Instantel Micromate Sound Level Microphone User manual

1 / 5Instantel

Instruction Sheet

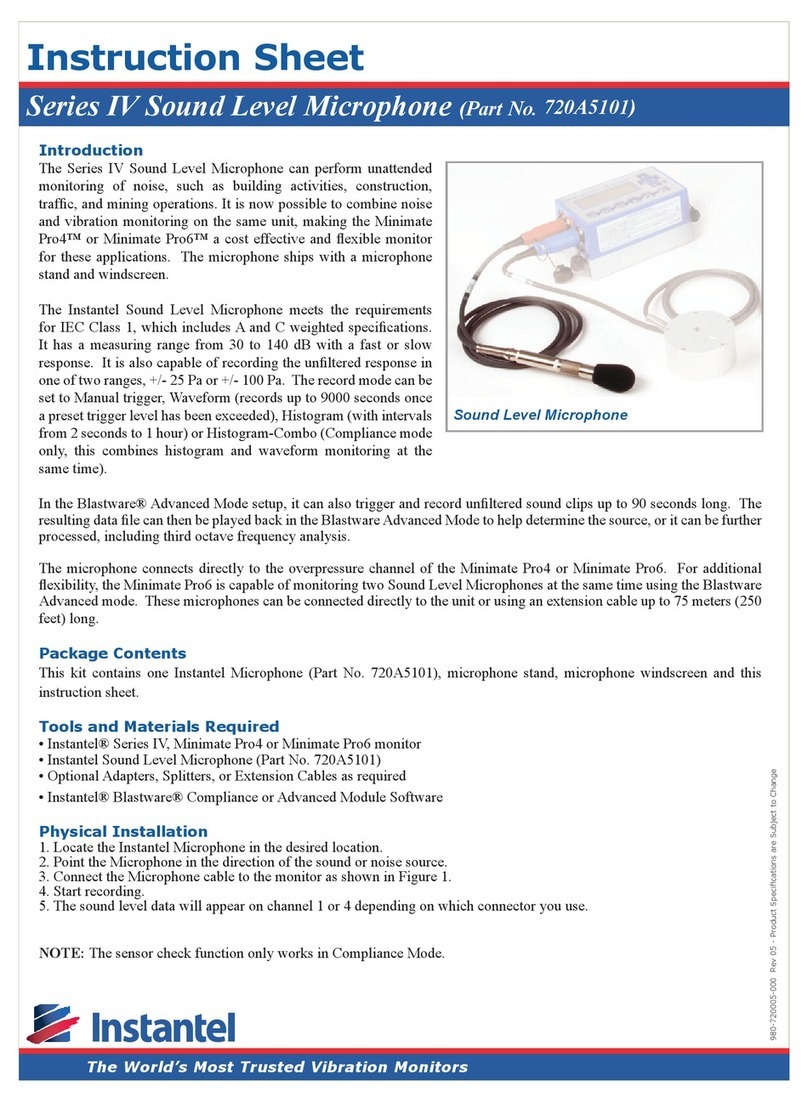

The Sound Level Microphone for the Micromate monitoring

unit, automates noise monitoring from building activities,

construction, trac, and mining operations. The Micromate

monitoring unit combines noise and vibration monitoring in

the same unit, making it a cost effective and exible device for

these applications.

The Sound Level Microphone meets the requirements for IEC

61672 Class 1, including A and C weighted specications and

has a measuring range from 30 dB to 140 dB with a Fast or Slow

response.

There are four record modes to choose from:

• Manual trigger

• Waveform (records up to 90 seconds, once triggered)

• Histogram (2 seconds to 30 minute intervals)

• Histogram-Combo (records both Histogram and Waveform

simultaneously)

Sound Level Microphone

Tools and Materials Required

Choose one of:

• Micromate ISEE Base Unit. . . . . . . . . . . . .(P/N: 721A2501)

• Micromate DIN Base Unit . . . . . . . . . . . .(P/N: 721A2601)

• Micromate Swedish Blasting Base Unit . . .(P/N: 721A3601)

• Micromate Swedish Pile Driving Base Unit. .(P/N: 721A3801)

• Sound Level Microphone . . . . . . . . . . . . .(P/N: 721A2301)

(stand and windscreen included)

• Extension cables, as required

10 m (33 ft). . . . . . . . . . . . . . . . . . . . (P/N: 721A0803)

30 m (100 ft) . . . . . . . . . . . . . . . . . . .(P/N: 721A0801)

