InPOWER SS-FD23 User manual

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

1 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

OWNERS MANUAL

InPower Model SS-FD23

Contents

1. Introduction............................................................ 2

2. Installation Procedures.......................................... 3

3. Operation............................................................... 6

4. Mechanical Drawing .............................................. 10

5. Status LED and Troubleshooting........................... 11

6. Installation Location............................................... 13

7. Start/Stop Ignition/BCM/SS-FD23 Wiring.............. 16

8. Contact Information ............................................... 16

Electronic Start/Stop/Elevated Idle Control Module

for Ford 2023 F250-F600

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

2 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

1. Introduction

InPower’s SS-FD23 Start/Stop/Elevated Idle Module provides Start/Stop Functions

and an elevated Idle selection. This product is compatible with the 2023 F250-F600. It

is designed to be mounted under the Steering column near the OBDII connector and

the Trailer Brake Controller Module.

Modules come with various modes of control: Start, Stop, and two preset RPM speeds

(one default setting and another selectable).

Note: The elevated idle functions will only operate if the Chassis Ready

Conditions are satised. LED diagnostic indicators are provided to aid in system

troubleshooting. These LEDs are located on the module opposite the connector.

Chassis Ready Conditions typically could be:

• No vehicle speed

• Accelerator not depressed

• Engine up to Operating Temperature

• Shifter in Park

• Service brake not depressed

• Engine running below base idle

• No Diagnostic Trouble Code (DTC). Check Engine light must be off.

• Other hindering conditions will be detailed in the Body Builder’s Guide (www.

eet.ford.com/truckbbas/)

SS-FD23-01 - Special for Stellar Has Data Bus T-Harness

SS-FD23-02 Standard Product - Harness with Blunt Cut Wires DataBus T-Harness

SS-FD23-03 - T-Harness for DataBus with Short Blunt Cut Wires for all IO

SS-FD23-04 - Harness with T-Harness Ignition Connector

The SS-FD23-02 kit includes two cables.

The cable 1 connects the module to the SEIC Interface (Group 3) blunt cut wires, and

connects to the Ignition Switch (Group 1) via Blunt Cut Wires for controlling the engine.

Control Interface (Group 2) Blunt Cut Wires connect the control inputs and outputs for

the SS-FD23-02 and to the PTO. Cable 1 also provides connections to Battery and

Ground, and also provides decoded PARK and PARK BRAKE signals.

The cable 2 connects to the Trailer Brake Controller Module (See Page 12) and picks

up the Data Bus via a T-Harness. This provides PARK and PARK BRAKE data to the

SS-FD23-02 which provides discrete wires to the user for those signals.

The SS-FD23-04 kit includes two cables.

The cable 1 connects the module to the SEIC Interface (Group 3) blunt cut wires, and

connects to the Ignition Switch (Group 1) via T-Harness for controlling the engine.

Control Interface (Group 2) Blunt Cut Wires connect the control inputs and outputs for

the SS-FD23-04 and to the PTO. Cable 1 also provides connections to Battery and

Ground, and also provides decoded PARK and PARK BRAKE signals.

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

3 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

The cable 2 connects to the Trailer Brake Controller Module (See Page 12) and

picks up the Data Bus via a T-Harness. This provides PARK and PARK BRAKE

data to the SS-FD23-04 which provides discrete wires to the user for those signals.

Truck Body Builder Advisory Service:

www.eet.ford.com/truckbbas/

1.1 Interface Selection

This section discusses the interface for the SS-FD23-02

1. The SS-FD23 needs to be located close to the Steering Column so that the

wires that connect to the ignition switch RUN wire (Yellow-Group 1) to the

RUN-IN and RUN-OUT (White-Group 1) can be connected easily. The Start

Signal (Lt. Blue) goes to the START wire from the ignition switch.

2. The connection to the Data Bus via a T-Harness to the Trailer Brake

Controller Module (Page 12) so it needs to be located close to it near the

OBDII connector.

3. ENABLE (Pink, Group 2) is a 12V signal that will enable the SS-FD23 for

operation and turn on the interfaces.

4. RPM1-Gnd Pulse (Tan, Group 2) requires a pulse to Ground to select RPM1,

and a second Ground Pulse to turn RPM1 off (back to RPM STBY - Default).

5. RPM1-12V (Violet, Group 2) requires 12V to enable RPM1, and removing

12V from this line will turn RPM1 off (back to RPM STBY - Default). RPM

Gnd Pulse (Tan) is not available as long as 12V is applied to this line.

6. START/STOP (Brown, Group 2) requires a pulse to Ground to Turn Engine

On, and a second Ground Pulse to Turn the Engine Off. RPM is used to

check Engine Status.

7. The Power Connections are Battery (Red, Group 2) rated at 15 Amps, and

Ground (Black, Group 2) connected to Battery Ground.

8. Outputs

• The PTO Interface is the PTO OUT (Orange, Group 2) 12V (10A Max)

which turns on when SEIC PTO RLY goes to Ground.

• U-IGNITION 12V (Yellow/Red, Group 2) remains on as Engine Stop (5A

Max) is on. Turned ON/OFF when ENABLE is turned ON/OFF. This is

for uptter components needing to remain powered during a shut down

sequence.

