InnerSpace Ventaire Manual

Instruction Guide for

Scope Drying Unit

Ventaire™Endoscopy System

888-435-2256 | innerspacehealthcare.com

2

Introduction

System Overview ........................................................................3

System Specifications..................................................................4

Replacement Information.............................................................4

InnerSpace Barcodes ..................................................................4

• Using InnerSpace Scope Barcodes ........................................4

• Using Embedded Manufacturers’ Scope Barcodes ................4

• Using InnerSpace User Barcodes ..........................................4

InnerSpace Support .....................................................................4

System Administrators

Setup ..........................................................................................5

Settings ......................................................................................5

• Exporting Data .....................................................................6

• Drying ..................................................................................6

• Sound ..................................................................................7

• Filters and Tubes .................................................................7

• Attaching Barcode Stickers ..................................................7

• Importing Users....................................................................8

• Importing Scopes .................................................................8

• Wi-Fi ...................................................................................8

• Factory Reset .......................................................................8

System Operators

Status Indicators .........................................................................9

Drying a Scope .........................................................................10

Pausing a Drying Cycle .............................................................10

Removing a Scope ....................................................................11

Restarting Scope Drying Unit ....................................................11

Appendix

Care and Maintenance ..............................................................12

Product Ordering and Replacement Information ........................12

Instructions ...............................................................................13

• Removing and Replacing Tubes ..........................................13

• Removing and Replacing Air Filter ......................................13

• Connecting Scope Drying Unit to Building’s Air Supply ........13

• Mounting a Scope Drying Unit to IV or Scope Pole ..............14

• Mounting a Scope Drying Unit to Wall .................................15

Instruction Guide for Scope Drying Unit

Table of Contents

3

System Overview

Healthcare-associated infections (HAIs) affect one out of every 31

hospital patients at any given time, according to the Department

of Health and Human Services’ Agency for Healthcare Research

and Quality. Over one million HAIs occur every year in the US,

leading to loss of life and rising healthcare costs. A drying device

that forces air through the interior lumens of the endoscope can

reduce the level of moisture inside the scope and, therefore, the

chance of contamination and infection.

InnerSpace’s Ventaire Endoscopy System includes products that

assist endoscopy staff in the safe and thorough drying, tracking,

and storage of reprocessed scopes, including scope drying and

tracking cabinets and scope drying units. Both products provide

consistent and continuous delivery of HEPA-filtered, pressurized

air into endoscope channels to keep scopes dry.

The scope drying unit offers a flexible solution for thoroughly

drying the interior lumens of endoscopes. The compact size of

the drying unit contributes to its flexibility – it can be placed on

a counter or other surface, including carts, or mounted on a wall,

IV pole, or scope pole. Scope drying units are available in two

versions: one version has a compressor that supplies air, and the

other version connects to a building’s air supply. The scope drying

unit’s compressor is balanced for low-vibration operation.

Once the unit’s drying cycle is complete, the endoscope can be

placed in a scope drying and tracking cabinet for continued drying

and venting or stored in an endoscope cabinet. The drying unit

works with all major endoscope brands.

A scope drying unit includes a barcode scanner. Disposable

tubes and connector kits are needed to operate the unit and are

purchased separately. See Appendix for order information.

Instruction Guide for Scope Drying Unit

Introduction

• Easy-to-read touchscreen and intuitive interface

• Notifies operator when tubes and filters need replacement

• Barcode scanning streamlines operation

• Can dry two scopes at the same time

• Uses disposable connectors

• Collects scope drying activity, including date and time of

operation, the operator, and scope identification. Customizable

settings ensure drying process complies with organization's

guidelines

• Compatible with InnerSpace Cloud platform for remote

management and monitoring

• Lists of users and scopes can be uploaded and downloaded

via USB or InnerSpace Cloud

4

System Specications

Dimensions (nominal)

• Exterior: 7.5"w x 8"d x 10"h

• Display screen: 5" diagonal length

Unit with compressor

• Air output:

·Compressor output: 5 PSI (maximum PSI)

·LPM: 1.65 CFM (46.7 LPM)

• Decibels:

·71 dB

• Weight: 14.3 lb

• Electrical requirements: 115 VAC (less than 2 amps)

• Power cord length: 10 feet

Unit without compressor

• Compressor output: Not to exceed 10 PSI

• Weight: 8.1lb

• Electrical requirements: 115 VAC (less than 2 amps)

