INSBUD IB-TRON 1000 GWC User manual

Electronic controller

to control Ground Heat Exchanger

IB – Tron 1000 GWC

InsBud company supports policy of development. The right to making changes and

improvements in products and manuals without prior notice reserved!

The contents of this manual - the text and graphics are owned by InsBud company

or its subcontractors. It is legally protected.

Products is marked

and has been produced in accordance with ISO 9001 standard

v1.2

„INSBUD”

ul. Niepodległości 16a

32-300 Olkusz

POLAND

sales department: +48 (32) 626 18 00

sales department: +48 (32) 626 18 18

technical department: +48 (32) 626 18 07

technical department: +48 (32) 626 18 08

fax: +48 (32) 626 18 19

e-mail: [email protected]

www.insbud.net 3

ENGLISH

Contents

IB-TRON 1000 GWC

Basic information __________________ 4

Features _________________________ 4

Technical data_____________________ 5

Available models __________________ 5

Scope of delivery __________________ 5

General considerations _____________ 5

Structure _________________________ 6

LCD Display_______________________ 7

Connection _______________________ 7

Temperature sensors _______________ 8

Operating principle ________________ 8

Example of operating_______________ 9

Exemplary connection diagram ______ 10

Example of Controlling by Water Heat

Exchanger ________________________ 11

Calibration _______________________ 12

Clock ____________________________ 12

Clock displaying ___________________ 12

Day of the week ___________________ 12

Temperature units _________________ 12

Work mode _______________________ 13

Test period and test break ___________ 13

Hysteresis ________________________ 13

Keyboard lock_____________________ 13

GUARD function ___________________ 14

Factory settings ___________________ 14

Test of relays ______________________ 14

Modes of temperature displaying _____ 14

Software version___________________ 15

Network communication ____________ 15

Errors____________________________ 15

Remote Control ___________________ 16

Warranty _________________________ 16

www.insbud.net

4

ENGLISH

BASIC INFORMATION FEATURES

IB-Tron 1000 GWC controller is indepen-

dent microprocessor controller with large

LCD display. The controller is designed to

control work of valves, air dampers, electric

air heaters, pumps, fans and other two- and

three-point controlled appliances (on/o).

IB-Tron 1000 GWC controller allows to con-

trol process of heating, cooling and ventila-

tion. The thermostat chooses source of heat

or cold in intelligent way including testing

periods. An example of this type of installa-

tion is controlling of ground heat exchanger

(GHE).

A professional and intelligent controller

to control systems where you have to cho-

ose source of heat or cold from two die-

rent sources! This is not a simple dierential

controller!

Large, blue backlit (optional) LCD di-

splay which shows current tempe-

rature, a day of the week and other

information.

Easy, intuitive operating and

programming.

Measurement of two temperatures T1

and T2

Power supply from network - it doesn’t

reguire batteries - with baterry memory

backup

Displayed temperature with 0,1 ºC

accuracy

Esthetic and modern design

Large load - to 2 kW - allows to direct

connection most of electrical applian-

ces without the use of contactor.

The possibility of calibrate device

(external sensors on long wires, inde-

pendent calibration of T1 and T2)

Adjustable hysteresis

Testing periods of devices to measure

Heating mode (winter) and cooling

mode (summer)

GUARD function - protection devices

from damage

TEST function

Network, RS - 485 or Ethernet commu-

nication (optional)

The possibility of remote control

(optional)

Keyboard lock

www.insbud.net 5

ENGLISH

TECHNICAL DATA SCOPE OF DELIVERY

GENERAL CONSIDERATIONS

AVAILABLE MODELS

Energy consumption: < 2 W

Storage temperature: -5 ÷ 50 ºC

Displayed temperature: -20 ÷ 140 ºC

every 0,1 ºC

Accuracy: 1 ºC

Hysteresis: 1 ÷ 5 ºC

Test breaks: 1 ÷ 999 min.

Test period: 0 ÷ 999 sec.

Maximum load: 2000 W

Power supply 230V AC

Casing: ABS

Dimensions [mm]: 120x120x23

Display: LCD (4``)

Control: Electronic

Protection rating: IP30

Battery settings protection:

» 36 months

1x Controller (the main panel)

1x Relay box

1x Built-in temperature sensor

1x Operating manual

1x Operating manual for network (only

with NW model)

1x Pilot of remote control with battery

(only with RC model)

HDuring installation of controller, the

supply of electricity should be turned

o. It’s recommended to entrust the in-

stallation a specialized institution.

The controller is for surface-mounting,

it sticks out 23mm.

In the controller a relay box is separa-

tely on the 20cm wire and dimensions

30/50/65mm

IBuilt-in RT sensor is complete with

thermostat. FT sensor isn’t supplied

with thermostat.

