16575268_ed2 5

Start the Adjusting Nut (214), indented side rst, onto the Holder

and run it nger tight against the compression of the Spring.

Install the Bit Holder Stop (216) in the groove.

Assembly of the Attachment, Gearing and Motor

109

107

110

105 102

103 111

101

104

106

108

(Dwg. TPC400)

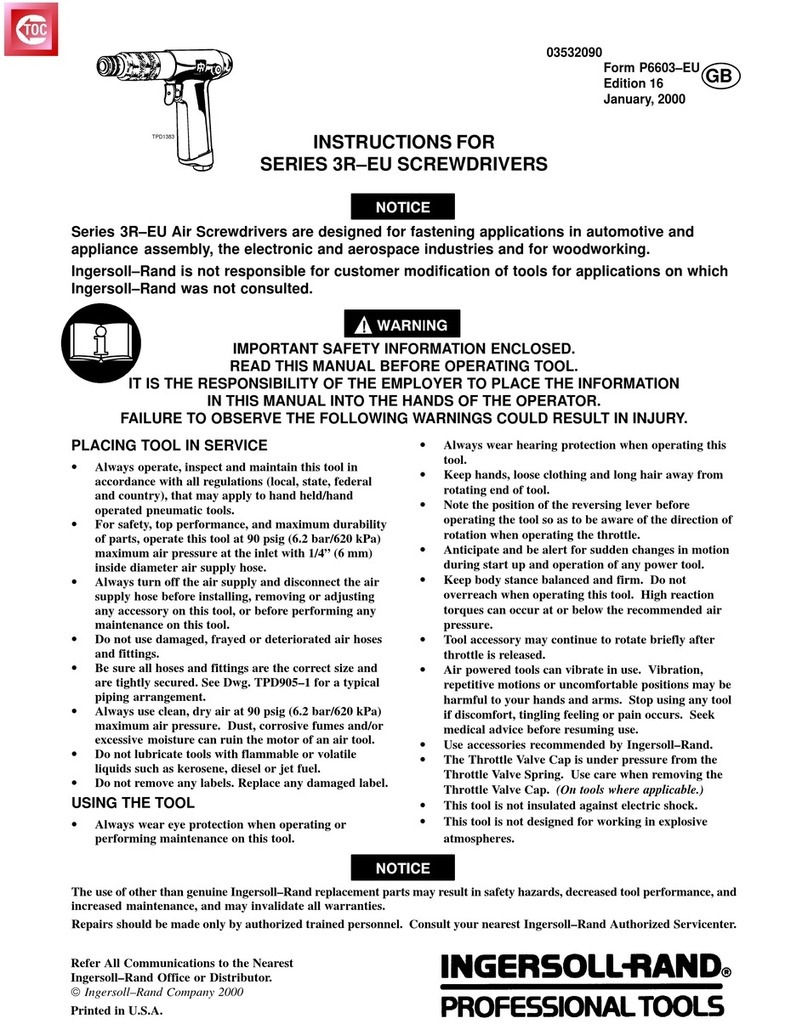

Slip the Rear End Plate (102) on the rear hub of the Rotor (101)

and install the Retainer (103) in the groove.

Hold the Rotor vertically and clamp the short hub in leather-

covered or copper-covered vise jaws.

Insert a Vane (105) in each slot.

Place the Cylinder (104), front end up, over the Rotor and onto

the Rear End Plate. To determine which end of the Cylinder is the

front end, hold the Cylinder horizontally, facing one end. Position

the external groove for the Dowel (110) at the top as shown in

the motor illustration. If the air ports through the cylinder wall

are in the bottom right quadrant, you are facing the front of the

Cylinder. When assembling the motor, be sure to properly install

the Cylinder. The motor will not operate properly if the Cylinder

is inverted.

Slip the Front End Plate (106) over the rotor shaft. Press the Front

Rotor Bearing (108) into the Bearing Housing (107), and slide the

Bearing, followed by the Retaining Washer (109), onto the shaft.

Obtain a sti steel rod 3/32”(2.3 mm) diameter and approximately

10” (254 mm) long to use as an assembly dowel.