75 m (250 ft) . . . . . . . . . . . . . . . . . . .(P/N: 721A0802)

Custom Extension Cable Kit . . . . . . (P/N: 721A3201)

• THOR software . . . . . . . . . . . . . . . . . . (free version)

• THOR Advanced software . . . . . . . . . . . . . (P/N: 72300201)

• A choice of three optional eld calibration devices:

- Delta OHM HD9101 Class 1

- Brüel & Kjaer Sound Calibrator Type 4231

- Rion NC-74 Sound Calibrator

Range of Applications

• Construction

• Mining

• Building Activities

• Trac

• Quarries

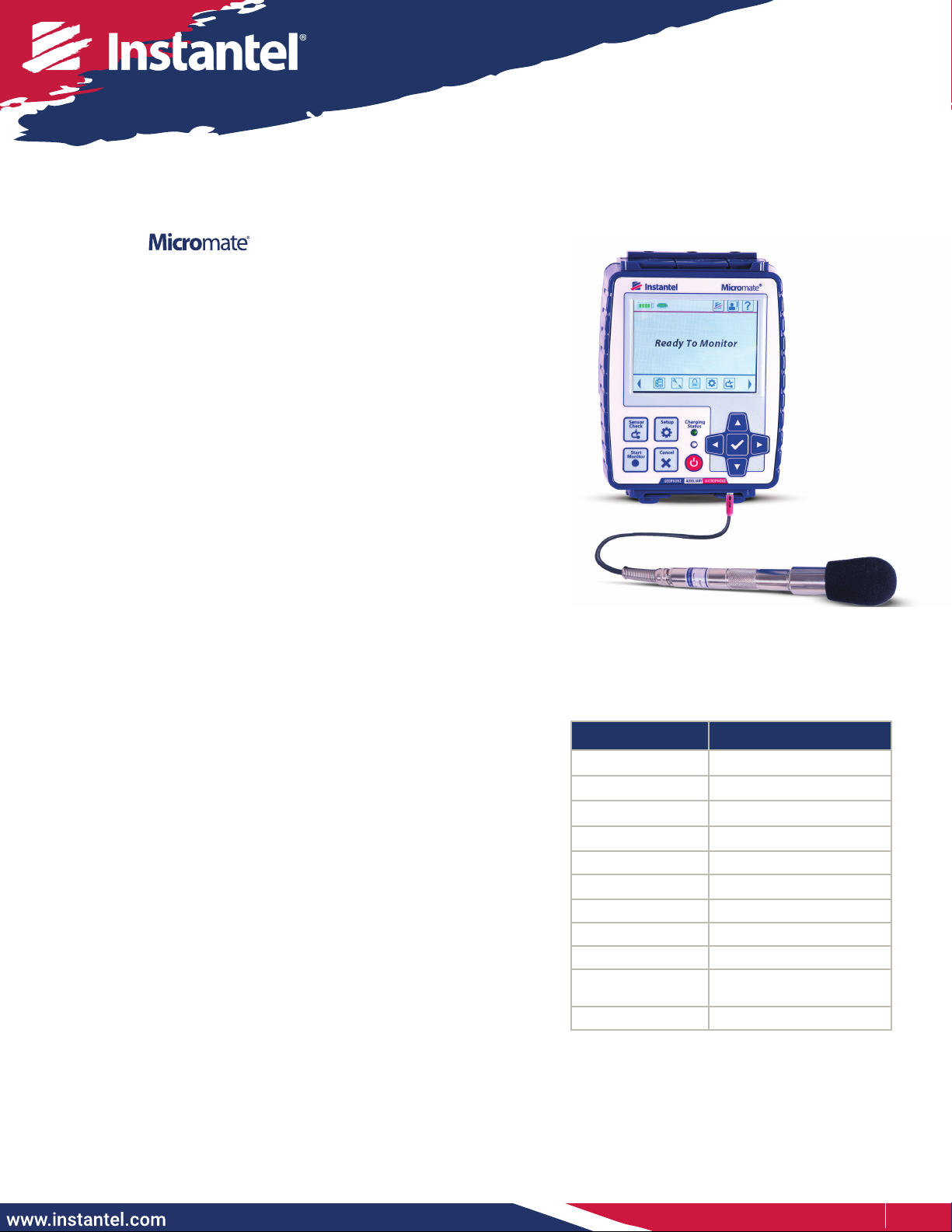

Specications

Field Values

Response Standard IEC 61672 Class 1

Frequency Weighting A-Weight or C-Weight

Response Fast (125 ms) or Slow (1 s)