• Decoded PARK (Dk Blue Group 2) and PARK BRAKE (White/Black

Group 2) discrete wires are available as discrete wires (GND True).

These reect the current status of the PARK BRAKE and PARK for the

vehicle and are enabled by the RUN (+12V True) line.

(Total for PTO and Ignition 12 should be less than 13A total)

9. SEIC Blunt Cut Wires

• PTO_RLY (Lt Blue, Group 3) - PTO Relay

• PTO REQ1 (Yellow/Green, Group 3) PTO Request

• PTO RPM (Dark Green, Group 3)

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

4 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

!

!

Warning!

2. Installation

2.1 Safety Precautions

This electronic Start/Stop/Elevated Idle product has been designed and manufactured

to meet the intended application requirements and specications. Any modications to

the product or to the installation procedure can be dangerous and will void InPower’s

warranty.

• Read and understand the instructions in this manual and other manuals before

starting the installation.

• Make sure that the vehicle battery power is disconnected during the

installation of the Start/Stop module.

• Reconnect the battery when the system installation is complete.

• Wear appropriate safety equipment, such as protective eyeglasses, faceshield and

clothing when installing equipment and handling the battery.

• Be careful when working near a battery. Make sure that the area is well ventilated

and that there are no ames near the battery. Never lay objects on the battery that

can short the terminals together. If battery acid gets in your eyes, immediately seek

rst aid. If acid gets on your skin, immediately wash it off with soap and water.

• Avoid disconnecting and making connections to the SEIC and PTO with the vehicle

powered.

2.2 Getting Started

IMPORTANT NOTE: Once again! Please obtain the specic SEIC installation

instructions for your vehicle model from Ford. Wire colors and locations may vary

from model to model and even between different years for the same model. The

guide may be obtained from Ford’s Body Builder Advisory Service.

(www.eet.ford.com/truckbbas/)

Carefully disconnect the battery before making any electrical connections.

2.3 Mounting

Mount the SS-FD23-02 module under the dash near the steering column.

2.4 Wiring

First, identify the GROUND Wire (Black, Pin12, Group 2) and connect it to a solid

battery ground prior to any other connections.

Connect the 12V power (Battery, Red, Pin17, Group 2) to a fused battery feed (Battery

still disconnected on the vehicle).

Proceed with connecting the Group1 wires to the Ignition switch (RUN-IN, RUN-OUT,

and START) then connect the Group2 Wires to the Control Interfaces (descriptions

called out in the 2.5 Control Interface section). Also refer to Section 7 Start/Stop Ignition/

BCM/SS-FD23-02 Wiring Page 16.

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

5 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

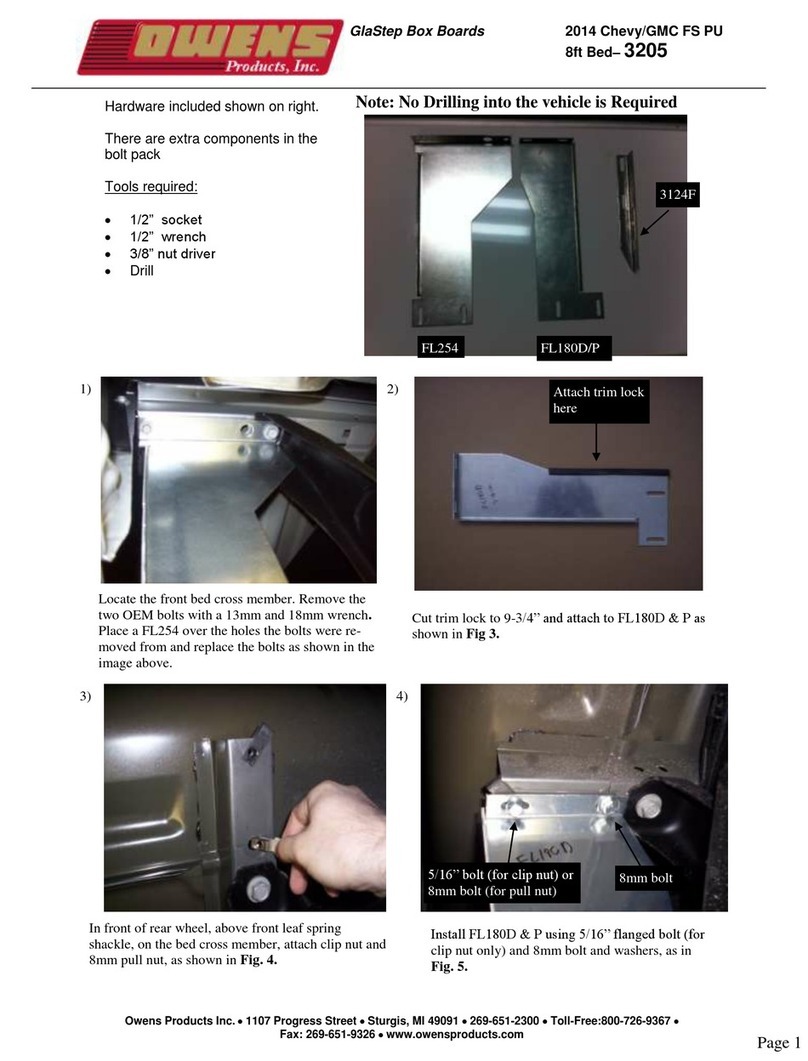

Yellow

White

Body Control

Module

RUN

Ignition Switch Connection Diagram

Blunt Cut Wires SS-FD23-02

START

Violet/Orange

SS-FD23-02

RUN-IN

RUN-OUT

START

Ignition Switch

Start

RUN (IGN)