• Power cord length: 10 feet

Replacement Information

The scope drying unit includes a disposable filter and tubes

that will need to be replaced (filter every 6 months, tubes every

24 hours). Connectors are single use. To find the connector

kit compatible with your endoscope or to order replacement

products, call InnerSpace Customer Service at 888-435-2256 or

innerspacehealthcare.com/Ventaire

InnerSpace Barcodes

A drying unit can read one dimensional (1D) barcodes, including

most endoscope manufacturers’ barcodes. Depending on the

administrator’s setup of the scope database, a scope can be

scanned using the InnerSpace endoscope barcode stickers

provided or the endoscope manufacturers’ barcode.

A set of InnerSpace barcode sticker sheets for ID badges and

endoscopes is included with the scope drying unit. Scanning

badges and scopes saves time for both administrators and

system operators compared to manually entering information

into the system.

InnerSpace Support

For questions about your scope drying unit, call InnerSpace

Customer Service at 888-435-2256.

Instruction Guide for Scope Drying Unit

Introduction

5

Setup

Administrators have access to the settings menu and can add

and remove user and administrator profiles; add, edit, and delete

scope inventory; and view system details. Users can connect

scopes and manage drying cycles.

Most of the steps that system administrators complete in the

initial setup will not need to be repeated, but administrators

can continue to add, edit, and delete existing information,

such as users, scopes, and scope drying times. Users will see

information and interact with the system interface based on the

administrator’s setup.

After the Ventaire drying unit is powered, the main screen

will be displayed.

Settings

Settings allows administrators to set up system defaults, export a

report, input a list of users and scopes, connect to network, and

reset tubing and filter replacement notifications.

To access the settings menu, select the settings icon at the top

right corner of the screen. A screen prompting the administrator

to enter a PIN will appear. Enter the default admin PIN of 0001 to

access the system and take you to the Settings menu.

Instruction Guide for Scope Drying Unit

System Administrators

6

Exporting Data

Allows the administrator to download a report of all available

scope data, including dates and times scopes were dried, scope

activity, user and scope information, scope drying time, and when

tubes and filters were replaced.

To generate a report, select Settings and then Export Data. Insert

a USB into the port on the drying unit. After the system registers

that a USB has been inserted, select Download Report. When the

report is downloaded, remove the USB from the drying unit and

insert it into a computer to view the report.

Drying

Allows the administrator to change the steps that users follow to

dry a scope and to change scope drying durations.

The system default requires users to scan the InnerSpace

barcode on their ID badge, but administrators can edit the steps

to include scanning barcodes on both an ID badge and a scope

to initiate drying.

To change the steps that users will follow, select or deselect the

boxes that apply to your process.

The drying unit is preconfigured with default settings for drying

durations, but it is the responsibility of those using the system to

determine drying durations based on the organization’s guidelines

and/or the guidelines provided by the endoscope manufacturer.

The drying default of 10 minutes is based on tests that tracked

the amount of moisture in the air within the channels of an

endoscope through a 10-minute drying cycle. Humidity probes

were attached to an endoscope at the air/water port, the suction

port, and the distal tip. After 10 minutes of continuous drying, the

moisture level dropped until it reached ambient humidity levels.

To change the drying cycle default, choose the right or left drying

port and then tap “+” or “–” until you reach the desired duration.

Instruction Guide for Scope Drying Unit

System Administrators

7

Sound

Allows the administrator to adjust the sound settings when a

barcode is scanned and when a drying cycle is complete.

To change sound settings, select or deselect the sound setting boxes.

Filters and Tubes

Allows the administrator access to the drying unit’s air filter and

tube settings. It notifies when each should be replaced as well as

when they last were replaced. When it is time to replace the tube

or air filter, select Replace Tubes or Replace Filter. Replace air

filters every 6 months (180 days) and tubes every 24 hours.

See page 13 for replacement instructions.

The drying unit will display reminders to replace the tubes and

air filter. To change the reminder notification screens, select Filter

& Tubes. Administrators can require that users scan the barcode

on their ID badge to dismiss a reminder notification and/or set

the snooze option for the notification, which allows the user to

complete one additional drying cycle.

To snooze a notification, select “Allow snooze reminders.” To

require users to scan the barcode on their ID badge to dismiss the

notification screen, select “User barcode required to dismiss.”

