3

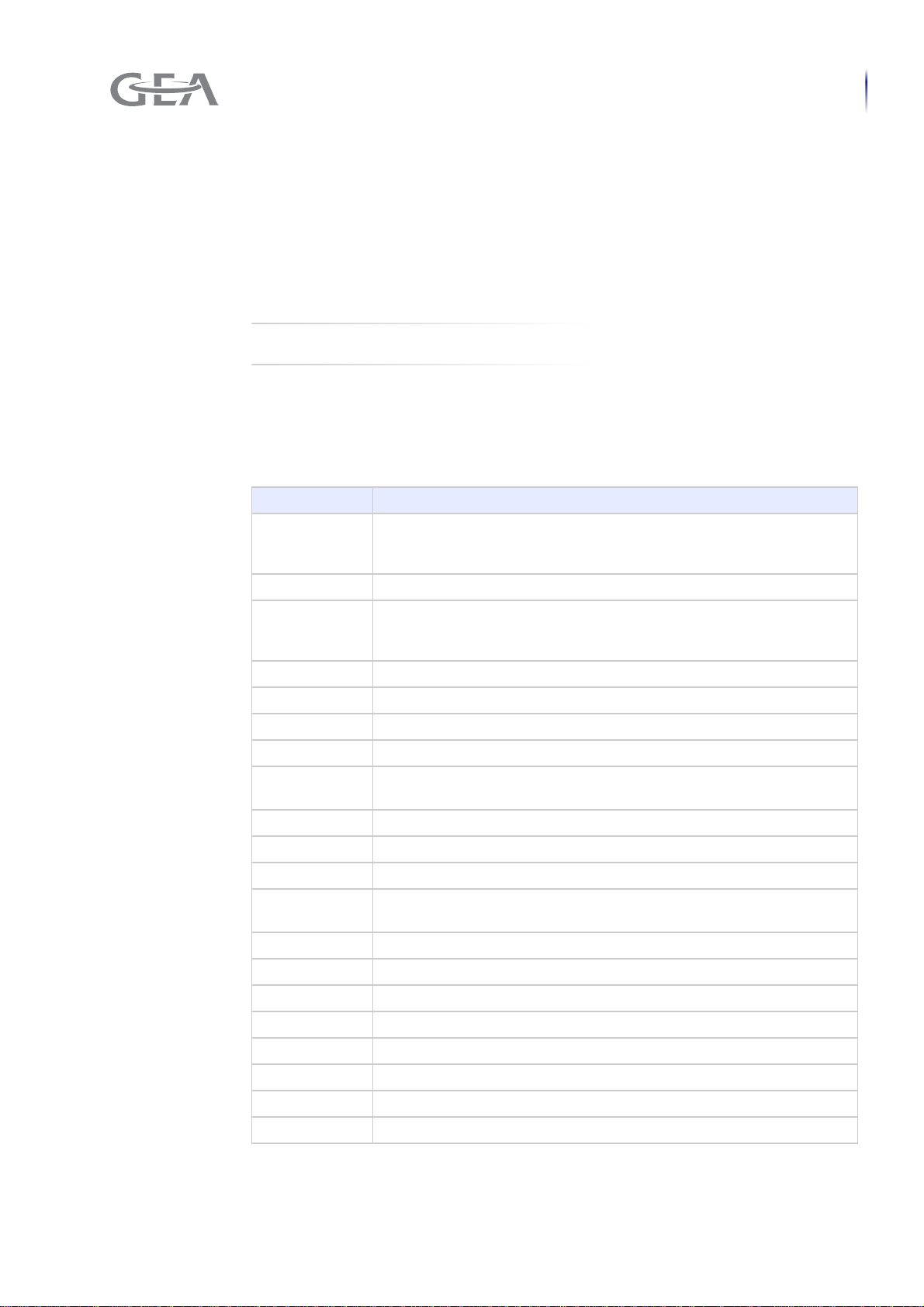

Table of Contents

Notes for the Reader ...................................................................................................................................... 5

Binding Character of These Operating Instructions ......................................................................................... 5

Notes on the Illustrations .................................................................................................................................. 5

Symbols and Highlighting ................................................................................................................................. 6

Abbreviations and Terms ................................................................................................................................. 7

Safety............................................................................................................................................................... 9

Safety Note ....................................................................................................................................................... 9

Operator's Duties .............................................................................................................................................. 9

Qualification of Staff ....................................................................................................................................... 10

Supplementary Regulations ........................................................................................................................... 11

Instructions for the Safe Operation ................................................................................................................. 12

•General Principles ...................................................................................................................................... 12

•Installation .................................................................................................................................................. 12

•Commissioning/Setup Mode ..................................................................................................................... 12

•Setting into Operation ................................................................................................................................ 13

•Operation ................................................................................................................................................... 13

•Shutting Down ........................................................................................................................................... 13

•Maintenance and Repair ............................................................................................................................ 14

•Disassembly ............................................................................................................................................... 14

•Environmental Protection ........................................................................................................................... 15

Signage .......................................................................................................................................................... 15

Residual Risk ................................................................................................................................................. 15

•Hazard Areas ............................................................................................................................................. 15

•Residual Dangers ....................................................................................................................................... 17

Declaration of Incorporation ........................................................................................................................... 18

Transport and Storage................................................................................................................................. 19

Scope of Supply ............................................................................................................................................. 19

Transport ........................................................................................................................................................ 19

Storage ........................................................................................................................................................... 19

Intended Purpose ......................................................................................................................................... 20

Designated Use .............................................................................................................................................. 20

Requirements for the Operation ..................................................................................................................... 20

Improper Operating Conditions ...................................................................................................................... 20

Conversion Work ............................................................................................................................................ 21

Installation and Commissioning ................................................................................................................. 22

Operating Conditions ...................................................................................................................................... 22

Notes on Installation ....................................................................................................................................... 23

Installation Dimensions .................................................................................................................................. 23

Installation ...................................................................................................................................................... 24

Removing ....................................................................................................................................................... 25

Setting into Operation ..................................................................................................................................... 26