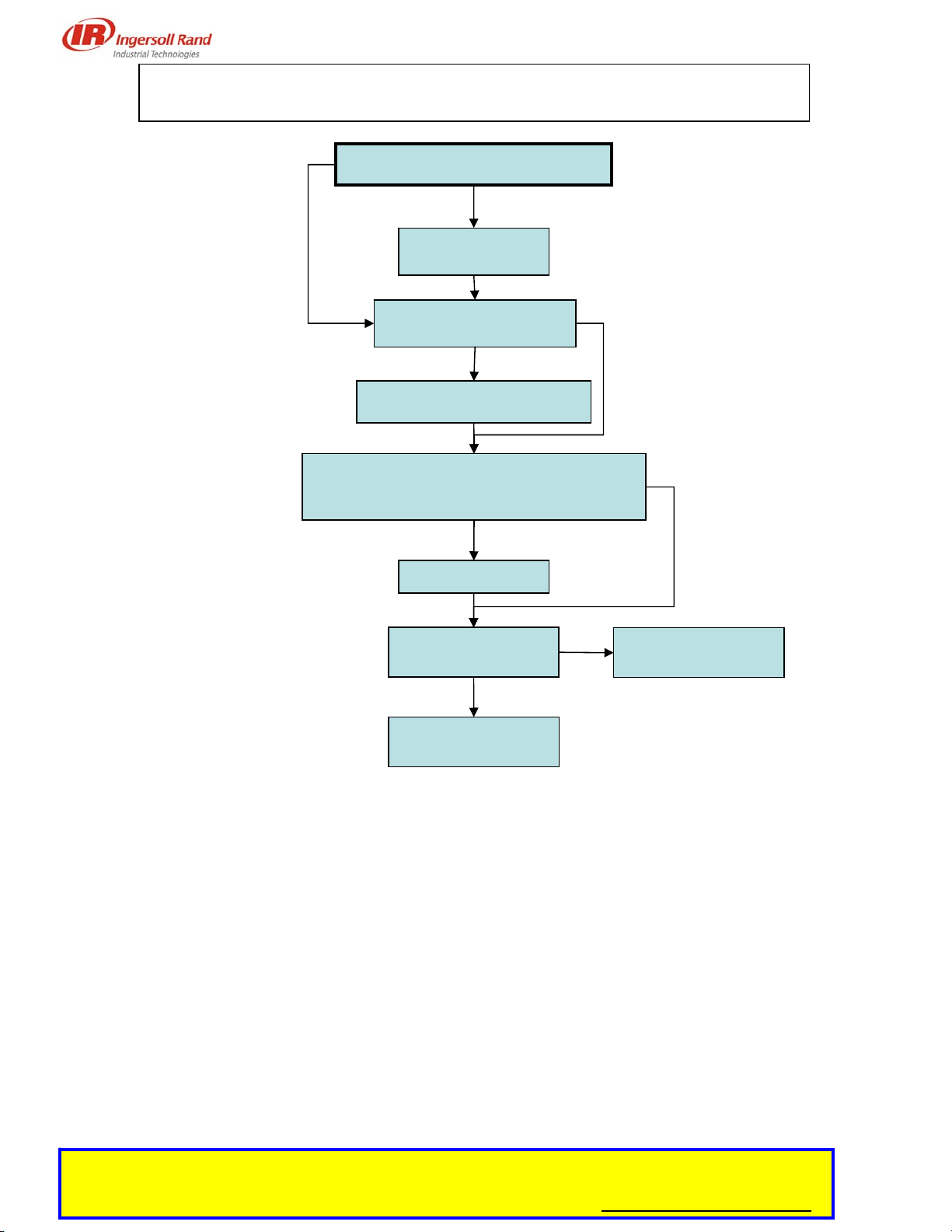

Unit trips while running

Power outage is unlikely

More than 3 consecutive “sec.disable” fault in the memory

See Appendix 1 for detailed explanation

on Sec Disable fault message