INSIGHT DLP DIRECTOR 1000 Manual

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance

Hardware Installation Guide

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 2

Section 1 Safety Notice and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Section 2 Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 3 Electrical and General Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 4 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 5 Unpacking the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 6 Prepare and Assemble the Rack Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 7 Installing the Rails on the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 8 Installing the Appliance in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 9 Rear Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 10 Front Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 11 Bezel Installation on the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table of Contents

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 3

AC input voltage: 100 - 240V (auto-range)

Input frequency range: 50-60 Hz

Rated input current: 100 - 127V ~/7.0A Max

200 - 240V ~/3.5A Max

1. Safety Notice and Warnings

2. Ratings

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause

undesired operation.

No Telecommunications Network Voltage (TNV)-connected PCBs shall be installed.

CAN ICES-3 (A)/NMB-3(A)

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference,

in which case the user may be required to take adequate measures.

VCCI Warning

This is a product of VCCI Class A Compliance.

Environmental Warning

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate.

This notice is required by California Code of Regulations, Title 22, Division 4.5, Chapter 33:

Best Management Practices for Perchlorate Materials. This product/part includes a battery

that contains perchlorate material.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 4

3. Electrical and General Safety Guidelines

CAUTION

This appliance is intended for installation in restricted areas only. Initial setup and maintenance

should be performed by qualified personnel.

CAUTION

Power down the appliance following the operating system’s proper power down procedure

using the front panel I/O power button. Unplug the AC power cord(s) before servicing.

CAUTION

To avoid electrical shock, check the power cords as follows:

nThis product is to be installed in Restricted Access Location only.

nUse the exact type of power cords required.

nUse power cord(s) that came with safety certifications.

nPower cord(s) must comply with AC voltage requirements in your region.

nThe power cord plug cap must have an electrical current rating that is at least 125% of

the electrical current rating of this product.

nThe power cord plug cap that plugs into the AC receptacle on the power supply must be an IEC 320,

sheet C13, type female connector.

nPlug the power cord(s) into a socket that is properly grounded before turning on the power.

CAUTION

Required operating conditions for the appliance are -

nTemperature: 10 to 35oC.

nHumidity, non-condensing: 8 to 90%.

CAUTION

CLASS 1 LASER PRODUCT

APPAREIL À LASER DE CLASSE 1

CAUTION

Risk of explosion if the battery is installed upside down or is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

DISPOSING OF BATTERY BACKUP UNITS - IF APPLICABLE

WARNING

If the BBU is damaged in any way, toxic chemicals may be released.

The material in the battery pack contains heavy metals that can contaminate the environment.

Federal, state, and local regulations prohibit the disposal of rechargeable batteries in public landfills.

Be sure to recycle the old battery packs properly. Comply with all applicable battery disposal and

hazardous material handling laws and regulations in the country or other jurisdiction where you

are using the BBU.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 5

3. Electrical and General Safety Guidelines (continued)

WARNING

There is danger of an explosion if the battery is incorrectly replaced. Replace it only with the same

or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

WARNING

Disconnect the power supply at the circuit breaker before accessing any components. Turning off

the system power supply switch does not reduce the risk of electrical shock from the power supply

terminal block.

CAUTION

nTo prevent the unit from overheating, never install the appliance in an enclosed area that is not

properly ventilated or cooled. For proper airflow, keep the front and back sides of the appliance clear

of obstructions and away from the exhaust of other equipment.

nBe aware of the locations of the power switches on the chassis and in the room, so you can disconnect

the power supply if an accident occurs.

nTake extra precautionary measures when working with high voltage components. Do not work alone.

nBefore removing or installing main system components, be sure to disconnect the power first.

Turn off the system before you disconnect the power supply.

nUse only one hand when working with powered-on electrical equipment to avoid possible

electrical shock.

nUse rubber mats specifically designed as electrical insulators when working with computer systems.

nThe power supply or power cord must include a grounding plug and must be plugged into

grounded outlets.