Yellow

White

Body Control

Module

RUN

Ignition Switch Connection Diagram

Connectorized SS-FD23-04

START

Violet/Orange

SS-FD23-04

RUN-IN

RUN-OUT

START

Ignition Switch

Start

RUN (IGN)

SS-FD23-04 Cable

Momentary to GND

+12V

+12V Level

Types of Switches for Control of SS-FD23

RUN

After termination of all wires, connect the the J1 cable to the SS-FD23.

2.5 Control Interface (Operation)

Determine the combination of two high idle speed modes needed (RPM1 and RPM-

STBY).

The customer needs to supply switches for the ENABLE, START/STOP, and RPM1

modes. These modes are selected by wires in the Group 1 bundle.

The RUN-IN line provides power for the SS-FD23 and if not present, places the unit in

an ultra low power state (micro Amperes).

The RUN-OUT line provides the control for the Body Control Module to indicate

the Ignition is on to the Body Control Module that the vehicle is ready to start (if all

conditions are conducive)

The ENABLE 12V line (Group 2 - Pink Wire) will take the Module out of StandBy when

True. If Ignition is ON but Enable is not True, the SS-FD23 will monitor the Chassis

Data Bus for status, but will not operate the Start-Stop, High Idle functions and

outputs. If Enabled, removal of +12V from this Pin will shut off the High Idle, returning

the engine to running at normal idle, turn off the outputs (except for PARK and PARK

BRAKE), and will place the SS-FD23 in StandBy.

The RPM1 Trigger Gnd Pulse on this Wire (Group 2 - Tan) if in RPM STBY, will

change the system to RPM1. A second Pulse to Ground will change the system to

RPM STBY.

The RPM1 12V on this Wire (Group 2 - Violet) if in RPM STBY, will change the system

to RPM1 as long as 12V is present. Removing 12V will return the unit to RPM STBY.

The START/STOP Switch is connected the START/STOP Input Wire (Group 2 - Brown

Wire) to supply a Ground Pulse to Start the Engine (unit will enter into RPM STBY

Mode). A second Pulse to Ground will Stop the Engine. RPM messages are used to

verify Engine Status. The START/STOP LED indicates switch activity.

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

6 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

PARK - (Dk Blue - Group 2) A GND True decoded signal from the Data Bus that

indicates the gearshift is in Park Position (Flashes if not in position). Output is enabled

by the RUN line.

PB (Park Brake) - (White/Black - Group 2) A GND True decoded signal from the Data

Bus that indicates if the Park Brake is set (Flashes if not set). Output is enabled by the

RUN line.

