PRINTED IN CANADA

Page 4

SPECIFICATIONS

GENERAL

Sensing Element.................. Various thermistors and RTD's

Sensor Accuracy................... RTD Class A: ±0.15°C (±0.27°F) @ 0°C (32°F)

RTD 1/3 DIN: ±0.1°C (±0.18°F) @ 0°C (32°F)

RTD 1/10 DIN: ±0.03°C (±0.054°F) @ 0°C (32°F)

NTC Thermistor Type 39: ±0.05°C (±0.09°F),

0 to 70°C (32 to 158°F)

NTC Thermistor Type 55: ±0.03°C (±0.054°F),

0 to 70°C (32 to 158°F)

NTC Thermistor Type 40/46: ±0.1°C (±0.18°F),

0 to 70°C (32 to 158°F)

Operating Conditions ........ 0 to 50°C (32 to 122°F), 0 to 95 %RH non-condensing

Wiring Connections............ Screw terminal block (14 to 22 AWG)

Sensor only: Pigtail, 2 or 3 wire

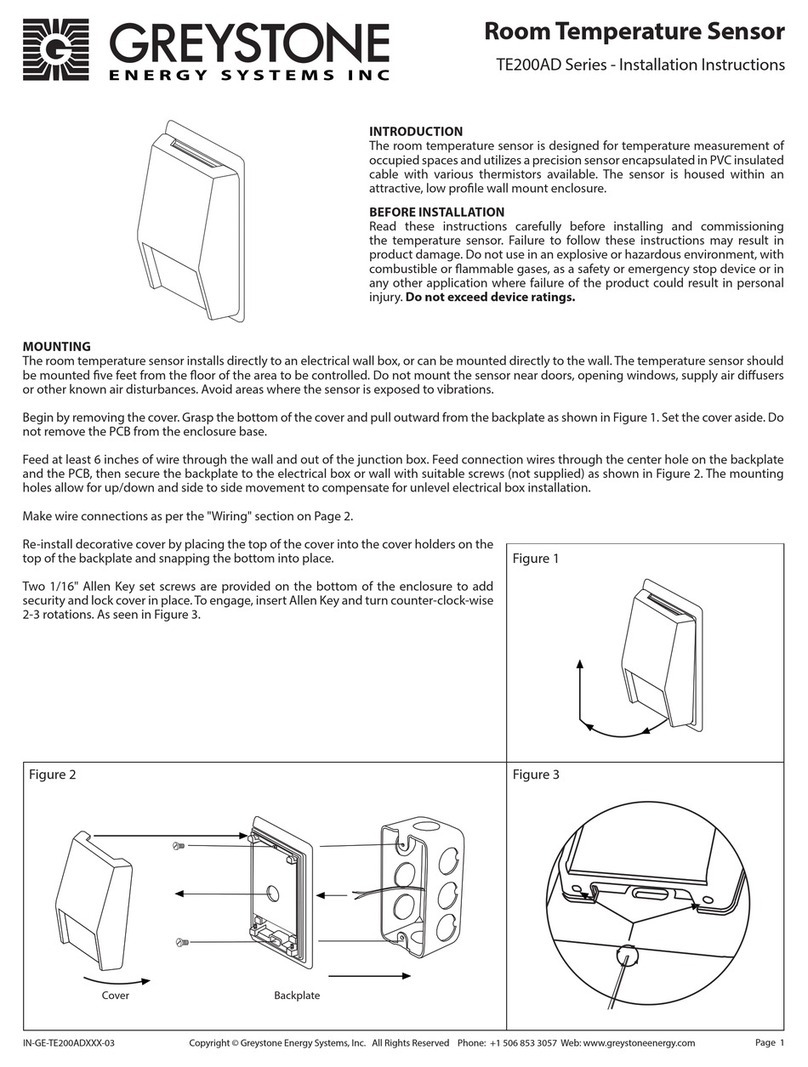

Enclosure................................ White ABS, IP30 (NEMA 1)