RT sensor is on the 20cm wire and it can

be bring out at the back of casing.

IRT sensor can be extended according

to needs or it can be replaced by ano-

ther type of sensor (if it’s needed).

IChange of RT sensor doesn’t invalidate

the warranty.

HThe controller gives 230V voltage on

the output (support of pump, valve, air

damper, heating mat etc.). If thermostat

has to operate normally open/normally

closed device, so-called: contact device

(for example: gas heating stove), it will

be required additional normally open/

normally closed relay. Wa have these re-

lays in our oer.

BL - blue backlight (backlight is activa-

ted by pressing any button and deacti-

vated after a certain period of inactivity)

RC - IR remote control

NW - thermostat to work in the network

(RS-485 or Ethernet communication)

www.insbud.net

6

ENGLISH

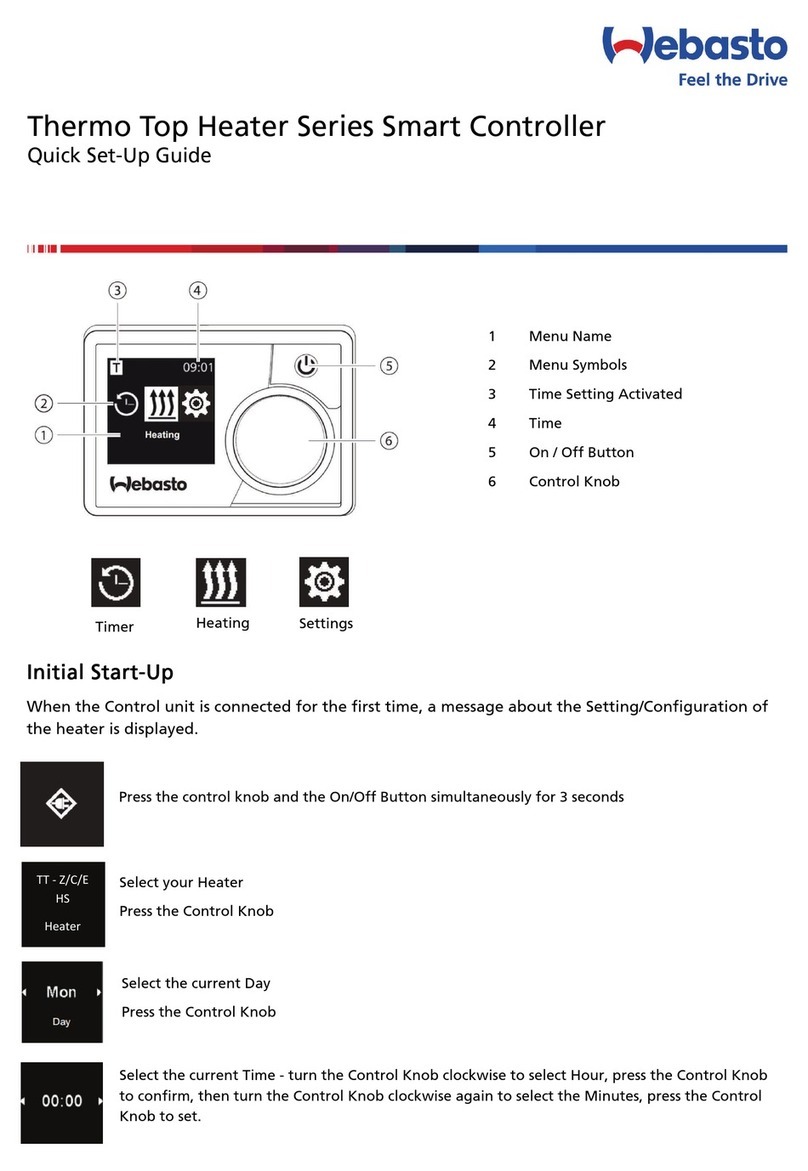

STRUCTURE

PROG

MODEL

TIME

RT SENSOR

DAY

HEATING

COOLING

DEL

CANCEL THE

ENTERED DATA

MODE

PLUS MINUS

ENTER

www.insbud.net 7

ENGLISH

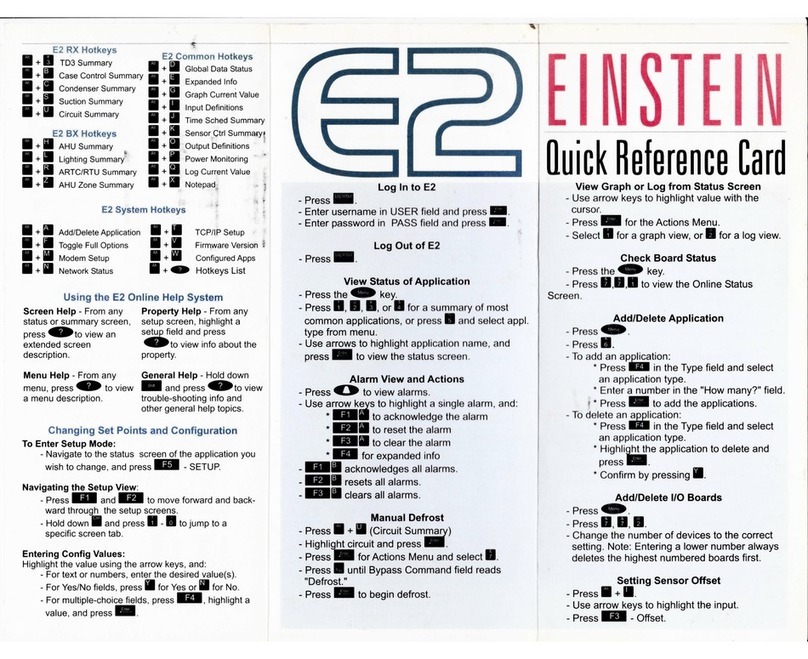

LCD DISPLAY

CONNECTION

A DAY OF THE

WEEK HOUR

TEMPERATURE/

SETTING

MODE OF

DISPLAYING

WORKIDENTYFICATION

OF SENSOR

NETWORK

HEATING

(WINTER)

COOLING

(SUMMER)

KEYBOARD

LOCK

AM

PM

NET

RT

FT MODEL AF

1 - 2 FT sensor

3 - 4 power supply 230V AC

5 A phase appears (L) when cho-

osing FT source

6 A phase appears (L) when cho-

osing RT source

Two loose wires with thermistor come

out from the controller, it can be cut

and connect external RT sensor

www.insbud.net

8

ENGLISH

TEMPERATURE SENSORS OPERATING PRINCIPLE

IComplete with controller is NTC thermi-

stor on the 20cm wire. It can function

as a one sensor if there isn’t required an

additional casing of sensor. The second

sensor isn’t supplied with termostat.

IThe sensors can be extended to any

length but we should remember that

extension above 10m may cause a de-

viation of measurement with each me-

ter and falsifying results. Therefore, for

distance above 10m device has to be

calibrated. Sensors have to be extend

of wires:

» to 50 meters 2x 0,75 mm2

» above 50 meters 2x 1,50 mm2

The controller is compatible with NTC

10kΏ sensors having the following

characteristics:

Temperature

[ºC]

Resistance

[Ώ]

-50 687 803

-40 346 405

-30 181 628

-20 99 084

-10 56 140

0 32 960

10 20 000

20 12 510

25 10 000

30 8 047

40 5 310

50 3 588

60 2 476

70 1 743

80 1 249

