INHECO DWP User manual

Doc ID: 900434-001

March 2018

INHECO Single Position Incubators

Incubator MP / DWP

Part No.: 7300003 / 7300006

Incubator Shaker MP/ Shaker DWP

Part No.: 7300013 / 7300009

INHECO 02

Doc ID: 900434-001

March 2018

INHECO Industrial Heating and Cooling GmbH reserves the right to modify their

products for quality improvement. Please note that such modifications may not be

documented in this manual.

This manual and the information herein have been assembled with due diligence.

INHECO GmbH does not assume liability for any misprints or cases of damage resulting

from misprints in this manual. If there are any uncertainties, please feel free to contact

[email protected]. → How to contact INHECO, page 6.

The brand and product names within this manual are registered trademarks and belong

to the respective titleholders.

INHECO 02

Doc ID: 900434-001

March 2018

Table of Contents

Important Notes ......................................................................................... 03

General Information ..................................................................................... 03

Explanation of symbols................................................................................ 04

Abbriviations and Glossary .......................................................................... 04

Warranty ...................................................................................................... 05

How to contact INHECO .............................................................................. 05

Product Description .................................................................................. 06

Intended Use ............................................................................................... 06

Scope of Supply........................................................................................... 07

Functional Elements .................................................................................... 08

Labels .......................................................................................................... 09

Technical Data............................................................................................. 10

Shaker functionality Incubator Shaker MP / DWP ....................................... 12

Thermal functionality Shaker MP / Shaker DWP ......................................... 13

Safety instructions .................................................................................... 14

Product-specic Risks ................................................................................. 14

Technical Alterations ................................................................................... 15

Malfunctions................................................................................................. 15

Hardware installation ................................................................................ 16

Scope of Supply........................................................................................... 16

Initial Operation............................................................................................ 16

Electrical Details General ............................................................................ 18

Adress Switch .............................................................................................. 19

Connecting devices ..................................................................................... 19

Mechanical Integration................................................................................. 21

Labware Use and Detection ........................................................................ 22

Communication with the Incubator.......................................................... 23

Integration in workstation............................................................................. 23

COM port identication ................................................................................ 23

Example conguration of several Incubators to the USB Host PC .............. 25

Operation.................................................................................................... 26

Typical Process Example for integration in robotic systems........................ 26

............................................................................................... 28

Cleaning....................................................................................................... 28

Decontamination.......................................................................................... 28

Servicing ..................................................................................................... 28

Software updates......................................................................................... 28

Calibration and Adjustment.......................................................................... 29

Trouble-Shooting & Support ........................................................................ 29

Return to INHECO only with RMA Number ................................................. 30

Transportation and Storage ......................................................................... 30

Shut Down and Disposal ............................................................................. 30

Assembling the transportation lock.............................................................. 31

Quality......................................................................................................... 32

Final QS Tests ............................................................................................ 32

Calibration and Adjustment.......................................................................... 32

Automatically self test AQS ......................................................................... 32

Failures ....................................................................................................... 33

Drawer failure ............................................................................................... 33

Accessories................................................................................................ 35

Appendix .................................................................................................... 36

INHECO 03

Doc ID: 900434-001

March 2018

1

1.1. General Information

Read the user instructions completely. The manual explains how to handle the Incubator

DWP, Incubator MP, Incubator Shaker DWP and Incubator Shaker MP (Incubator

devices). For the operation of the Incubator devices a third party workstation software is

strongly recommended. → Communication with Incubator devices®, chapter 5

The manual explains how to handle the INHECO stackable devices.

In case the instructions contained in this manual are not followed, injury or product

damage cannot be excluded.

Missing or insufficient knowledge of the manual leads to loss of liability against

INHECOGmbH.

This manual is part of the Incubator devices and must be retained until the unit is

disposed of and must be passed on with the Incubator device when the unit is taken

over by a new user.

The Incubator devices meet the acknowledged rules of technology and comply with

today‘s standards.

Manual instructions must be followed in order to limit the safety risk during operation of

the unit.

Security-related warnings in this manual are classified into three hazard levels:

- The signal word WARNING indicates hazards which – without precautionary

measures – can result in serious injury or even death.

- The signal word CAUTION is given to indicate hazards which – without precautionary

measures – can result in minor to moderate injuries or could disturb the proper

functioning of the unit.

- The signal word NOTE stands for the general precautionary measures that have to

be taken to avoid damaging the device.

- The signal word NOTICE stands for the general measures that help using the device.

Contact INHECO in case there are any uncertainties of how to operate or how to handle

the Incubator devices.

Your opinion about this manual provides us with valuable insights on how we can

improve this document. Please do not hesitate to direct your comments to

[email protected], → How to contact INHECO, page 6

INHECO 04

Doc ID: 900434-001

March 2018

1.2. Explanation of symbols

Symbol Explanation

A possible danger, leading to serious bodily harm is being pointed out to you.

Caution: hot surface

Excenter within the device

Indication for electrostatic discharge (ESD)

·Bullet points indicates an instruction.

-Hyphens refer to enumeration.

→indicates refer to and are mostly an active link

Blue writing indicates a software button

1.3. Abbriviations and Glossary

The document uses the following terms

CC Communication controller

Controller Microprocessor with on chip peripheral

Cyclic Redundany Check

FCS Firmware Command Set

Heater Same as Temperature Controller

IVD (D) In vitro diagnostic (directive)

Micro Plate

Polymerase Chain Reaction

Pulse-Width Modulation

Shaker Controller for shaker regulation

TBC To Be Continued

Temperature

Controller

Controller for heat regulatioin

Universal Serial Bus

CE Conformity Mark

Nationally Recognized Testing Laboratory

Dynamic Link Library

PC Personal Computer

European Union

SBS Society for Biomolecular Screening

DWP Deepwell Plate

IVD In vitro diagnostics

FDA Food and Drug Administration

DIP Dual In line package

N.A. Not Applicable

Room Temperature

wo without

wwith

INHECO 05

Doc ID: 900434-001

March 2018

1.4. Warranty

The warranty period starts on the date of shipment. Any damage caused by operating

the Incubator device outside the specifications and guidelines leads to the loss of

warranty. Broken seals on INHECO devices lead to the loss of warranty as well.

INHECO will only accept parts / devices for return that do not pose a threat to the health

of our staff. In particular, the devices may not have been used in Biosafety Level 3 and 4

environments, or have been exposed to radioactive or radiation materials. → Cleaning

and Decontamination, page 37.

Devices exposed to Biosafety level 3 and 4 Environments are not accepted by INHECO

for return.

1.5. How to contact INHECO

INHECO GmbH

Address Fraunhoferstr. 11

82152 Martinsried

Germany

Telephone - Sales +49 89 899593 120

Telephone - Techhotline +49 89 899593 121

Fax +49 89 899593 499

E-Mail - Sales [email protected]

E-Mail - Technical -Hotline [email protected]

Website www.inheco.com

Technical Support & Trouble Shooting Instructions:

http://www.inheco.com/service/technical-support.html

INHECO 06

Doc ID: 900434-001

March 2018

2

2.1.