CAUTION

Electric Static Discharge (ESD) can damage electronic components. To prevent damage to your system

board, it is important to handle it very carefully. The following measures can prevent ESD damage to

critical components.

nUse a grounded wrist strap designed to prevent static discharge.

nKeep all components and printed circuit boards (PCBs) in their antistatic bags until ready for use.

nTouch a grounded metal object before removing the board from the antistatic bag.

nDo not let components or PCBs come into contact with your clothing, which may retain a charge

even if you are wearing a wrist strap.

nHandle a board by its edges only; do not touch its components, peripheral chips, memory modules

or contacts.

nWhen handling chips or modules, avoid touching their pins.

nPut the motherboard and peripherals back into their antistatic bags when not in use.

nFor grounding purposes, make sure your computer chassis provides excellent conductivity between

the power supply, the case, the mounting fasteners and the motherboard.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 6

Setup location, rack and appliance precautions

nElevated Operating Ambient Temperature - If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than room ambient. Therefore, consideration

should be given to installing the equipment in an environment compatible with the maximum ambient

temperature (Tma) specified by the manufacturer.

Always keep the rack’s front door and all panels and components on the appliances closed when not

servicing to maintain proper cooling.

nReduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow

required for safe operation of the equipment is not compromised. Leave enough clearance, approximately

25 inches in the front, and 30 inches in the back of the rack to enable you to access appliance components

and allow for sufficient air flow.

nMechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition

is not achieved due to uneven mechanical loading.

ALL RACKS MUST BE MOUNTED SECURELY.

Ensure that all leveling jacks or stabilizers are properly

attached to the rack. If installing multiple appliances in a rack, make sure the overall loading for each

branch circuit does not exceed the rated capacity.

Do not slide more than one appliance out from the rack at a time. Extending more than one appliance at a

time may result in the rack becoming unstable. Install your appliance in the lower part of the rack because

of its weight and also for ease in accessing appliance components.

nCircuit Overloading - Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this

concern.

nReliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch circuit

(e.g. use of power strips).

Install near appropriate AC outlets, and Ethernet hubs or individual jacks. Be sure to install an AC Power

Disconnect for the entire rack assembly. The Power Disconnect must be clearly marked. Ground the rack

assembly properly to avoid electrical shock.

4. Site Preparation

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 7

5. Unpacking the Appliance

Make sure the ship kit includes the correct installation hardware shown below:

nEight Phillips flat head screws

nTwo power cords

nApair of 4-post rack sliding chassis rail and rack assemblies

NOTE: Use the hardware

supplied with your specific

rack if different from the

hardware supplied in this kit.

DCB

AE F

Eight Phillips

flat head screws

Two power cords

Complete chassis and adjustable rack rail assembly (inside view)

Complete chassis and adjustable rack rail assembly (outside view)

Inner fixed chassis rail attaches to the appliance

(To be removed from the adjustable rack rail assembly

and will attach directly to the appliance)

Adjustable rack rail assembly

which will be installed and attached to the front and back of the rack)

A

B

C

D

E

F

Inner fixed chassis rail

Chassis rail locking pin

Chassis rail release button

Adjustable rack rail, front bracket

Adjustable rack rail, center sliding rail

Adjustable rack rail, rear bracket

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 8

Adjustable rack rail

assemblies

Side View

Side View

Angle View

Angle View

4-post rack

B

A

C

AC

4-post rack

assemblies

Adjustable rack rail

A

assemblies

Adjustable rack rail

B

C

Angle View

A

Angle View

Angle View

4-post rack

Angle View

C

4-post rack

Side View

4-post rack

Side View

Side View

Side View

Inner fixed chassis rail

Release button

Outer adjustable rack rail assembly

6. Prepare and Assemble the Rack Rails

Step 2

Rack Rail Assembly

A. In the front, align the front bracket of

the adjustable rack rail assembly with

three holes in the rack. The rack rail

assembly will attach to the rack

behind the holes in the front. Insert

and tighten two of the flat head

screws in the top and bottom holes

as shown in the illustration on the

right. The center hole will remain

empty for later use to secure the

appliance in the rack.

B. Slide the rack rail assembly back to

attach the rear bracket to the rear of

the rack.

C. In the rear, insert and tighten two of

the flat head screws through the top

and bottom holes of the rear bracket

to the rear of the rack. The rear

bracket will attach to the rack behind

the post with the holes.

