Gasboy 9800A Series User manual

SERIES 9800A

PUMPS AND DISPENSERS

DIAGNOSTIC MANUAL

C35797

REV. 03/07/03

Copyright 2003 by Gasboy International LLC All rights reserved.

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission of Gasboy International LLC. Gasboy International LLC believes that the information in this document is

accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or other

rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

GASBOY INTERNATIONAL LLC LANSDALE, PA

035282 Rev. 1267

GASBOY INTERNATIONAL LLC

707 North Valley Forge Rd. Lansdale, PA, 19446 ●(215) 855-4631 ●FAX: (215) 855-0341

IMPORTANT WARNINGS AND SAFEGUARDS

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

OF A FUEL SPILL.

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to the entire system. Instructions

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

including trucks. All containers must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and other

exposed moving parts at all times.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

03/07/03 Contents-1

CONTENTS

Section 1: INTRODUCTION

About this Book......................................................................................... 1-1

Using the Troubleshooting Section........................................................... 1-1

Section 2: CHASSIS WIRING

Junction Boxes.......................................................................................... 2-1

AC Junction Box .................................................................................. 2-1

DC Junction Box.................................................................................. 2-1

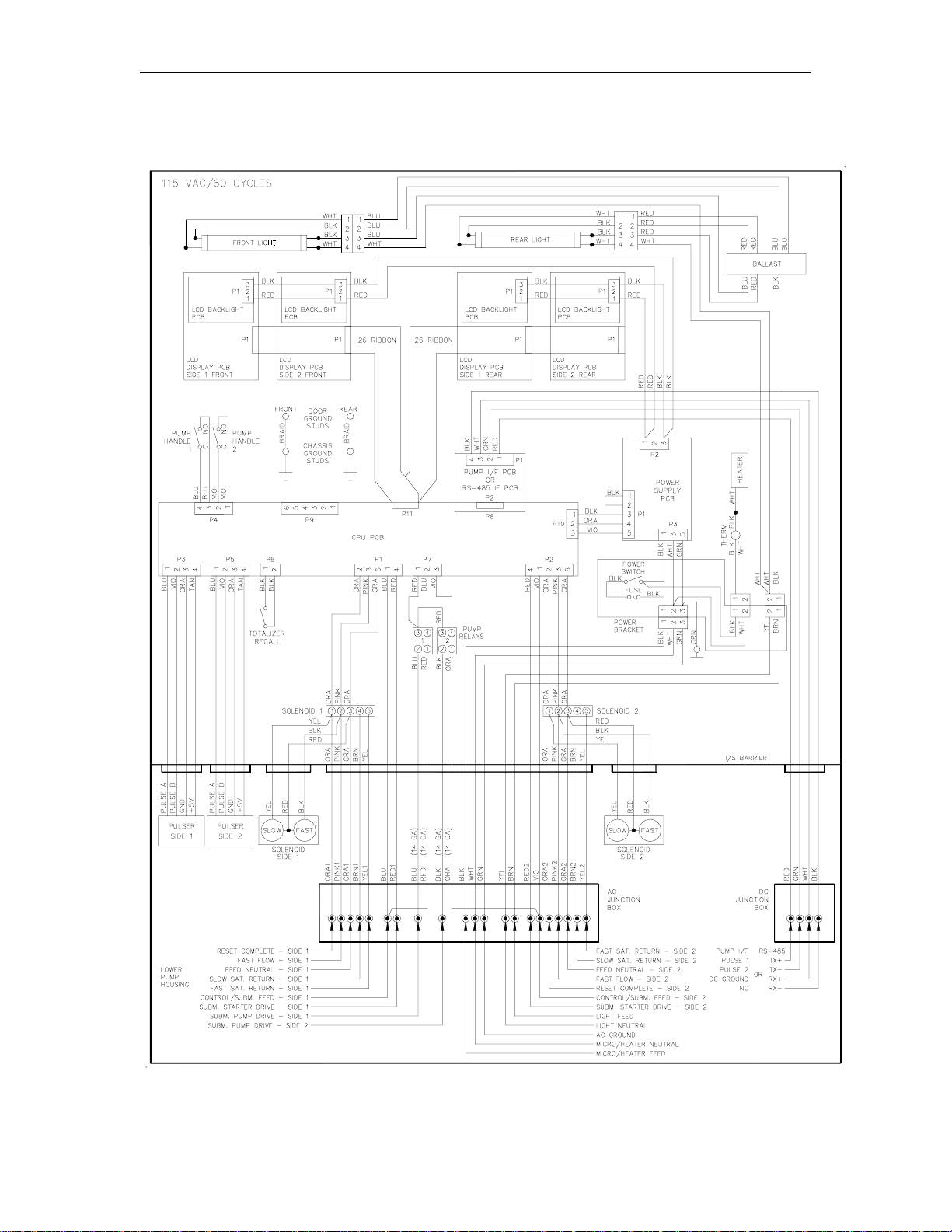

115VAC/60 Cycle Pump Wiring................................................................ 2-3

115VAC/60 Cycle Dispenser Wiring......................................................... 2-4

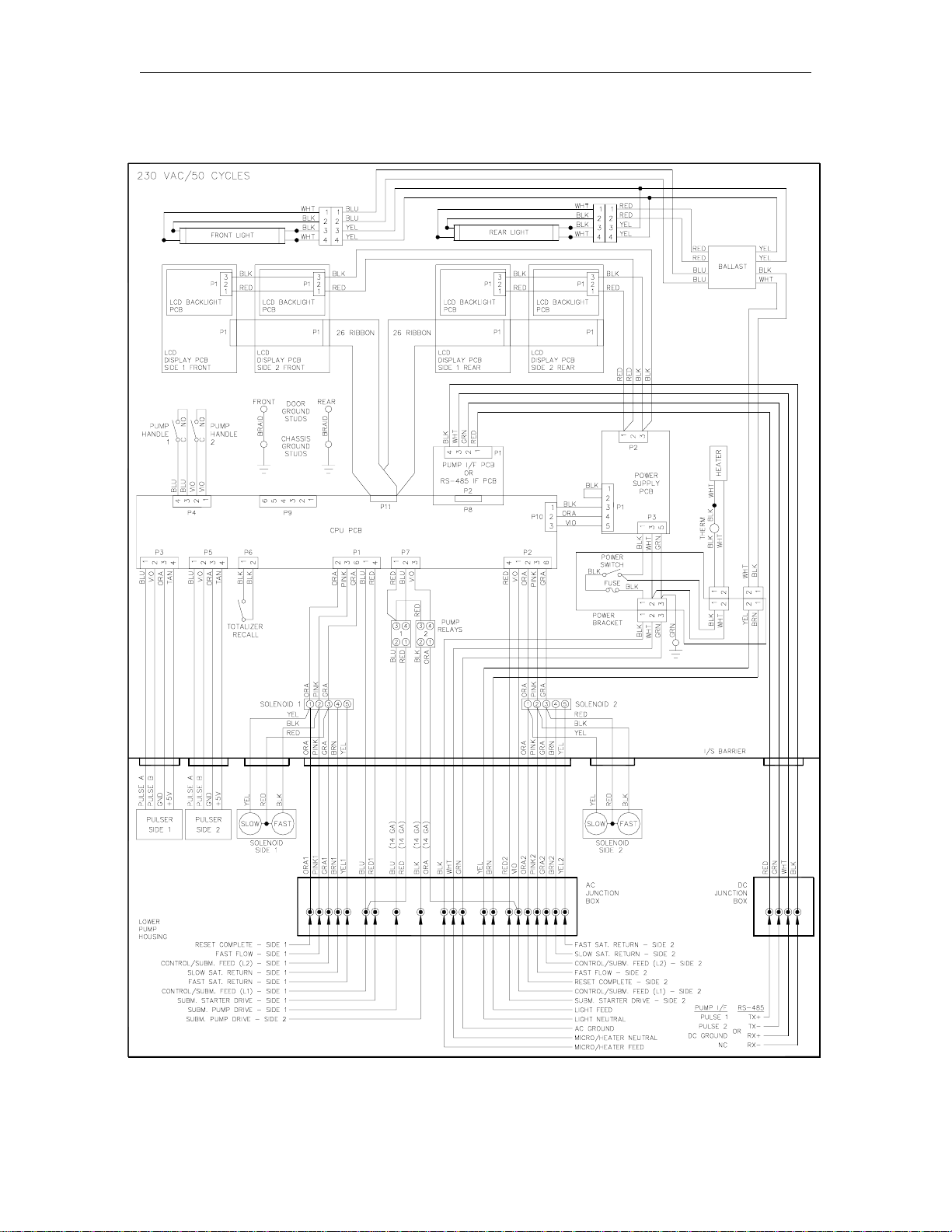

230VAC/50 Cycle Pump Wiring................................................................ 2-5

