Innotech TEMP User manual

© INNOTECH Arbeitsschutz GmbH. Irrtümer, Druckfehler, technische Änderungen vorbehalten!

© INNOTECH Arbeitsschutz GmbH. Errors and misprints accepted. We reserve the right to make technical changes.

DE – ACHTUNG: Die Verwendung des Innotech-Produktes ist erst zulässig nachdem

die Gebrauchsanleitung in der jeweiligen Landessprache gelesen wurde.

DE

EN – ATTENTION: Use of the Innotech product is only permitted after the instruction

manual has been read in the respective national language.

EN

IT – ATTENZIONE: L’utilizzo del prodotto Innotech è permesso solo previa lettura

del manuale di istruzioni nella lingua del paese corrispondente.

IT

FR – ATTENTION : L’utilisation du produit Innotech n’est autorisée qu’après

la lecture du mode d’emploi correspondant dans la langue du pays.

FR

NL – ATTENTIE: Het gebruik van dit Innotech product is pas toegestaan, nadat

degebruikshandleidingindetaalvanhetbetreendelandgelezenwerd.

NL

SV – O B S : Denna Innotech-produkt får inte användas, förrän bruksanvisningen

på respektive lands språk har lästs igenom.

SV

DK – GIV AGT: Det er først tilladt at anvende Innotech-produktet, før end brugsvej-

ledningen på det pågældende lands sprog er læst.

DK

ES – ATENCIÓN: El uso del producto Innotech sólo está permitido después de que

se hayan leído las instrucciones de uso en el idioma del respectivo país.

ES

PT – ATENÇÃO: O uso do produto Innotech apenas é permitido depois de ter lido as

instruções de uso na respectiva língua nacional.

PT

PL – UWAGA: korzystanie z produktu Innotech jest jedynie dozwolone po przeczy-

taniupodręcznikawjęzykunarodowym.

PL

RO – ATENŢIE:UtilizareaprodusuluiInnotechesteautorizatăabiadupăceaufost

cititeinstrucţiunileoriginaledeutilizareînlimbaţăriirespective.

RO

SL – POZOR: Uporaba izdelka Innotech je dovoljena šele po tem, ko navodila

preberete v svojem jeziku.

SL

CZ – POZOR:PrácesvýrobkemInnotechjepovolenaažpoprostudovánínávodu

kpoužitívpříslušnémjazycedanéhostátu.

CZ

SK – POZOR:PoužívanievýrobkuInnotechjepovolenéažpotom,keďstesi

prečítalinávodnaobsluhuvjazykupríslušnejkrajiny.

SK

HU – FIGYELEM: Az Innotech termékek használata csak az után engedélyezett,

miután saját nyelvén elolvasta a használati utasítást.

HU

TR - DİKKAT: INNOTECHürünününkullanımınaancakilgiliülkenindilindesunulmuş

olankullanımkılavuzununtamamenokunmasındanveanlaşılmasındansonraizinverilir.

TR

TEMP

Instruction manual

EN

2TEMP / 200122 / www.innotech.at

Prior to use, the following safety instructions and the current state of the art

must be taken into consideration.

-Keeptheseinstructionsforinstallationandusewiththeproductandcarefullyll

out the acceptance log, the test sheet and the test log.

- Completely read the instruction manual.

- Understand and accept the possibilities and restrictions of the protective equip-

ment as well as the risks associated with its use.

- TEMP should only be installed by specialised/competent experts familiar with

the safety system and in compliance with the current state of the art.

- You must be familiar with these instructions, as well as with the local safety

regulations as a prerequisite for installing and using the system. You must also

bephysicallyandmentallytandtrainedintheuseofPPE(PersonalProtective

Equipment).

-Medicalconditions(cardiovascularproblems,intakeofmedicines,alcohol)can

aectthesafetyoftheuserwhenworkinginhighplaces.

-Adheretotherespectiveaccidentpreventionregulations(e.g.workingonroofs)

wheninstalling/usingtherestraintsystem(andwhenascendingto,entering,

and descending from the roof).

-Measures(emergencyplan)mustbespeciedforfastrescuepriortoinstalling/

using the fall prevention system. Attention: after a fall, a longer period of suspen-

sion in personal protective equipment can cause severe injuries or even death

(suspensiontrauma).

- Before starting the work, you must ensure that no objects can fall to the ground

fromtheworksite.Theareabelowtheworksite(sidewalk,etc.)mustbekept

clear.

-Theinstallersmustensurethatthegroundissuitedforxingtheanchorage

device. If in doubt consult a structural engineer.