Repeat steps A, Band Cto install the

other rack rail assembly on the other side

of the rack.

NOTE: Use the hardware

supplied with your specific

rack if different from the

hardware supplied in this kit.

Step 1

Mounting Hardware Assembly

nSeparate the inner fixed chassis rails

from the outer adjustable rack rail

assemblies.

nPull each inner fixed chassis rail out

as far as possible.

nDepress the release button and slide

the inner rail completely out.

nPut these rails aside for later

installation on the appliance.

NOTE: Make sure the rail assemblies are aligned

in the rack not only in the front and back but

also on the left and right sides to allow proper

appliance installation.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 9

Chassis rail key hole Chassis rail key hole

Chassis rail locking pin

Chassis rail key hole

AA A

B B B

Chassis standoff tabChassis standoff tabChassis standoff tab

Inner fixed chassis rail

Appliance chassis

(side view)

Chassis rail key hole

off tabChassis stand

e view)(sid

Appliance chassis

xed chassis rainner fiI

inpChassis rail locking

Chassis rail key holeChassis rail key hole

A

Boff tabChassis standoff tab

l

Chassis rail key hole

in

Chassis rail key hole

A

Boff tabChassis standoff tab

Chassis rail key hole

A

B

off tab

nMount the inner fixed chassis rails to each side of the appliance. Slide the chassis rail key hole cut outs

through the chassis standoff tabs on the side of the appliance as shown below. Slide the chassis rail

toward the back of the appliance. The chassis rail locking pin will secure the rail in place.

7. Rail Installation on the Appliance

Locate the fixed chassis rails that were put aside in Step 1 on page 8

8. Installing the Appliance in the Rack

A

B

ID

1

2

3

4

A

A

C

C

B

BB A

C

4

4

3

C

B

B

A

A. Align the inner fixed chassis rails on the appliance with the assembled rack rail components previously

installed in the rack. Carefully slide the appliance into these rails until you hear the rails click into place.

B. Slide the chassis rail release button forward to release the chassis rail. Push the appliance all the way

into the rack.

C. Secure the unit in the rack by pressing the thumb screws on either side of the appliance into the holes in

rack and tighten each one.

NOTE: When removing the appliance from

the rack, you will need to pull the chassis

release button forward in order to release

the appliance from the rack. Carefully slide

it out supporting the unit on both sides at

all times.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 10

MGMT SPAN DLP eth3 eth4 eth5 eth6 eth7

K L M N

O

P

Q V X

A B

CF

D E G I

R S T

U

H

W

J

AB

CF

DE G

H

I

K

C

J

AN

DLP

MGMT

SP

LM

N

O

P

F

eth3

Q

RS T

H

eth7

eth6

eth5

eth

VX

T

U

W

W

9. Rear Panel Connections

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Power Supply Module #1 Fan

Power Supply Module #1 AC Receptacle

Power Supply Module #1 Lock

Power Supply Module #2 Fan

Power Supply Module #2 AC Receptacle

Power Supply Module #2 Lock

PCIe x8 Connector

Three USB Ports

PCI Card Expansion Port

Power Supply Module #1

Power Supply Module #1 System Status LED

Power Supply Module #2

Power Supply Module #2 System Status LED

MGMT Port

SPAN Port

DLP Port

eth3 Port

Video Port

Serial Port

IPMI Port

eth4 Port

eth5 Port

eth6 Port

eth7 Port

Power Supply Condition

Output ON and OK

No AC power to both power supplies

AC present / only 12 VSB on (PS off) or PS in

cold redundant state

AC cord unplugged or AC power lost; with a

second power supply in parallel still with AC

input power

Power supply warning events where the power

supply continues to operate; high temp, high

power, high current, slow fan

Power supply critical event causing

a shutdown; failure, OCP, OVP, fan fail

Power supply FW updating

LED State

GREEN

OFF

1Hz Blinking

GREEN

AMBER

1Hz Blinking

AMBER

AMBER

2Hz Blinking

GREEN

Power Supply Status LED

There is a single bi-color Power Good LED on each power supply

module to indicate power supply status. The LED operation is defined

in the following table.