INHECO’s Incubators (Incubator MP, Incubator DWP, Incubator Shaker MP and

Incubator Shaker DWP) are automated and compact single incubating positions for the

use in fundamental research, drug discovery, clinical research and diagnostic

applications in automated liquid handling stations.

The incubators can be used as stand-alone devices or stacked to form a tower. The

flexible design of the incubator devices allow even stacking of different devices in one

tower. The unique vibration reduced shaking principle offers free programmable shaking

curves (orbital, linear, eight, elliptic, etc) and amplitudes. The precise automated drawer

system guarantees a direct and easy access by robotic grippers and pipetting heads.

The Incubator devices have a built-in precise temperature and shaker control (only

shaker devices), plate loading sensors, several test routines and an USB interface for

controlling the devices, enabling the use of the Incubator products in FDA, IVD compliant

environments and applications. Software and verification tools are available to form a

complete thermal solution for all kinds of incubation applications.

The Incubator devices are designed specifically for use in Life Science and In Vitro

Diagnostics. The Incubator devices are prepared for easy integration into IVD

applications, but the final IVD validation has to be performed by the first marketer (IVD

application).

When using the devices of the Incubator family in a Biosafety Laboratory Environment,

the user of the device is responsible for labeling the device according to the WHO

Laboratory Biosafety Manual (ISBN 92 4154650 6). The user is furthermore responsible

for operating the devices of the Incubator family depending on the biosafety level

regulations according to the WHO Laboratory Biosafety Manual.

A technical skilled integrator has to install and integrate the Incubator. The Incubator

should be used exclusively by laboratory professionals trained in laboratory techniques

with labautomation systems and having studied the instructions for use of this

instrument.

INHECO 07

Doc ID: 900434-001

March 2018

2.2. Scope of Supply

Before initial operation, make sure that the shipment of your unit and its scope of supply

is complete and no parts are damaged.

In case of parcel or product damages, make photos of the damaged boxes and products

and email them to T[email protected] immediately. Transportation damages must

be reported to INHECO within 7 days of delivery. The following components should be

included in each shipment:

Fig.1: Components

( 1 ) Incubator 1) ( 3 ) 15 - Pole Sub-D-Connector

( 2 ) USB cable ( 4 ) Power cord Europe, UK or US (not scope of supply unless ordered)

( 5 ) Power supply (not scope of supply unless ordered)

1) Image differs depending on which system has been ordered

3

1

2

45

INHECO 08

Doc ID: 900434-001

March 2018

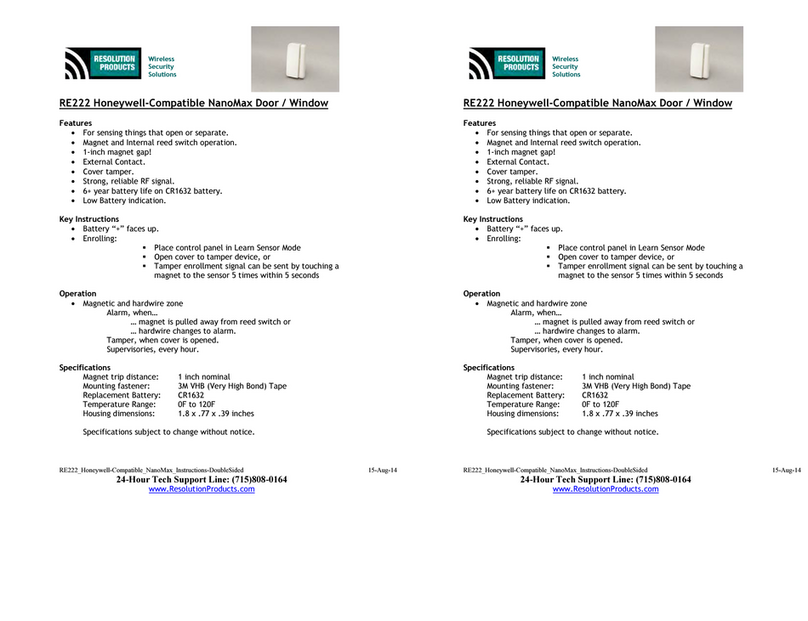

2.3. Functional Elements

Figure 2 introduces the terminology of the Incubator´s functional elements.

Fig.2: Functional elements

( 1 ) Fan ( 4 ) USB Connnector ( 7 ) 15 pole Sub-D-Connector male.

( 2 ) Loading drawer ( 5 ) Address Switch ( 8 ) 15 pole Sub-D-Connector female.

( 3 ) Front door ( 6 ) Power Connector

INHECO 09

Doc ID: 900434-001

March 2018

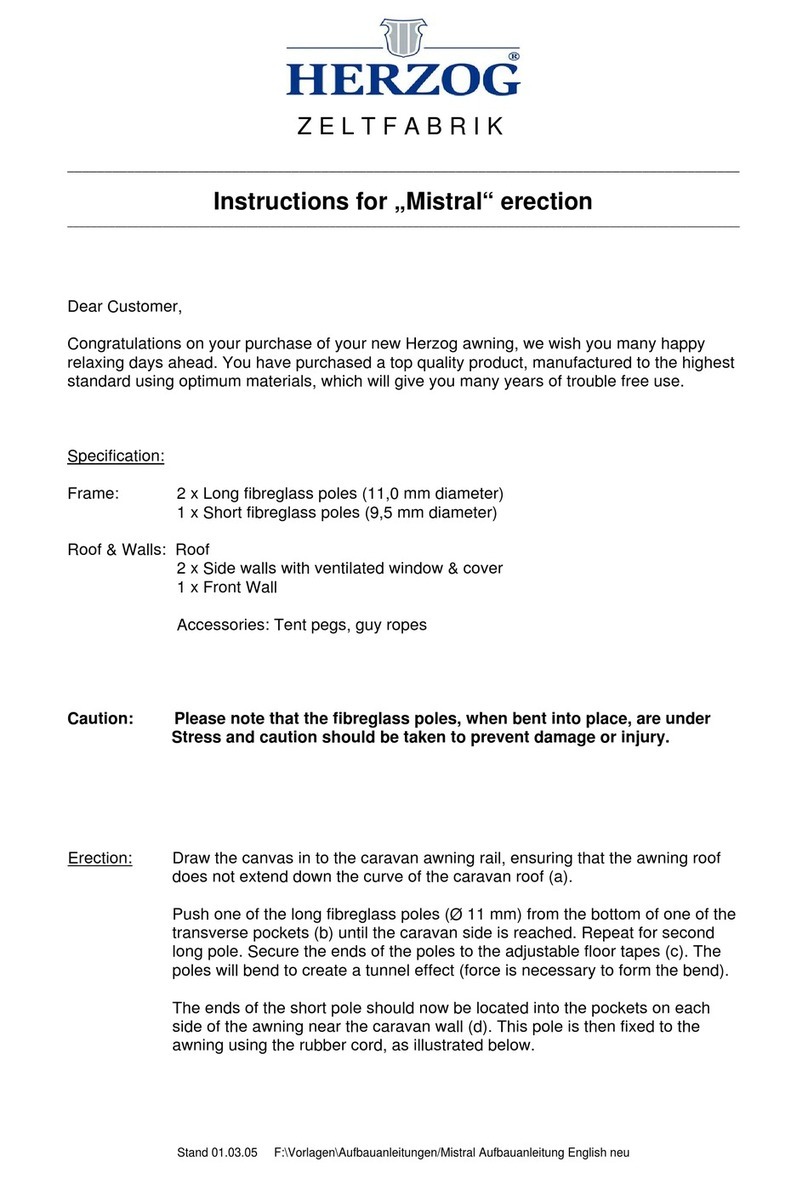

2.4.

