Innovative EBB & FLOW User manual

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

Complete InstrucƟonal Guide

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

7/16” WRENCH

7/16” SOCKET

LEVEL

POP RIVET TOOL

TAPE MEASURE

WE RECOMMEND AN IMPACT

GUN FOR LARGER JOBS

POWER DRILL

ΈFOR BENCHES LARGER THAN 5’Ή

WE RECOMMEND A

PNEUMATIC RIVETER FOR

LARGER QUANTITIES

MALLET

CAULK GUN

TOOLS NEEDED FOR ASSEMBLY

Level

Mallet

Pop

Riveter Caulk Gun

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

PARTS LIST

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

CONFIRM ALL PARTS ARE PRESENT BEFORE STARTING INSTALLATION

ΈA1Ή

SQUARE TO SQUARE CLAMP

ΈA5Ή

BENCH CORNER

ΈA9Ή

STRINGER PIPE INSERT

ΈONLY USE ON BENCHES OVER 27 FTΉ

ΈA12Ή

SCREEN FOR BULKHEAD FITTING

ΈB2Ή

HEADER

ΈE1Ή

END FRAME

ΈONLY USE ON BENCHES OVER 5 FTΉ

ΈB3Ή

BENCH CROSSBAR

ΈA13Ή

3/4 BULKHEAD FITTING

ΈB1Ή

LEGS ΈLEG SUPPORTSΉ

ΈA10Ή

SIDE RAIL JOINER PLATE

ΈONLY USE ON BENCHES OVER 24 FTΉ

ΈA6Ή

1/4 ͳ20 BOLT & NUT

ΈA7Ή

BENCH GLUE

ΈA8Ή

BENCH FILTER

ΈA2Ή

POP RIVET

ΈA3Ή

FLAT WASHER

ΈA4Ή

LOAD BEARINGPLUG

ΈA11Ή

TEK ΈSELFͳTAPPINGΉSCREWS

CRIMPED ENDS

SHOULD BE FACING UP WHEN

YOU BEGIN ATTACHING

SQUARE TO SQUARE CLAMPS

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

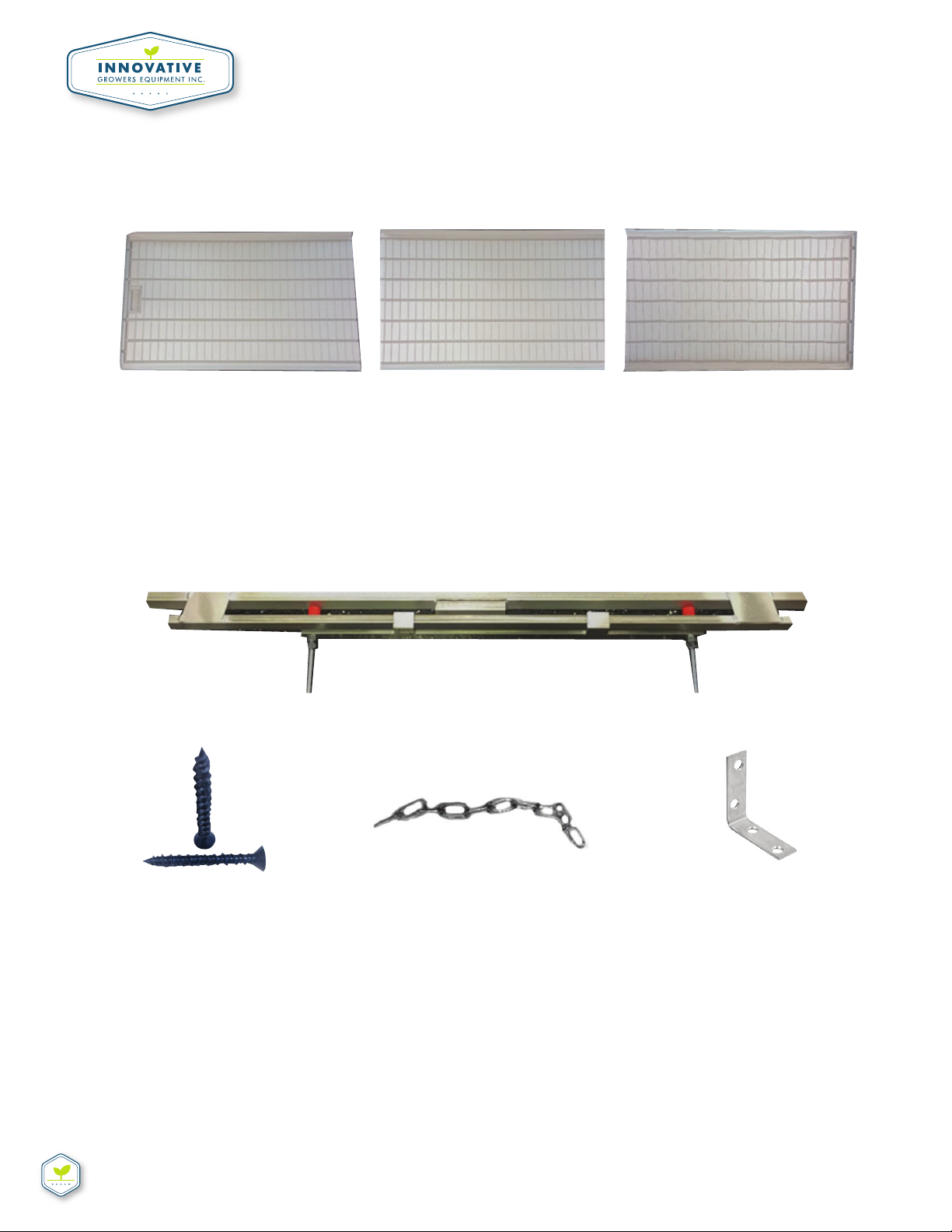

BENCH TRAYS

PARTS INCLUDED WITH MAX ROLL TABLES

CONFIRM ALL PARTS ARE PRESENT BEFORE STARTING INSTALLATION

TRAY GLUE IS USED TO SEAL TRAYS TOGETHER ΈA7Ή

ΈS1Ή

ANITͳTIP / MAX ROLL HEADER

ΈS2Ή

TAP CON SCREWS

ΈS3Ή

SAFETY CHAINS

ΈS4Ή

LͳBRACKET

END TRAY

ΈWITH DRAIN MOLDINGΉ