230VAC/50 Cycle Dispenser Wiring......................................................... 2-6

115VAC/60 Cycle Front Load Option Pump Wiring.................................. 2-7

115VAC/60 Cycle Front Load Option Dispenser Wiring........................... 2-8

230VAC/50 Cycle Front Load Option Pump Wiring.................................. 2-9

230VAC/50 Cycle Front Load Option Dispenser Wiring........................... 2-10

Section 3: ELECTRONIC HEAD ASSEMBLY

Overall Layout........................................................................................... 3-1

CPU PCB.................................................................................................. 3-2

Connectors........................................................................................... 3-3

Jumpers............................................................................................... 3-5

LED Indicators ..................................................................................... 3-6

Test Points........................................................................................... 3-6

SW Switches........................................................................................ 3-6

Address Switches ................................................................................ 3-8

Pulser Output Rate Switches............................................................... 3-8

LCD Display PCB (C01373)...................................................................... 3-9

Connector ............................................................................................ 3-9

Jumpers............................................................................................... 3-10

Sale Backlight PCB (C06372)................................................................... 3-11

Connector ............................................................................................ 3-11

RS-485 Interface PCB (C06389) ............................................................. 3-12

Connectors........................................................................................... 3-12

LED Indicators ..................................................................................... 3-13

Pump Interface PCB (06425).................................................................... 3-14

Connectors........................................................................................... 3-15

LED Indicators ..................................................................................... 3-15

Power Supply PBC ................................................................................... 3-16

Connectors........................................................................................... 3-17

LED Indicators ..................................................................................... 3-17

Test Points........................................................................................... 3-17

Pump Relays............................................................................................. 3-18

Connectors........................................................................................... 3-19

Ballast Assembly....................................................................................... 3-20

Connectors........................................................................................... 3-20

Fluorescent Lamp Assembly (C06398), Fluorescent Lamp (033412)...... 3-21

Connector ............................................................................................ 3-21

GASBOY Series 9800A

Contents-2 03/07/03

Heater/Thermostat Cable Assembly......................................................... 3-22

Connector ............................................................................................ 3-22

Power Bracket Assembly (C06436).......................................................... 3-23

Connectors........................................................................................... 3-23

Section 4: TROUBLESHOOTING

Using This Section.................................................................................... 4-1

Section 5: REPLACEMENT INSTRUCTIONS

General Information .................................................................................. 5-1

Electronic Component Access.................................................................. 5-2

Replacing the Platform Assembly............................................................. 5-3

Replacing the CPU PCB........................................................................... 5-5

Replacing the LCD Display PCB............................................................... 5-6

Replacing the Sale Backlight PCB............................................................ 5-7

Replacing the Power Supply PCB ............................................................ 5-8

Replacing the RS-485 or Pump I/F PCB .................................................. 5-9

Replacing the Ballast Cable Assembly..................................................... 5-10

Replacing the Heater Cable Assembly..................................................... 5-13

Appendix: PARTS LIST

Using This Parts List................................................................................. 1

9800A Single Assembly – Front View....................................................... 2

9800A Single Assembly –Side View......................................................... 4

9800A Twin Assembly –Front View.......................................................... 6

9800A Twin Assembly –Side View ........................................................... 8

9840A Assembly – Front View.................................................................. 10

9840A Assembly –Side View.................................................................... 12

9840A Chassis.......................................................................................... 14

9840AX Chassis........................................................................................ 16

9850AS Chassis........................................................................................ 18

9850AXS Chassis..................................................................................... 20

9850AXTW1 Chassis................................................................................ 22

9850AXTW2 Chassis................................................................................ 24

9852A, 9853A Chassis ............................................................................. 26