In normal operation the Power Good LED on Power Supply Module 1

will be SOLID GREEN and the LED on Power Supply Module 2 will BLINK

GREEN (redundant standby), if the system is powered down both LEDs

will BLINK GREEN.

CAUTION

Slide rail/mounted equipment is not

to be used as a shelf or a work space.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 11

9. Rear Panel Connections (continued)

MGMT SPAN DLP eth3 eth4 eth5 eth6 eth7

31 2

MGMT

SPAN

DLP

eth3

eth4

eth5 eth6

eth7

3

AN

DLP

MGMT

SP

T

ANSP

MGM

DLP

eth3

1

3eth

eth7

eth6

eth5

eth4

2

4

5eth

eth

6

7eth

eth

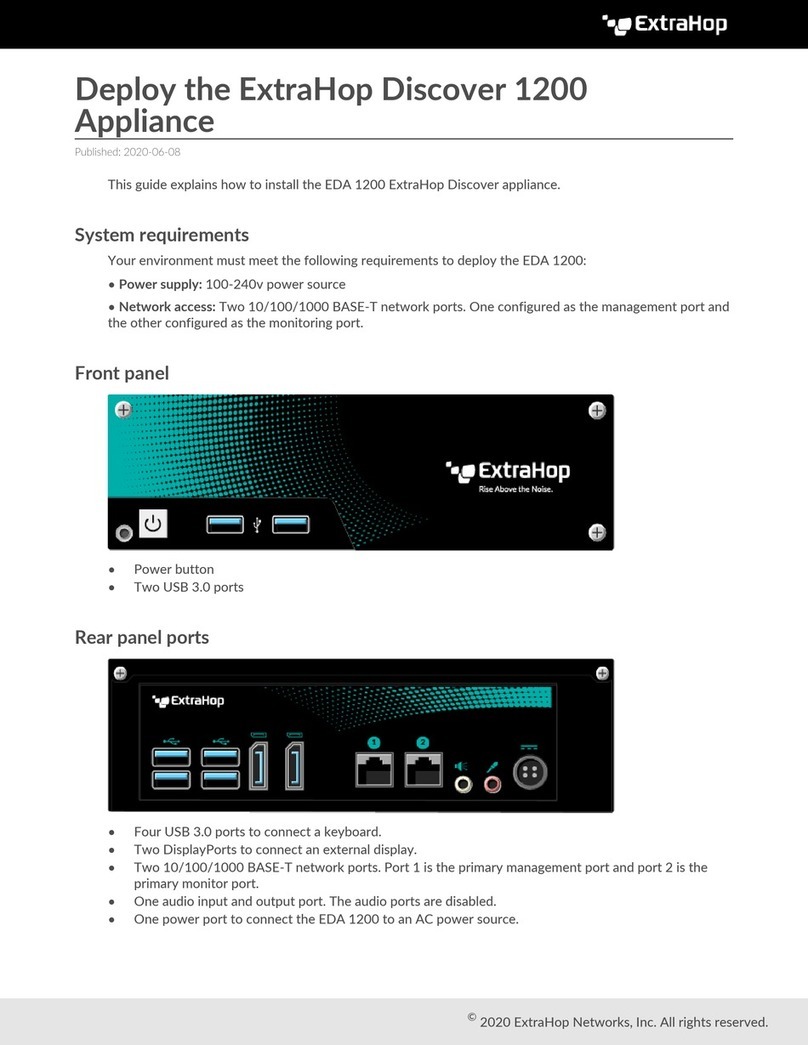

Step 1: Connect the Ethernet cables.

Step 2: Connect any other required cables.

Step 3: Connect the power cords.

Step 4: Proceed to Section 10, Front Panel Operation on page 12.

NOTE: The server offers redundant, hot-swap capability. The connections

to AC mains should be made in a manner appropriate to local code and

consistent with customer power distribution with or without redundant

sources.

CAUTION

The power supply is only hot-swappable if you have a redundant system with

two power supplies installed. If you only have one power supply installed,

before removing or replacing the power supply, you must first take the server

out of service, turn off all peripheral devices connected to the system, turn off

the system by pressing the power button, and unplug the AC power cord

from the system or wall outlet.