90 911

100 647

In the controller we have to set three time

values:

Testing break - value in minutes spe-

cifying, at what time do the measuring

test. This value depends on devices,

which ‘receive’ heat or cold and more

precisely depends on how often the

temperature conditions may change

in this device. In the typical size of GHE

(typical family house) this value is most

in the range of 10 ÷ 30 minutes.

Testing periods - value in seconds spe-

cifying, how long device has to work

before reading of sensor reaches the

appropriate level of temperature (star-

ting period, starting delay ). Testing pe-

riod is set separately for each device.

In case of installation of GHE the rst devi-

ce is directly external inlet probe and sensor

has to be placed near to the inlet probe (di-

rect measurement of external temperature).

Testing period of this device should be set

to 0 (there isn’t any delay, the reading is cur-

rent). The second device is GHE. Delay of this

device should be set to optimal value for the

GHE - mostly it’s time to move air through

the GHE (it depends on length and size of

GHE). For the typical size of GHE (for typical

family houses) this delay is in the range of 20

÷ 120 seconds.

Depending on the mode in which the con-

troller operates (heating or cooling), device

chooses warmer or colder device.

The controller is intelligent. It means that it

remembers readings and change the tem-

peratures on the both devices. For example:

when controller during data analysis deter-

mines that there is probability of more favo-

rable temperature conditions on the second

device than currently used device, may be

www.insbud.net 9

ENGLISH

OPERATING PRINCIPLE

EXAMPLE OF OPERATING

EXAMPLE OF OPERATING

to be higher than the air temperature

from the GHE, the controller will switch

devices so that the air was taken from

the external inlet probe (it happens

immediately because testing period of

inlet probe is set on 0 seconds but inc-

luding hysteresis).

If the outside temperature falls below

the last memorized temperature which

was on the GHE or from the appropriate

algorithm, the controller„suspects”that

air temperature from the GHE will be hi-

gher than outside temperature or 15mi-

nutes (testing break)have passed since

the last switching air dampers. The GHE

is turning on (on thirty-seconds testing

period). After the test, the controller

decides from where take the air.

