OPERATOR’S MANUAL AND SALES AND ENGINEERING DATA

INCLUDING: SPECIFICATIONS, SERVICE KITS, GENERAL INFORMATION, PARTS, TROUBLESHOOTING.

INCLUDE MANUALS: AF04XX-XX Air Motor (pn 97999-1466) & S-632 General Information Manual (pn 97999-624).

RELEASED: 9-15-10

(REV. 01)

AF0409AX3XXXX-XX-X

Basic Oil Pump

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

The original language of this manual is English.

4-1/4” AIR MOTOR

9:1 RATIO

4” STROKE

PUMP DATA

SERVICE KITS

Use only genuine ARO® replacement parts to assure compat-

ible pressure rating and longest service life.

637489 for repair of AF044X-XX air motor.

637486 for lower end pump.

65823 packing kit assembly.

SPECIFICATIONS

Model Series

(refer to option chart)

. . . . . . . . . . . AF0409AX3XXXX-XX-X

Pump Type. . . . . . . . . . . . . . . . . . . . . . . . . Air Operated, Two-Ball Pump

Drum Size. . . models AF0409AX3P31 . . . . Remote Mounting

models AF0409AX3P34 . . . . 16 gallon

models AF0409AX3P35 . . . . 55 gallon

Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9:1

Air Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AF044X-XX

Motor Repair Kit. . . . . . . . . . . . . . . . . . . . . . . 637489

Motor Diameter . . . . . . . . . . . . . . . . . . . . . . . 4-1/4” (10.8 cm)

Stroke (double acting). . . . . . . . . . . . . . . . . 4” (10.2 cm)

Air Inlet (female) . . . . . . . . . . . . . . . . . . . . . . . 1/2 - 14 NPTF - 1

Air Exhaust (female). . . . . . . . . . . . . . . . . . . . 1-1/4 - 11-1/2 NPTF - 1