END TRAYMIDDLE TRAY

FOR LONGER BENCHESΉ

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

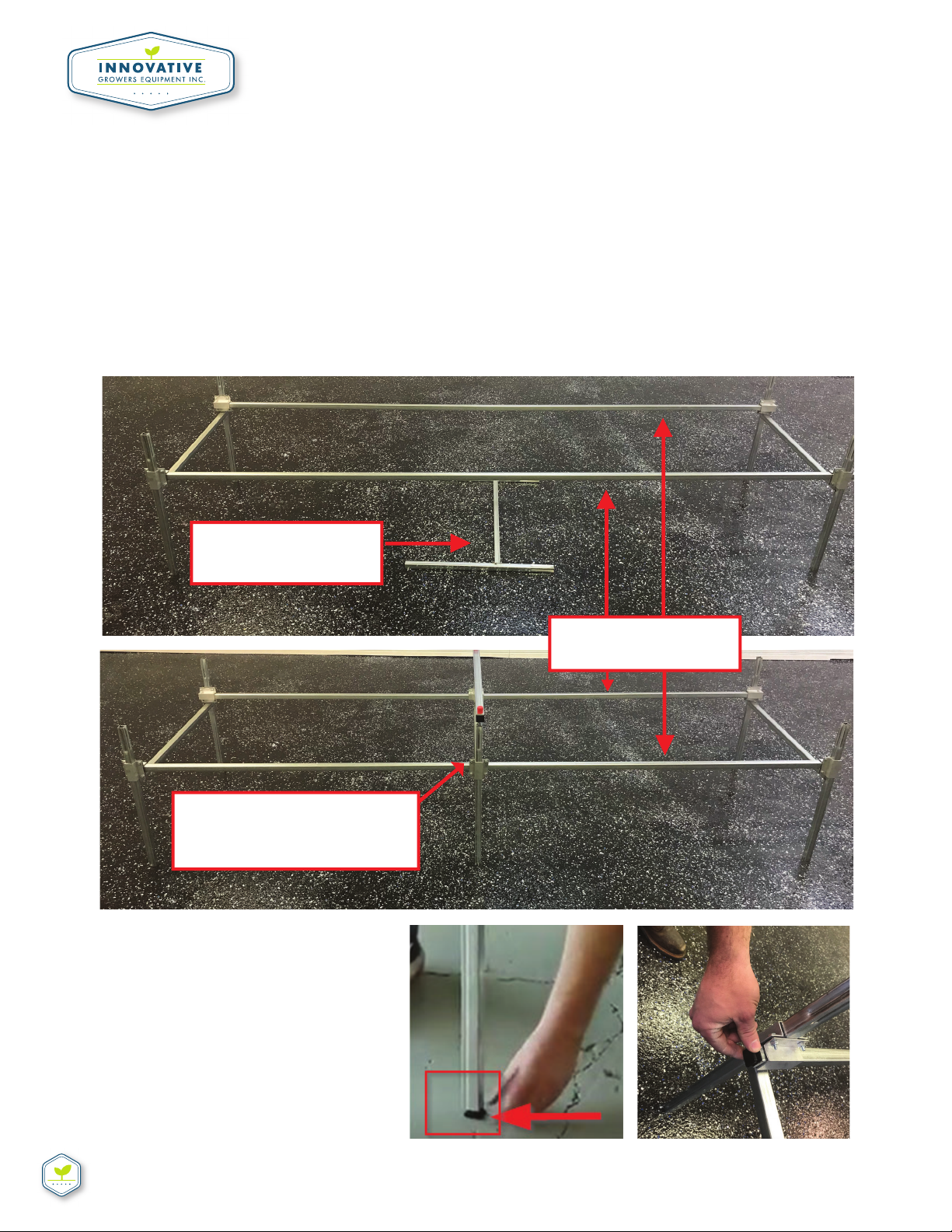

STEP #1

Lay out the stringer pipe and leg support pieces (B1) on the ground as shown in

the picture below.

STEP #2

Stand up one of the leg supports (B1) on end

(ridged end up as shown in Figure 1) and rest the

end of the stringer pipe on the bar connecƟng

the two leg ends. Please go to InnovaƟve

Growers Equipment youtube page if you need

further instrucƟons on this.

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

FIGUIRE 1

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

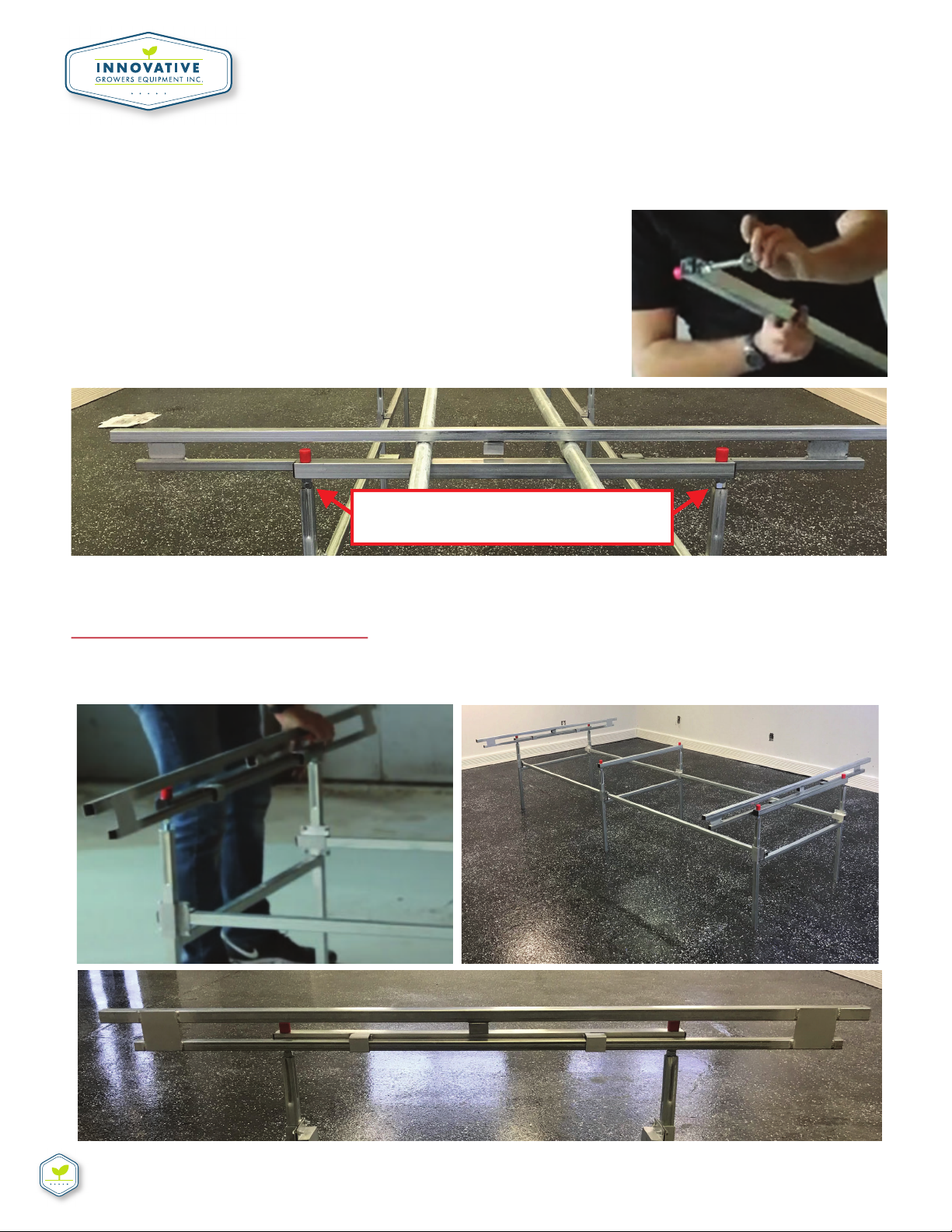

STEP #3

Take two clamps (A1) and line them up

perpendicular to one another

(outside one verƟcally and inside one horizontal).