9853AHC Chassis..................................................................................... 28

9852AX, 9853AX Chassis......................................................................... 30

9852ATW1 Chassis Assembly.................................................................. 32

9853ATW1M Chassis Assembly............................................................... 34

9852AXTW1, 9853XTW1 Chassis Assembly........................................... 36

9852ATW2, 9853ATW2 Chassis Assembly ............................................. 38

9852AXTW2, 9853AXTW2 Chassis Assembly......................................... 40

Assembly Breakdowns

Air Separator Assembly ............................................................................ 42

Barrier, Intrinsically Safe (IS), Front Load Nozzle Option......................... 43

Check Valves............................................................................................ 44

9800A Single Dial Enclosure .................................................................... 45

9800A Twin Dial Enclosure....................................................................... 46

9840A, 9840AX Dial Enclosure................................................................. 47

Flange Assembly....................................................................................... 48

Motor Mount.............................................................................................. 48

Contents

0069 Contents-3

Support Assembly..................................................................................... 48

Float Assembly.......................................................................................... 49

Float Assembly Breakdown ...................................................................... 50

High Hose Retriever Parts........................................................................ 51

Internal Retriever Breakdown ................................................................... 52

9840A Manifold Assembly ....................................................................... 53

9840AX Manifold Assembly...................................................................... 53

9853AHC Pump Discharge....................................................................... 54

9853AHC Manifold.................................................................................... 54

9853ATW1M Manifold Assembly.............................................................. 55

9800AXTW1 Manifold Assembly .............................................................. 55

Mechanical Totalizer................................................................................. 56

9850A, 9850AX, 9850AXTW Meter Assembly ......................................... 57

Liquid Controls Meter Cover Assembly Breakdown (9850A) .................. 58

Liquid Controls Meter Housing Assembly Breakdown (9850A)............... 60

9840A, 9852A,9853A, 9853AHC, 9852ATW1, 9852ATW2, 9853ATW2,

9853ATW1M Meter Assembly............................................................. 62

9852AXTW1, 9853AXTW1, 9840AX Meter Assembly ............................. 63

9852AXTW2, 9853AXTW2 Meter Assembly ............................................ 64

9800A Meter Assembly Breakdown.......................................................... 66

9840A Motor.............................................................................................. 68

9850A Motor.............................................................................................. 69

9852A, 9853A Motor................................................................................. 70

9853AHC Motor ........................................................................................ 71

9852ATW1 Motor...................................................................................... 72

9852TW2, 9853ATW2, 9853ATW1M Motor............................................. 73

9853ATW2, 9853ATW1M Motor, 380V .................................................... 74

Nozzle Boot, Front Load Option................................................................ 75

9840 Pumping Unit Assembly................................................................... 76

9850A Pump and Platform Assembly....................................................... 77

9852A, 9853A Pumping Unit Assembly.................................................... 78

9853AHC Pumping Unit Assembly........................................................... 79

9852ATW1 Pumping Unit Assembly......................................................... 80

9853ATW1M Pumping Unit Assembly...................................................... 81

9852ATW2, 9853ATW2 Pumping Unit Assembly..................................... 82

Pumping Unit Assembly Breakdown......................................................... 84

Blackmer XU2A Pump and Platform Assembly Breakdown..................... 86

Reset......................................................................................................... 88

Strainer Body/Check Valve Assembly ...................................................... 88

Discharge Assemblies

9840A Discharge – 097230 ...................................................................... 89

9840A Discharge, Canada-ATC 097264 .................................................. 89

9840A Valve Discharge - 097239 115V, 097240 230V............................ 90

9840AX Discharge - 097241 115V, 097242 230V.................................... 91

9840AX Discharge – Canada-ATC 097415.............................................. 92

9840AX Filter Discharge - 097243 115V, 097244 230V........................... 93

9840AX Satellite Discharge - 097245 115V, 097246 230V,

Canada-ATC 097416........................................................................... 94

9850A, 9850AX Discharge Valve Assembly 097305 115V,

097311 230V, Canada-ATC 097426 ................................................... 95

