AF0475LXXXXXX-XX-X Page 3 of 4

PUMP DISASSEMBLY

NOTE: All threads are right hand. Disconnect air supply

and relieve all system pressure prior to servicing. Carefully

remove the parts, inspect for damage, nicks or excessive wear

and determine if any parts will need replacement.

1. Clamp (2) extension tube horizontally in a vise. Unthread

from air motor base. Take care to support motor weight

until the connecting rod is also disconnected.

2. Pull (1) connecting rod up until ats for 5/8” wrench are

exposed.

3. Use 5/8” wrench flats on each rod to unthread (1) con-

necting rod from the air motor rod.

4. Clamp (4) lower tube horizontally in a vise. Use a rod

or pipe to unthread and remove (8) primer tube. Allow

primer (9) to pull (12) spacer sleeve, (13) gasket and (14)

valve seat out of the (8) primer tube as it is being re-

moved.

5. Remove (10) retainer ring and unthread (9) primer from

(7) primer rod.

6. Remove (11-18) from (6) primer rod.

7. Remove (15) truarc ring, releasing (16) “U” cup. NOTE: Do

not remove (17) guide unless replacement is necessary.

8. With (4) lower tube still clamped horizontally in a vise,

unthread and remove (2) extension tube and (19) gasket.

9. Using a the 5/8” wrench ats on the (1) connecting rod

and the 3/4” wrench flats on the plunger (3), unthread

and remove the (1) connecting rod from the (3) plunger.

NOTE: Do not damage the o.d. of (3) plunger in any way.

10. Using a 5/32” diameter rod in the cross hole of (9) primer

rod and the 3/4” wrench ats on the plunger, unthread

and remove (9) primer rod, releasing (6) ball and (5) ball

stop.

PUMP REASSEMBLY

NOTE: Replace all soft parts with new ones included in

the repair kit. Refer to the illustration (Figure 2, page 2) for

“U” cup seal direction.

1. Assemble (5) ball stop and (6) ball into (3) plunger,

securing with (7) primer rod. NOTE 1: Torque (7) primer

rod to 50-60 ft lbs (67.8-81.3 Nm). NOTE 2: Items 3-7 are

not individually serviceable but must be replaced as an

assembly (97365).

2. Thread (1) connecting rod to (3) plunger, using 5/8” and

3/4” wrench ats respectively. NOTE: Tighten (1) con-

necting rod to 50-60 ft lbs (67.8-81.3 Nm).

3. Assemble (17) guide and (16) “U” cup into (18) valve

body, securing with (15) truarc ring. NOTE: Assemble

chamfered corner of (17) guide into (18) valve body rst.

4. Assemble (11) guide washer and (15-18) foot valve as-

sembly onto (7) primer rod.

5. Assemble (12) spacer sleeve, (13) gasket, and (14) valve

seat into (8) primer tube.

6. Thread (8) primer tube to (4) lower tube and hand

tighten.

7. Push piston assembly down as far as possible and thread

(9) primer onto (7) primer rod, securing with (10) retainer

ring.

8. Assemble (19) gasket and (2) extension tube to (4) lower

tube and hand tighten.

9. Ensure (91415) packings (3x), (90142) washer, (90143)

spring, and (90140) washer are secure inside of (AF0465)

air motor base.

10. Pull (1) connecting rod up until ats for 5/8” wrench are

exposed.

11. Using the 5/8” wrench ats on (1) connecting rod and

the air motor rod, thread and tighten. NOTE: Torque (1)

connecting rod to 50-60 ft lbs (67.8-81.3 Nm).

12. Assemble (2) extension tube to air motor base. Clamp

base horizontally in vise and tighten (8) primer tube to

340-360 ft lbs (461.0-488.1 Nm) in order to tighten tub-

ing components simultaneously.