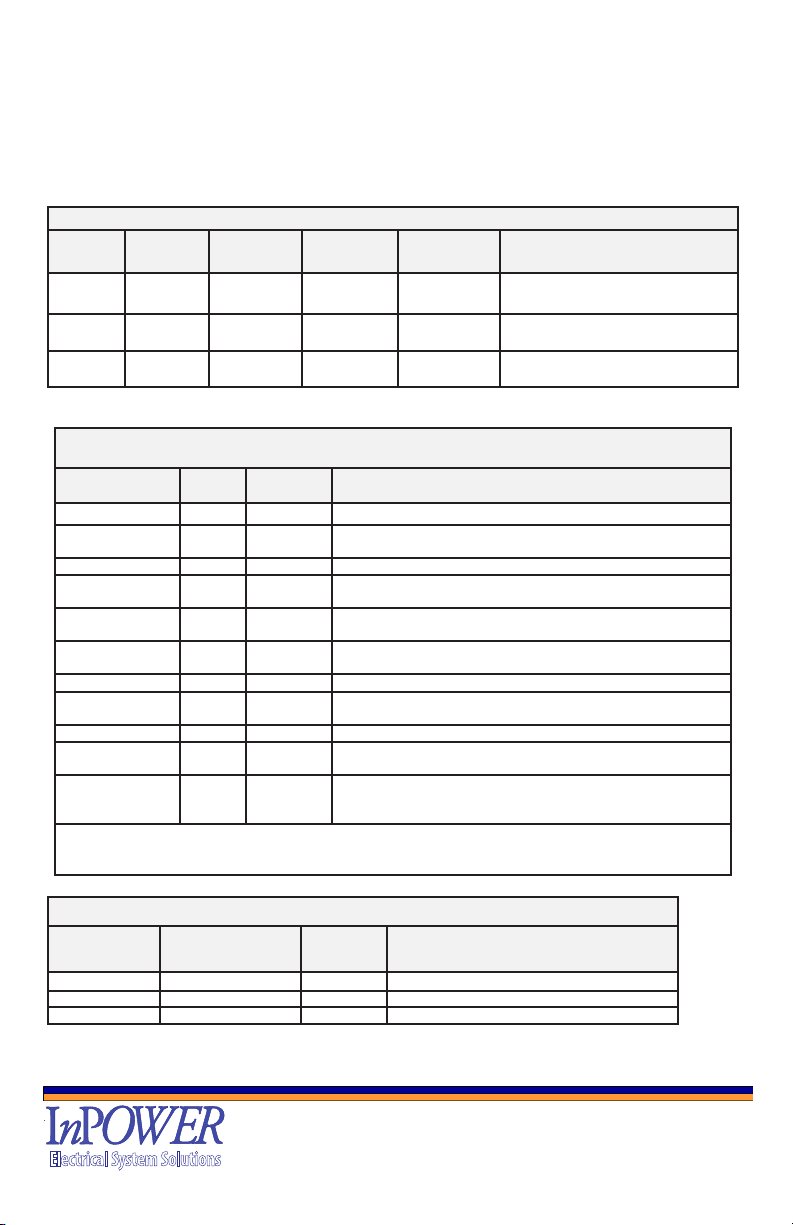

Group 1

Function Wire

Color

Connector

P1 Pin #

Connection

SS-FD23-02

Connection

SS-FD23-04

Description

RUN-IN Yellow 1 Blunt Cut Connector To the SS-FD from the Ignition

Switch

RUN-

OUT

White 11 Blunt Cut Connector Goes from the SS-FD to the Body

Control Module

START Violet/

Orange

14 Blunt Cut Connector Goes to the START Wire from the

Ignition Switch

Group 2

Function Wire

Color

Connector

P1 Pin #

Function

ADJUST** Lt Grn 3 Adjustment for RPM1 and RPM STBY

PARK Dk Blue 4 Current State of PARK Output (GND True). Output available if

RUN is True. (1A Sink Max)

ENABLE 12V Pink 5 IN1- Enable 12V - Wakes up SS-FD23-02 and Enables Functions

RPM1 (GND)** Tan 6 1st Gnd Pulse will select RPM1, 2nd Gnd Pulse will return the

module to RPMSTBY

RPM1 (12V)** Violet 7 12V activates RPM1 as long as it’s present. This automatically

masks out any selection by a GND Pulse on Pin 6 (RPM1(GND))

START/STOP Brown 8 In4- Start/Stop GND - Pulse to Gnd Starts Engine, 2nd Pulse to

Gnd Stops Engine.

GND** Black 12 Battery Ground connect to a solid Battery Ground.

Park Brake White/

Black

13 Decoded Park Brake Out (GND True) - Current state of PB, Output

available by RUN = TRUE. (1A Sink Max)

BATTERY** Red 17 Battery +12Vdc connect to Battery +12 (Rated at 15Amps)

PTO OUT*Orange 19 PTO Output connect to PTO Solenoid maximum 10 Amps (turns

on when SEIC PTO-RLY goes to Ground)

U-IGNITION* Yellow/

Red

20 Ignition that will remain on during engine stop (maximum 5 Amps)

and is disabled by Enable (used for Uptter Ignition dependent

components)

* Total Current of PTO_OUT and IGNITION should not be > 13 Amps DC.

** These wires are for use with setting remote variable RPM

SEIC Group 3

Function SS-FD-02 Wire

Color

P1 Pin # Signal Output Level

PTO RLY Lt Blue 2 Ground Active Indicates OK to Engage PTO

PTO RPM Dk Green 10 0.4-4.5V

PTO REQ1 Yel/ Green 16 Positive (Out High 6)

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

7 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

PTO OUT (Orange Wire - Group 2) provides a connection to the PTO Solenoid

capable of driving up to 10 Amps max (Note PTO OUT and U-IGN should never

exceed a combined current of 13 Amps).

U-IGNITION - 12V Uniterrupted Ignition (Yellow/Red Group 2) is ON whenever

ENABLE it ON and is used for support of uptter components that may need to remain

powered during the engine shut-down sequence.

The Power Connections are Battery (Red wire - Group2) rated at 15 Amps, and

Ground (Black - Group2) connected to Battery Ground.

PTO RLY (PTO Relay) - (Lt. Blue, Group 3) Indicates the PTO Relay is OK to be

engaged. LED Indicator ashes if not OK - Usually indicates problems with Chassis

Ready Conditions.

SEIC PTO RPM (Dk Green Wire - Group 3)

SEIC PTO Req1 (Yellow/Green Wire - Group 3)

3. Operation

When the vehicle is parked and Chassis Ready Conditions are satised, the Start

and Stop Functions and engine idle speed may be controlled by selection of one of the

modes: START, STOP, RPM1 (RPM STBY is ON when ENABLE is ON, ENG ON is

ON, and RPM1 is OFF). The preset RPM modes may be adjusted via applying +12V or

GND to the gray RPM ADJUST wire (RPM Adjustment Procedure, page 8).

Chassis Ready Conditions:

• No vehicle speed

• Parking brake set

• Shift selector in Park

• Accelerator not pressed

• Service brake not pressed

• Engine running and at Base Idle

• No Diagnostic Trouble Code (DTC). Check Engine light must be off.

NOTE:While the engine is in high idle, should the throttle be deactivated by one

of the Chassis Ready Conditions changing, the engine will return to normal speed.

The throttle will ash the diagnostic LEDs to indicate the cause of the deactivation.