The identification label with part number and serial number also contains important

technical indications. The electrical specification on the label must meet your local

situation. The label is placed on the back panel of the Incubator device. The identification

label must not be removed. If it has become illegible or falls off, it has to be replaced by a

new identification label. New labels can be ordered at INHECO. In case the label is

missing and you do not know the part number and serial number, they can also be read

out with the software ( IVDD Incubator software) which can be downloaded from the log

in section of www.inheco.com. → Manual INHECO Incubator Shaker control.

Incubator MP Incubator DWP

1000

INHECO GmbH

82152 Martinsried / Germany

04PN:

SN:

Input: 24V

7300003

Incubator MP

2016-09

Rev.:

30W

Fuse: F3.15A

Incubator Shaker MP Incubator Shaker DWP

Fig.3:

1000

INHECO GmbH

82152 Martinsried / Germany

04PN:

SN:

Input: 24V

7300013

Incubator Shaker MP

2016-09

Rev.:

50W

Fuse: F4.0A

Examples of identication labels

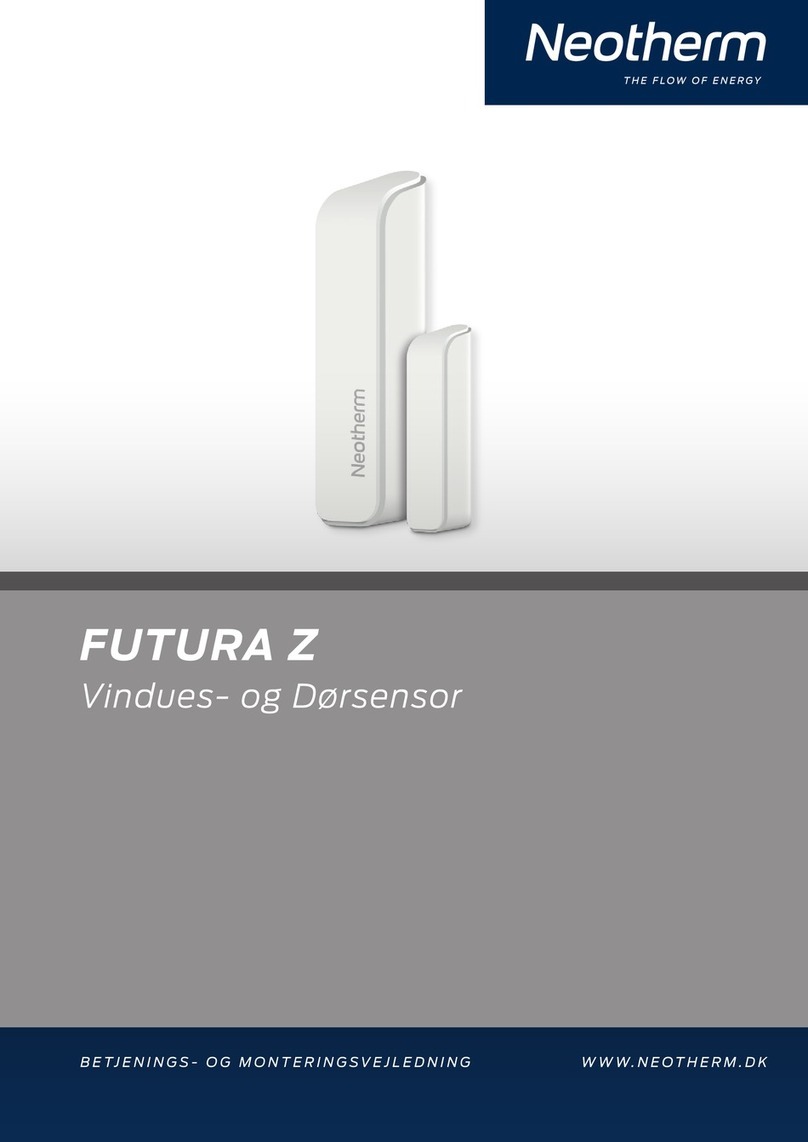

Fig.4: Labels outside device or package

Fig.5: Labels within the device

1000

INHECO GmbH

82152 Martinsried / Germany

05PN:

SN:

Input: 24V

7300006

Incubator DWP

2016-09

Rev.:

45W

Fuse: F3.15A

1000

INHECO GmbH

82152 Martinsried / Germany

05PN:

SN:

Input: 24V

7300009

Incubator Shaker DWP

2016-09

Rev.:

65W

Fuse: F4.0A

Devices are ESD sensible

Transport Lock (3 pieces)!

Always use during

transportation!

Remove transport lock

before use!

