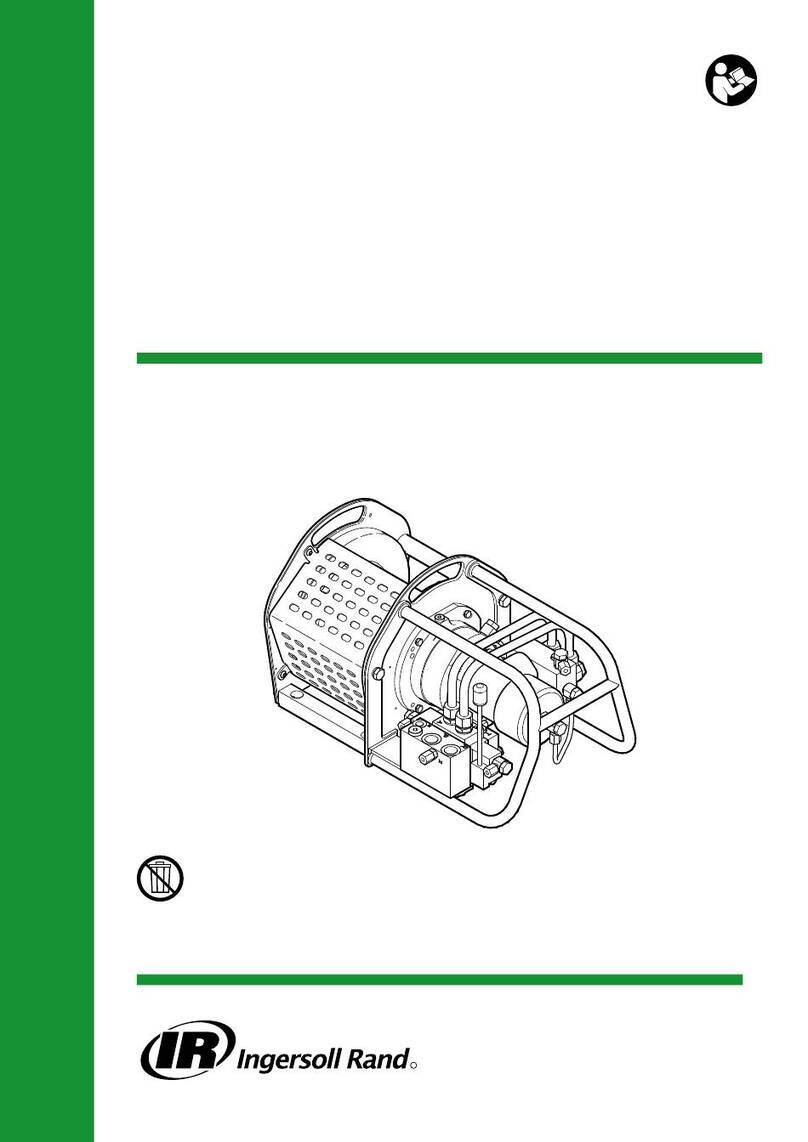

This manual provides important information for all

personnel involved with the safe installation, operation

and proper maintenance of this product. Even if you feel

you are familiar with this or similar equipment, you should

read this manual before operating the product.

Danger, Warning, Caution and Notice

Throughout this manual there are steps and procedures

which, if not followed, may result in an injury. The

following signal words are used to identify the level of

potential hazard.

Danger is used to indicate the

presence of a hazard which will

cause severe injury, death, or

substantial property damage if the

warning is ignored.

Warning is used to indicate the

presence of a hazard which can

cause severe injury, death, or

substantial property damage if the

warning is ignored.

Caution is used to indicate the

presence of a hazard which will or

can cause injury or property damage

if the warning is ignored.

Notice is used to notify people of

installation, operation, or

maintenance information which is

important but not hazard-related.

Safety Summary

l

This winch was designed to meet ANSI A10.22-1990

which limits its use as part of a system for personnel

lifting. There are other components required to

complete the system. It is the users responsibility to

supply all other components necessary to properly

complete the lifting system in accordance with the

regulations that pertain to the lifting application.

l

It is the owner’s and user’s responsibility to check

and to conform to all regulations (local, state, federal

and country) that may apply to the use of a winch or

winch system for lifting and lowering people before

using a Man-Rider@ winch for personnel movement.

l

The supporting structures and load-attaching devices

used in conjunction with this winch must provide an

adequate safety factor to handle the rated load, plus

the weight of the winch and attached equipment. This

is the customer’s responsibility. If in doubt, consult a

registered structural engineer.

Ingersoll-Rand Man-Riders winches are designed and

manufactured to meet or exceed standards and

specifications established for base mounted drum hoists as

defined by ASME B30.7 and for the purpose of personnel

handling as defined by ANSI A10.22 - 1990.

In furnishing customers Man-Rider@ winches,

Ingersoll-Rand does not warrant the suitability of these

winches for any particular use. It is the owner’s and user’s

responsibility to determine the suitability of this winch for

a particular application.

Ingersoll-Rand Man-Rider® winches manufactured to

ANSI A10.22 standards are designed as a component in

the Personnel Lifting System. Ingersoll-Rand approval

for use of this winch in Man-Rider@ applications

automatically terminates for any of the following reasons:

1. Winch is not installed in an approved personnel lifting

system.

2. Winch is not properly maintained in a safe working

condition, with all parts intact and properly adjusted.

3. Winch is used in applications not approved by codes

and regulations, or application is inconsistent with

manufacturer’s operation and maintenance manual.

4. More than one winch is used to attach to a common

load.

5. Winch design or functions are altered or changed in

any manner from the purchased original without prior

approval by Ingersoll-Rand.

This manual has been produced by Ingersoll-Rand to

provide company personnel, dealers, mechanics and

operators with the information required to install, operate,

and maintain the products described herein.

It is extremely important that mechanics and operators be

familiar with the servicing procedures of these products, or

like or similar products, and are physically capable of

conducting the procedures. These personnel shall have a

general working knowledge that includes:

1. Proper and safe use and application of common

mechanics’ hand tools as well as special

Ingersoll-Rand or recommended tools.

2. Safety procedures, precautions and work habits

established by accepted industry standards.

Ingersoll-Rand can not know of, nor provide all the

procedures by which product operations or repairs may be

conducted and the hazards and/or results of each method.

If operation or maintenance procedures not specifically

recommended by the manufacturer are conducted, it must

be ensured that product safety is not endangered by the

actions taken. If unsure of an operation or maintenance

procedure or step, personnel should place the winch in a

safe condition and contact supervisors and/or the factory

for technical assistance.

2