IIn our oer are available air dam-

pers with actuators with dierent

cross-section.

earlier testing of the second device.

Typical GHE installation. The controller is de-

signed to decide from where take the air:

from the GHE - there is closing of the air

damper with actuator from the exter-

nal inlet probe. The air damper with ac-

tuator is opening from the GHE simul-

taneously and the controller starts the

GHE fan.

from the external inlet probe - there

is closing of the air damper with ac-

tuator from the GHE and turning o

the GHE fan. The air damper with ac-

tuator is opening from the inlet probe

simultaneously.

Testing period of inlet probe is set on 0 se-

conds (current measurement without delay).

RT sensor is placed near external inlet probe

so as to measure the outside air temperature

(shady, sheltered from the wind and moistu-

re place).

Testing period of GHE is set on 30 seconds

(this is air ow from the onlet probe of GHE

to recuperator). FT sensor is placed in the

ventilation duct from the GHE before the

recuperator.

Testing break is set on 15 minutes.

Heating mode is set (selection of a hotter

heat source). In the summer the controller

by pressing single button switches onto the

cooling mode to cooling the building.

Exemplary logic of device operating:

The air is taken from the GHE.

When the outside temperature is found

www.insbud.net

10

ENGLISH

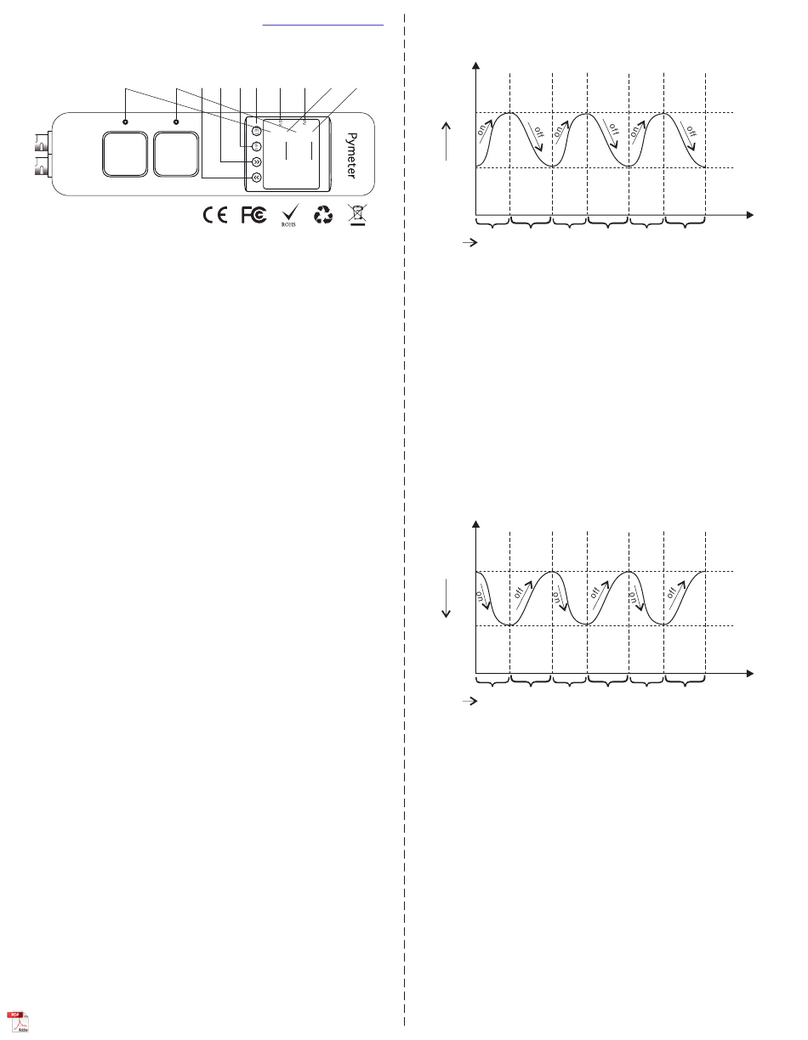

EXEMPLARY CONNECTION DIAGRAM

RT

sensor

External inlet

Used, warm air

Used, cold air

Fresh, warm air

Outside

GHE

FT

sensor

P1

P2

sn

B

ud

IB-Tron 1000GWC

2

3

1

4

5

6

Sensor

FT

Sensor

RT

L

N

14 1424 24

11 11

12 12

21 21

22 22

A2 A2

A1 A1

repeater

repeater

np.IB-F200

np.IB-F200

P 1

P2

G.W.C

Brown(open)

Brown(open)

Green (closed)

Green (closed)