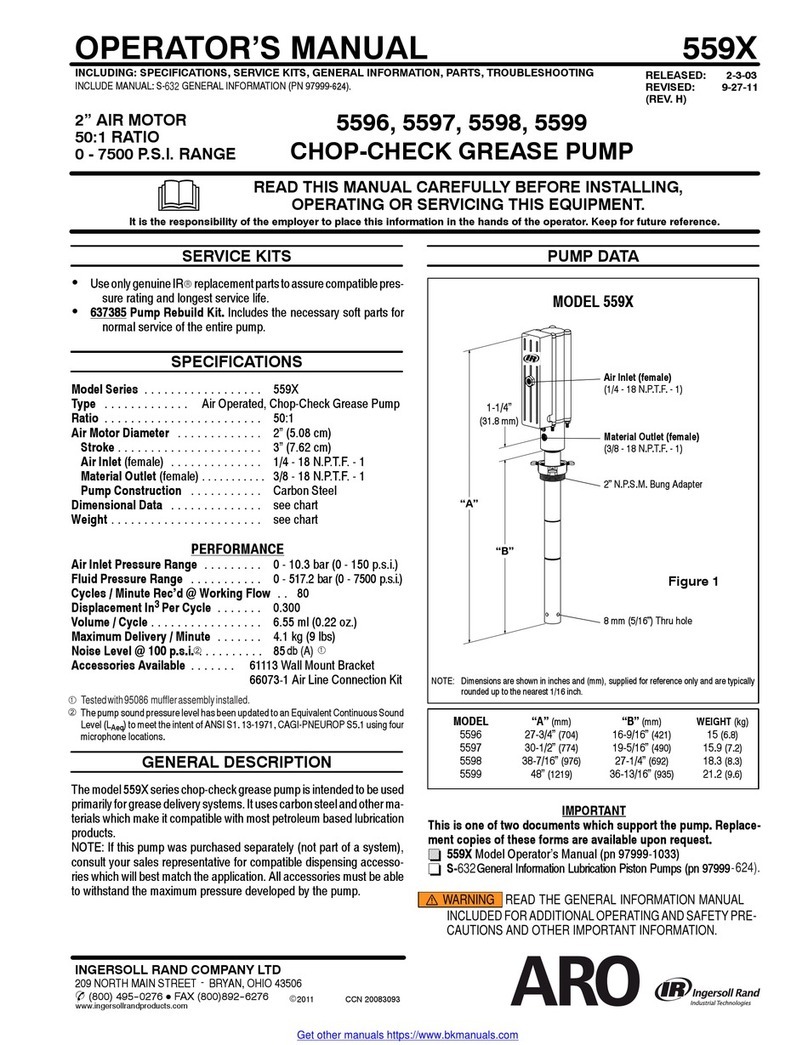

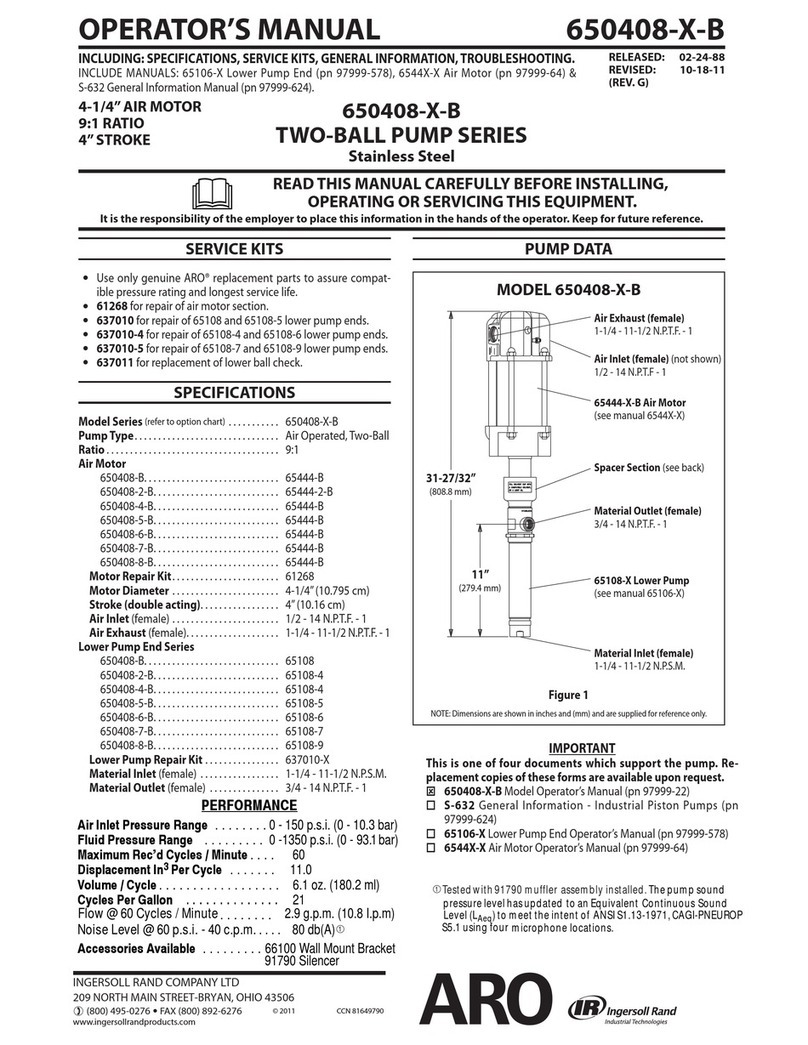

DIMENSIONS

AIR INLET

61°

CENTERLINE OF

MATERIAL OUTLET