Caution Hot Excenter label in shaker

INHECO 10

Doc ID: 900434-001

March 2018

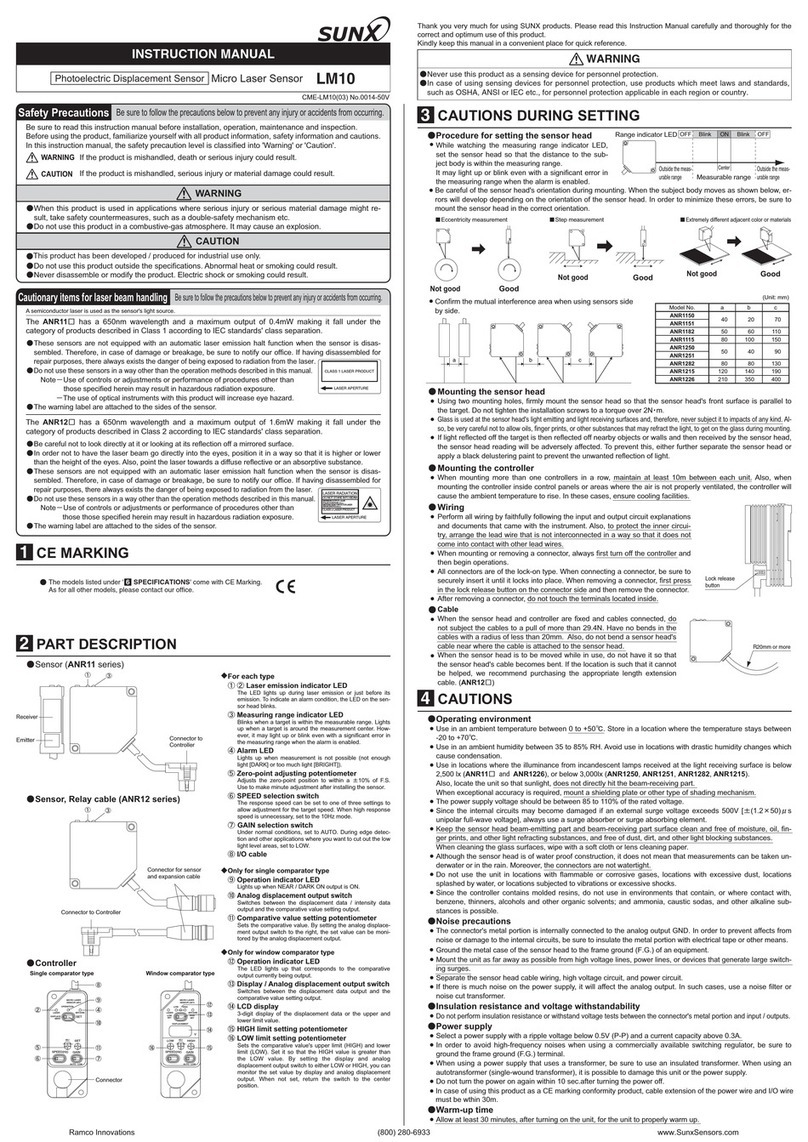

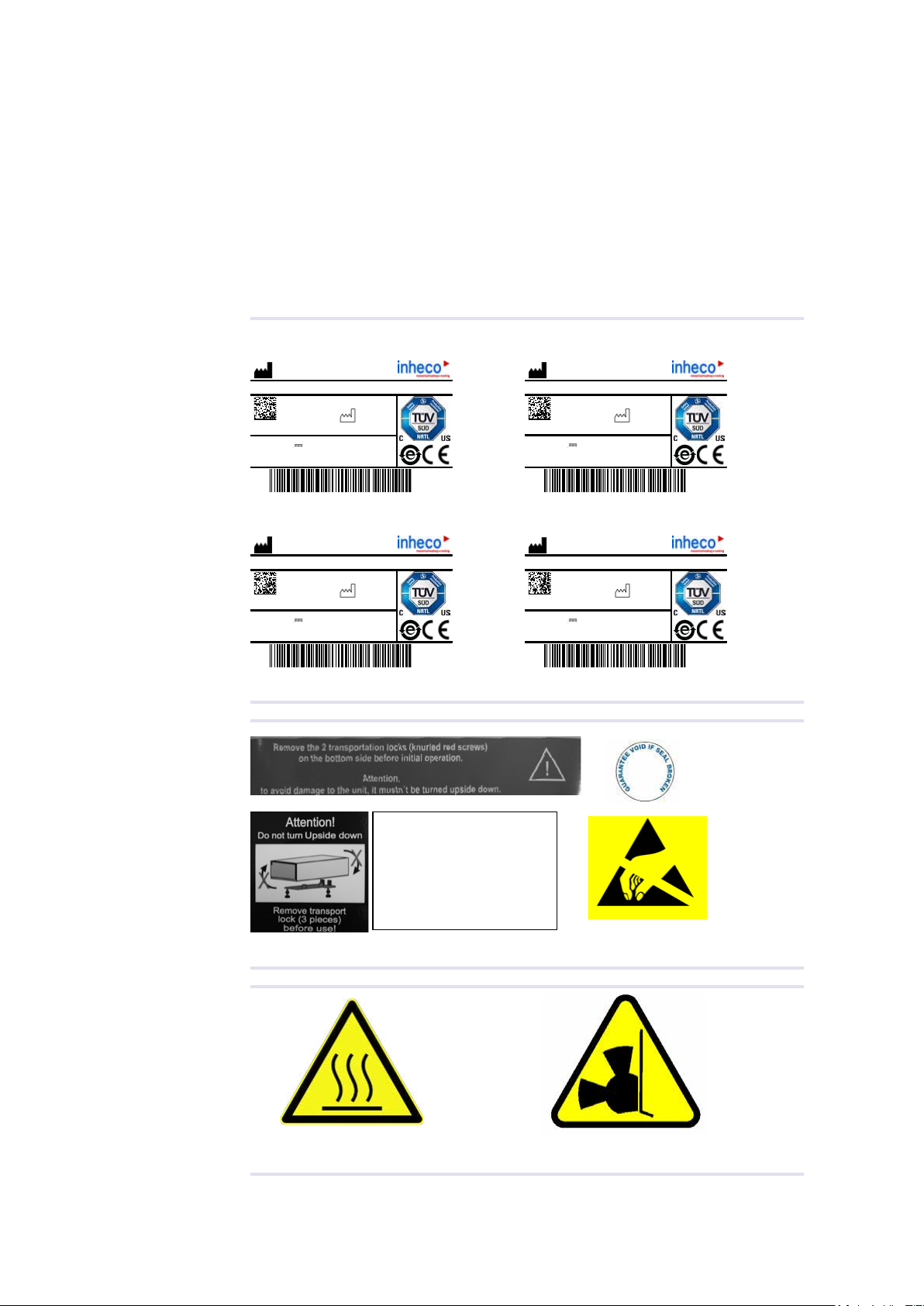

2.5. Technical Data

Technical Data incl. Dimensions

Incubator type MP DWP Shaker

MP

Shaker

DWP

Input voltage 24Vdc

Input power 30W max 45W max 50W max 60W max

Maximum numbers of devices per pow-

er supply (2400121)

6433

Temperature range Room temperature + 5K

up to +80°C (+175°F)

RT+ 5K,

RT + 10K (for shaking

longer than for 1 hour) up

to +80°C (+175°F)

Tolerable realtive humidity ambient 10-80% relative (non condensing)

at +20°C (+68°F) up to +30°C (+86°F)

Maximum load of the shaker platform N.A. 250 g

Shaker frequency range N.A. 6.6 Hz to 30 HZ → 400

rpm to 1800 rpm

Maximum shaking amplitude

(dierence between the maxima)

N.A. 3 mm

Shaking direction N.A. Arbitrary programmable:

e.g. orgital / linear

Dimension in YModule w connector cable 295.5 mm

Dimension in YModule wo connector

cable

268.5 mm

Dimension in XModule 149 mm

Dimension in ZModule wo pin 58 mm 104 mm 88,5 mm 139 mm

Open drawer incl. door YDrawer 193.5 mm 223.5 mm 209 mm 239 mm

Dimension of the thermal chamber in

ZChamber

18 mm 50 mm 18 mm 53 mm

Weigth 2.5 kg 3.4 kg 4.5 kg 5.4 kg

Maximum Number of devices in one

stack due to interaction during shaking

and power limitation of power supply

5432

Fig.6: Dimensions

YDrawer

ZChamber

XModule

ZModule

YModule

INHECO 11

Doc ID: 900434-001

March 2018

Drawer Specications

Accuracy of the end position of the drawer in x,

y and z (drawer open); single unit, all parts at

specied ambient temperature

±0,30 mm

Maximum Drawer load 0,25 kg

Open drawer resistance for a force in Z-axis

without plastic deformation

10 N

Enviromental Conditions

Maximum operation height

Tolarable relative humidity Operation 10-80% relative (non condensing) at

+20°C (+68°F) up to +30°C (+86°F)