84mm W x 119mm H x 29mm D (3.3" x 4.7" x 1.15")

Country of Origin...................Canada

OVERRIDE SWITCH

Switch Type............................ Front panel, momentary push-button,

N.O., SPST, 50 mA @ 12 Vdc

FAN SPEED SWITCH

Range....................................... Auto, O, Low, Medium, High

Signal ....................................... Resistance: 2K, 4K, 6K, 8K, and 10K Ω standard

(custom ranges available)

SET-POINT SLIDE POT

Range....................................... Front panel pot as resistive output, 20 to 20K Ω

Custom Spans Available....1K, 2K, 5K, 10K, or 20K Ω

OCCUPIED INPUT

Signal Type...............................Digital input, 0-5 Vdc, active low

Action.........................................Causes "OCC" segment to light on LCD

LED INPUT

Signal Type...............................Active high, low, or 2 wire, 5 V current limit standard

LED Colors................................Red, Green, or Yellow

Power Supply........................ 5 Vdc standard, 10 Vdc or 24 Vdc optional

LCD DISPLAY

Power Supply..........................12-24 Vdc / 24 Vac ± 10%

Consumption @ 24 Vdc.......13 mA max (no backlight) 23 mA max (with backlight)

Protection Circuitry...............Reverse voltage protected

Range .........................................0.0-35.0°C or 32.0-95.0°F

jumper selectable

Resolution ................................0.1°C/°F

Display Size ..............................38.1mm W x 16.5mm H (1.5" x 0.65")

Digit Height .............................11.43mm (0.45")