Frequency Range 10 Hz - 20 kHz

Amplitude Range 30 dB to 140 dB max 160 dB

Trigger Levels 33 dB to 140 dB

Sample Rates 1,024 - 4,096 S/s

Resolution 0.05 dB (display limit 0.1dB)

Cable Length 2 m (6.5 ft)

Maximum Cable

Length 75 m (250 ft)

Temperature Range -10° to 50°C (14° to 122°F)

Note: Micromate units with serial numbers below 8000 require a factory update to support the Sound Level Microphone.

for the Monitoring Unit

2 / 5Instantel

Micromate Monitoring Unit Setup

1. On the Micromate monitoring unit keypad, press the Power button.

Note: To navigate the menus, use the arrow keys followed by the checkmark key or tap on the touchscreen display.

2. Press the Setup key then tap View/Edit Current Setup.

3. Tap Active Sensors until either Microphone or Geophone/Microphone is selected.

4. Tap Microphone Type until Sound Level is selected.

5. Select the desired Record Mode (Waveform Manual, Waveform, Histogram or Histogram-Combo).

6. Tap Trigger Level, then tap Microphone Trigger until Enabled is selected.

7. Tap Trigger Level, then swipe up or down on the spinner wheel or use the arrow keys.

8. Press the Checkmark key, this prompts you to save any changes. Use the Checkmark key to save the changes

or the Cancel key to cancel the changes and return to the previous screen.

9. Tap Response Time to toggle between Fast=125 ms (milliseconds) or Slow=1 s (second).

10. Tap Frequency Weighting to toggle between either A (A-Weight) or C (C-Weight).

11. Tap LN1 then swipe up or down until the desired value is reached.

12. Tap LN2 then swipe up or down until the desired value is reached. (Note: LN2 must be greater than LN1)

13. Tap either the Save icon on the touchscreen display or press the Cancel key for a prompt to save the

changes to a Setup File.