Transportation and

storage

-10°C to +60°C [+14°F to +140°F],

non condensing

Temperature Operation +20°C to + 30°C (+68°F to +86°F)

Transportation and

storage

10°C to + 60°C (+14°F) to 140°F),

non condensing

INHECO 12

Doc ID: 900434-001

March 2018

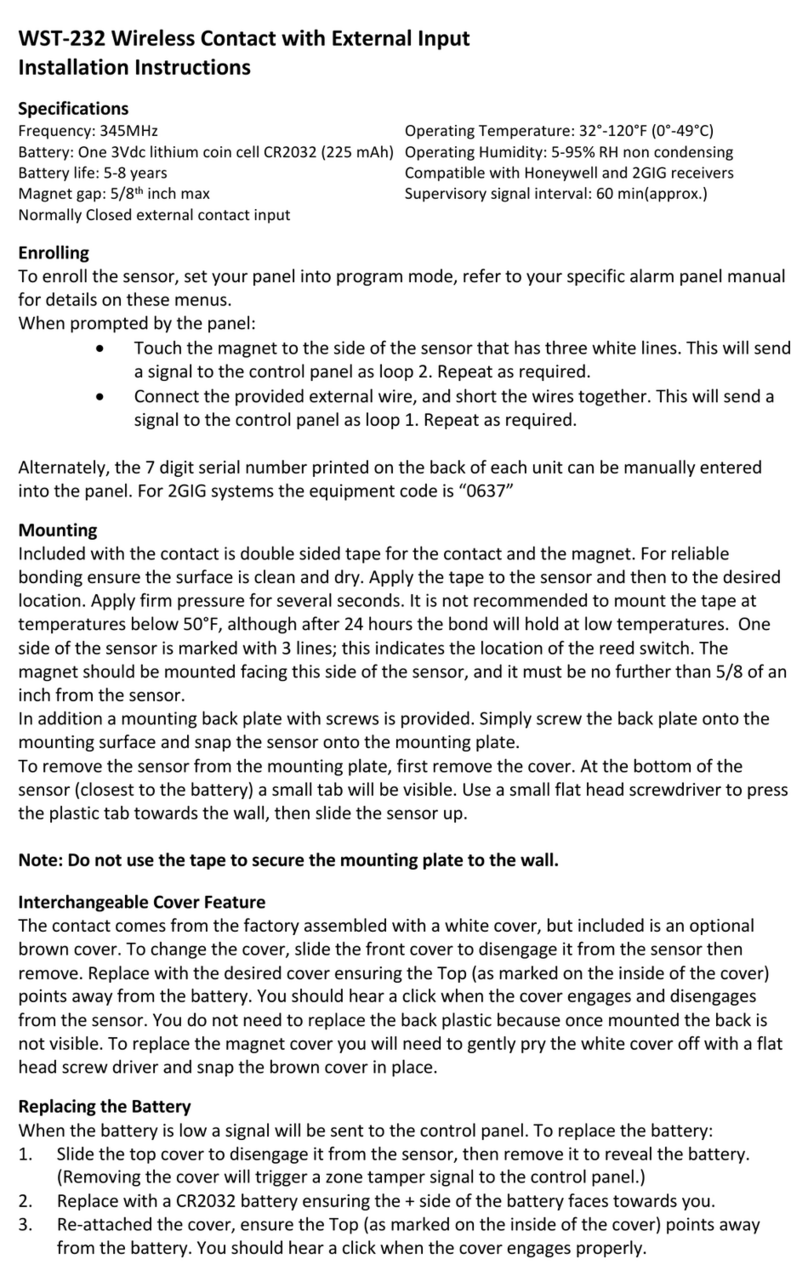

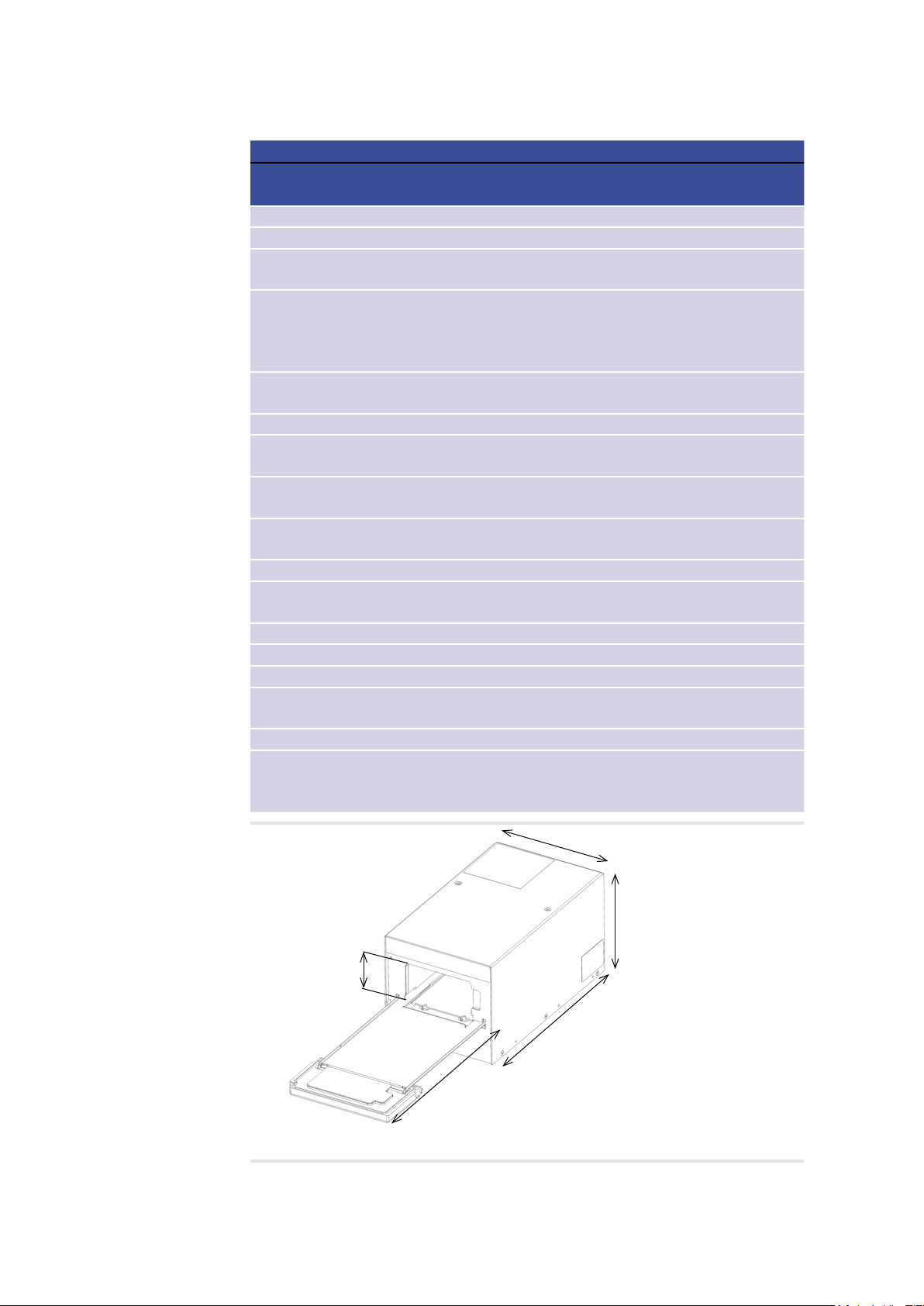

2.6.