***When lined up place the screws (A6) through the

holes facing inward and screw in the nuts (A6) from

the inner porƟon of the frame as shown in Figure 2

STEP #4

Perform the same steps on the other end of the leg support shown. You’ll now have one

end of the bench standing as shown below on Figure 3

Inside Clamp

PosiƟon

Outside Clamp

PosiƟon

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

FIGUIRE 2

FIGUIRE 3

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

STEP #5

Now stand up the leg support on the opposite end of the frame and aƩach the clamps on

each corner on that side as well. Then stand up any leg supports in the middle of the

frame and repeat the steps again unƟl the frame is complete (shown on Figure 4a & 4b).

NOTE: Longer tables will require addiƟonal leg supports in the middle of the frame so just use the

diagrams aƩached for reference. They will provide spacing requirements

STEP #6

Once the legs are all standing, you

can insert the load bearing plugs

(A4) into the boƩom of all the

welded legs. (B1 – see Figure 5).

Also, install them to the ends of the

stringer pipes on each corner of the

frame (shown on Figure 6).

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

FIGUIRE 4a

FIGUIRE 4b

STRINGER PIPE

UNATTACHED

LEG SUPPORT

ATTACH ALL REMAINING

LEG SUPPORTS TO THE

FRAME

FIGUIRE 5

FIGUIRE 6

INSTRUCTIONS FOR INNOVATIVE ARCHIVAL ROLLING BENCHES

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

STEP #7

Insert the flat washers (A3) in the bolts of the

pre-assembled headers (B2) and slide the bolts

through the opening of the crimped end of the

leg supports (B1 – shown on Figure 7).

STEP #8

***FOR MAX ROLL TABLES ONLY - If you have a max roll table, insert your max roll head-

ers (S1) into legs (B1) like you would regular headers (Figure 8). The locaƟon for these

headers will be labeled on your aluminum side rails as well as your custom bench diagram

FIGUIRE 7

FLAT WASHERS INSERTED HERE

FIGUIRE 8

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

STEP #9

***FOR MAX ROLL TABLES ONLY - Now, take the rolling pipe and slide them through the

opening of the swinging bar aƩached to the anƟ-Ɵp (S1) on one end of the table and

push it through the opening at the other end of the table (see Figures 9, 10, 11)

Note: if the bench is over 24’ you

will have swedged pipe to connect

to addiƟonal rolling pipe).

FIGUIRE 9

FIGUIRE 10

FIGUIRE 11

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

STEP #10

Next, take the end frames (E1) and lay

them across the rolling pipe on each of

the table (Figure 12a and Figure 12b )

STEP #11

Lay out the bench cross bars (B3) over the rolling pipe equally spaced across the bench as

shown in Figures 13a, 13b

Be sure the pre-punched holes are FACING UP when they’re laid across the bench.

FIGUIRE 12a FIGUIRE 12b

FIGUIRE 13a

FIGUIRE 13b

INNOVATIVEGROWERSEQUIPMENT.COM

Call 815-991-5010 or email us at sales@innovaƟvegrowersequipment.com if you have any quesƟons

EBB & FLOW BENCH ASSEMBLY INSTRUCTIONS

FOLLOW INSTRUCTIONS BELOW ΈCONT.Ή

STEP #12

Bench corners (A5) should now be riveted to the END aluminum pieces using the pop

rivets (A2). Figure 14a shows one of the bench corners before its connected to the

aluminum end piece with the pop rivets in the holes. Figure 14b shows what the rivets

should look like aŌer they’ve been riveted. Figure 14c shows what both end aluminum

rails should look like aŌer all the bench corners have been riveted to them. Figure 14d

shows the bench rails and corners connected.

NoƟce the bench corners are now connected to the aluminum

FIGUIRE 14b FIGUIRE 14d

FIGUIRE 14a

FIGUIRE 14c

Table of contents

Other Innovative Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Millcreek

Millcreek 406 Operator's manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

AQUA FLOW

AQUA FLOW PNRAD instructions

Tru-Turf

Tru-Turf RB48-11A Golf Green Roller Original instruction manual

BIOGROD

BIOGROD 730710 user manual

Land Pride

Land Pride RCF2784 Operator's manual

Makita

Makita UM110D instruction manual

BOERBOEL

BOERBOEL Standard Floating Bar Gravity Latch installation instructions