9850A Discharge Assembly - 097302, Canada-ATC 070087 .................. 95

9850AS Discharge, Satellite Pipe Assembly 097308 115V,

GASBOY Series 9800A

Contents-4 03/07/03

097335 230V, Canada-ATC 097434 ................................................... 96

9850AXS Discharge, Valve Pipe Assembly, 097321 115V,

097323 230V, Canada-ATC 097435 ................................................... 97

9850AXTW Discharge 097326 115V, 097329 230V, Canada-ATC 097428 98

9850AXTW Discharge 097348 115V, 097349 230V, Canada-ATC 097436 99

9852A, 9852AX Discharge - 097300 115V, 097301 230V,

Canada-ATC 097418........................................................................... 100

9852ATW1, 9852AXTW Discharge - 097324 115V, 097325 230V,

Canada-ATC 097419 .......................................................................... 100

9852ATW2 Discharge - 097352 115V, 097353 230V,

Canada-ATC 097420........................................................................... 100

9852A, 9852AX Filter Discharge - 097306 115V, 097307 230V,

Canada-ATC 097424........................................................................... 101

9852ATW1, 9800AXTW Filter Discharge - 097333 115V, 097334 230V,

Canada-ATC 097425........................................................................... 101

9852AX Satellite Discharge - 097303 115V, 097304 230V,

Canada-ATC 097429........................................................................... 102

9800AXTW Satellite Discharge - 097327 115V, 097328 230V,

Canada-ATC 097430........................................................................... 102

9852AX Filter, Satellite Discharge - 097309 115V, 097310 230V............ 103

9852AXTW Filter, Satellite Discharge - 097336 115V, 097337 230V...... 103

9852A Discharge – 097188; Canada-ATC 097273.................................. 104

9852A Filter Discharge – 097359, Canada-ATC 097338 ........................ 104

9852ATW2 Discharge Assembly – 097209; Canada-ATC 097417.......... 105

9852ATW2 Filter Discharge Assembly – 097208; Canada-ATC 097417. 105

9853A, 9853AX, 9853AHC Discharge - 097312 115V, 097313, 230V,

Canada-ATC 097421........................................................................... 106

9853AXTW Discharge - 097339 115V, 097340 230V,

Canada-ATC 097422........................................................................... 106

9853ATW2, 9853ATW1M Discharge - 097355 115V, 097356 230V;

Canada-ATC 097423........................................................................... 106

9853A, 9853AX Filter Discharge - 097316 115V, 097317 230V.............. 107

9853AXTW Filter Discharge - 097343 115V, 097344 230V..................... 107

9853A, 9853AHC Discharge Assembly – 097171, Canada-ATC 097269 108

9853A Filter Discharge Assembly - 097361 ............................................. 108

9853ATW1M, 9853ATW2 Discharge Assembly – 097155,

Canada-ATC 097266........................................................................... 109

9853AX Satellite Discharge - 097314 115V, 097315 230V,

Canada-ATC 097431........................................................................... 110

9853AXTW Satellite Discharge - 097341 115V, 097342 230V,

Canada-ATC 097432........................................................................... 110

9853AX Filter, Satellite Discharge - 097318 115V, 097319 230V............ 111

9853AXTW Filter, Satellite Discharge - 097345 115V, 097346 230V...... 111

9853ATW2F Discharge Assembly – 097205; Canada-ATC 097433........ 112

Electronic Assembly

Electronic Platform Assembly................................................................... 114

Electronic Platform Options ...................................................................... 116

9800A Kits and Accessories.................................................................. 118

03/07/03 1-1

Section 1

INTRODUCTION

ABOUT THIS BOOK

This book was written to assist the authorized service representative (ASR) or technician in

troubleshooting the Series 9800A. This manual contains:

• a functional description of each part

• wiring connections

• illustrations of the circuit boards and their indicators, connectors, jumpers, and switches

• diagnostic test procedures

• a troubleshooting (Problems) section.

USING THE TROUBLESHOOTING SECTION

The Troubleshooting section lists common problems, probable causes, and corrective action to

be taken. The probable causes and checks for each problem are presented in logical sequence,

allowing you to rule out one set of symptoms before going on to the next. Thus, following the

procedures as listed should help isolate your problem.

A double line at the end of a problem sequence indicates the last of the checks for that problem.