Attaching Barcode Stickers

Follow these instructions to attach barcode stickers to ID badges

and endoscopes:

ID badge barcode stickers

• Scan barcode to identify a user. Peel and affix sticker firmly to

their ID badge

Endoscope barcode stickers

• Scan barcode to identify an endoscope. Peel and affix sticker

firmly to the endoscope

After an InnerSpace ID badge or scope barcode sticker is affixed,

administrators can scan the barcode to add a user or scope to the

drying unit system.

To reorder sticker sheets, contact InnerSpace Customer Service at

Instruction Guide for Scope Drying Unit

System Administrators

8

Importing Users

User names are added to the system by importing them using

a USB device. To add a user, the user’s name, email address,

department, and PIN will need to be entered. The PIN needs to

match the PIN on the ID badge barcode sticker assigned to

that user.

To add a user, download a CSV file to a USB from the settings

menu under Import Users. Insert the USB into the side port on the

drying unit. Once the system registers a USB has been inserted,

Download Template will appear. Select to download to the USB.

Remove the USB and insert into a computer to view and add

user information.

Add user information to the CSV file, save it, and then reinsert the

USB into the port on the drying unit. Select Import Users to upload

the user information.

Importing Scopes

Scopes are added to the system by importing them using a USB

device. To add a scope, the scope serial number, brand, model

number, internal ID, description, and barcode need to be entered.

The barcode will need to match the barcode on the InnerSpace

endoscope barcode sticker sheet for that scope or match the

endoscope manufacturer’s barcode.

To add a scope, download a CSV file from the settings menu

under Import Scopes. Insert the USB into the side port on

drying unit. Once the system registers a USB has been inserted,

Download Template will appear. Select to download to the USB.

Remove the USB and insert into a computer to view and add

scope information.

Add scope information to the CSV file, save it, and then reinsert

the USB into the port on the drying unit. Select Import Scopes to

upload scope information.

Wi-Fi

Allows the administrator to connect to a wireless network.

InnerSpace Support Technicians will provide the service needed to

connect a device to Wi-Fi and can be reached at 888-435-2256.

Factory Reset

To reset, select Reset Device. The system will shut down and

reboot. All preexisting data will be erased and will need to be

uploaded again.

Instruction Guide for Scope Drying Unit

System Administrators

9

System Operators

A system operator checks scopes in, connects scopes, and

manages the drying process.

For questions or help with the scope drying unit, contact

InnerSpace Customer Service at 888-435-2256.

Status Indicators

Operate the system from the main screen.

The main screen uses color and a timer to show the drying process.

Green: The right or left port is available and ready for a scope to

be connected and dried.

Blue: The right or left port is in use and drying a scope. The timer

indicates minutes left in drying cycle. When timer is at 0:00, the

right or left drying port has completed the drying cycle, and the

scope can be removed.

Instruction Guide for Scope Drying Unit

System Operators

10

Drying a Scope

Before initiating the drying process, a scope must be attached

to a connector and tube. How the connector is connected to the

scope depends on the type of connector you are using. Go to

innerspacehealthcare.com/Ventaire for connector kit instructions.

To begin a drying cycle:

Select Start for port that tube is attached to.

The display prompts the user to connect the

tube to a connector and then to the scope.

Depending on your administrator’s system setup, you may either

be required to scan the barcode on your ID badge or to scan both

the barcode on your ID badge and the barcode on the endoscope.

All scanned information will appear on the display.

The user can change the drying cycle duration by selecting “+” or

“-” until the desired duration is reached, and then select Start or

make an additional scan of either the barcode on an ID badge or

scope to initiate drying.

The main screen appears with a blue banner identifying the right

or left port, displaying Drying, and a timer showing time left in the

drying cycle.

Pausing a Drying Cycle

To pause a drying cycle, select Pause. To resume drying,

select Resume.