Modes of Operation:

Enable:

Description:

Once the module is powered up by turning on the Ignition, it waits in StandBy mode

until a steady 12V enable signal is detected on the ENABLE input (Pink - Group2).

Then the module detects if Engine is ON or OFF via the Data Bus Engine RPM

message and goes to RPM-STBY if the Engine is ON. If the 12V enable signal is

removed the module returns to the low power mode after turning off all outputs and

all LEDs except the BUS ON (showing Bus trafc), and if the Engine is ON and High

Idle is selected, it will also return to standard Idle speed.

If the RUN is on, then the PARK and PARK BRAKE Outputs will be present.

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

8 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

Engine Off/Start Section:

If the engine is OFF, the RUN is ON, and the ENABLE line at +12V, the module waits for

an open circuit to ground transition on START/STOP (Brown - Group2) input and then

runs the remote engine start routine. The START output will only be activated if the Park

Brake status and the Shift Park position are both True. If a RPM Messages show engine

activity, the module will transition to the Engine On routine. If RPM Messages do not

indicate operation within 5 seconds, the module will return to engine OFF state.

Enable: Steady +12V on Enable (Pink-Group 2) Enables Module and

Outputs

Start/Stop: A Pulse from Open to Gnd (Brown - Group 2) starts the

Engine if the Engine is Off and the Chassis Ready

Conditions are met, if Engine running, additional Pulse to

GND will Stop Engine.

Engine On/High Idle Section:

After a 5 second delay for the engine rpm to stabilize (via RPM messages), the PTO

REQ1 and PTO RPM outputs are turned on. The module now waits on an open circuit

to ground transition on the PTO RLY input indicating the SEIC is active. The module

now turns on the PTO output and the engine rpm is increased to the RPM STBY

speed.

When the unit is on, the default RPM will be RPM STBY. If an open circuit to ground

transition is detected on RPM1 input (Tan, Group2), the engine rpm is changed to the

RPM1 set point. If another open circuit to ground transition is detected on the RPM1

input, the engine rpm is changed back to the RPM STBY speed.

Preset RPM Modes

Activation:

When Off: Enable: Apply +12 V to Enable (Pink Wire - Group2)

Enables Unit

Engine is OFF: A GND Pulse on Start/Stop (Brown Wire - Group 2)

Starts Engine and goes to RPM STBY (Default High Idle RPM).

In RPM STBY: Apply GND Pulse to RPM1 (Tan Wire - Group2),

GND Pulse Select unit goes to RPM1.

In RPM1: Apply GND Pulse to RPM1 (Tan Wire - Group2) and the

unit goes to RPM STBY.

Or In RPM STBY: Apply 12V to RPM1 (Violet Wire - Group2),

+12V Select unit goes to RPM1 (locks out use of Tan Wire).

In RPM1: Remove 12V from RPM1 (Violet Wire - Group2) and the unit

goes to RPM STBY.

Deactivation:

In Any Mode: Removal of Enable 12V (Pink Wire - Group 2)

(Engine Running) Disables RPM1 or RPM STBY and Shuts Off High Idle

and goes to standard idle speed.

In RPM1 or STBY: A GND Pulse on Start/Stop (Brown Wire - Group 2)

(Engine Running) Stops Engine (U-Ignition Remains ON)

Default RPM Settings

+/- 5% Tolerance (Ford Interface Dependent)

RPM-STBY -

approx

870 RPM Gas, 950 RPM Diesel

RPM1 -

approx 1200 RPM Gas, 1500 RPM Diesel

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

9 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

Calibration Range: Varies based on vehicle model.

Generally, 900 RPM to 2200 RPM (gas) or 900 to 2800 RPM (diesel)

Both the RPM STBY set speed and the RPM1 set speed are adjustable using the

ADJUST input. Any adjustments made will be automatically stored after an open

circuit is detected on the RPM ADJ input for 5 seconds.

To Calibrate an RPM, Select the RPM and then apply +12V (up) or Gnd (down) to

the RPM Adjust Input, (Lt. Green - Group 2).

RPM Adjustment Procedure:

1. Activate the mode desired for adjustment by Enabling the unit and then running

at the RPM-STBY or by selecting RPM1 with a Gnd pulse on the RPM1 (Tan

Wire - Group 2) Line or alternately by applying 12V to the Violet wire - Group 2

for RPM1.

2. Locate the ADJUST wire (Lt Green - Group 2) in the harness. Apply +12V

to this wire to raise the RPM or to GND the wire to lower the RPM. For each

second that +12V is connected to the RPM ADJUST wire (Lt Green, Group2),

the RPM will increase by 50 RPM per second. Likewise, if the RPM ADJUST

wire is tied to GND, the RPM will decrease at a rate of 50 RPM per second.

Releasing it from either +12V or Ground will steady the RPM.

Note: For each bump of less than a half second, the RPM will move by 25RPM up or

down (depending on whether Adjust is bumped to +12V or GND). If connected to +12V

or GND for a second (or more) it will increase by 50RPM for each second the Adjust is

connected to the voltage.

The new RPM Value is automatically saved after Five (5) Seconds

Note 1: A minimum of 910 RPM is recommended for PTO to activate.