If your 9800A still is not working, recheck your symptoms and follow another problem sequence if

necessary. If you encounter problems you cannot solve by using this manual, call GASBOY

customer service at 1-800-444-5529.

Checks and corrective actions requiring voltage measurements assume familiarity with and are

done with a voltmeter unless noted that an oscilloscope or ohmmeter should be used.

03/07/03 2-1

Section 2

CHASSIS WIRING

JUNCTION BOXES

All field wiring connections to the Series 9800A dispensing unit are made in the unit’s junction

boxes. The 9800A wiring is split into two classifications, AC and DC. A junction box is provided

for AC; a DC junction box is optional. AC and DC wiring must never be mixed in any common

junction box, conduit, or trough. See the Series 9800A Installation/Operation Manual for detailed

instructions. The following lists the wires that can be found in the junction boxes along with a

brief description of each. A more detailed description can be found in the Series 9800A

Installation/Operation Manual.

AC Junction Box

AC Ground - Grounding for the Series 9800A

Micro Feed - Hot side of power for the microprocessor register electronics.

Micro Neutral - Neutral side of power for the micro feed.

Control Pump Motor Feed - Hot side of power used to authorize the control line to the

dispensing unit. Two lines provided for twins. Also powers slow and fast flow valves, when

valves are used.

Neutral Feed - Neutral side of the power supplied on the Control/Pump Motor or

Control/Submersible Feed lines.

Control/Submersible Feed - Hot side of the power used to authorize the control line to the

dispensing unit. Provides power to slow and fast flow valves along with the switch detect signal.

Two lines provided for twins.

Submersible Starter Drive - Controls Submersible Starter Relay. Two lines provided for twins.

Submersible Drive - Active only when submersible drive relays are provided. Controls

submersible starter relay or submersible pump. Two lines provided for twins.

Reset Complete (Switch Detect)/Slow Flow - For use with fuel management system, indicates

reset process is complete and dispensing unit is ready to dispense product; if applicable, also

controls remote slow flow valve (satellite). Two lines provided for twins.

Fast Flow - Controls remote fast flow valve (satellite). Used only with two-stage solenoid valves.

May provide remote control or monitoring of fast flow. Two lines provided for twins.

Phase 2 Feed - Hot feed; opposite phase of pump motor feed.

Slow/Fast Satellite Returns - Used only with satellites in nonsimultaneous applications. Four

lines are provided with twins.

Light Feed - Hot side of power for fluorescent lights.

Light Neutral - Neutral side of power for the light feed.

GASBOY Series 9800A

2-2 03/07/03

DC Junction Box

Pulser - When the dispensing unit includes the optional pulser interface, a pulser output is

provided. This pulser output provides a DC output to indicate the quantity dispensed. This is an

open collector output. A DC ground line from the monitoring equipment should be connected to

the DC ground line provided from the electronic register. This output can sink up to 100 milliamps

DC at voltages up to 24 VDC. The pulse rate can be configured by a sealable DIP switch for

rates of 1, 10, 100, 250, 500, or 1000 pulses per unit (gallons) or 1, 10, 100, or 250 pulses per

unit (liters). This output should only be used when monitoring of the dispenser’s operation is

desired. An additional output is provided for a twin. These lines must be capped when not in

use.

RS-485

When the dispensing unit includes the optional RS-485 interface, RS-485 lines are provided.

This interface allows the user to connect a GASBOY CFN Series System directly to the Series

9800A dispensing unit. These lines must be capped when not in use.