Instruction Guide for Scope Drying Unit

System Operators

11

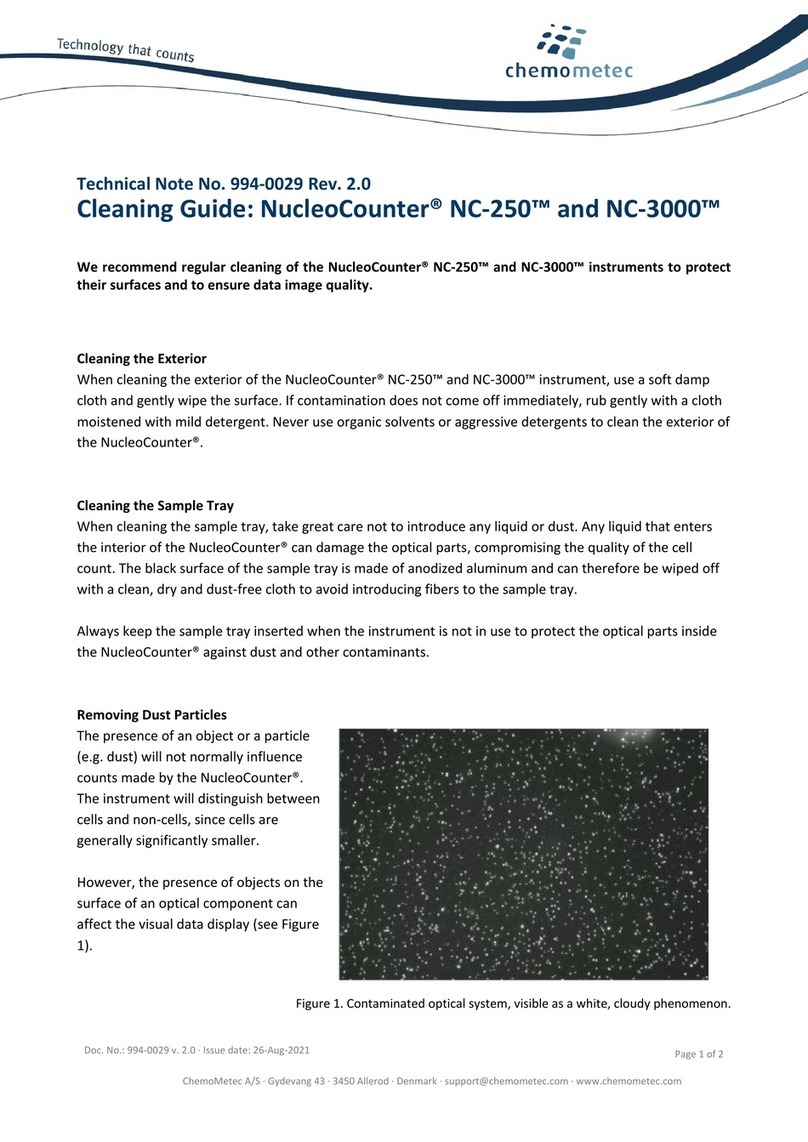

Restarting Unit

You may need to restart the system if it freezes or has another

issue that can’t be resolved. To turn off unit, flip the switch above

the plug on the bottom left side of the scope drying unit. When

turned back on the system will reboot. All information previously

entered and saved repopulates.

Instruction Guide for Scope Drying Unit

System Operators

Removing a Scope

When the drying cycle is complete, the blue banner displays

Complete, and the user can remove the scope.

Select Remove Scope, and then disconnect the connector from

the scope and tube.

Before discarding connector, inspect it to ensure it is fully intact

and that there are no broken pieces remaining in the suction and

air water valves. The connectors and all connector kit parts can

then be thrown out.

12

Care and Maintenance

The drying unit’s air tubes must be replaced every 24 hours,

and the unit’s air filter every 6 months (180 days). See page 13

information on tube and air filter replacement.

Follow these recommendations to disinfect, clean, and care for

your scope drying unit.

Cleaning materials:

• The best choices for disinfection are compounds that contain

quaternary ammonium

• Use a 10%-50% isopropyl alcohol solution as an option when

quaternary ammonium compounds aren’t available

• Don’t use abrasive cleaning pads

• Don’t leave cleaning compounds on the surface; wipe surfaces

dry after cleaning

• A 10% (or less) mixture of active bleach and water can be used

though not recommended

Recommended disinfectant/cleaning products:

• Hepacide Quat®II virucidal disinfectant cleaners

• PDI® Sani-Cloth®cleaner

• CaviWipes™ disinfectant cleaner

• Virox®disinfectant cleaner

Tubing should be cleaned with Sani-Cloth®wipes after every use.

Product Ordering and Replacement

Information

To order replacement parts, contact InnerSpace Customer Service

at 888-435-2256 or innerspacehealthcare.com

Replace the HEPA air filter (SVDUAF) every 6 months.