Black

Black

Red

Yellow

Pe

Pe

21

2422

11

14

12

A2

A1

21

14

12

pin diagram of relay base

Air damper

Air damper

Power 230V AC

Closing signaling

Closing signaling

www.insbud.net 11

ENGLISH

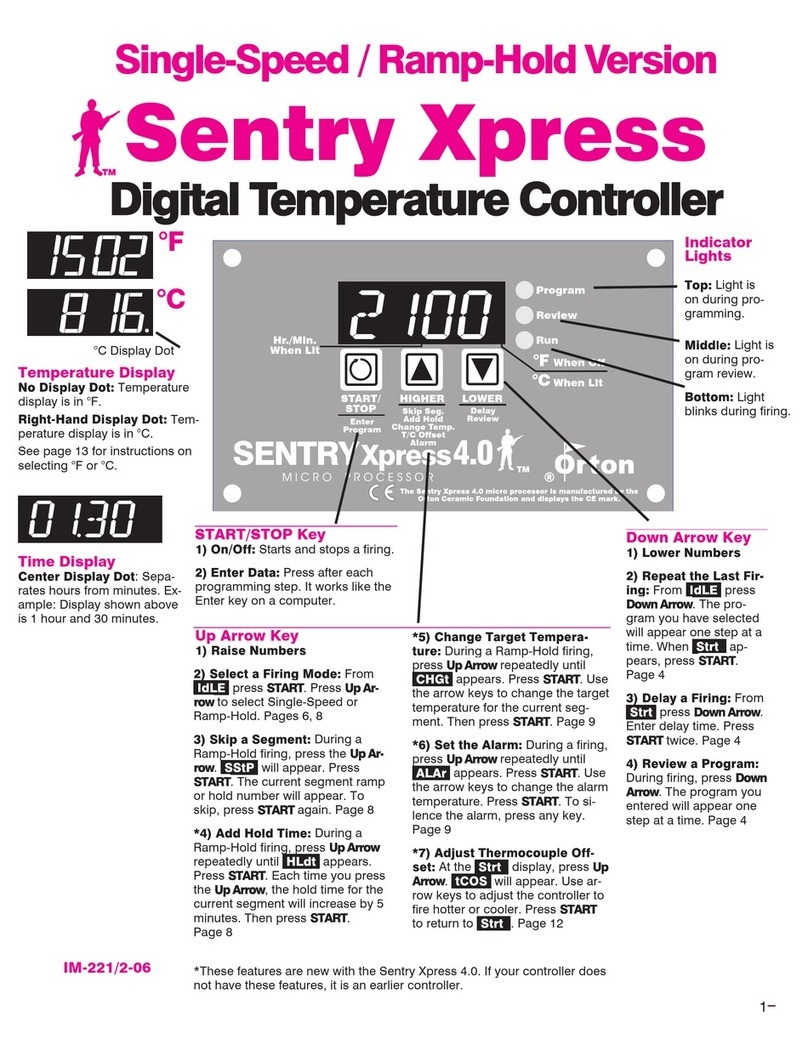

EXAMPLE OF CONTROLLING WATER HEAT EXCHANGER

IB-Tron 1000 GWC controller measures two temperatures: outside temperature (by RT sen-

sor) and air temperature after passing through the heater, when water circulation pump is

turned on (glycol or brine), by FT sensor. Measurement of the outside temperature (RT) is

current, measurement of air temperature (FT) at the switching on heater has to be cyclic.

Testing period should be as short as possible but has to ensure proper stabilization of the

air temperature after passing through the heater (installation which leads water, heater and

air from the heater has to warm up).

If the controller after this testing period recognizes that favorable temperature conditions

provides water heat exchanger, the pump still works and measurement of FT temperature

is current. Measurement of RT temperature is current too, so if favorable temperature con-

ditions are at the external inlet probe, the P1 pump will be turned o.

If favorable temperature conditions after testing period are still at the external inlet probe,

P1 pump is turned o. The pump is again turned on only after testing period.

Bottom source

P1

FT

Sensor

RT

Sensor

sn Bu d

IB-Tron 1000GWC

2

3

1

4

5

6

FT

Sensor

RT

Sensor

Power 230V AC

L

N

Pump P1

1

2

Fresh, warm air

Used, warm air

Used, cool air

Fresh, cold air

Outside

www.insbud.net

12

ENGLISH

CALIBRATION

ZEGAR

TEMPERATURE UNITS

CLOCK DISPLAYING

DAY OF THE WEEK

After proper connection the controller is re-

ady to work. The controller is factory calibra-

ted to work with standard sensor. However,

with long wires, displayed temperature may

be dierent from real temperature.

In this case you have to calibrate the device

by yourself.:

A clock doesn’t aect to controller work. It’s

only information.