14. Select the Checkmark and then Save to Current File/Overwrite File.

15. Perform steps 13 and 14 a second time for the higher level settings.

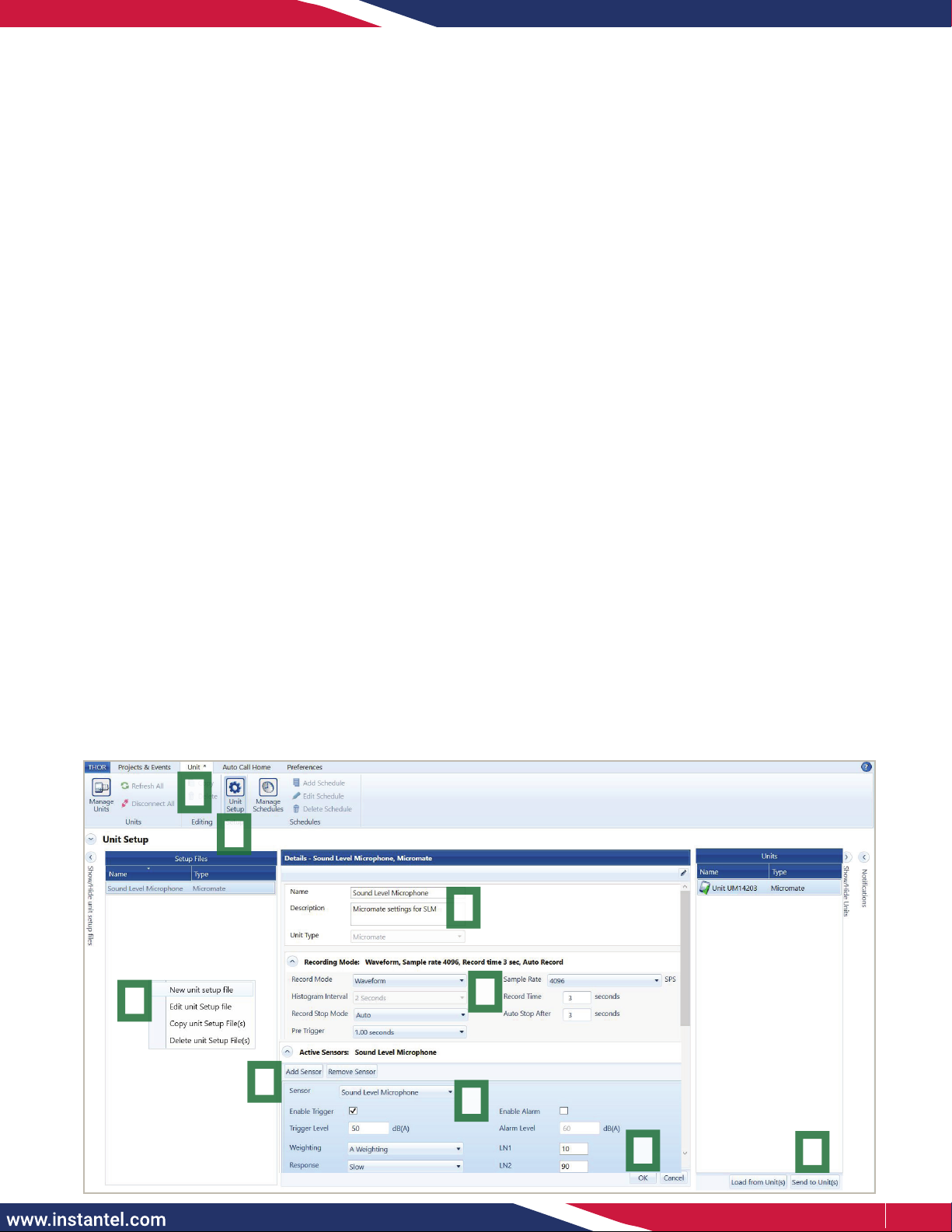

THOR Software Setup

The Sound Level Microphone for the Micromate monitoring unit can be congured using THOR software and then sent

to the connected unit.

1. Within the THOR software, click on the Unit Tab.

2. Click on the Unit Setup icon.

3. In the Unit Setup section, right-click and select New Unit Setup File.

4. Fill in the details and select Unit Type: Micromate.

5. Select the desired Record Mode and ll in the recording details.

6. Under Active Sensors, click on Add Sensor.

7. Under Sensor select Sound Level Microphone.

8. Fill in any Trigger details for Trigger level, Weighting, Response, LN1 and LN2 and click OK. In this section

you can also congure the external alarm.