Manifold and manifold auxiliary water tubes connect to the scope

drying unit to effectively vent HEPA-filtered air through endoscope

channels. Manifold tubes are for endoscopes without water jet

ports; manifold auxiliary water tubes are for endoscopes with

water jet ports.

Replace the tubing every 24 hours:

• Manifold Tube, pack of 1: SVDMT1

• Manifold auxiliary water tube, pack of 1: SVDWAT1

Connector kits should be replaced after every use. All connector

kits come in packages of 100. For connector kit product numbers,

go to innerspacehealthcare.com/Ventaire

Instruction Guide for Scope Drying Unit

Appendix

13

Instructions

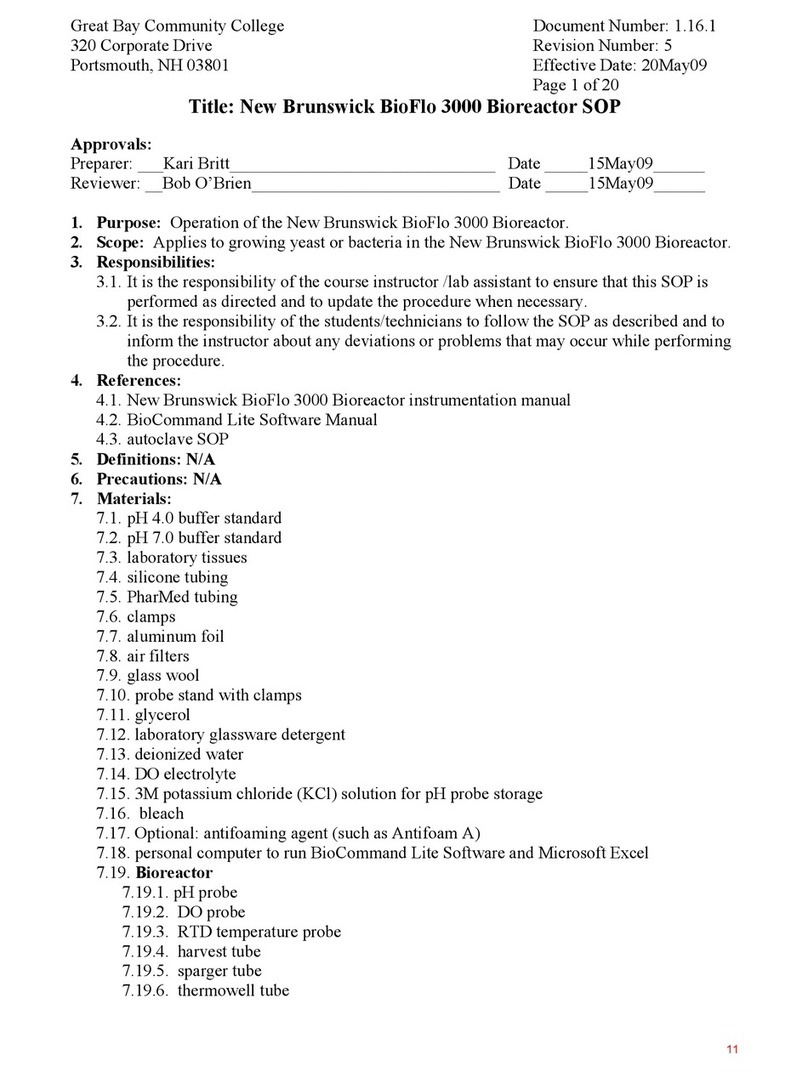

Removing and Replacing Tubes

Follow these instructions to remove and replace drying tubes.

To remove:

Turn the tube fitting to the left to loosen and remove the tube from

the port on the scope drying unit

To replace:

Connect a new tube to the port by turning the tube fitting to the

right until tube is firmly attached

Removing and Replacing Air Filter

Follow these instructions to remove and replace the air filter on

the scope drying unit.

To remove:

Press the quick release buttons on the top and bottom of the air

filter, and pull out and discard the filter

To replace:

Insert the new air filter. The quick release buttons will reset once

the filter is attached

Connecting Scope Drying Unit

to Building’s Air Supply

Follow these instructions to connect a scope drying unit to a

building’s air supply.

