ungerglobal.com

•Checksystemforcracks.•Besurecoverisinlockedposition.•Donotexceedpressureof115psi(8Bar).•Keepdischargelineopenandholdyellowleverdowntoremovetrappedairfromsystem.•ForuseonlywithdrinkingwaterBeforeservicingsystem:•Shutoffdrinkingwatersupplyandopenwaterfedwashpoletubingdischargeline.•Disconnectwatersupplyandallowtanktodrain.Spilledresinisaslippinghazard.Cleanupspilledresinimmediately.Washhandsthoroughlyafteruse.Wearsafetygoggles.Incaseofeyecontact,immediatelyusheyesthoroughlywithcleanwater.Consultdoctorifsymptomspersist.Donotstoreresininopenorunlabeledcontainers.Storeinacool(15°Fto100°F),dryplace.Disposeofinaccordancewithapplicablefederal,state/provincial,andlocalregulations.AllHydroPowermodelsrequiretheuseofmixedbedionexchangeresin(commonlyreferredtoasde-ionizingresin).Thisresinwillrequirereplacementandhandling.

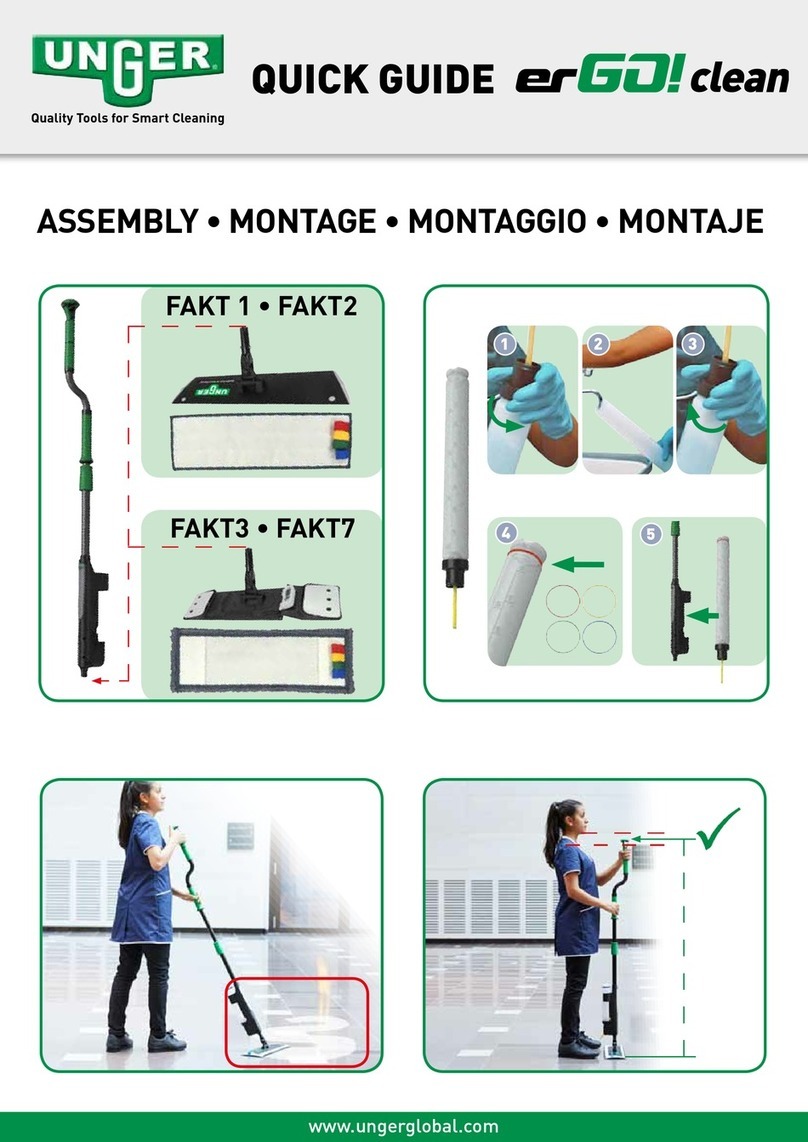

System Set Up

LOCATE JOBSITE WATER SUPPLY

Unger recommends testing the onsite water supply for both tem-

perature and TDS (total dissolved solids) prior to working. Higher TDS

levels reduce the DI systems capacity.

• Inspect system – ensure DI resin bag(s) are installed.• Set up system in upright position.• Choose a stable onsite location.CONNECT WATER SUPPLY (GARDEN HOSE)

TO SYSTEM INLET CONNECTION

• Quick connect ttings are supplied with the HydroPower system.• Thread garden hose directly onto inlet connection on/off valve.CONNECT WATERFED WASH POLE TUBING

• Install quick connect adapter to waterfed wash pole hose.• Ensure all waterfed wash pole on/off valves are in “OPEN” position.TURN FEED WATER SUPPLY “ON” SLOWLY

• Inspect system as it pressurizes and begins producing “purewater”• Turn on TDS meter and inspect “purewater” quality. A reading of ‘0’

is best and indicates the system is running properly (product water

contains zero parts per million total dissolved solids).• Adjust ow at waterfed wash pole brush head by: - On/Off Valve - Waterfed wash pole control (on/off) valve. 1

2

3

4

1

Building/Facility

2

3

4

Replacing DI Resin

SHUT-OFF FEED WATER SUPPLY

• Disconnect waterfed wash pole tubing.• Depress yellow lever on system head assembly.RELEASE SYSTEM HEAD ASSEMBLY

• Use a counter-clockwise quarter-turn to release

system head assembly; remove and set aside.

• Reach into housing and remove exhausted resin

by hand; discard according to local regulations.

REPLACE RESIN

• Drop in new resin bag(s) by hand – be sure to seat bags

with zip-tie facing up. Pat down bag by hand to

ensure seated properly.

• Inspect system head assembly: O-ring and

FloWaterTM distribution lter are in good condition.

Re-coat O-ring with silicone lubricant only.• Re-install DI System head assembly, push down rmly,

then quarter-turn clockwise.• System is ready to be operated.RECONNECT WATERFED WASH POLE TUBING

• Turn “ON’ water supply.TEST SYSTEM TDS

1

2

3

4

5

1

2

3

4

5