Parameter Value

Amplitude range 0.0 – 3.0 mm*

Speed range 6.6 – 30.0 Hz*

Speed precision ±2 Hz

Load 40 – 250g* (weight of plate and liquid and adapter)

Supervision speed and amplitude (closed loop controller)

Shaker movement

North – South (linear)

East – West (linear)

Round (orbital)

“Eight” (this is possible but not recommended because it might damage the

shaker)

Shaker Movement

Amplitude accuracy** ±20% (of the target amplitude)

Phase shift accuracy** ±11°

** validated for the Heating Plate movement / average value over 10 cycles

Single Axis (North – South and East – West) Shaker Load: 100g

Shaker

Speed [Hz]

Shaker amplitude [mm]

Single device

10 X = 1.0 to 2.2

or

Y = 1.0 to 2.2

X = 1,0 to 1.9

or

Y = 1.0 to 1.9

15 X = 1.0 to 2.7

or

Y = 1.0 to 2.7

X = 1.0 to 2.4

or

Y = 1,0 to 2.4

20 X = 1,0 to 1.2

or

Y = 1.0 to 1.2

X = 1.0 to 1.2

or

Y= 1.0 to 1.2

Shaker

Speed [Hz]

Shaker amplitude [mm]

Single device

10 X = 1.0 to 2.2

Y = 1.0 to 2.2

X = 1,0 to 1.9

Y = 1.0 to 1.9

15 X = 1.0 to 2.7

Y = 1.0 to 2.7

X = 1.0 to 2.4

Y = 1.0 to 2.4

20 X = 1.0 to 1.2

Y = 1.0 to 1.2

X = 1.0 to 1.2

Y = 1.0 to 1.2

Shaker

Speed [Hz]

Shaker amplitude [Hz]

Single device Triple Stack

X = 12 /

Y = 24

X = 1.0 to 2.4

Y = 1.0 to 2.4

X = 1.0 to 2.2

Y = 1.0 to 2.2

X = 15 /

Y = 30

X = 1.0

Y = 1.0

X = 1.0

Y = 1.0

* For detailed shaker performance, see chapter below.

X

Y

front

shaking table

INHECO 13

Doc ID: 900434-001

March 2018

2.7.

Parameter Value

Temperature

range

Room Temperature plus 5K to +80°C [+176°F]

Accuracy abso-

lute (@ ambient

temperature

stability ±1K)

The accuracy is dened as the dierence between the target temperature of

the heating plate and the average of the measured temperature on the heating

plate. The heating plate temperature is measured at 5 positions on the heating

plate according to the INHECO measurement head PM-0105. The 5 measure-

ment positions are according to the Plate positions A1, H1, E6, A12 and H12.

Target Temp. Validation Tool

+37°C [+98,6°F] ±1

+60°C [+140°F] ±1.5

+80°C [+176°F]

(temperatures higher than +60°C re-

duces the uniformity over the labware)

±2

Uniformity mea-

sured in well

Uniformity is dened by the maximum dierence between lowest and highest

temperature according to a Greiner 96 Flat Bottom Plate (Postitions A1, A12,

E7, H12)

Target Temp. Validation Tool

+37°C [+98,6°F] ≤1.8

Evaporation in

unsealed Micro

Plates (can be

reduced by using

lid or cover)

Incubator temperature +37°C

[+98,6°F], max. 25% loss of liquid in

4 h, deionized water, room tempe-

rature 24-26°C [75,2-78,8°F], rel.

humidity 40-50%, altitude at 410 m

over Sea level

Incubator temperature +37°C

[+98,6°F], max. 32% loss of liquid in

4 h, deionized water, room tempe-

rature 24-26°C [75,2-78,8°F], rel.

humidity 40-50%, altitude at 410 m

over Sea level

Heatup time

at start tempe-

rature +20°C

[+68°F] with tar-

get temperature

+37°C [+98°F}

max.30 min;

Volume 280µl

per well. *

max.100 min;

Volume 1.5 ml

per well. **

max.30 min;

Volume 280µl

per well. *

max.120 min;

Volume 1.5 ml

per well. **

* The target temperature is reached when all sensors are in the tolerance band of 37°C ±1°C [98,6°F ±3,6°F]

Measured with: 1)

** The target temperature is reached when all sensors are in the tolerance band of 37°C ±1°C [98,6°F ±3,6°F]

Measured with: 1)

INHECO 14

Doc ID: 900434-001

March 2018

3

3.1.

Follow the safety instructions given below in order to avoid danger for user and device.

General

- The Incubator devices ("the unit") hardly require any maintenance, for minor

maintenance interventions refer to → Servicing, page 37 and Quality, page 41.

- The main power connector of the unit must always be accessible to shut down the

system in case of emergency.

- The unit has to be placed in an upright position.

- Standing ground must be solid, even and stable to bear the devices weight.

- Free air supply must be ensured to prevent damage to the . Do not cover the

ventilation openings at the front and rear panel at any time.

- Ensure a minimum of at least 250mm or 10 inches of free space between the

ventilation openings and adjacent devices or walls.

- Do not exceed minimum or maximum ambient temperature and humidity conditions

during operation or storage of the unit → Technical Data, page 11.

- The unit must not be used in environments with risk of explosion

- The unit is for indoor use only.

- The unit must not be used if the Incubator, the power adapter housing or the power

cable show visible signs of damage.

- Make sure that the electrical specifications on the label at the rear panel of the battery

charger meet your local situation.

Crushing Hazard:

- The excenter can possibly pinch your skin when changing its position.

Burning Hazard:

- The Incubator can burn your skin, even after switching off the Incubator it can still be

hot and could seriously burn your skin.

Electrical Shock:

- The unit must not be used if the unit itself or the power cable shows visible signs of

damage.

- You can suffer an electric shock and injuries, if the Incubator is not connected properly

or if you do not disconnect the unit from the wall power outlet before opening the

housing.

- Never connect or remove the power plug with wet hands.

- Make sure that the Incubator does not get in contact with liquids while the unit is

connected to the power outlet.

- Original power cable provided by INHECO has to be used to guarantee safe and

NOTICE

Turning a shaker unit upside down might require a renewal of the shaker drive. Keep the

screws for later transportation purposes.