Material Outlet (female) . . . . . . . . . . . . . . . 3/4 - 14 NPTF

Lower End Pump

models AF0409A13XXXX . . . . . . . . . . . . . . 60873

models AF0409A43XXXX. . . . . . . . . . . . . . . 65033-1

models AF0409A53XXXX. . . . . . . . . . . . . . . 65033

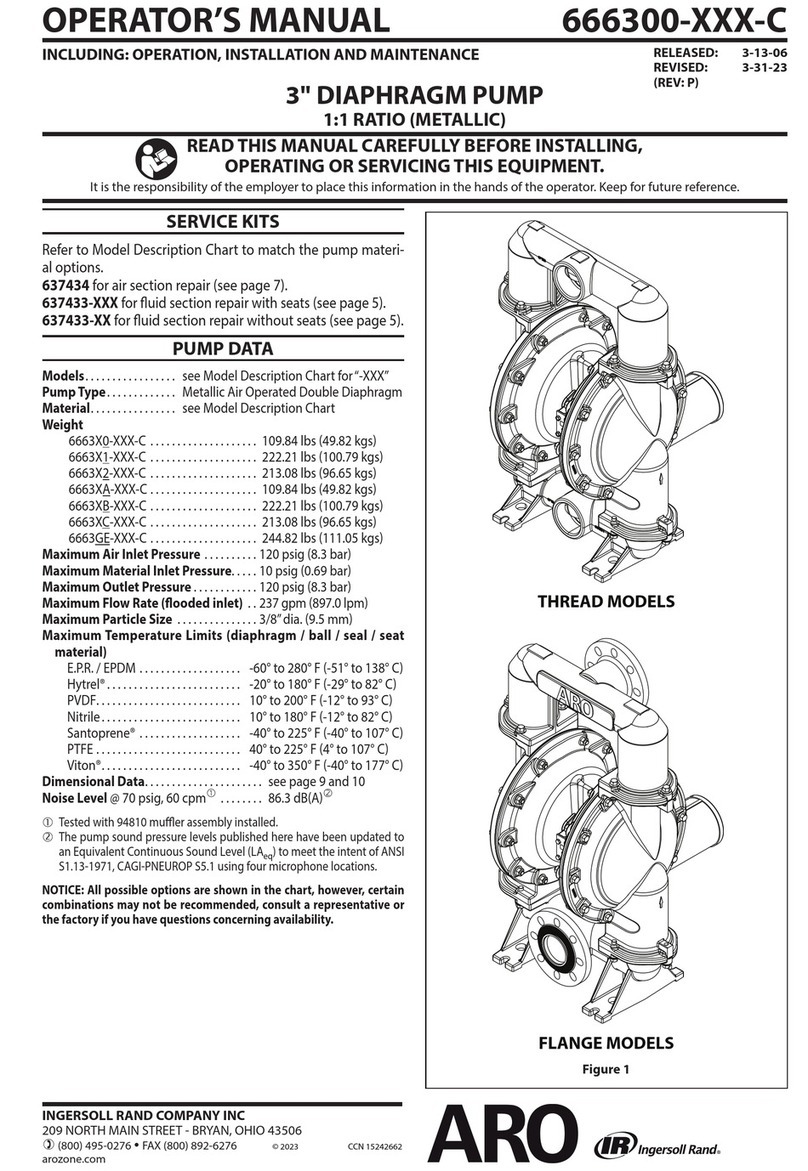

Dimensional Data. . . . . . . . . . . . . . . . . . . . . . . . see gure 1

PUMP PERFORMANCE

Air Inlet Pressure Range . . . . . . . . . . . 0 - 150 p.s.i.g. (0 - 10.3 bar)

Fluid Pressure Range . . . . . . . . . . . . . . 0 - 1350 p.s.i.g. (0 - 93.1 bar)

Maximum Rec'd Cycles / Minute . . . . . . . . . 75

Displacement In. Per Cycle . . . . . . . . . . . . . . 12.0

Volume / Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.65 oz. (196.8 ml)

Cycles Per Gallon . . . . . . . . . . . . . . . . . . . . . . . . 19.2

Maximum Working Flow Rate. . . . . . . . . . . . 3.9 g.p.m. (14.8 l.p.m.)

Noise Level @ 60 p.s.i. - 40 c.p.m. c. . . . . . 81.8 db(A)d

c

The pump sound pressure level has been updated to an Equivalent Continuous

Sound Level (LAeq) to meet the intent of ANSI S1.13-1971, CAGI-PNEUROP S5.1

using four microphone locations.

GENERAL DESCRIPTION

The 9:1 ratio is an expression of the relationship between the eec-

tive air motor area and the eective lower pump area. When 150 p.s.i.

(10.3 bar) of air pressure is supplied to the air motor, the lower pump

end will develop a maximum 1350 p.s.i. (93.1 bar) of uid pressure (at

no ow). As the uid control is opened, the ow rate will increase as

the air motor cycle rate increases to keep up with demand.

y

y

y

y

Figure 1

NOTE: Dimensions are shown in inches and (mm) and are supplied for reference only.

Air Inlet (female)

1/2 - 14 NPTF - 1

Material Outlet (female)

3/4 - 14 NPTF

AF044X Air Motor

(see manual AF044X-X)

Model “A”

(mm)

“B”

(mm) “C” (mm)

AF0409A13XXXX 29.363”

(745.8)

16.613"

(422.0)

15.112"

(383.8)

AF0409A43XXXX 42.376”

(1076.4)

29.626"

(752.5)

28.125"

(714.4 )

AF0409A53XXXX 50.782”

(1289.9)

38.032"

(966.0)

36.532"

(927.9)

AF0409A13XXXX

IMPORTANT

This is one of five documents which support the pump. Re-

placement copies of these forms are available upon request.

:AF0409AX3XXXX Model Operator’s Manual (pn 97999-1490)

S-632 General Information - Air / Hydraulic Operated Piston

Pumps (pn 97999-624)

60873Lower End Pump Manual

65033 Lower End Pump Manual

AF04XX-XX Air Motor Operator’s Manual (pn 97999-1466)

“A”

“B” “C”

Lower End Pump

(see Specications Chart for

details)