LOWER PUMP DISASSEMBLY

LOWER PUMP REASSEMBLY

PAGE 4 OF 4 66266- X

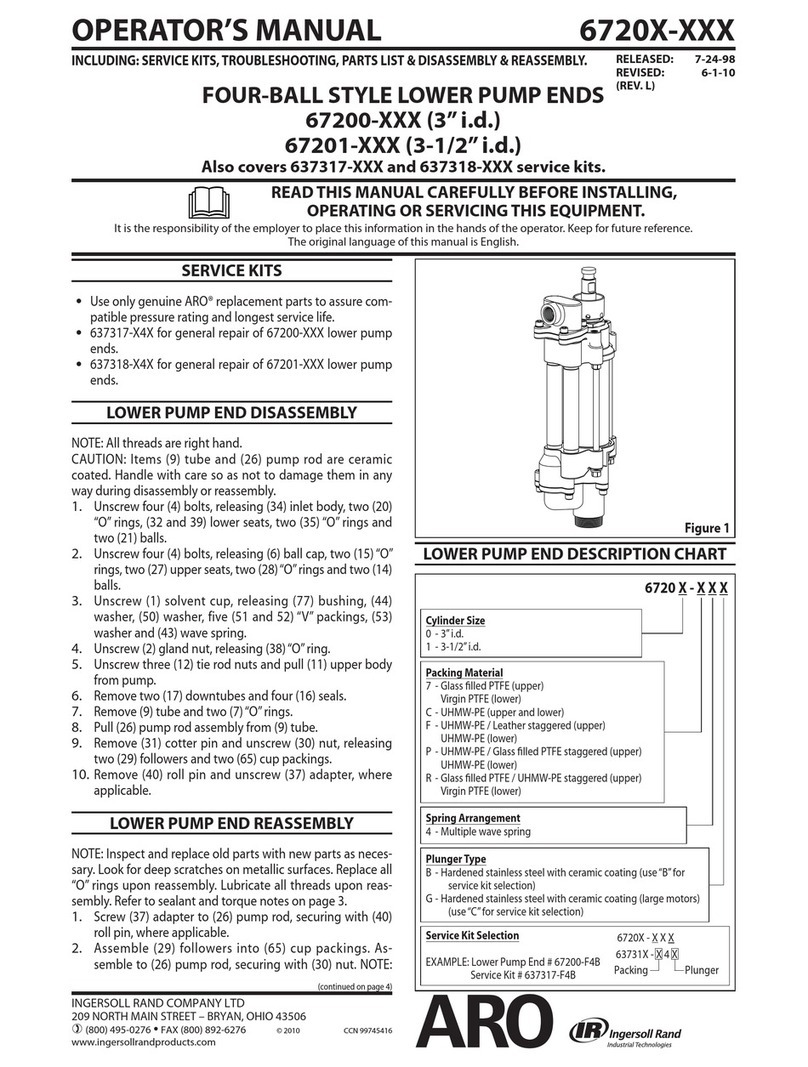

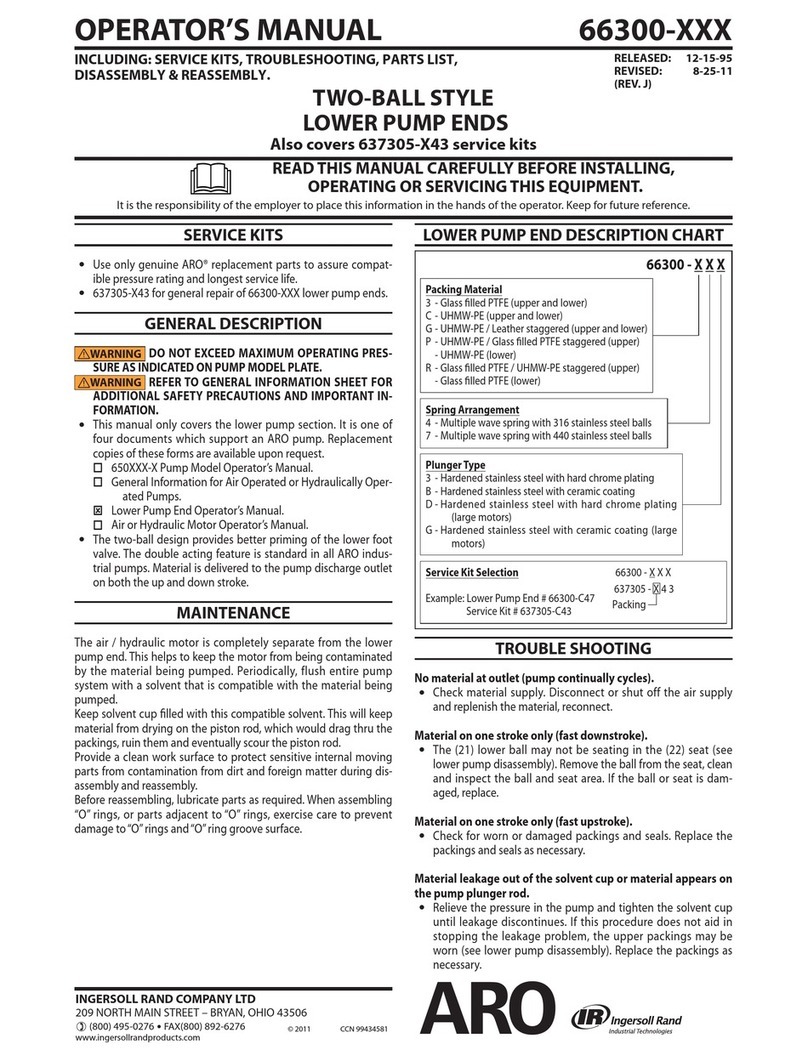

PACKING OPTIONS AND SERVICE KITS

UPPER PACKING MIDDLE PACKING LOWER PACKING

LOWER PUMP SVCE. KIT 51 (X) ‘‘V” PACKING 52 (2) ‘‘V PKG 55 (X) ‘‘V” PKG 59 (4) ‘‘V” PKG 65 (1)‘‘U” CUP

66266- XXX 637074- XXX PART NO (QTY) [MT’L] PART NO [MT’L] PART NO (QTY) [MT’L] PART NO [MT’L] PART NO [MT’L]