To set current hour please:

Temperature can be displayed in ºC and ºF

To change units please:

Time can be displayed in 24-hour system or

12-hour system.

To change mode of time displaying please:

Day of the week doesn’t aect to controller

work. It’s only information.

To set current day of the week please:

DEL

TIME

DAY

DAY

PROG

TIME

MODE

+

+

+

-

-

-

Press and hold. On display start a-

shing current value of the calibra-

tion settings and kind of sensor.

By repeatedly pressing button you

can change calibrated sensor.

Press and hold. On display start

ashing current value of the clock

settings.

Press the button. On display start

ashing a day of the week.

Press for 3 seconds both buttons.

Press and hold two buttons for 3

seconds.

Calibrate sensor by setting the ap-

propriate value settings.

Set current hour (longer holding

the button will faster change

time)

Set current day of the week

» MON - Monday

» TUE - Tuesday

» WED - Wednesday

» THU - Thursday

» FRI - Friday

» SAT - Saturday

» SUN - Sunday

Conrm the data.

Conrm the data.

Conrm the data.

www.insbud.net 13

ENGLISH

WORK MODE HYSTERESIS

KEYBOARD LOCK

TEST PERIOD AND TEST BREAK

The controller can work in two modes:

Heating mode (selection of warmer

source)

Cooling mode (selection of colder

source)

To change mode please press the button:

Hysteresis means a delay in switching on/

switching o the device. If it’s higher value

of the hysteresis, controlled device performs

less cycles (e.g: air dampers) - therefore vita-

lity of the device increases.

In normal conditions it’s recommended to

set hysteresis value to 1ºC. Value setting of

hysteresis depends on where is the measu-

rement (e.g. for liquid suggested is higher

hysteresis).

To change value of hysteresis please:

To protect controller from unwanted change

settings, you can lock controller keyboard.

When keyboard lock is activated, on display

is visible a padlock symbol and keyboard do-

esn’t respond to pressing keys.

To activate/deactivate keyboard lock please:

To set the appropriate testing periods for RT

and FT and testing break please:

Press and set testing break. Adju-

stable value is in minutes. RT and

FT symbol are invisible on display.

Press and set testing period for RT.

Adjustable value is in seconds. RT

symbol is visible on display.

Press for 3 seconds.

Press and set testing period for FT.

Adjustable value is in seconds. FT

symbol is visible on display.

Cooling

Heating

MODE

MODE

MODE

+

+

+

+

-

-

-

Conrm the data.

+

-

Press and hold. On display start

ashing current value of settings

hysteresis.

Set hysteresis value.

Conrm the data.

www.insbud.net

14

ENGLISH

GUARD FUNCTION

FACTORY SETTINGS

TEST OF RELAYS

If the controlled device (e.g.: air damper, va-

lve or pump) is not working for a long period

of time, it may be damaged. Therefore it is

important that each element was periodi-

cally turned on even when there is no need

from point of view of system logic.

This protective function is GUARD function.

It monitors work of controlled devices.

If the device doesn’t change its status of

the operating by 240 hours, the controller

changes the status for 20 seconds.

To activate/deactivate GUARD function

please:

TEST function is used to check the control-

led device (e.g.: air damper) - if it’s well con-

nected and working properly.

To test relays please:

To reset controller and go back to factory

settings please:

Press for 3 seconds. On display

will appear the status of GUARD

function.

ON - turned on

OFF - turned o

Press for 3 seconds both buttons.

Press for 3 seconds both buttons

to go back to normal work.

PROG

Model

Model

+

+

-

-

Set the status of function.

Set relay status by repeatedly pres-

sing the button.

ON - choice of RT

OFF - choice of FT

Press for 5 seconds both buttons.

Conrm the data.

MODES OF TEMPERATURE DISPLAYING

ControllercandisplayRT andFTtemperature

in three modes::

AF - alternating, RT and FT temperatu-

re are displayed every few seconds.

A- RT temperature is continuously

displayed.

F- FT temperature is continuously

displayed.

To change mode of displaying temperature

please:

MODEL

Press repeatedly to change mode.

Choosen mode is shown on the

display.

Conrm the data.

www.insbud.net 15

ENGLISH

ERRORS

On display may appear symbols that signify:

LO - temperature on current sensor is

below the lower measuring range.

HI - temperaturw on current sensor is

above the upper measuring range.

ERR - current sensor is not connected

or is damaged.

IVisible symbol of RT and FT in the cour-

se when appears above symbol of this

error, determines the current sensor

(sensor which concern the error)

If you want to free update your software,

please contact us.

Press for 5 seconds both buttons.

On display will show software

version.

Turn o the controller by button

so that on display was visible only

temperature.

Turn on the controller by button to

go back to normal work.

