Inland IT-16 User guide

1

INLAND TECHNOLOGY INCORPORATED IT-16™ / IT-30™

ASSEMBLY and INSTRUCTIONMANUAL February 9, 2022

Inland Technology Incorporated

Pollution Prevention By Design

IT-16™/ IT-30™

PARTSWASHER CLEANER / RECLAMATION SYSTEM

Assembly and Instruction Manual

2

Inland Technology Incorporated

Introduces the

IT-16™/ IT-30™

PARTSWASHER CLEANER / RECLAMATION SYSTEM

Inland Technology Incorporated enjoys an enviable reputation within the Defense Community as

the leader in solvent substitution and waste reduction technologies. Most of Inland Technology

Incorporated products and systems are Type Classified, have National Stock Numbers, and are

in the Defense Supply System.

These machines are designed as remote reservoir partswashers. They both meet or exceed

most air quality requirements for remote reservoir solvent cleaning.

Both the IT-16™ and IT-30™ are equipped with the Inland Technology Incorporated

EDGE TEK™ Filtration System, a unique element that filters down to .01 of a micron nominal.

When properly managed, this system used with Inland Technology Incorporated

BREAKTHROUGH®, SKYSOL®, or SKYSOL®100 solvents, generally extends solvent life for

several years. Documented waste reduction in DoD averages 99% per installation for this waste

stream.

BREAKTHROUGH®, SKYSOL®, or SKYSOL®100, as opposed to other cleaning compounds,

are environmentally compliant and have been given a toxicity clearance from the U.S. Army

Center for Health Promotions and Preventative Medicine (CHPPM). Installations and units who

currently use Inland Technology Incorporated products have frequently been nominated for and

have received a variety of prestigious awards.

Enjoy your IT-16™ and IT-30™ Partswasher/Weapons Cleaning System using either

BREAKTHROUGH®, SKYSOL®, or SKYSOL®100 solvents.

3

TECHNICAL DATA:

IT-16™ Partswasher Cleaner / Reclamation System NSN 4250-01-381-8061:

Inland Technology Incorporated developed the IT-16™ for high-volume usage. This machine

was designed as a smaller version of our IT-30™ Partswasher / Reclamation System for limited

space restrictions.

Specifications: Overall dimensions: 31” l x 22” w x 53” h

Inside tub dimensions: 26” l x 17” w x 7” h

16 gauge steel tub

1 drain baskets

Heavy-duty steel work tray

One flow-thru brushes

One hydraulic lid assists

Solvent capacity: 14 gallons

Electrical requirements 120V, 60Hz, 1.7A

110 volt 500 GPH pump

IT-30™ Partswasher Cleaner / Reclamation System NSN 4250-01-381-8078:

Inland Technology Incorporated developed the IT-30™ for high volume-usage. This system

provides a motor pool partswasher that has a handier size requiring less solvent for operations

and making acquisition more cost effective. It is equipped with Inland Technology EDGE TEK™

Filtration System, a unique element which filters down to .1 of a micron nominal. When properly

managed, this system usually extends solvent life for several years. It is designed as a remote

reservoir partswasher and meets or exceeds most air quality requirements for remote reservoir

solvent cleaning.

Specifications: Overall dimensions: 37” l x 27” w x 63” h

Inside tub dimensions: 32” l x 20” w x 8” h

14 gauge steel tub

1 drain basket

1 flow-thru brush

One hydraulic lid assist

Solvent capacity: 25 gallons

Work light

Electrical requirements 120V, 60Hz, 1.7A

110 volt 500 GPH pump

4

Assembly Instructions for Barrel Mounted Washer:

1. Remove all items and packing material frombox.

2. Set the partswasher top on two supports with the bottom

of the unit a minimum of thirty (30) inches above the

floor. Do Not place the partswasher sink overthe

barrel before completing the assembly instructions.

3. Install the pump-motor assembly including the pump

inlet screen and hang it under the partswasher sink.

(Figure 1)

Be sure to slide the pump hanger hook through the

channel located on the bottom of the partswasher.