- If uncertainties arise during installation/use it is imperative that you contact

themanufacturer(www.innotech.at).

- Ensure that stainless steel does not come into any contact with swarf or steel

tools, as this may lead to corrosion.

- You should plan, install and use the restraint system in such a way that no one

can fall over the edge if the personal protective equipment is used properly.

(Seeplanningdocumentsatwww.innotech.at)

1SAFETY INSTRUCTIONS

EN

3

TEMP / 200122 / www.innotech.at

- When fastening the TEMP, always use a carabiner or INNOTECH travelling eye-

bolt and wear personal protective equipment in accordance with the information

contained in this instruction manual.

- For horizontal use, only those fasteners may be used that are suited for this

purposeandhavebeentestedfortherespectiveedges(sharpedges,sheetwith

trapezoidal corrugations, steel girder, concrete, etc.).

Attention: avoid pendulum fall!

- Fall arrest devices may only be used if approved for horizontal lifeline systems

by the manufacturers of these fall arrest devices.

- Make absolutely sure that the restraint system cannot be endangered by

sharp edges.

-Thereisahazardwhencombiningindividualelementsofthespeciedunits,since

the safe function of one of the elements can be impaired through the combination.

(Followthespecicinstructionsprovidedwitheachelement!)Incorrectapplica-

tions can result in severe or fatal injuries.

- After a fall and the resulting strain, you must stop using the restraint system and

haveitcheckedbyanexpert(componentparts,fasteningtothesubstrate,etc.).

- TEMP was developed for personal safety and may not be used for other purposes.

Neverattachundenedloadstotherestraintsystem.

- Do not use restraint systems if wind speeds exceed normal parameters.

- Do not make any changes to the approved anchorage device.

- If you provide the restraint system to external contractors, the familiarity with

theinstructionsforinstallationandusemustbeconrmedinwriting.

- Each person active in the areas where there is danger of falling is responsible for

ensuring that the connection to the anchorage system is kept as short as possible

to prevent the possibility of a fall.

A product that does no longer appear to be safe must no longer be used and

must be replaced immediately!

1SAFETY INSTRUCTIONS

EN

4TEMP / 200122 / www.innotech.at

PRIOR TO EACH USE THE USER MUST INSPECT:

- Before use, you must inspect the entire restraint system for obvious defects

(forinstance,reliableoperationofbucklesandratchets;loosescrews,deforma-

tion,abrasion,corrosion;beltsandseamsforweathering,fray,burnmarks,

chafe marks, cracks, cuts or other damage, etc.)

- The steel cable loops of the end locks: Ø = 220 mm

- Check the cable sag when the system is under tension.

(Re-tightenasnecessary:–seesection13“Tighteningthesystem”)

- In addition, use the acceptance log, test sheet and test log to verify that

the protective equipment is suitable for the application.

If there are any doubts concerning the reliable operation of the restraint system, it must

nolongerbeusedandcheckedbyanexpert(writtendocumentation).

ANNUAL INSPECTION: (=sections16/17)

- The complete safety device must be subjected to an inspection by a competent/

specialised expert who is familiar with the restraint system. Depending on the

intensity of use and environment it may be necessary to shorten the inspection

intervals. The inspection must be documented on the test sheet, which must be

stored along with the protective equipment.

ATTENTION! STOP USING THE EQUIPMENT IF:

- Damage or wear to its components is obvious.

- Stress has occurred due to falling.

- Defects have been detected during regular inspections.

- The service life has elapsed.

-Theproductidenticationisnolongerlegible.

Retire the equipment if a visual inspection performed by the owner or a competent/

specialisedexpertrevealeddecienciesorthePPEhasexpired.Whenyouretirethe

equipment, you can be certain that it will not be used again in future applications.

2INSPECTION/SERVICE LIFE

EN

5

TEMP / 200122 / www.innotech.at

The service life of the TEMP depends on the respective use and cannot be generally

denedduetodierentfrequenciesofuse,useconditions,careandstorage.

When used in compliance with the use guidelines and inspected annually by a competent/

specialised expert, the device has a service life of up to 10 years dating from the year

ofproduction(=markedontheharnessstrap).

Under normal use conditions there is a two year warranty on all components against

manufacturing defects. However, if the system is used in particularly corrosive atmos-

pheres, this period can be shortened.

Ifthereisstrain(afall)thewarrantyclaimisvoidforthosecomponentsthathavebeen

designed to absorb energy, or that may possibly be deformed and, therefore, must

be replaced. Attention: INNOTECH does not assume any warranty in case of improper

installation.