9. Select the Micromate unit and click Send to Unit(s) to send the conguration le to the Micromate unit.

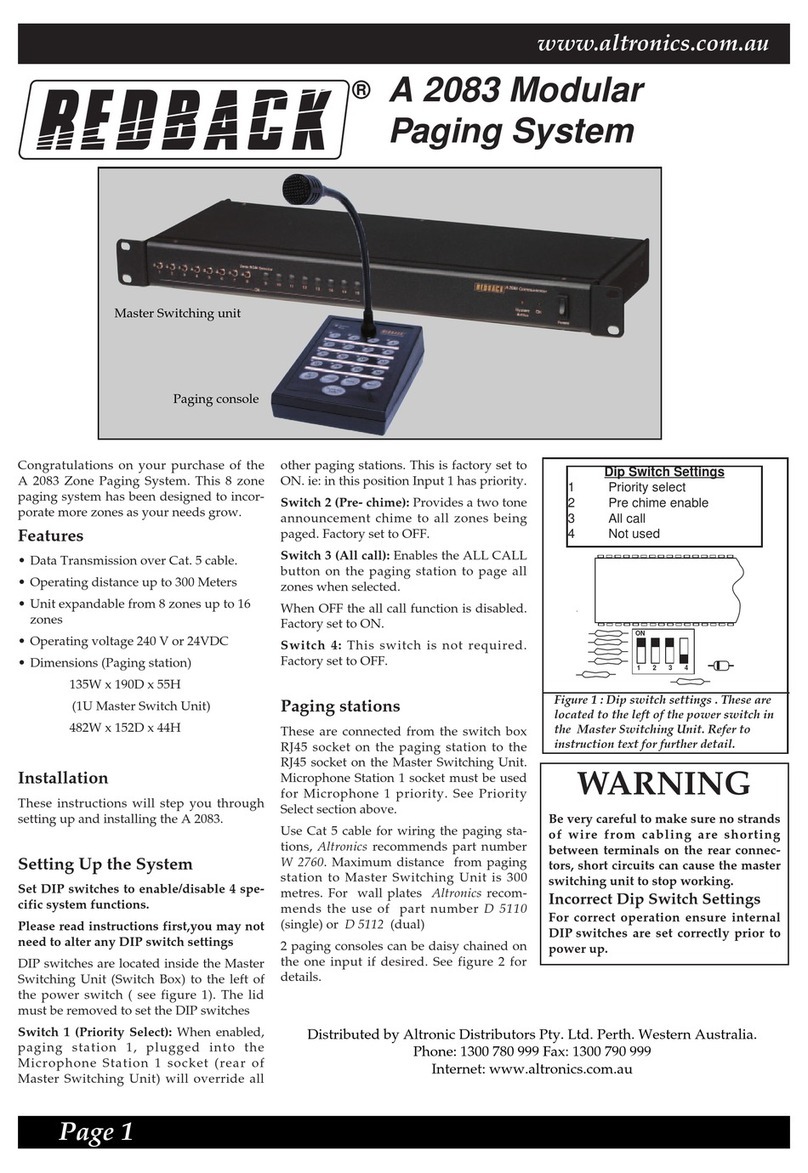

1

2

3

4

5

89

7

6

3 / 5Instantel

Field Calibration

The Micromate monitoring unit provides an option to calibrate the Sound Level

Microphone in the eld. A eld calibration only uses one reference signal of 94 dB

at 1 kHz. (The Brüel & Kjaer Sound Calibrator Type 4231 is also capable of generating

a 114 dB signal, make sure you set the device to 94 dB at 1 kHz.) A successful eld

calibration will store the values for Sound Pressure, Gain and Offset on the hardware

of the microphone, if there is an error during calibration, no values are overwritten.

In this case you can either try again or have the Sound Level Microphone calibrated

at Instantel or one of its authorized calibration facilities. Reports generated by

the Micromate monitoring unit will specify the serial number, calibration date and

calibration method.

Example:

Factory Calibration: UA12345, January 1, 2022 by Instantel

Field Calibration: UA12345, January 1, 2022 by Field Calibration

Note: Swapping Sound Level Microphones from one Micromate unit to another Micromate unit is permitted. As

calibration values are stored on the Sound Level Microphone, this will not impact any Micromate unit settings.

Field Calibration Procedure

1. Turn on the Micromate unit and connect the Sound Level Microphone, then press the Setup key on the unit.

2. Tap Maintenance Menu then scroll down and tap Calibrate Sound Level Microphone.

3. Follow the eld calibration device’s operator instructions to properly join the microphone with the eld

calibration unit. Set the reference to 94 dB at 1 kHz then turn the calibrator on.

Note: When using either of the three 94 dB eld calibrators, it is recommend that the ambient noise be at least 30 dB

lower than this reference signal.

For additional information please see https://www.pcb.com/Contentstore/mktgcontent/WhitePapers/

WPL_36_Acoustic_methods_calibration_PCB.pdf

4. Tap the Calibrate button on the Micromate monitoring unit screen.

5. Tap the Checkmark key to conrm the Proceed with calibration popup box. This will display Running Calibration.

6. When the calibration is nished, the Micromate unit will display Field Calibration Complete along with the

values for the measured Sound Pressure, Gain, and Offset.

7. In the Field Calibration Complete conrmation box, tap the Checkmark key.

Important Notes:

•

Only use an Instantel recommended calibration device (see the Tools and Materials Required section).

• Remove the microphone’s windscreen

before

attaching it to the field calibration device, as this can

impede proper calibration.

• Slide the Sound Level Microphone into and out of the eld calibration device

without

twisting either end.

• Before reinstalling the Sound Level Microphone in the eld,

hand-tighten

the microphone’s housing

extension and cap.

Calibration

The Sound Level Microphone

must be sent

to a manufacturer certied calibration facility, or Instantel headquarters

for calibration. Please visit our calibration facility locator at www.instantel.com. Instantel recommends calibrating all

Sound Level Microphones once a year and provides the Next Calibration dates on the unit and sensors. The factory

calibration process ensures that the microphone is performing as it was designed and accurately measuring

according to the IEC 61672 Class 1 standard.

Using a manufacturer certied facility ensures the proper procedures are followed when calibrating your

microphone. This removes any uncertainty associated with the reliability and measurement accuracy of your

microphone. It also helps ensure the integrity of the measured recorded events if they are ever called upon as

evidence in a court of law. Using unauthorized facilities may have negative legal consequences if the reference

equipment is not traceable, the proper procedures are not followed or if the certication documents are incomplete.

Please visit our calibration facility locator at instantel.com.

Note:

Field calibration is not

as precise as factory

calibration.

The Field Calibration

Procedure will change

the date and overwrite

the factory calibration

values.

The tracability will then

be linked to the Field

Calibration device.

4 / 5Instantel

Installing the Sound Level Microphone Stand

(See also Section 14.4. of the Micromate Monitoring Unit Operator Manual)

The microphone installation procedures are based on ISEE eld practice guidelines for blasting seismographs.