Symbols.....................................°C, °F, OCC

Backlight ...................................Enable or disable via jumper

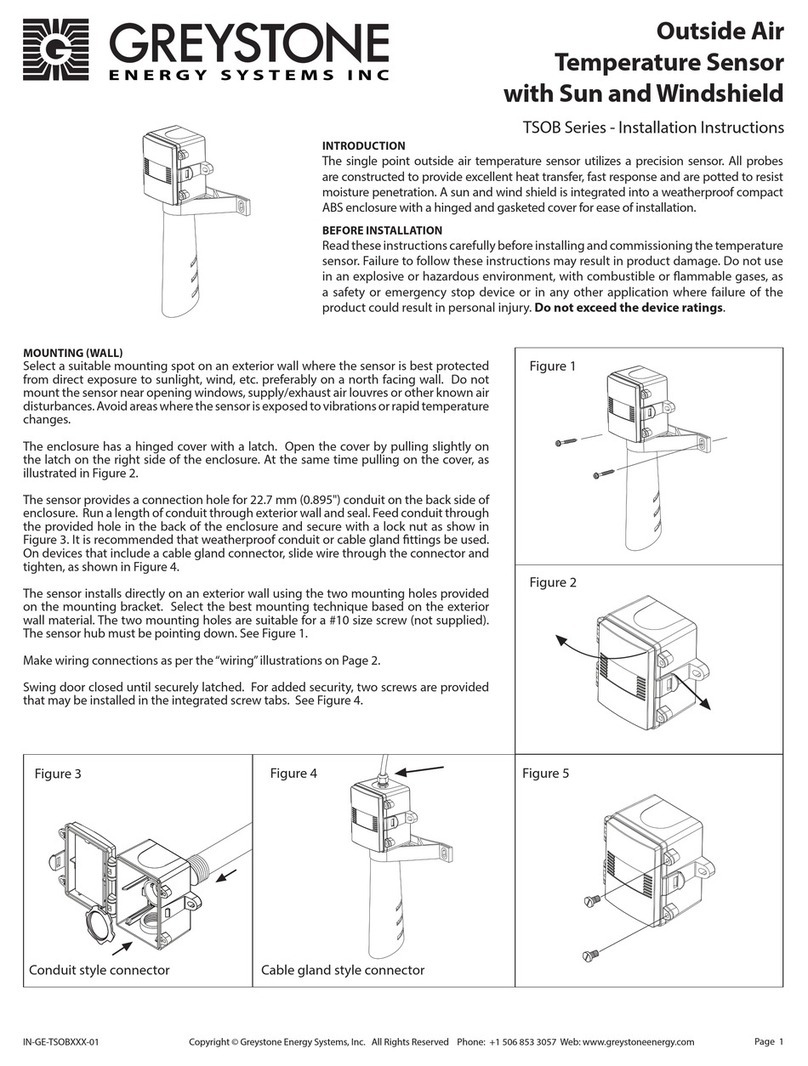

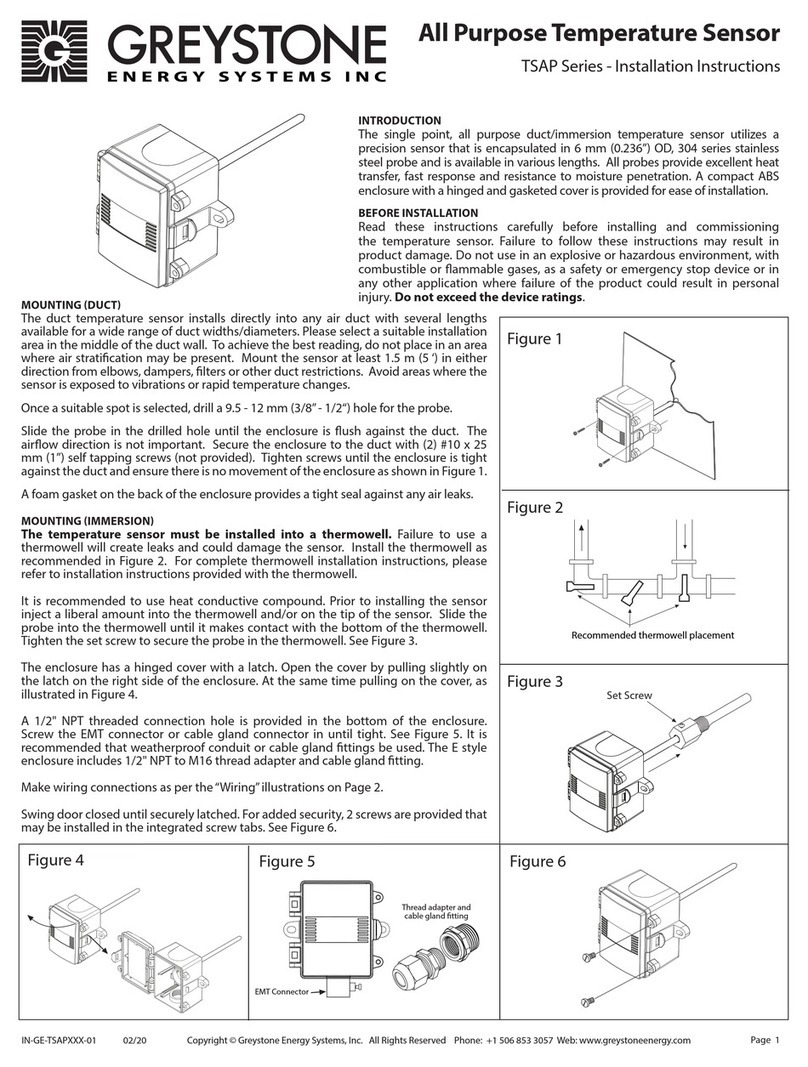

DIMENSIONS

84 mm

3.3"

29 mm

1.15"

119 mm

4.7"

58 mm

2.3"

82.6 mm

3.25"

NOTE: The sensor accuracies listed in the specifications section apply to the sensing element only prior to

product assembly and may not be reflected in the complete assembly.

Due to the measurement uncertainty, it is possible, that the true resistance value of the single delivered

sensor at 0°C can be out of the defined tolerance class. Profiling each assembly to take into consideration

lead wire and the attachment method should be completed.

IN-GE-HATSRCXXX-02 Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com