Uninterrupted Ignition Output:

During the engine start and stop routines, the ignition run feed is turned off which

also turns off the ignition power to the uptter switches. The Uninterrupted Ignition

Output (Yellow/Red Wire, Group 2) provides a 12V output for equipment that needs

a continuous ignition signal. This output is rated at 5A.

IGN

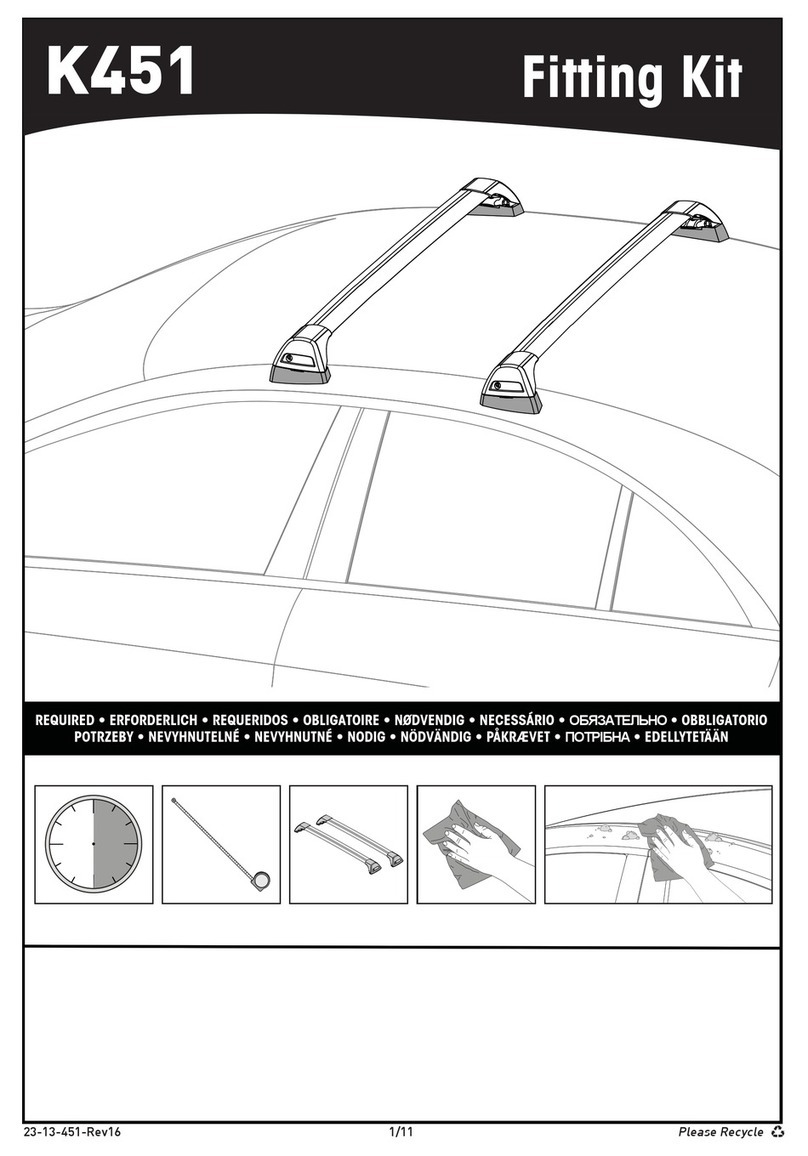

(RUN)

ON?

No

ENABLE

ON?

Turn On

Module

Start Data Bus

Monitor

Yes

No

Blink ENG OFF

250mS On, 3Sec Off

All others OFF

Yes

No

Enable

Park and Park Brake Outputs

and Enable Start/Stop and

High Idle Functions

SS-FD23-02 IGNITION and ENABLE

Control for Module Operation

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

10 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

Running Engine

Chassis

Conditions

Met?

Yes

Chassis Conditions

No vehicle speed

Parking brake set

Shift selector Park

Accelerator not pressed

Service brake not pressed

Engine run (< 1000 RPM)

Check Engine OFF.

No

ENABLE Pin at

12Vdc?

No

RPM1

Transition GND

to 12V?

RPM STBY

No

RPM1

Yes

Yes

RUN Conditions

Check

RUN

Conditions

Change (or

Start/Stop)?

Yes

No

Go to

Standard

Idle

RPM1

Transition GND

to 12V

No

Yes

Yes

Start/Stop

transition GND to

12Vdc?

No

Yes

Go to

STOP

Routine

No

Go to

Standard

Idle

Start/Stop

transition GND to

12Vdc?

No

Yes

Go to

STOP

Routine

RUN

Conditions

Change (or

Start/Stop)?

Stopped Engine

Chassis

Conditions

Met?

Yes

No

ENABLE Pin at

12Vdc?

No

Yes

RUN Conditions

Check

Start/Stop

transition GND to

12Vdc?

Yes

Start Routine

No

Chassis Conditions

No vehicle speed

Parking brake set

Shift selector Park

Accelerator not pressed

Service brake not pressed

Check Engine OFF.