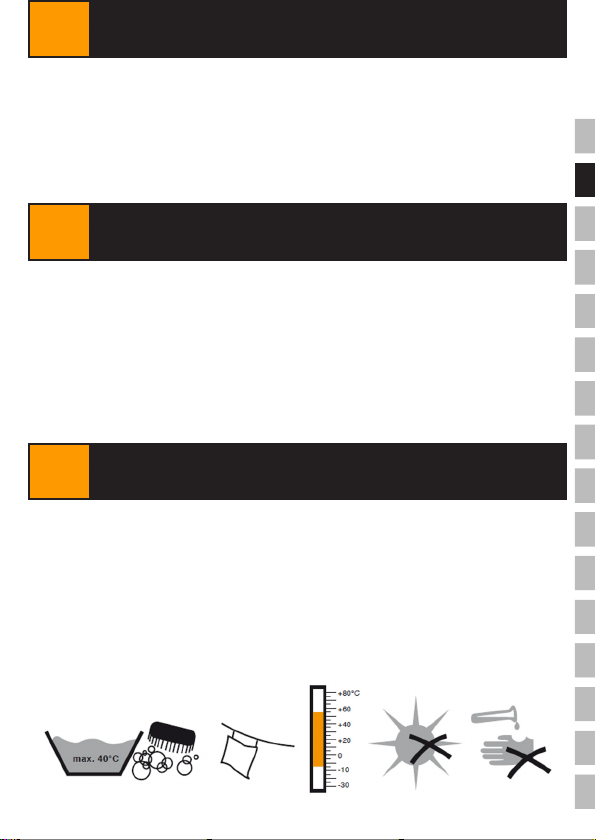

Store the restraint system in a suitable protective sheath to protect it from UV radiation,

chemicals,moisture,sourcesofheatandotherenvironmentalinuences.

IF NECESSARY:

Clean the harness strap using lukewarm water and mild soap, rinse it with clear water

andletitdryintheair(neverdryitinthelaundrydryeroraboveasourceofheat).

3SERVICE LIFE

4WARRANTY

5STORAGE/CARE

EN

6TEMP / 200122 / www.innotech.at

uENDS-10

uSZH-10

6DIMENSIONS/MATERIAL

-End lock ENDS-10:

anodised aluminium,

AISI 304 stainless steel,

galvanised steel

-Polyester harness strap:

50x4,000mmwithpowder-coatedsteelendtting

and protective polyester sleeve with smooth

PVC coating Ø 35 x 2,000 mm

-Ratchet:

50mm,18teeth,5,000daN;

composed of galvanised steel and plastic handle

-SZH-10 intermediate bracket:

AISI 304 stainless steel and nickel-plated steel

-Polyester harness strap:

50 x 2,500 mm

including sewn-in ratchet:

50mm,18teeth,5,000daN;

composed of galvanised steel and plastic handle

uAIO SEIL-30

-Stainless steel cable:

AISI316stainlesssteel,diameter:Ø8mm(7x7)

breakingload:37kN

33

51,4114,5

48

49,5

31,5

21

33

51,4114,5

48

49,5

31,5

21

33

51,4114,5

48

49,5

31,5

21

62

94

115

88

35

58,5

34

0,5

O

9

65

62

94

115

88

35

58,5

34

0,5

O

9

65

EN

7

TEMP / 200122 / www.innotech.at

7STANDARDS

8ANCHORAGE SUBSTRATE

9SIGNS & MARKINGS

INNOTECHTEMPhasbeentestedandcertiedinaccordancewith

EN 795:2012 TYPE B and EN 795:2012 TYPE C.

THE NOTIFIED AUTHORITY PARTICIPATING IN THE TYPE TEST:

DEKRATestingandCerticationGmbH,Dinnendahlstr.9,44809Bochum,C0158

ThetypetestwasperformedinaccordancewithEN795:2012.

It is best to install the horizontal lifeline system above the user.

The basic prerequisite is a static, carrying substructure.

The carrying structure used to fasten the TEMP must have great inherent stability

and a minimum strength of 22 kN.