SOFTWARE VERSION

InsBud company supports policy of

development. Thats why rights to making

changes and improvements in products and

manuals without prior notice reserved!

Our company is open to all suggestions to

improve our controllers. If you have any idea

to add new features or require unusual solu-

tions, please contact us.

This manual applies to IB-Tron 1000 GWC

controller with software version number

001

If your controller has other software version,

operation and functionality may be dierent

from information contained in this manual.

To check software version please:

NETWORK COMMUNICATION

Controller is also available in versions

adapted to work in network.

There are versions based on RS-485 or

Ethernet communication.

Issues relating to network communication

of controllers are contained in separate

manuals connected with IB-System.

www.insbud.net

16

ENGLISH

REMOTE CONTROL WARRANTY

WARRANTY

RC model allows to remote control of

controller.

Comprehensive, remote operating of

the controller.

Dimensions: 85x40x5 mm

Battery: CR2025 3V (included)

Warranty is given for 24 months from

date of purchase of goods.

Any defect disclosed in warranty pe-

riod will be removed within 21 working

days, counting from date of adoption

of goods for service.

In need of import goods or parts from

abroad, repair time is extended by time

required for their transportation.

Customer provides product to service

at their own cost.

At time of repair service will not provi-

de buyer replacement product

Warranty repairs will be made upon pre-

sentation of properly and legibly lled

your hardware warranty card, signed by

guarantor and with sale document

Warranty covers only defects arising

from causes inherent in goods. They

are not covered damage resulting from

external causes such as: mechanical in-

jury, pollution, ooding, weather, im-

proper installation or improper wiring

and operations. Warranty does not ap-

ply in case customer’s unauthorized

repairs, changes in software (rmware)

and device formatting.

Due to natural material use, some of

them are not covered by warranty (for

example: cables, battery, charger, micro

switches, buttons).

In event of unjustied claims for war-

ranty repair, all additional cost are on

customer’s side.

Service has right to refuse to perform

warranty repairs for following: dieren-

ces between documents and goods

marks, make repairs on their own by cu-

stomer, changes in product construc-

tion without authorization. This case

warranty is not valid anymore.

If it is not possible to test product be-

fore its purchase (sale at distance), it

is possible to return goods within 10

days. Returned goods cannot bear si-

gns of exploitation, it must contain all

elements with which it was delivered.

In the case of return of purchased go-

ods all shipping costs are on buyer side.

Before return of goods please contact

with seller.

Terms of warranty may be changed by

local InsBud company partner.

www.insbud.net 17

ENGLISH

WARRANTY

„INSBUD”

ul. Niepodległości 16a

32-300 Olkusz

POLAND

sales department: +48 (32) 626 18 00

sales department: +48 (32) 626 18 18

technical department: +48 (32) 626 18 07

technical department: +48 (32) 626 18 08

fax: +48 (32) 626 18 19

e-mail: [email protected]

Table of contents

Popular Temperature Controllers manuals by other brands

AERMEC

AERMEC NRL0280E Installation and maintenance manual

EPH Controls

EPH Controls R17 operating instructions

urmet domus

urmet domus Bitron Home 902010/27 Quick start manual

Kingspan

Kingspan Temperature differential controller Installation and operating instructions