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 12

ID

1

2

3

4

See Detail Illustration and Chart

for Front Panel Information

USB Ports

Video Port

for Front Panel Information

See Detail Illustration and

Video Port

USB Ports

for Front Panel Information

ChartSee Detail Illustration and

Press the Power Button once to power the appliance on.

System

Status LED

ABCDEF G

HI

ABCD

HIStatus LED

System

EF G

ASystem ID Button with Integrated LED

BNMI Button (recessed, tool required for use)

CSPAN Activity LED

Deth3 Activity LED

ESystem Cold Reset Button

FHard Drive Activity LED

GPower Button with Integrated LED

HMGMT Activity LED

IDLP Activity LED

10. Front Panel Operation

System Status LED

There is a bi-color (Green/Amber) LED on the Front Panel (shown on

the left). The LED operation is defined in the following table.

Criticality

Not ready

OK

Degraded - system is

operating in a degraded state

although still functional, OR

system is operating in a

redundant state but with an

impending failure warning

Non-critical - system is

operating in a degraded

state with an impending

failure warning, although

still functioning

Critical, non-recoverable -

system is halted

LED Color

OFF

GREEN

GREEN

AMBER

AMBER

System State

System is not operating

Solid - On

~1 Hz blinking

~1 Hz blinking

Solid - On

INSIGHT DLP DIRECTOR 1000 & 2000 Appliance Hardware Installation Guide www.insightdlp.com Page 13

ID

1

2

3

4

21

Right Fixed

Bezel Tab

{

{

Left Flexible

Bezel Tab

2

abBezel T

lelexibLeft F

{

1

{

abBezel T

ixedht FRig

Step 1: Align the bezel with the front of the appliance. Insert the top and bottom bezel tabs on the right side

of the bezel into the handle on the right side of the appliance.

Step 2: Swing the left side of the bezel in toward the appliance. Press in on the bezel to engage the top and

bottom bezel tabs on the left side of the bezel into the handle on the left side of the appliance.

11. Bezel Installation on the Appliance

Copyright ©2014-2015 INSIGHT DLP. All rights reserved.

2301 Columbia Pike

Suite 125

Arlington, VA 22204

877-610-5625

877-605-8482 (F)