- 113, -- 153 -637074- G43 93661- 1 (5) [L] ------- -- 93662- 1 (4) [L] 93678- 1 [L] ------- --

- 313, -- 353 -637074- 343 93661- 2 (5) [T] ------- -- 93662- 2 (4) [T] ------- -- 90911 [T]

- 513, -- 553 -637074- G43 93661- 2 (3) [T] 93661- 1 [L] 93662- 2 (4) [T] ------- -- 90911 [T]

- C13, --C53-637074- C43 93661- 4 (5) [UH] ------- -- 93662- 2 (4) [T] ------- -- 90911 [T]

- D13, --D53-637074- D43 93661- 4 (3) [UH] 93661- 1 [L] 93662- 1 (4) [L] 93678- 1 [L] ------- --

-After May 15, 1995 these models are no longer available. EXAMPLE: 66266- 113 is replaced by 66266- G43 & Service kit is 637074-G43.

Note: All threads are right hand.

1. Remove (6) pump body from (9) suction tube, by sliding it off three

(10) tie rods.

2. Remove (7) gasket from top of (9) suction tube.

3. Remove three (10) tie rods.

4. Pull (9) suction tube off the MIDDLE packing and valve section and

out of (25) adapter.

5. Push (26) plunger rod to expose the primer assembly

6. Remove (33) nut, (32) valve plate and (31) washer from (30) primer

rod.

7. Pull (26) plunger rod and remove MIDDLE packing, valve section

and (30) rod from (15) chamber body.

8. Remove (7) gasket out of (25) adapter.

9. With the aid of a flat bladed screwdriver remove (25) adapter, (21)

valve body, (22) valve seat and two (23) gaskets out of (15) cham-

ber body. Use the flat bladed screwdriver to pry on the slot on (25)

adapter.

10. Remove (24) ‘‘O” Ring from (14) adapter.

11. With retaining ring pliers, remove (37) retaining ring from (21) valve

body, then remove the packings out of (21) valve body.

12. Using provided wrench flats, remove (30) rod from (34) valve rod.

Again, using wrench flats remove (34) valve rod from (26) plunger

rod.

CAUTION: DO NOT mar or damage surfaces of any of these rods.

13. Slide the MIDDLE packing assembly off (34) valve rod.

14. Clamp (34) valve seat in a vise and remove (36) valve seat nut, then

remove the MIDDLE packing assembly off (28) valve seat.

15. Remove (1) solvent cup from (6) pump body. Now remove UPPER

packing assembly out (6) pump body.

Note: All rubber goods and packings should be lubricated with a com-

patible lubricant prior to assembly.

1. Assemble (21) valve body with LOWER packings. Refer to Packing

Options Chart on page 2.

2. Retain LOWER packing assy. in (21) valve body with (37) retaining

ring.

3. Assemble (28) valve seat MIDDLE packings. Refer to Packing Op-

tions Chart on page 2.

4. Secure the MIDDLE packing assy. with (36) valve seat nut.

5. Slide (21) valve body with LOWER packingsonto the end of (30) rod

opposite the wrench flats. Install (21) valve body with the beveled

end onto rod

6. Screw (30) rod into (34) valve body and tighten.

7. Place (24) ‘‘O” Ring on (25) adapter.

8. Slide (25) adapter onto the (34) valve body & (30) rod assy with the

wider diameter opening going on first & fit it over (21) body.

9. Slide (28) valve seat and MIDDLE packing assy over (34) valve

body. Be sure to place beveled end of (28) valve seat against bevel

of (34) valve body.

10. Screw (34) valve body into (26) plunger rod and tighten. Use

wrench flats.

11. Place one (23) gasket inside (15) chamber body, followed with (22)

valve seat with beveled side up. NOTE: If stringy or filled materi

al is being pumped, then reverse the (22) valve seat. Next place

second (23) brass gasket against top of (22) valve seat.

12. Place (26) plunger, (28) valve seat and MIDDLE packing assy along

with (30) rod & (25) adapter assy into (15) chamber body with the

primer rod end going in first.Slide the (25) adapter into place in the

(15) chamber body.

13. Place (7) gasket in (25) adapter.

14. Lubricate the MIDDLE packing assy and the inside of (9) suction

tube. Carefully slide (9) suction tube over (26) plunger and MIDDLE

packing assy into (15) adapter.

15. Install three (10) tie rods.

16. Place (7) gasket on end of (9) suction tube. NOTE: Apply a small

amount of grease on gasket to help keep gasket in place.

17. Slide (6) pump body over (26) plunger rod onto (10) tie rods. Seat

the (9) suction tube into (6) pump body.

18. Assemble the UPPER packing onto the (26) plunger rod and slide

into (6) pump body.

19. Install (1) solvent cup and hand tighten.

20. Push (26) plunger rod to expose (30) rod at bottom of pump. Place

(31) washer, (32) plate with beveled edges away from pump and

(33) nut onto (30) rod. Tighten (33) nut.

21. Push (30) rod until rod is inside (15) chamber body. Tighten (1) sol-

vent cup

.

PN 97999- 057