Make sure the scope drying unit is off

Connect a ¼” quick-disconnect hose to the air valve on the unit

Turn unit on. Air is now ready to flow through unit

Caution: Make sure air is regulated to 10 PSI maximum.

Pressure exceeding 10 PSI can damage endoscopes.

Instruction Guide for Scope Drying Unit

Appendix

14

Instructions

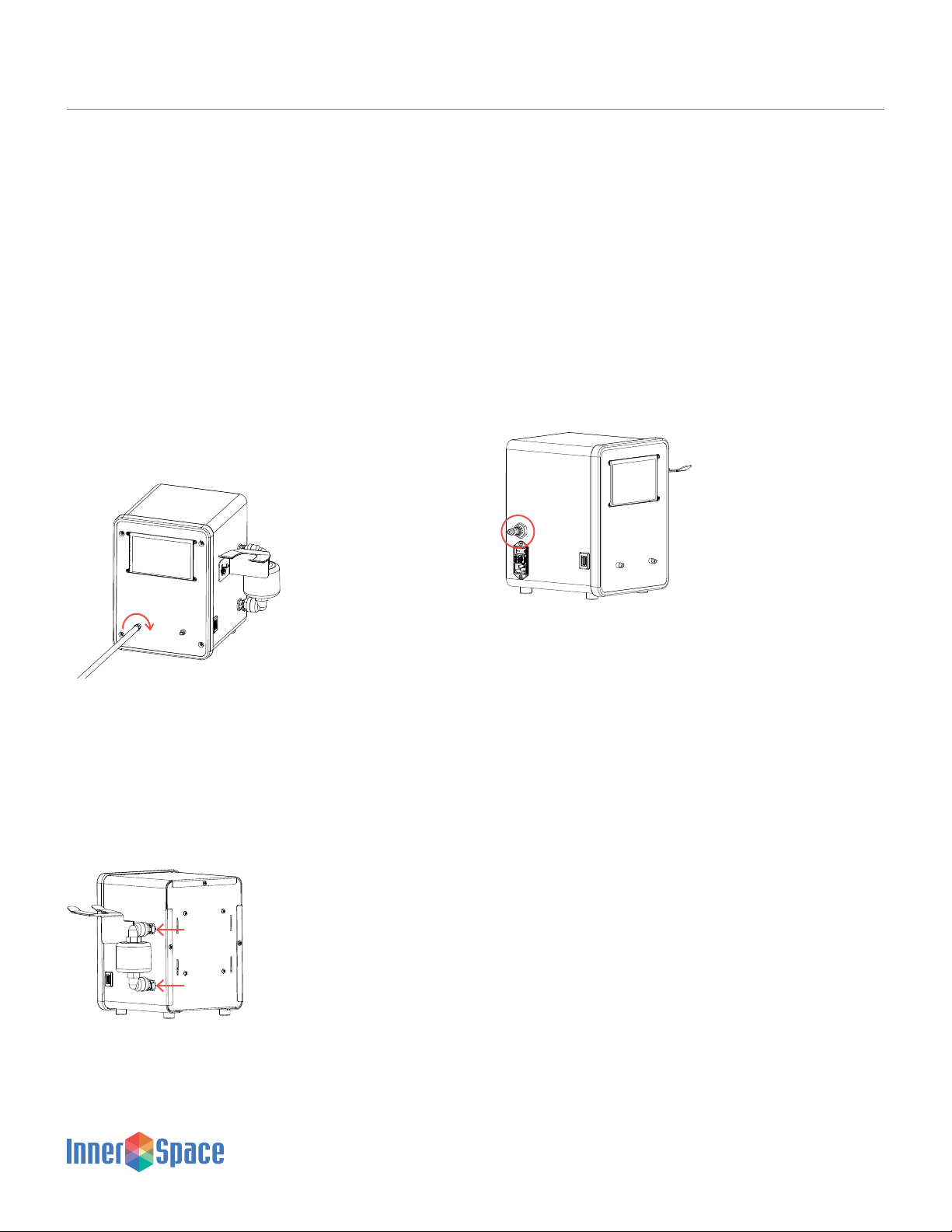

Mounting a Scope Drying Unit

to IV or Scope Pole

Follow these instructions to mount a scope drying unit to an IV or

scope pole.