Chassis Wiring

03/07/03 2-3

115VAC/60 CYCLE PUMP WIRING

GASBOY Series 9800A

2-4 03/07/03

115VAC/60 CYCLE DISPENSER WIRING

Chassis Wiring

03/07/03 2-5

230VAC/50 CYCLE PUMP WIRING

GASBOY Series 9800A

2-6 03/07/03

230VAC/50 CYCLE DISPENSER WIRING

Chassis Wiring

03/07/03 2-7

115VAC/60 CYCLE FRONT LOAD OPTION PUMP WIRING

GASBOY Series 9800A

2-8 03/07/03

115VAC/60 CYCLE FRONT LOAD OPTION DISPENSER WIRING

Chassis Wiring

03/07/03 2-9

230VAC/50 CYCLE FRONT LOAD OPTION PUMP WIRING

GASBOY Series 9800A

2-10 03/07/03

230VAC/50 CYCLE FRONT LOAD OPTION DISPENSER WIRING

Chassis Wiring

03/07/03 2-11

This manual suits for next models

20

Table of contents

Other Gasboy Dispenser manuals

Popular Dispenser manuals by other brands

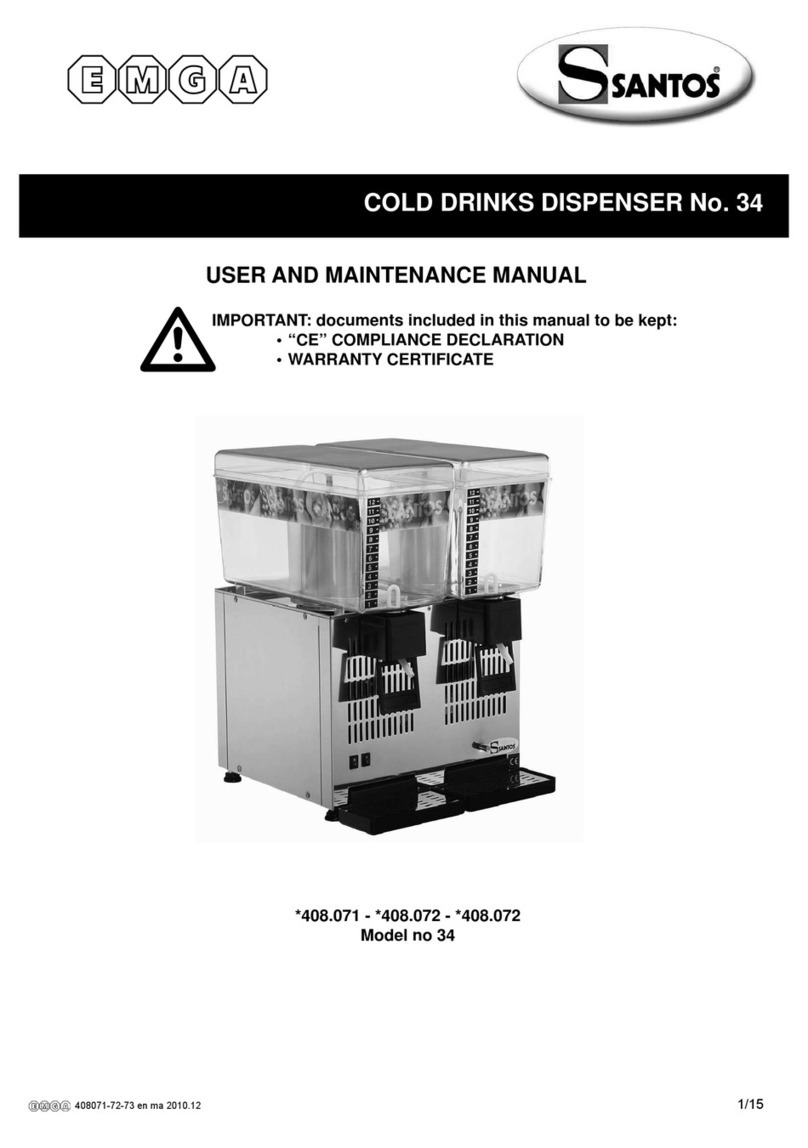

Santos

Santos 34-1 User and maintenance manual

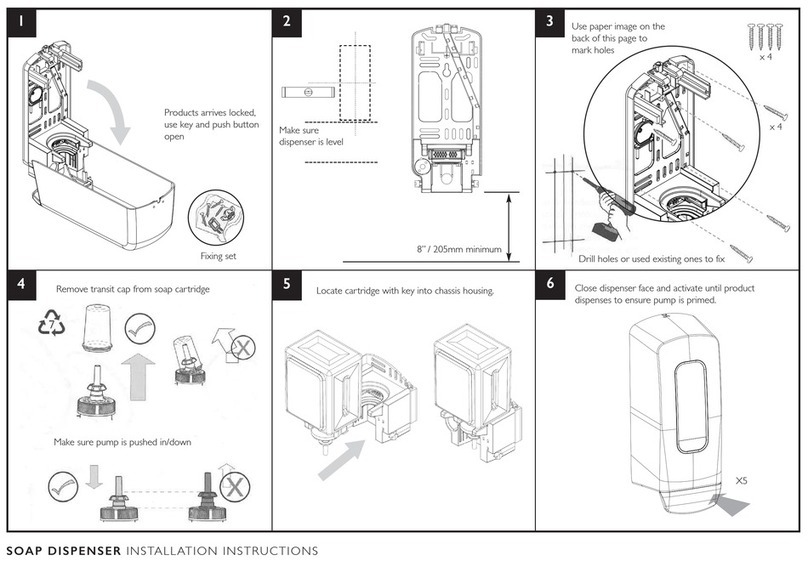

Dolphin

Dolphin Excel installation instructions

Ever Sharp Technology

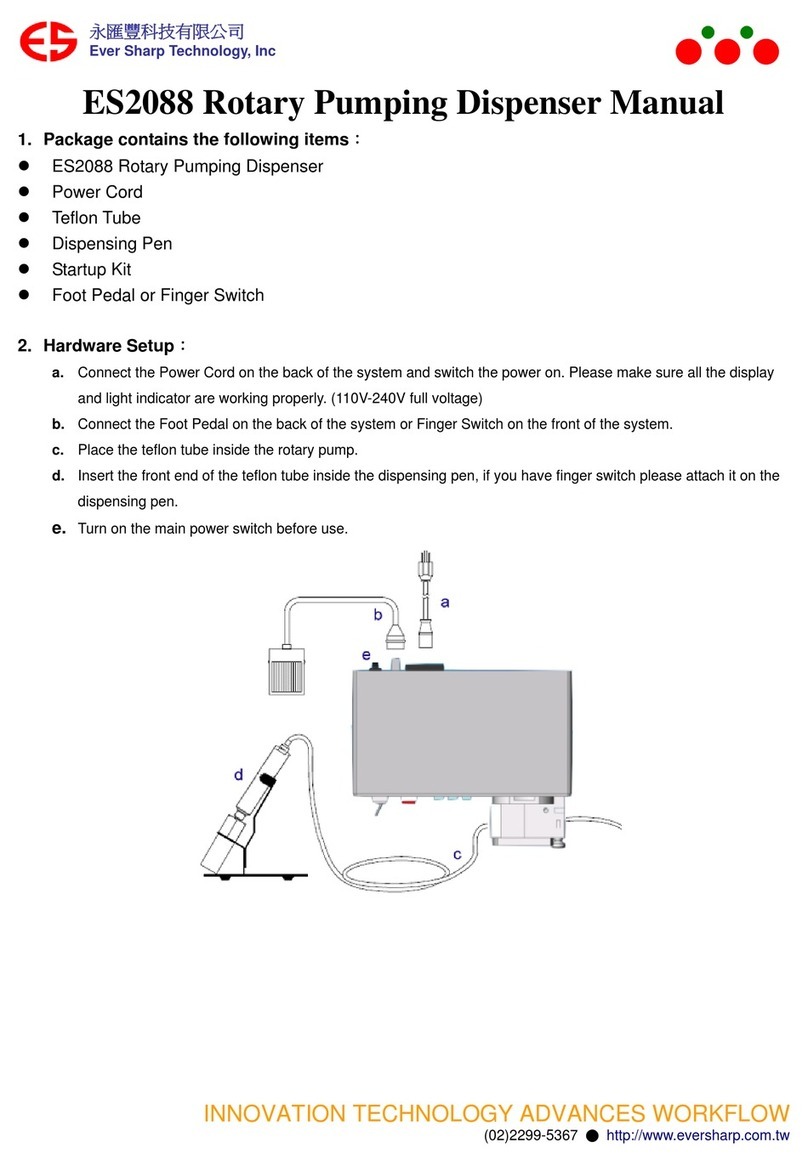

Ever Sharp Technology ES2088 manual

Cornelius

Cornelius Quest Bib Option Kit installation manual

San Jamar

San Jamar Tear-N-Dry Essence quick start guide

ZEP

ZEP D-4000 Plus Service instructions