Do not force. It will be necessary to tilt the assembly

slightly to the front to slide the hook through the channel.

The pump inlet should face the front side of the sink.

Note that the pump should draw fluid from the center

of the solvent drum.

4. Bolt the filter assembly to the partswasher lip. Normal

installation is on the left side of the upper lip of the unit.

Hold in position and secure. (Figure2)

5. Install 6 ft. hose on pump assembly using clamps

provided. Pick up tank and put on barrel with pump

hanger into hook. Put hose and electric cord through hole

in back of partswasher. The electrical cord goes to the

electric box plug. Install hose from chrome filter (out) to

bushing in back of partswasher. (Figure3)

6. Install the hose coming from the pump to the “IN” port

on the pre-filter canister housing head. Tighten the hose

clamp.

For the IT-30™ Only:

7. Place the fluorescent bulb in the protective sleeve. Place

the two (2) round tube end covers over the pins and insert

the tube into position on the partswasher lid. (Figure4)

Plug the power cord for the fluorescent light into the back

of the master switch box located on the lower right front of

the sink. (Figure 5)

Figure 1

Figure 2

Figure 3

Figure 4

5

8. Plug the power cord for the pump-motor into the back of

the master switch box located on the lower right front of

the sink.

9. Plug the cord from the master switch box into any

standard grounded, 110 VAC, 60 Hertz, fused power

source. Warning, do not turn the master switch on until

the solvent has been added to the solvent reservoir

barrel; damage may result to the pump.

10. Add the solvent to the solvent reservoir barrel by pouring

it into the partswasher. The reservoir barrel should be

approximately 2/3/full.

11. Turn the master power switch on (Figure 6) and verify that

the light and pump come on. Check for leaks at all hose

fittings and filters. If leaks are detected, shut off master

power switch and correct. Verify that the solvent flows

into both the goose neck and flow thru cleaning brush by

changing the valve at the base of the goose neck in the

bottom of the sink. Always run pump at least 45 minutes

each day.

SERVICING:

Figure 5

Figure 6

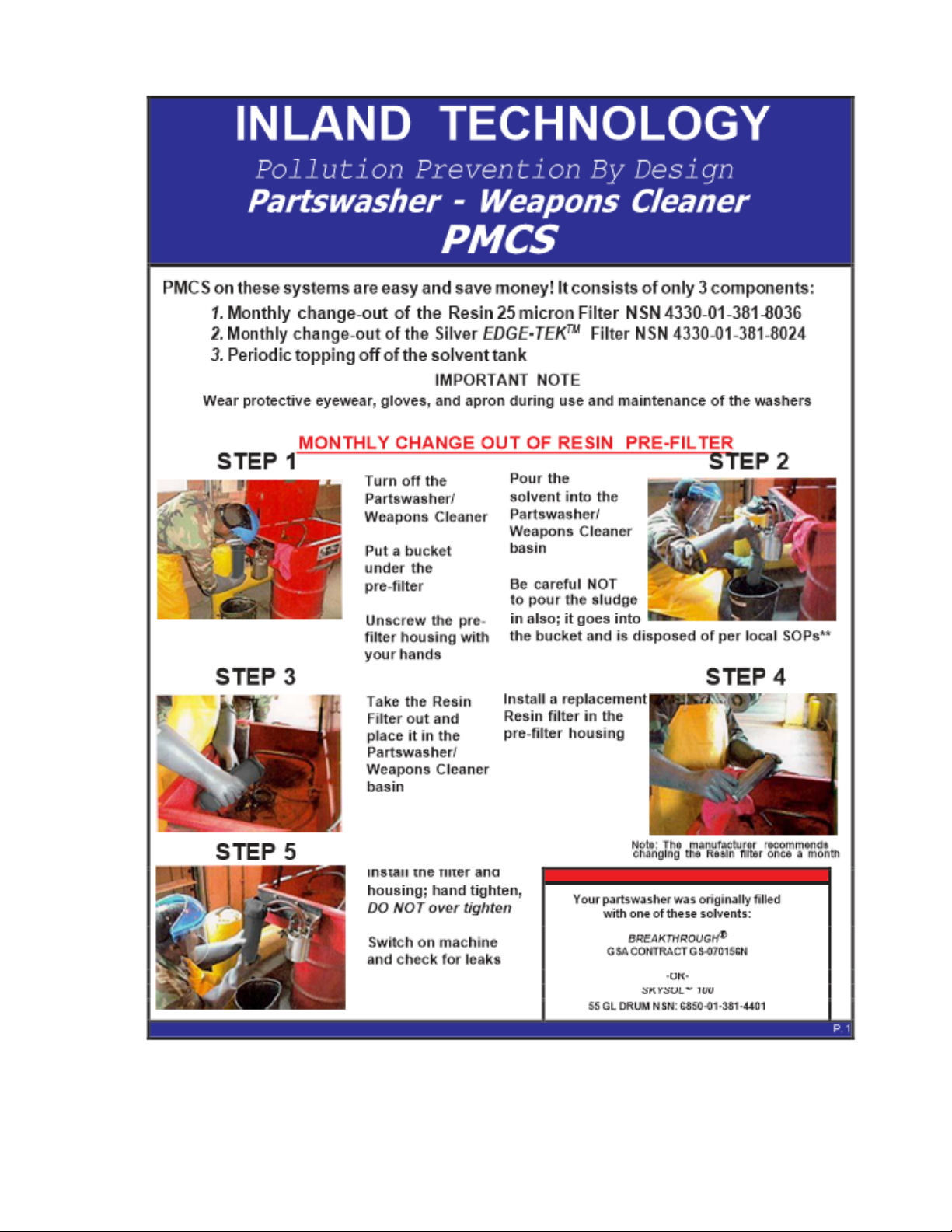

Routine maintenance and servicing of the EDGE TEK™ Partswasher units is a very simple

and can be normally accomplished within five minutes per unit. It is suggested that routine

maintenance be accomplished at fixed intervals such as once per month. At this schedule

time, the following should be accomplished.

1. Turn partswasher off.

2. Visually inspect exposed electrical wiring for damage. Repair ifrequired.

3. Verify that works light and pump-motor are securely plugged in. Verify that the

partswasher primary power cord is securely pluggedin.

4. Remove partswasher strainer and observe solvent level in the barrel. Add solvent

so level is approximately two-thirds (2/3) of the barrel. DO NOT OVER FILL.

Replace parts washer strainer.

5. Remove pre-filter canister. Pour excess solvent into the partswasher. Remove filter

element. If stainless steel element is used, remove debris from the element and

canister into the satellite collection drum. If Resin element is used, remove and set

inside of partswasher to drain. Replace cleaned stainless steel element or new

Resin element into canister and screw canister on filter head. DO NOT OVER

TIGHTEN.

6

6. Remove the EDGE TEK™ filter canister by removing retaining strap. Pour excess

solvent in partswasher. Remove wire retaining ring from inside of canister. Remove

EDGE TEK™ filter by pulling on the wire loop in the center of the filter element.

Remove wire loop from filter element. Set EDGE TEK™ element in partswasher to

drain. Place wire loop in center of new filter. Slide new EDGE TEK™ filter into

canister with wire loop facing out. Replace wire retaining ring. Set canister on filter

head, replace retaining strap and tighten. DO NOT OVER TIGHTEN. Direct solvent

flow away from draining element. Turn pumpon.

7. Observe full solvent flow from flex hose.

8. Turn manual flow valve to nylon flow-thru brush. Observe flow through flex hose is

stopped. Observe full flow through brush. Return manual flow valve to flex hose.

Observe full through flexhose.

9. Verify fluorescent light is operational. If not, turn unit off, remove primary power to

the unit and replace bulb. Observe that white end caps are in place at both ends of

fluorescent bulb.

10. Observe that power switch is lighted. If not, and unit is on, turn unit off, remove

primary power to the unit and replace electricalassembly.