Included:

• Mounting bracket

• 2 U-bolts

• 4 nuts

Tools needed:

• Flat-head screwdriver

• Wrench

Step 1

Position bracket so the arrow faces up

Step 2

Place bracket against the pole at desired height. Typical height of

unit is approximately 4’ 9” (57”) from the floor to the center of the

unit’s screen

Step 3

Place U-bolts over the pole and through the center holes in the

back of the bracket. Insert and turn the 4 nuts clockwise with

wrench until firm and the U-bolts are tightly in place

Step 4

Line up the 4 tabs on the bracket with the 4 channels on the back

of the unit. Push down gently on the scope drying unit until firmly

in place

Step 5

Use the flathead screwdriver to tighten the cam lock on each side

of the mounting bracket, making sure the arrow on the cam lock

is pointed up or down when the lock is tight

Instruction Guide for Scope Drying Unit

Appendix

UNLESS OTHERWISE SPECIFIED

DIMENSIO NS ARE IN INCHES[MILLIMETERS]

TOLERANCES ARE:

ANGLES: 1/2

.X .050[1.27]

.XX .030[0.76]

.XXX .015[0.38]

Part free of burrs & sharp edges2.

Notes:

Min bend radius required1.

813000213

14ga Plain Carbon Steel

Reference

Validation/Verification

Inspection

Definition

Symbol

B11

1:2

POWDER COAT GREY PC316

Material

Sheet

Scale

Description Part No

Finish

Mount, Wall, Tabletop

( )

Sheet Size

BT

www.solairem edical.com

Drawn By:

Office: 888.4 35.2256 PO Box 2 808

Fax: 616. 743.5944 Grand Rapids, M I 49501

OF

FLAT PATTERN

UP 90° R .03

UP 90° R .03

6.91 175.58

5.00 127

27.301.075

2.22.088

3.000 76.20

.775 19.68

.300 7.62

REVISIONS

REV. DESCRIPTION DATE ENG.