Stopped Engine

Stopped Engine

Engine

Running? RPM

via Data Bus

Yes

No

No

Yes

5 Second Delay

RPM

Data Bus

Indicates

ENG RUN

No

Yes

Stopped Engine

Running Engine

5 Second Delay

Start/Stop Check

Start/Stop Check

SS-FD23 SW Operational Flow Chart

Engine

Running? RPM

via Data Bus

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

11 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

4. Mechanical Drawing

SS-FD23-02 (-04) I/O Harness

P1

3.74”

4.4”

2.62”

0.2” dia

0.8”

0.4”

J1 Wire Color Function

Pin2 Lt. Blue PTO RLY

Pin10 Dk Green PTO RPM

Pin16 Yellow/Grn PTO REQ1

GROUP 3 - SEIC Interface

72”

0.7”

J1

www.InPowerLLC.com

Made in the USA

LOT:1234567890

ENG OFF

ENG ON

RPM1

RPM STBY

START/STOP

PTO RLY

PARK

PARK BRAKE

START/STOP HIGH IDLE

SS-FD23

1

2

3

4

5

6

7

8

11

12

13

14

15

16

18

20 9

10

17

19

J1

111

1020

3”

J1

www.InPowerLLC.com

Madein the USA

LOT:1234567890

ENG OFF

ENG ON

RPM1

STBY

START/STOP

PTO RLY

PARK

PARK BRAKE

111

1020

J1 Color Signal

Pin3 Lt. Grn ADJUST

Pin4 Dk Blu PARK OUT

Pin5 Pink IN1 ENABLE 12V

Pin6 Tan IN2 RPM1 GND

Pin7 Violet

IN3 RPM1 12V

Pin8 Brown IN4 Start/Stop GND

Pin12 Black GND

Pin13 White/Blk PARK BRAKE OUT

Pin17 Red BAT+

Pin19 Orange PTO OUT

(10A)

Pin20 Yel/Red U-IGN

(5A)

GROUP 2 User Interface

J1 Color Signal

Pin1 Yellow RUN IN

Pin11 White RUN OUT

Pin14 Violet/OR START

Orange

Yellow/Red

Pink

Lt Green

Dk Blue

White/Black

Tan

Brown

Black

Red

Violet

GROUP 3 - SEIC

GROUP 2

GROUP 1 Ignition Interface

Yellow

White

Violet/Orange

Orange

Yellow/Red

Pink

Lt Green

Dk Blue

White/Black

Tan

Brown

Black

Red

Violet

24”

3”

32”

GROUP 1

P2

J2

P1

GROUP 3 - SEIC

GROUP 2

Yellow

White

Violet/Orange

GROUP 1

START/STOP HIGH IDLE

SS-FD23

Dk Grn

Yel/Grn

Lt Blue

Dk Grn PTO RPM

Yel/Grn PTO REQ1

Lt Blue PTO RLY

3”

Trailer Brake

Controller Interface

Data Bus T-Harness

Trailer Brake

Controller

Module

Refer to Page 12 of the

Owners Manual OM-255

for Location

32”

3”

Electrical System Solutions

Electrical System Solutions

Electrical System Solutions

J2

3”

Yellow

White

Violet

/Orange

24”

GROUP 1

Ignition

Interface

T-Harness

Ignition

Interface

Module

To Body

Control

Module

SS-FD23-04 Group 1

Harness Deviation

Make certain to

Connect the

Power Feed (Red)

to the actual

Battery and not

the Ignition

Blunt Cut Wires

Blunt Cut Wires

Blunt Cut Wires

Connectorized Ignition

5. Installation and Troubleshooting

5.1 Please refer to the Throttle Selector Guide found on our website for the most up-

to-date compatibility information.

(www.inpowerdirect.com/electronicthrottlecontrols_selector.php)

5.2 Check all wiring and make sure all connectors are plugged in rmly.

Refer to the Harness Wire Chart in Section 4 Mechanical, and check that wires are

connected to appropriate inputs and outputs.

Ford vehicle wire colors and locations may vary substantially between different models

and even different model years. Please obtain and consult the SEIC information for

your specic vehicle. Documentation may be obtained from Ford’s Truck Body Builder

Advisory Service (www.eet.ford.com/truckbbas/).

5.3 A series of 8 LEDs on side of the module provide diagnostic information for

troubleshooting purposes. The LEDs are labeled and correspond to RPM modes and

safety interlocks necessary to bring the vehicle to high idle. If no LEDs are illuminated,

the unit does not have power from RUN.

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

12 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

See LED Troubleshooting Flowchart.

5.4 While engine is in high idle, if one of the Chassis Ready Conditions changes state,

the engine will return to factory idle. The unit then will ash the diagnostic LEDs (PTO

RLY, PARK, or PARK BRAKE) to indicate the cause of the high idle deactivation. Then,

once conditions are restored, after a ten second delay, it will return the vehicle to the

preset high idle speed. This feature may be used to troubleshoot intermittent problem.

5.5 LED Troubleshooting Flowchart

Unit Has No

IGNITION

No

PARK BRAKE - engaged?

PARK - gear shift in PARK?

PTO RLY - will Flash if not at ground (Chassis

Conditions not met)

If ON, indicates

that SS-FD23 is

ENABLED, and

Engine is

Stopped.

RPM STBY

RPM1

RPM1 and ENG ON

illuminated, High Idle

RPM1 Setpoint

selected.

ENG OFF

ENG ON

If ON, indicates

that SS-FD23 is

ENABLED, and

Engine is Running.

RPM STBY and ENG ON illuminated, High Idle RPM STBY

is selected (Default).