www.insightdlp.com

Other manuals for DLP DIRECTOR 1000

1

This manual suits for next models

1

Table of contents

Other INSIGHT Network Hardware manuals

Popular Network Hardware manuals by other brands

TP-Link

TP-Link Kasa Smart KP200 user guide

Symantec

Symantec S200 Series Safety and compliance guide

TelcoBridges

TelcoBridges TSBC Series Installation guides

Datawave

Datawave R02 user manual

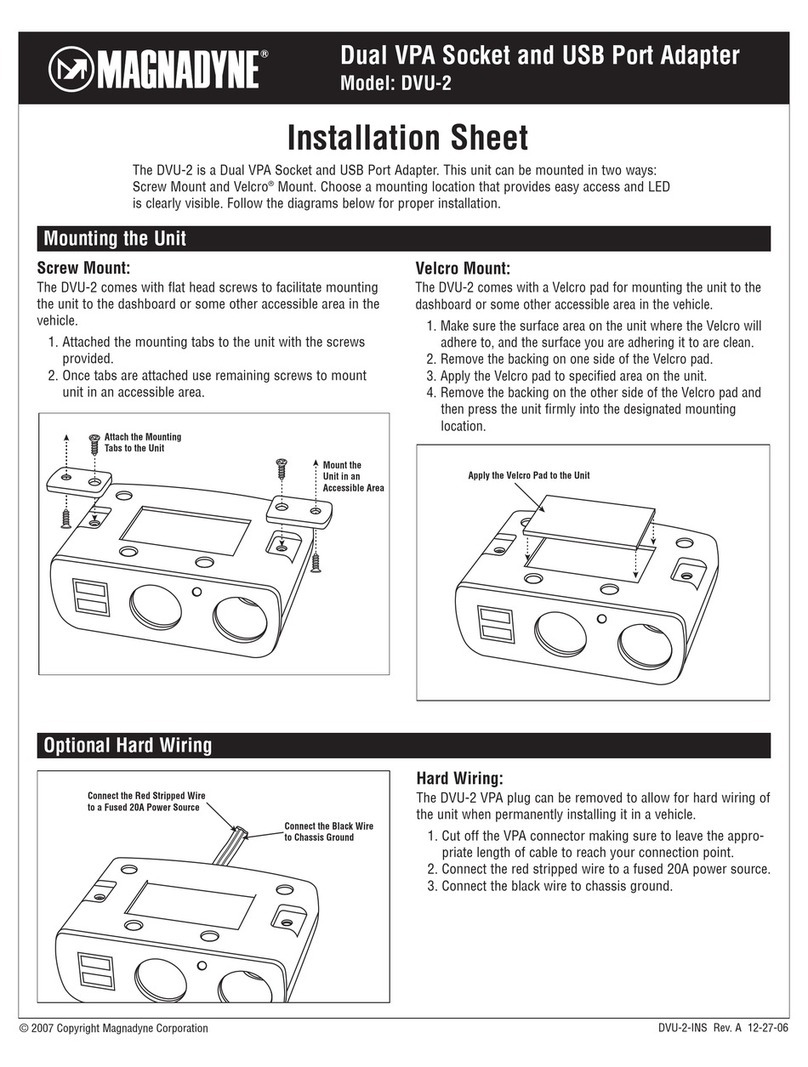

Magnadyne

Magnadyne Dual VPA Socket and USB Port Adapter DVU-2 Installation sheet

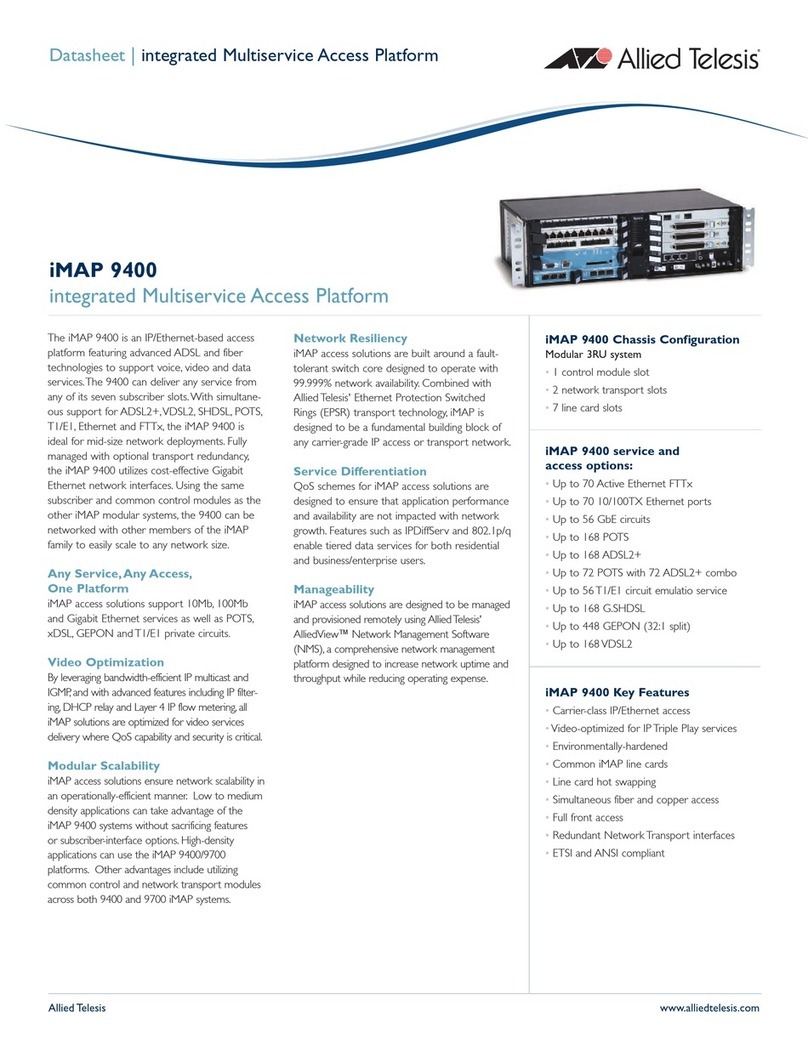

Allied Telesis

Allied Telesis iMAP 9400 datasheet