Align the dowel groove in the Rear End Plate (102), Cylinder (104)

and Front End Plate (106) with the dowel hole through the Rotor

Bearing Housing (107) and insert the rod.

Enter the Rear End Plate Gasket (111) into the Motor Housing (1

or 51), positioning the Gasket smoothly on the back bore so that

the dowel notch in the Gasket aligns with the dowel hole in the

Housing.

Enter the end of the assembly dowel in the dowel hole and slide

the motor assembly into the Housing. This is a sliding t and if

proper alignment is maintained, the assembly will enter under

only slight nger pressure. Do not drive, or otherwise force the

motor into position.

Replace the assembly dowel with the Cylinder Dowel (110). Make

sure the Cylinder Dowel is entered into and remains in the dowel

hole in the Housing. When in proper position, approximately 3/32”

(2.3 mm) of the Dowel protrudes from the face of the Bearing

Housing. If it is not in the hole, it will protrude approximately

7/32” (5.5 mm).

Work the Seal Support (119), large end rst, over the spindle shaft

and against the gear frame face. Follow with the Seal (120) and

the Grease Shield (121).

Install the Spindle Bearing (122), sealed side rst, over the spindle

shaft. Firmly support the Spindle (118) and press, do not drive,

the Bearing into position using an arbor that will contact only the

inner ring of the Bearing.

Slide the Ring Gear (112) into the Motor Housing (1 or 51), making

sure the Cylinder Dowel (110) enters one of the notches in the

end of the gear.

For N or J ratio, slide the Rotor Pinion Spacer (113) followed by

the Rotor Pinion (114) onto the spline shaft on the Rotor (101).

5.

6.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

For N ratio, slide a Gear Head Planet Gear (116) (13 teeth) onto

each of the three gear shafts on the Gear Head (115). Enter the

assembly into the Ring Gear (112) and slide it into engagement

with the Rotor Pinion. Slip the Bearing Retainer Washer (117) over

the spline on the Gear Head.

For all ratios, slide a Spindle Planet Gear (123) onto each of the

three gear shafts on the Spindle (118) and slide the assembly

into the Ring Gear and into engagement with the Rotor Pinion

or Gear Head.

In N ratio, a Gear Head Planet Gear (116) has 13 teeth and a

Spindle Planet Gear (123) has 14 teeth. Do not mix, mismatch

or switch locations with these small gears when reassembling

a Tool.

17. For Screwdrivers with No. 5C1, 5C3 or 5P1 Attachment, slide

the Clutch Driver (206 or 401) onto the Spindle (118) and install

the Retainer (207 or 402) in the groove.

For Screwdrivers with No. 5P1, Attachment, slide the Front

Jaw (406) onto the Bit Holder (407) and install the Front Jaw

Retainer (405) on the Bit Holder.

18. For Screwdrivers with 5C1 or 5C3 Attachments, slip the

Disengaging Plunger (222) and Plunger Spring (223) into the Bit

Holder (208) making sure the Plunger slides freely.

For Screwdrivers with 5P1 Attachments, slip the Plunger

Spring (404) and Disengaging Plunger (403) into the Bit

Holder (407) making sure the Plunger slides freely.

19. For Screwdrivers with 5C1 or 5C3 Attachments, enter the

opposite end of the Spring into the spindle bore while entering

the end of the Clutch Housing (201) into the Motor Housing

(1 or 51).

For Screwdrivers with 5P1 Attachments, enter the opposite

end of the Plunger into the spindle bore while entering the end

of the Clutch Plunger (409) into the Motor Housing (1 or 51).

For Screwdrivers with 5D1 Attachments, slide the Bit Holder

(303) onto the Spindle (118) while entering the end of the Clutch

Housing (305) into the Motor Housing (1 or 51).

20. Using a wrench, snug the Coupling Nut onto the Motor Housing.

Bump the back of the Motor Housing to seat the internal parts as

the Coupling Nut is tightened.

21. When the Coupling Nut is snug, connect an air supply line to

the Inlet Bushing (18 or 71) and check performance. If the Tool

does not function properly, loosen the Nut and realign the

components. If the Tool does function properly, tighten the Nut

to a minimum of 25 ft-lb (33 Nm) torque.

15.

16.