Orton

Orton Sentry Xpress 4.0 manual

Sorel

Sorel TDC 4 Installation and operating instructions

Omron

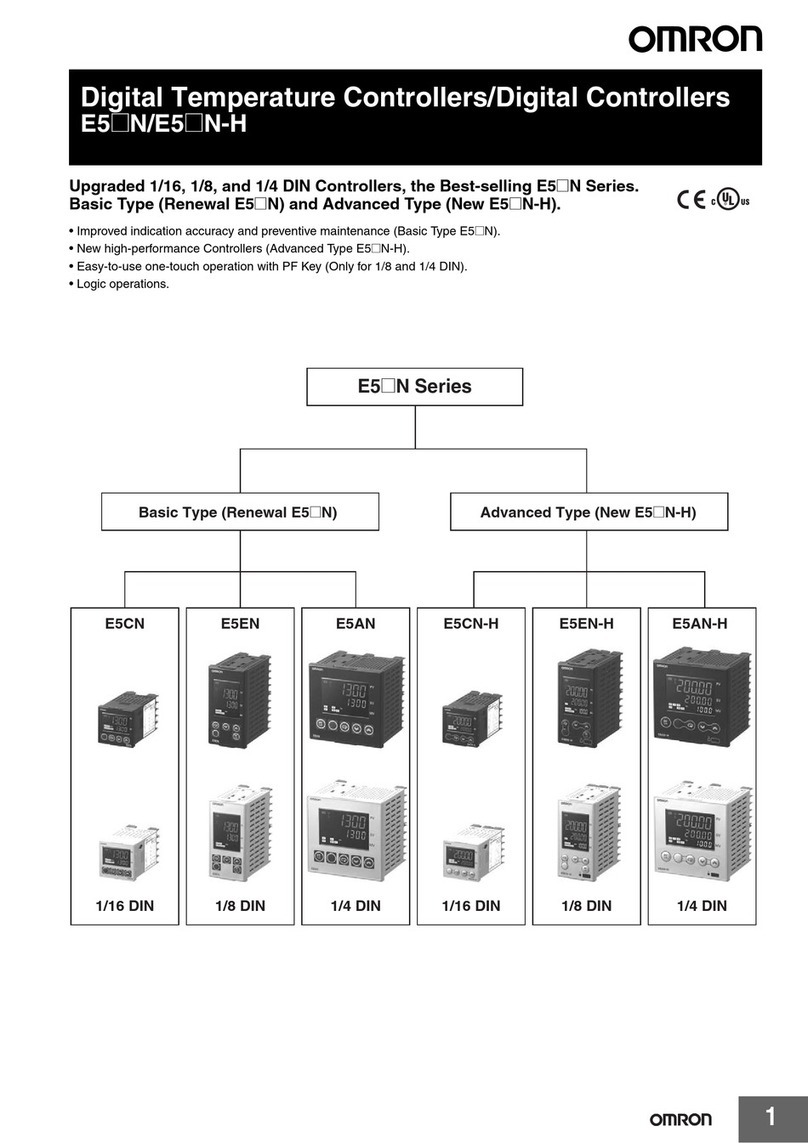

Omron E5_N-H Series manual

Qlima

Qlima DD 108 White operating manual

Store It Cold

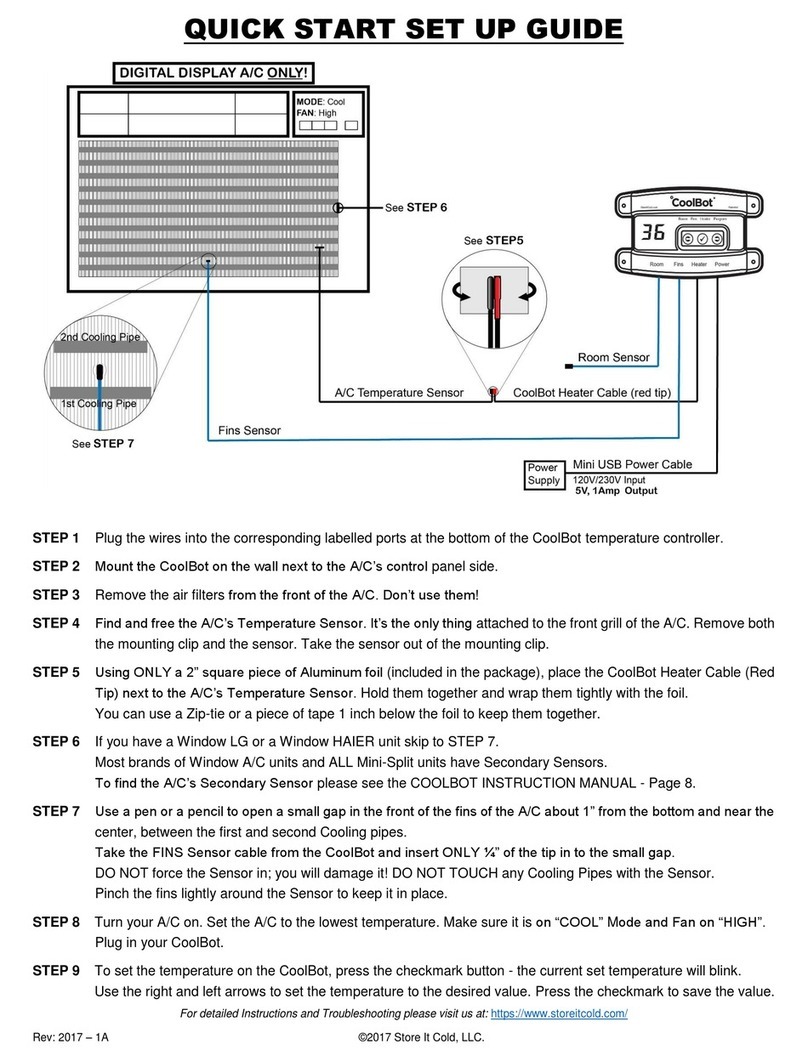

Store It Cold CoolBot Quick start setup guide

S+S Regeltechnik

S+S Regeltechnik THERMASGARD RGTF1 Series Operating Instructions, Mounting & Installation

Dometic

Dometic 9600011575 installation manual

Omron

Omron E5GN user manual