LED

CONDITIONS

LED (s) FLASHING

STOP/START If ON, indicates that the switch

feeding it is activated

STOP/START

BLINK

ENG OFF

LED?

Are Any

LEDs On? No

Yes

Yes IS

ENABLE

ON?

No

Yes

Data Bus Issue

IS

RUN

ON?

Yes

No

PARK

and PARK BRAKE

LEDs are Blinking and

vehicle is in PARK and

the PARK BRAKE

are set

Yes

IS

ENABLE

ON?

No

Yes

ENG OFF

ENG ON

RPM1

RPM STBY

START/STOP

PTO RLY

PARK

PARK BRAKE

SS-FD23-02 LED INDICATORS

– On if engine is stopped

(Blinks if RUN but No ENABLE)

– On if engine is running

– On if high idle is using the RPM1 set point

– On if high idle is using the rpm standby set point

– Indicates the START/STOP input is activated

– On if PTO RLY is at ground, flashes if not

– On if shifter in park, flashes if not in park

– On if park brake set, flashes if not set

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

13 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

Trailer Brake Controller Module Location (Data Bus) T-Harness

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

14 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

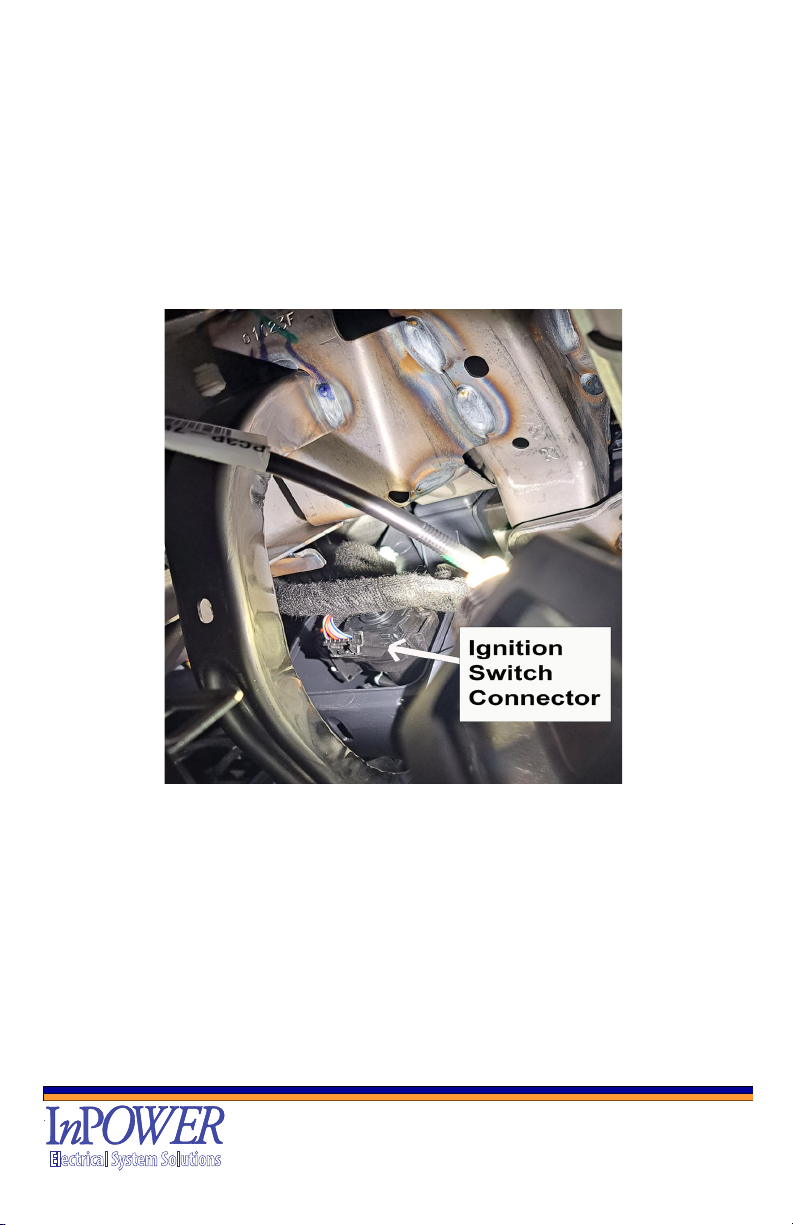

Ignition Switch Connector for IGN T-Harness

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

15 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

Installation of Ignition Switch T-Harness

SS-FD23 Owner’s Manual

Document: OM-255 Version Code: B

Date: May 31, 2023 Date: Aug 31, 2023

© Copyright 2023 InPower LLC

Page

16 of 16

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Electrical System Solutions

Contact Us

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035

740-548-0965

www.InPowerLLC.com

Table of contents

Other InPOWER Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Paxton Automotive

Paxton Automotive Novi Supercharger 1200 Owner's installation guide

Aim

Aim X90BGGK12MA user manual

Well

Well REC-BT-ACCENT-WL instruction manual

Broadfeet

Broadfeet DCNI-523-32 installation instructions

ECS Electronics

ECS Electronics HY-050-DH Fitting instructions electric wiring

ConWys AG

ConWys AG 21020503C Fitting instructions