3

1

2

3

4

5

6

7

8

9

EN

General table of contents

GENERAL

1.1 General warnings ..............................................................................5

ECA644 - ECA647 - ESE645 - ESE648

2.1 Assembly, set-up and connection of on-board control panels ECA644, ESE645, ECA647, ESE648 . . . . . . . . . . . . . . . . .6

2.2 Assembly ....................................................................................6

2.3 Set-up of auxiliary dip-switch functions B and C........................................................7

2.4 CP presence contact input connection (only for ECA644 and ECA647 models) ................................7

2.5 Air temperature probe assembly (only for models ECA644, ECA647) ........................................8

2.6 Cooling/Heating automatic settings (only for 4-tube units).................................................8

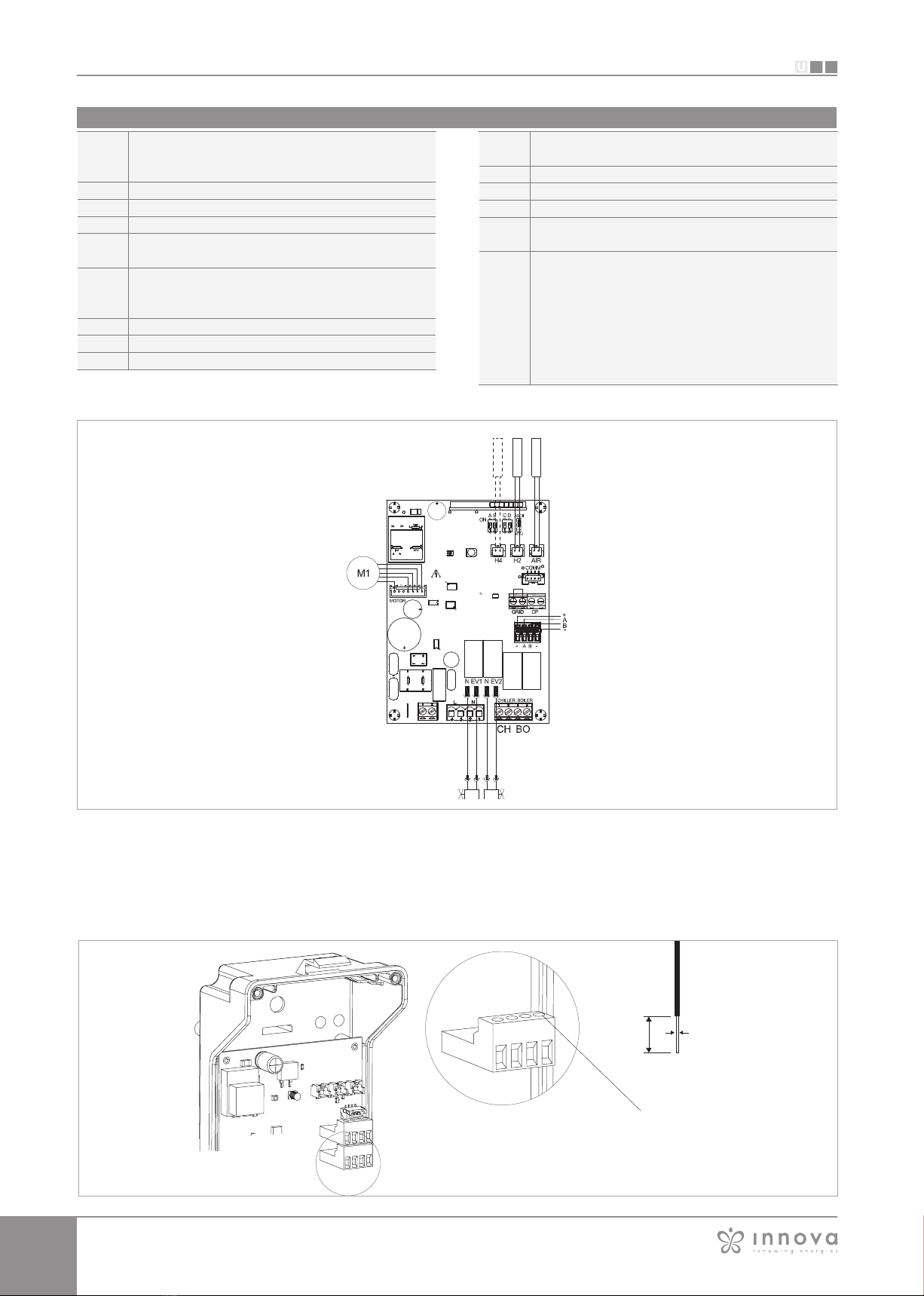

2.7 ECA644 and ECA647 connections .................................................................9

2.8 ESE645 and ESE648 connections ................................................................10

2.9 Continuous modulation circuit board for connecting remote thermostat (only for models ESE645 - ESE648) 11

2.10 LED Indications (Ref. A) (only for models ESE645 - ESE648) .............................................11

EDA649 - EDB649

3.1 Wall-mounted remote control panel assembly EDA649 - EDB649 .........................................12

3.2 Spring-loaded terminal connections -AB+ and CP .....................................................12

3.3 CP occupancy contact input connection ............................................................13

3.4 EDA649 - EDB649 Connections ..................................................................13

EWW649 - EWG649

4.1 Wall-mounted remote control panel assembly EWW649 - EWG649 ........................................14

4.2 Spring-loaded terminal connections -AB+ and CP .....................................................15

4.3 CP occupancy contact input connection ............................................................15

4.4 EWW649 - EWG649 Connections ................................................................16

E4T643

5.1 Assembly and connections for on-board control panel E4T643 ...........................................17

5.2 Assembly ...................................................................................17

5.3 Air temperature probe assembly ..................................................................18

5.4 E4T643 Connections ..........................................................................18

SETTINGS MENU ECA644 - ECA647 - EWF644 - EWF647 - EDA/EDB649 - EWG/EWW649 - E4T643

6.1 Setup menu .................................................................................19

E2T543

7.1 Assembly and connections for on-board control panel E2T543 ...........................................22

7.2 Assembly ...................................................................................22

7.3 Air temperature probe assembly ..................................................................23

7.4 E2T543 Connections ..........................................................................23

7.5 Water probe kit management E2T543 ..............................................................23

B3V137

8.1 Assembly and connections for on-board control panel B3V137 ...........................................24

8.2 Assembly ...................................................................................24

8.3 B3V137 Connections ..........................................................................25

8.4 Warnings table ...............................................................................25

B4V642

9.1 Assembly and fitting of fan control for remote control B4V642 ............................................26

9.2 Assembly ...................................................................................26

9.3 Connection diagram B4V642 with 3-speed thermostat .................................................27

9.4 B4V642 connections with 3-speed thermostat .......................................................27

9.5 LED signals .................................................................................28

9.6 Water probe management with 3-speed thermostat....................................................28