Name or logo of the manufacturer/reseller: INNOTECH

Type designation: TEMPENDS-10/TEMPSZH-10

Batch number of the reseller: 20xx/xx

Year of production: 20xx

Manufacturer’s ID no: P-xxxxx

Length: 4 m/2.5 m

Signs stating that the instructions specied

in the manual must be followed:

HARNESS STRAPS

Year of production

Length: 4 m

Year of production

Length: 2.5 m

EN

8TEMP / 200122 / www.innotech.at

EN 795:2012 TYP B

EN 795:2012 TYP C

TEMP-ENDS-10

13-03-10-Aufkleber-DE-A

SEILAUSLENKUNG MAX. 2,5

FALLDÄMPFER JA

0158

max.

JJJJ-..-...

Max. cable deection 2,5 m

Fall breaker YES

Name or logo of the manufacturer/reseller: INNOTECH

Type designation: TEMP

Numbers of the applicable standards: EN795:2012TYPEB

EN795:2012TYPEC

Maximum cable deection after a fall: 2.5 m

Fall breakers required: YES

DEKRA Testing and Certication GmbH:C0158

Year of manufacture and manufacturer’s serial number: 20xx - xx

Maximum number of people who will be secured: 4(including1personfor

rst-aidadministration)

Signs stating that the instructions specied

in the manual must be followed:

uEND LOCKS (= SYSTEM RATING PLATE)

The mobile horizontal lifeline system is suitable for temporary installation on various

base structures. Ideal for construction sites/building constructions of all kinds.

(Steel,facade,hallandbridgeconstruction,etc.)

Approved as a temporary horizontal lifeline system for 4 people(including1person

forrst-aidadministration)alongahorizontalandstraightspanwithapitch ranging

from 0° to a maximum of 15°.

SuitableforthefollowingfallprotectionsystemsinaccordancewithEN363:2008

• Restraint systems

• Workplace positioning systems

• Fall arrest systems

• Rescue systems

Safeapplicationrequiresthatyouobservethecorrespondingspecicationsprovided

by the PPE manufacturers.

For safety reasons, we recommend that you always use fall arrest systems as restraint

systems!TEMPisnotsuitableforabseilingwork(ropeaccesssystems(EN363:2008)).

9SIGNS & MARKINGS

10 USE INSTRUCTIONS

EN

9

TEMP / 200122 / www.innotech.at

Theusermustbecapableofselectingandproperlyhandlingthe“PersonalProtective

Equipment(PPE)againstfallsfromaheight”indueconsiderationofEN363:2008!

Theappropriate“PersonalProtectiveEquipment(PPE)againstfallsfromaheight”is

connected to the stainless steel cable of the TEMP anchorage device, which is spanned

horizontally,followingtheinstructionsofthePPE’smanufacturer(seeinstruction

manual for the PPE).

(E.g:EN353-2orEN354+EN355,etc.-->werecommendthatyouusea“Y”rope

or INNOTECH travelling eyebolt in connection with systems that include an intermediate

bracket.)

Attention!TheTEMPanchoragedeviceisttedwithshockabsorbersinordertoabsorb

theforcesgeneratedduringafall(harnessstraps+cableloopsoftheendlocks).Inthe

event of a fall, the stainless steel cable extends by contracting the cable loops, thereby,

absorbing the fall. This is why you need to make sure that, while using the fall arrest

system, you always leave enough free space below the user to prevent him from hitting

the ground in the event of a fall.

The minimum free space necessary between the fall point and the ground is

calculated as follows:

Free-fall height1(height of the unchecked fall until the PPE stops the fall)

+ Existingcablesagofthesystemafterinstallation

(checkduringuseandre-tightenasnecessary!)

+ Max.cabledeectionafterafallaccordingtotable(max.2.5m)

+ Manufacturer’sinstructionsofthePPEusedtopreventfallsfromaheight

(e.g.:max.brakingdistanceofthefallarrestdeviceasspeciedbythemanufacturer,etc.)

+ Shiftofthefall-arresteyeletattachedtothesafetyharnessinaccordancewithEN361

(approx.1.0m)

+ Safetymargin:1.0m

Length without intermediate bracket: Max.cabledeectionafterafall:(4people)

6m 1.1m

12m 1.7m

15m 2.0 m

20 m 2.5 m

1... can be avoided if positioned and used in the proper manner!

ThedeviceisattachedtothesystemonlybymeansoftheØ8mmstainlesssteelcablewhichisspanned

horizontally. Fastening the device to the harness strap, ratchet, etc. represents a safety risk and is prohibited!

INCORRECT APPLICATIONS

10 USE INSTRUCTIONS

EN

10 TEMP / 200122 / www.innotech.at

COMPONENTS TEMP SZH-10:

When storing the device, always secure the bolt at the end lock using the split pin!