CHANGE #

A Release for Prototype 7/21/2022

B Added Arrow and "UP" 11/18/2022

88.903.500

88.905.00 127

5.000 127

.75 19.05

.75 19.05

3.50

.18 4.50

1.250 31.75 1.000 25.40

15

Instructions

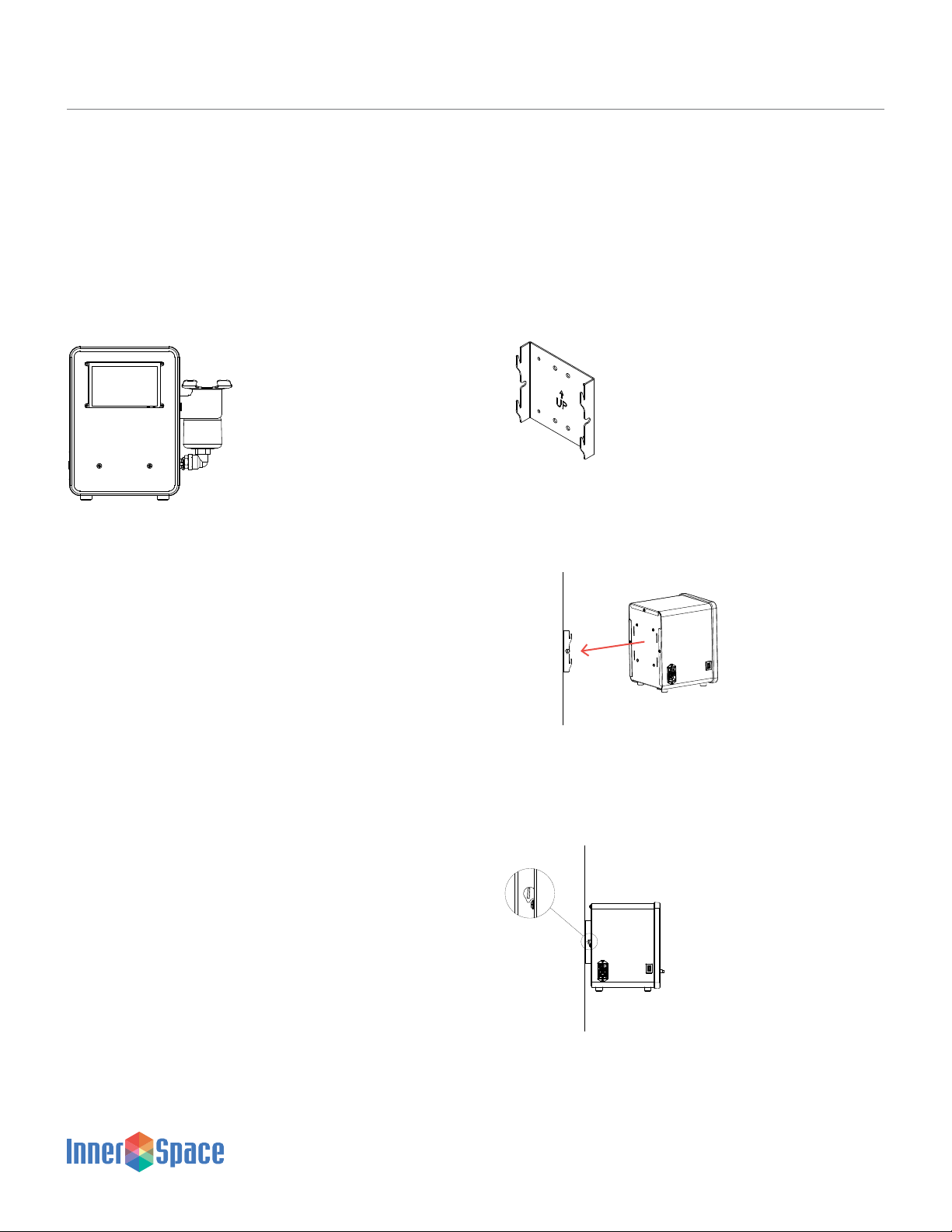

Mounting a Scope Drying Unit

to a Wall

Follow these instructions to mount a scope drying unit to a wall.

Included:

• Mounting bracket

• 4 wall anchors

• 4 screws

• Mounting template

Note: Use wall anchors when mounting unit to a hollow wall. If

mounting to wall studs, you will not need the wall anchors.

Tools needed:

• #8 Phillips head screwdriver

• Drill with 5/16” drill bit

Step 1

Place template at desired location on wall. Typical height of unit is

approximately 4’ 9” (57”) from the floor to the center of the unit’s

screen

Step 2

Drill 5/16” diameter hole into the 4 locations. Discard template

Step 3

Fold anchor in the middle. Insert anchor in hole and tap until it is

flush with wall. Only ¾” clearance is needed behind wall

Step 4

Position bracket so the arrow faces up and place it over the

anchors. Insert screws and tighten with screwdriver until screws

are flush with bracket face. Do not overtighten screws

Step 5

Line up the 4 tabs on the bracket with the 4 channels on the back

of the unit. Push down gently on the scope drying unit until firmly

in place

Step 6

Use the flathead screwdriver to tighten the cam lock on each side

of the mounting bracket, making sure the arrow on the cam lock

is pointed up or down when the lock is tight

Instruction Guide for Scope Drying Unit

Appendix

WALL

WALL

UNLESS OTHERWISE SPECIFIED

DIMENSIO NS ARE IN INCHES[MILLIMETERS]

TOLERANCES ARE:

ANGLES: 1/2

.X .050[1.27]

.XX .030[0.76]

.XXX .015[0.38]

Part free of burrs & sharp edges2.

Notes:

Min bend radius required1.

813000213

14ga Plain Carbon Steel

Reference

Validation/Verification

Inspection

Definition

Symbol

B11

1:2

POWDER COAT GREY PC316

Material

Sheet

Scale

Description Part No

Finish

Mount, Wall, Tabletop

( )

Sheet Size

BT

www.solairem edical.com

Drawn By:

Office: 888.4 35.2256 PO Box 2 808

Fax: 616. 743.5944 Grand Rapids, M I 49501

OF

FLAT PATTERN

UP 90° R .03

UP 90° R .03

6.91 175.58

5.00 127

27.301.075

2.22.088

3.000 76.20

.775 19.68

.300 7.62

REVISIONS

REV. DESCRIPTION DATE ENG.

CHANGE #

A Release for Prototype 7/21/2022

B Added Arrow and "UP" 11/18/2022

88.903.500

88.905.00 127

5.000 127

.75 19.05

.75 19.05

3.50

.18 4.50

1.250 31.75 1.000 25.40

16

Instruction Guide for Scope Drying Unit

Appendix

Template for Mounting a Scope

Drying Unit to a Wall

Drill 5/16” diameter hole into the 4 locations. Discard template

Table of contents