INHECO 15

Doc ID: 900434-001

March 2018

proper operation.

- The wall power outlet must have a ground earth connection (Safety Class 1).

- Where an ungrounded receptacle is encountered, a qualified electrician must replace

it with a properly (PE) grounded receptacle in accordance with the local electrical

code.

- Make sure that the electrical specification on the identification label at the side panel

meets your local situation. → Labels and Serial Numbers, page 10.

- When using the Incubator devices in a Biosafety Laboratory Environment, the user is

responsible for labeling it according to the WHO Laboratory Biosafety Manual (ISBN

92 4154650 6) and for operating the devices in accordance with the Biosafety Level

Regulations of the WHO Laboratory Biosafety Manual.

ESD Electrostatic discharge

- The Incubator devices are ESD (electrostatic discharge) sensitive devices.

Electrostatic charges as high as 4000V accumulate on the human body can

discharge without detection.

- Although the Incubator devices feature proprietary ESD protection circuitry,

permanent damages may occur to devices subjected to high energy electrostatic

discharge.

3.2. Technical Alterations

- Do not alter the product. Any modification or change which is not approved by

INHECO leads to the loss of warranty. Broken seals on INHECO devices lead to the

loss of warranty as well.

- Use only original parts provided by INHECO. Parts provided by other suppliers can

impair the functionality of the unit.

- Damages due to the use of non-original parts are excluded from INHECO's liability.

3.3.

- In case of a malfunction, switch off and disconnect the Incubator device immediately.

Make sure to inform the authorized person in charge.

- Make sure that the malfunctioning unit is not accidentally re-inalled and used before

the malfunction is eectively eliminated. → Trouble Shooting and Support, page 38.

INHECO 16

Doc ID: 900434-001

March 2018

4

4.1. Scope of Supply

Before initial operation, make sure that the shipment of your unit is complete and neither

packaging nor parts are damaged → Components, chapter 2.2, page 7. Keep original

packaging for future shipments.

The Power Supply and Power Cable are not part of the scope of supply, as for stacked

devices only the master device needs a Power Supply and Cable . They have to be

ordered separately → Chapter 9.

4.2. Initial Operation

A technical skilled integrator has to install and integrate the Incubator.

4.2.1. Disassembling the transportation screws

(only for Shaker devices)

After unpacking the Incubator Shaker device, the two red screws (transportation lock) at

the bottom side have to be unscrewed without tilting or turning the device upside down.

Keep the screws and plate for later transportation purposes. Do not dispose the original

package, as it might be needed for further transportation.

NOTE

Turning the unit upside down might require a renewal of the shaker drive calibration.

Keep the screws for later transportation purposes.

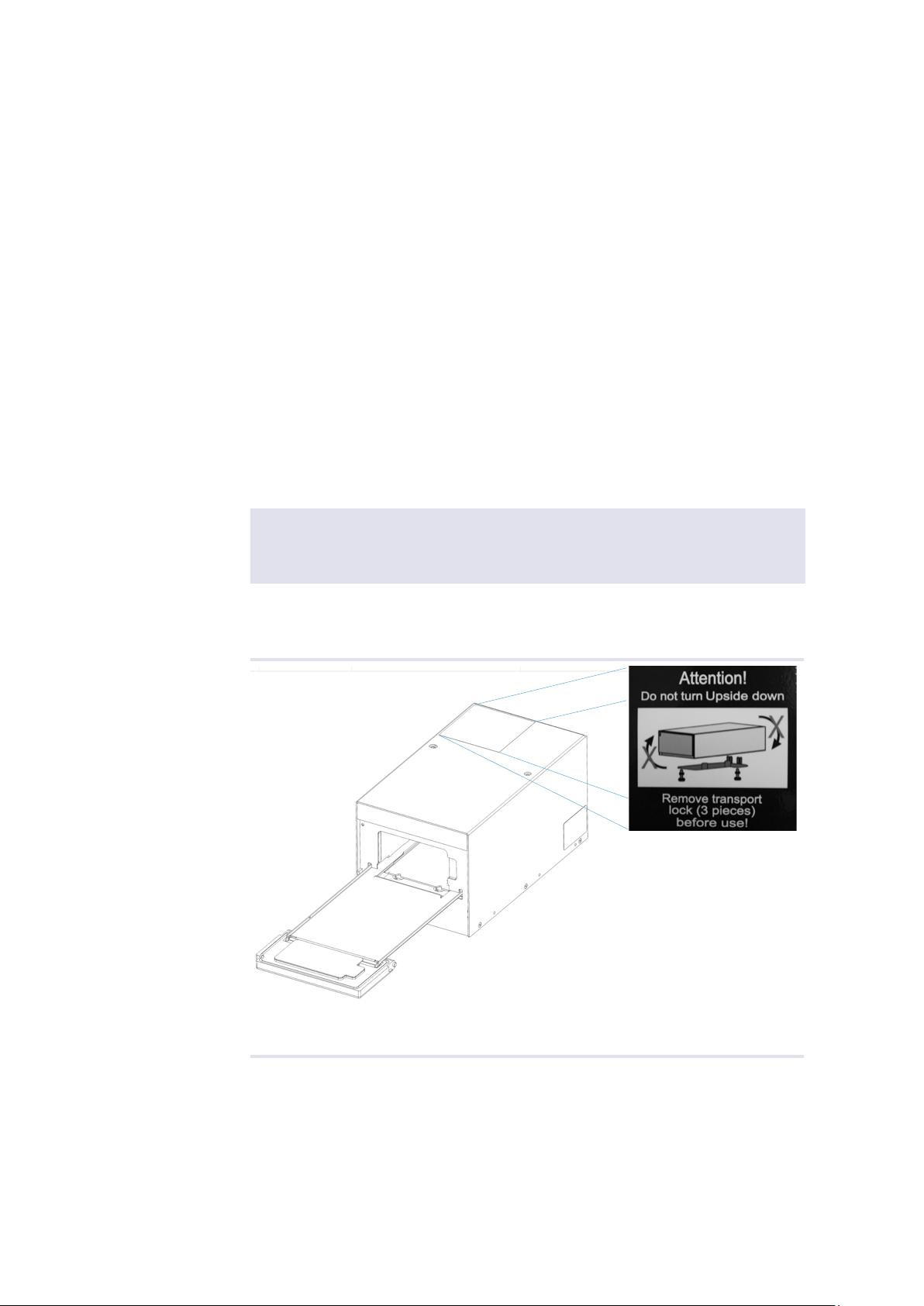

A transportation label on the top of the Shaker device is indicating where the

transportation lock is applied and also that you should not turn the device upside down.

Fig.7: Transportation label at the upper side

INHECO 17

Doc ID: 900434-001

March 2018

The transportation lock is a metal plate held with 2 screws at the bottom of the device

Fig.8: Transportation lock at the bottom of the device

• Turn the Incubator Shaker slowly to the left

NOTE!

Cover side in direction of assembler, like in gure 10!

• unscrew the screw just by hand.