COMPONENTS TEMP ENDS-10:

11 COMPONENTS

EN

11

TEMP / 200122 / www.innotech.at

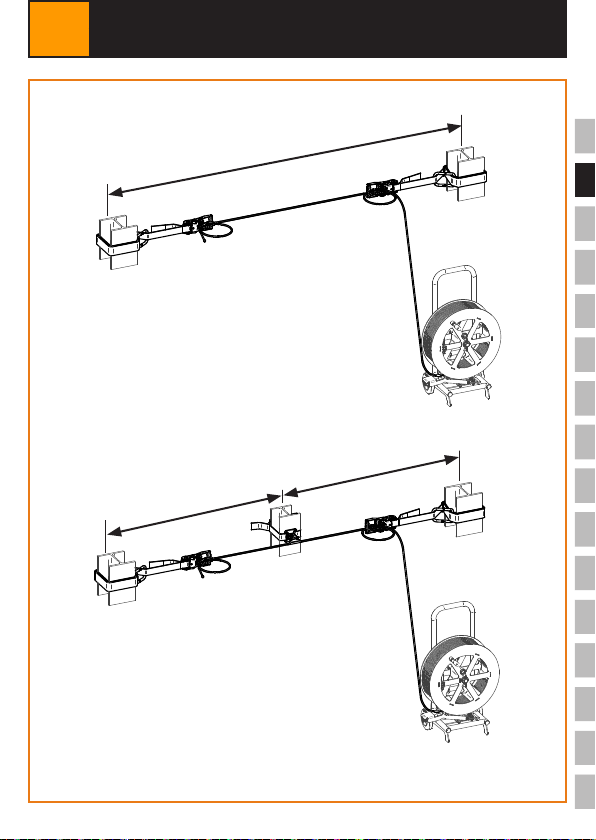

INSTALLATION EXAMPLE - OVERVIEW: (SCHEMATIC DRAWING)

Distances of 20 m or higher require that you install intermediate brackets

between the two end points. Field sizes: up to 20 m!

12 OVERVIEW – Distances

< 20 M

< 20 M

< 20 M

EN

12 TEMP / 200122 / www.innotech.at

CABLE LENGTHS OF 20 M OR HIGHER REQUIRE THAT YOU INSTALL

INTERMEDIATE BRACKETS. ATTACH THE CORRESPONDING NUMBER

OF INTERMEDIATE BRACKETS TO THE STAINLESS STEEL CABLE.

Beforebeginninginstallation,copythe“Signs&Markings(section 9)”foundonthe

harnessstraps/endlockstotheacceptancelog.(Willnolongerbevisiblelater!)

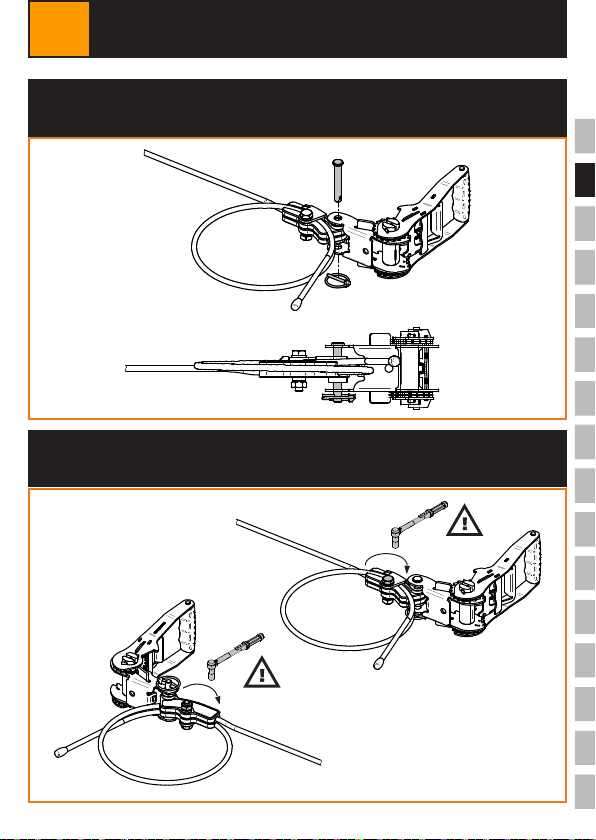

1. SLIP ON THE END LOCK UNTIL YOU REACH THE BOLT-LOCK-

ING DEVICE

TOOLS REQUIRED FOR INSTALLATION:

1atwrenchorsize17torquewrench

uFit the end lock at the loose end

of the cable

13 INSTALLATION

EN

13

TEMP / 200122 / www.innotech.at

3. PRESS THE STAINLESS STEEL CABLE INTO THE INNER GUIDE

OF THE END LOCK AT A DISTANCE OF AT LEAST 850 MM FROM

THE END OF THE CABLE AND LOCK IT IN PLACE BY HAND

2. AFFIX ONE OF THE INCLUDED Ø 8 MM PLASTIC PROTECTIVE

CAPS AT THE END OF THE CABLE. (3sparecaps)

13 INSTALLATION

≥

850 mm

A A

A - A

EN

14 TEMP / 200122 / www.innotech.at

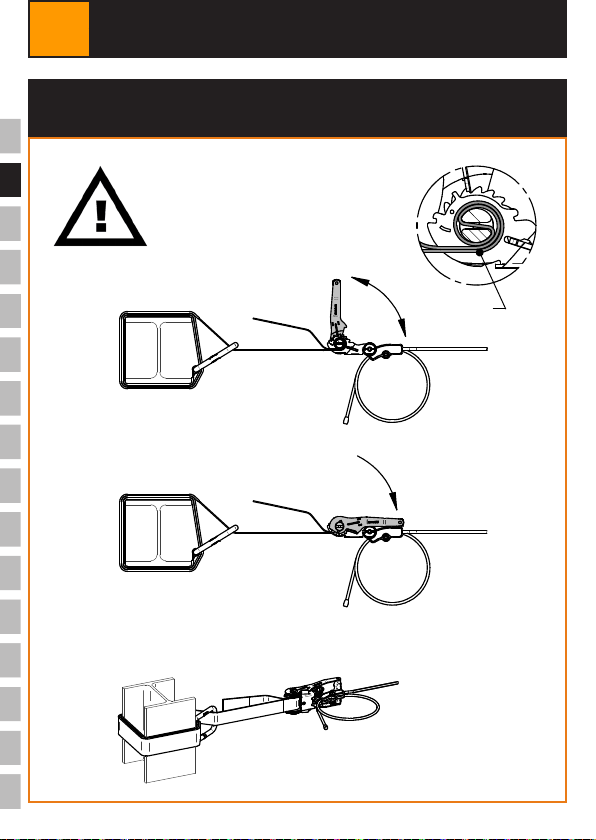

4. FORM A Ø 220 MM CABLE LOOP AND PRESS IT INTO THE

GUIDE ON THE EXTERIOR.

5. SCREW THE LOCKING MECHANISM IN PLACE

FOLLOWING THE ILLUSTRATION

13 INSTALLATION

Ø220

≥ 120

EN

15

TEMP / 200122 / www.innotech.at

25 Nm

25 Nm

Tighten the hex bolt

(25 Nm)

Connect the end lock to the

ratchet using bolt and split pin

13 INSTALLATION

EN

16 TEMP / 200122 / www.innotech.at

2. 3.1.

≥

900 mm

≥

900 mm

≥

500 mm

≥

900 mm

≥

900 mm

≥

500 mm

≥

900 mm

≥

900 mm

≥

500 mm

≥

900 mm

≥

900 mm

≥

500 mm

FASTENING POINTS (ANCHORAGE POINTS):

STRENGTH AT LEAST 22 KN !

The protective sleeve must cover any edges!

uLoop the harness strap around

the end point

13 INSTALLATION

EN

17

TEMP / 200122 / www.innotech.at

POSITION OF THE RATCHET:

Guide the harness strap through

the tension pulley of the ratchet

13 INSTALLATION

~ 300 mm

≥

900 mm

~ 300 mm

2

1

3

EN

18 TEMP / 200122 / www.innotech.at

> 3x

ü

The harness strap must be looped

at least 3 times around

the tension pulley!

uTie down the harness strap and

carefully lock the ratchet

13 INSTALLATION

EN

19

TEMP / 200122 / www.innotech.at

> 3x

≥

3 mm

N

ü

The harness strap must be looped

at least 3 times around

the tension pulley!

OPTIONAL:

Install intermediate brackets

13 INSTALLATION

EN

20 TEMP / 200122 / www.innotech.at

~ 600 mm

1. Pre-tension the stainless steel cable

2. Installthesecondendlockatadistanceofapprox.600mmfromthesecond

fastening point.

Proceedinthesamewayasforfasteningpoint1wheninstallingtheendlock

and fastening it at fastening point 2.

uFastening

on the opposite side

13 INSTALLATION

Table of contents

Other Innotech Accessories manuals