11. Verify that the lid fully closes. Verify that the proper fusible link isused.

DRAINING AN DESLUDGING:

It is recommended It is recommended to drain and desludge your partswasher / weapons

cleaner at least annually to remove any water condensation that will fall to the bottom of

the tank. If the water condensation is not removed, rust pitting will begin on the bottom of

the tank, which will cause leaks from the bottom of the tank. In high humidity areas or

where the machine is stored outside under a canopy this procedure should be done

every six months.

Step1: Acquire a cleanand empty 15-gallondrum.

7

Step 2: Place both flow-thru brushes into the large opening on the drum.

Step 3: Turn valve on the gooseneck off

Step 4: Turn the systemon.

Step 5: Whensolvent stopsflowingout of the brushes, turn machine off.

Step 6: Turnmachine on and continue todrain until pumploses suction.

Step 7: There will be solvent left in the tank.

Step 8: Using a dustpan or canister, remove remaining solvent. Scoopout any

sludge in the tankand dispose of IAW your local HAZMAT SOP.

Step 9: Wipe the interior of the drum with a clean dry rag.

Step 10: Refill to above the second rung with new solvent. Ensure that the solvent level is

the pump.

8

NOTE: DISPOSE OF ALL SLUDGE AND USED RAGS IN ACCORDANCE WITH YOUR

LOCAL HAZMAT AND ENVIRONMENTAL SOP’S.

AUTHORIZED REPLACEMENT SOLVENTS & FILTERS:

BREAKTHROUGHand SKYSOLSolvent:

You can now order either BREAKTHROUGH, SKYSOL, or SKYSOL®100 solvents direct

from GSA Advantage by typing the link below. After connecting to the link, type in the Contract

Number GS-07F0156N in the search box and you will be directed to Inland Technology

Incorporated’s products.

http://www.gsa.advantage.gov

Contract Number GS-07F0156N

BREAKTHROUGHMIL-PRF-680C Type II Solvent

GSA Advantage:

Gallons: Part#:

5 BT05

30 BT30

55 BT55

SKYSOL®MIL-PRF-680C Type IV Solvent:

Gallons:

Part #:

5

SKY05

30

SKY30

55

SKY55

SKYSOL100MIL-PRF-680C Type IV Solvent:

GSA Advantage:

Gallons Part#

5 SKY10005G

DLA:

5

Gallon Can

NSN: 6850-01-381-4423

55

Gallon Drum

NSN: 6850-01-381-4401

9

EDGE TEKTM Filters:

DLA: Box (12x1 each) NSN: 4330-01-381-8024

Industrial case (144 x1 each) NSN: 4330-01-455-6903

GSA Advantage:

Box (6x1 each) ETRK06

Resin Filters

DLA: Box (12x1 each) NSN: 4330-01-381-8036

GSA Advantage:

Box (6x1 case) RESRK06

Air Force EESOH-MIS System to Order Solvents:

This system allows authorized Air Force and Air National Guard units to order

BREAKTHROUGH®if it is authorized on their installation. BREAKTHROUGH®is listed in the

following sizes withinthis system:

BREAKTHROUGH®

55

Gallon Drum

6850PHM00002540

BREAKTHROUGH®

30

Gallon Drum

6850PHM00010318

WARRANTY:

In the interest of maintaining the highest possible customer satisfaction with our equipment and

technology, Inland Technology Incorporated offers the following warranty on all of our equipment:

“Both the IT-16™ or IT-30™ parts washers comes with a one-year warranty if only

BREAKTHROUGH®, SKYSOL, or SKYSOL100 and our filters are used in the machine.

Mixing or use of other brands of solvents can be detrimental to the system and will void the

warranty.”

CUSTOMER SERVICE:

Should you have any questions, comments, or concerns, our customer service line is open from

0800 –1700 Pacific Daylight / Standard Time, Monday –Friday.

Please contact us toll free at (800) 552-3100 or via email at inl[email protected]

10

11

This manual suits for next models

1