Fig.9: Screws screwable without screwdriver

• After the screws are removed the metal plate will have to be actively taken out of the

grid while you till keep the contact at one side.

Fig.10: Loosened metal plate

INHECO 18

Doc ID: 900434-001

March 2018

4.3. Electrical Details General

NOTE

Do not connect the Incubator Devices to the computer before software installation

routine asks you to do so → chapter 5, page 25

• Plug in the power supply and USB cable

Fig.11: Standard connection for one device

The device needs an electrical power supply that provides a stable 24Vdc voltage. The

power consumption for one device is max. 65 Watt. If more devices are stacked, the

power supply must be able to deliver the resulting power consumption. The polarisation

at the power connector at the back side is shown in the following picture. The red circle

shows the “plus-pole” and the black the “minus-pole”. Please contact INHECO →

power supply.

NOTE

Since the USB interface is not optimized for a secure real time data transfer, all

communication is secured by a cyclic checksum (CRC). In case the communication

between the computer and the Incubator Unit often fails due to timeouts, it is likely that it

is due to the computer. Consider the following with regards to communication stability:

- In case you encounter communication instability, verify the communication stability

with dierent computers of dierent congurations.

- Disconnect other devices from the computer which may interfere with the

communication stability.

- De-activate the automated Windows update. For integration purpose, use

INHECO’s DLL and Firmware Command Set → login section www.inheco.com

• check LED Status (optional)

LED status Description

green slow ashing Power is connected

green fast ashing USB connection to PC

green Device has been once initialized*

* If the software is closed and the device still connected with USB and to power the LED remains green. If the

software is restarted the devices have to be initialized again.

INHECO 19

Doc ID: 900434-001

March 2018

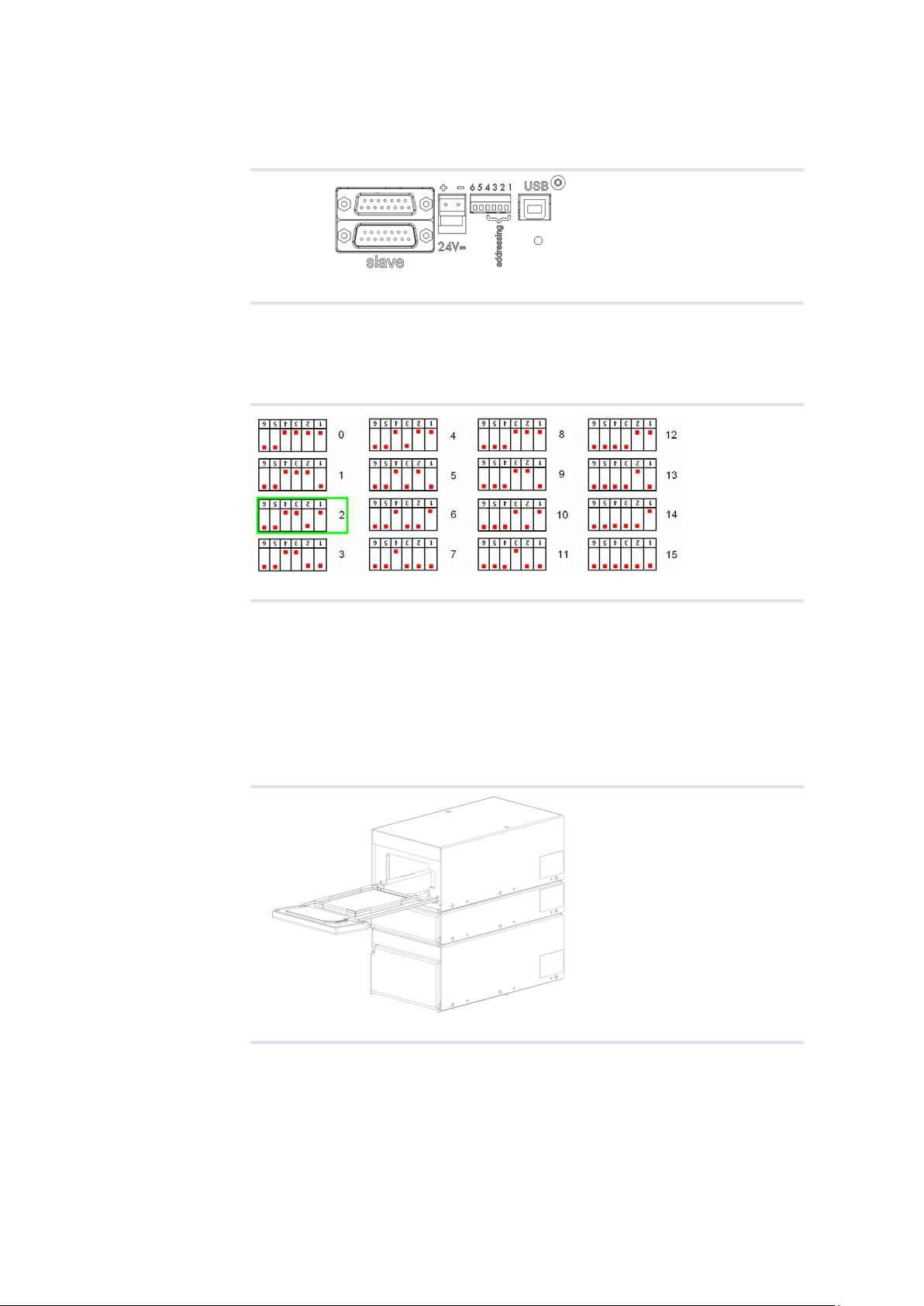

4.4. Adress Switch

A six-pole DIP-Switch can be found at the back side.

Fig.12: Rear side of Incubator showing the Address-Switch

Only the switches 1 to 4 are used for setting the address. These switches are for

identification, if more than one single-device or stack is connected to the PC with USB.

The default address is “2”. The recognition of the device/stack depends on the switches

position as shown in figure 13.

Fig.13: Address-Switch

4.5. Connecting devices

4.5.1. Stackable devices and multiple towers

INHECO’s compact single position Incubators are high performance plug & play

devices for the use on automated robotic platforms or as standalone units. They can

either be used as single devices or stacked in a tower. In addition multiple towers or

single devices can be controlled parallel from one host PC via USB. The combination of

different devices of the Incubator family in one tower is possible.

Fig.14: Example of stacked devices

Two devices are operated with one power supply and controlled via one USB interface,

the 15-pole SUB-D-Connectors on the back side are used for connecting the devices.

The following chapter shows, how the devices have to be connected. → Technical Data

for maximum allowed numbers of instruments, page 11.

This manual suits for next models

3

Table of contents

Other INHECO Accessories manuals

Popular Accessories manuals by other brands

Focusrite

Focusrite Clarett 4Pre USB user guide

promethean

promethean ActivPanel Digital Pen user guide

Microsonic

Microsonic mic+25/IU/TC instruction manual

Grandview

Grandview LF-MixxFII Installation and operation manual

Crucial Audio

Crucial Audio DUB-1 operating instructions

Action

Action S002029 instruction manual