This section illustrates the installation procedures recommended by Instantel. Your particular monitoring activities

may employ one, or a combination of all, of the following procedures.

The Sound Level Microphone is supplied with a 3-piece microphone stand. The top section has a clip to hold the

microphone, the extension section is threaded at both ends and the bottom section is pointed to assist in the

installation. When the three pieces are assembled, the microphone stand is approximately 0.8 m (33 in) tall. Additional

extension sections can be purchased if required. (Microphone Stand Extension Rod, P/N: 400-720020-000)

Stand Installation Steps:

1. Assemble the microphone stand at the desired location (see Figure 1). Section 1 has a pointed tip to drive the

stand into the ground. Section 2 has a male and female thread. Screw in the female threaded end of section 2

into the male threaded end of section 1. Section 3 contains the microphone clip. Screw in the female threaded

end of section 3 into the male threaded end of section 2.

2. Push the pointed end of the microphone stand into the ground. If the ground is too hard, use a rubber mallet

to install the microphone stand.

Note: Do not use a metal hammer or other hard object as it may damage the top of the microphone stand.

3. Attach the windscreen to reduce false triggering caused by wind.

4. Install the Sound Level Microphone in the clip at the top of the microphone stand and point the microphone

in the direction of the noise source.

5. Ensure that the microphone cable is securely attached to the Micromate unit.

6.

Press the Sensor Check key on the Micromate unit ensuring the microphone is properly attached and has

passed

the Sensor Check. If the Sensor Check fails, ensure the ambient noise is at a minimum and repeat the test.

Figure 2.

Soft Ground Installation

Figure 3.

Hard Ground Installation

Figure 4.

Installing the Microphone

Figure 1.

3-Piece

Microphone Stand

Section

1

Section

2

Section

3

Setting Up the Sound Level Microphone

1. If required, assemble the stand (see Installing the Sound Level Microphone Stand below).

2. Point the microphone in the direction of the sound or noise source.

3. Place the windscreen on the end of the microphone.

4. Connect the microphone to the Micromate unit by aligning the red end of the connector with the indicated

red microphone port.

5. Make sure the Micromate unit has the proper Setup File (see THOR Software Setup on page 2), then

perform a Sensor Check by pressing the Sensor Check key on the keypad.

5 / 5Instantel

721U2301 Rev 05

© 2022 Xmark Corporation. All Rights Reserved. Design, features, and specications are subject to change without notice.

INSTANTEL, INSTANTEL LOGO, and MICROMATE are trademarks of Xmark Corporation, or an aliate thereof.

Warranty

Instantel products come with a limited one-year warranty against defects in materials or workmanship unless otherwise

stated. The warranty begins on the date of shipment from the Instantel factory to the customer and is subject to certain

exclusions and conditions as stated below. Monitoring units and sensors will have the warranty extended for a second year

if they are returned to the Instantel factory for service and calibration within 30 days of the ‘Next Calibration’ date printed on

the calibration label located on the product.

If, within a period of one year from the date of shipment to a customer, the instrument fails to perform in accordance

with Instantel’s published specications under normal use and operating conditions, it will be repaired or replaced at the

sole discretion of Instantel free of charge. Components subject to fair wear and tear in regular use, as solely determined

by Instantel, are excluded from this coverage. This warranty will not apply if the damage or malfunction occurs due to (i)

adjustments, additions, alternations, abuse, misuse or tampering of the instrument; (ii) instrument operation or use contrary

to the operating instructions; (iii) power uctuations; or (iv) any other cause not within the cause or control of Instantel. If

inspection by Instantel fails to disclose any defect covered by this limited equipment warranty, the instrument will be repaired

or replaced at customer’s expense and Instantel’s regular service charges will apply. This warranty is non-transferable.

Any shipments returned directly to Instantel must have prior approval, and all packages must display the Return of Material

Authorization (RMA) number issued by Instantel. Shipping charges to Instantel’s factory will be paid by the customer and

return shipment to the customer will be paid by Instantel.

To protect your warranty, you must complete and return a Warranty Registration Certicate, or complete the online Warranty

Registration Form, within ten days of purchase. Products will be assumed out of warranty if no warranty card is on le at

Instantel. Retain this warranty statement and the proof of purchase for your records.

Except for the foregoing limited equipment warranty, Instantel makes no other warranties and hereby disclaims and excludes

all other warranties, whether statutory, express or implied, whether arising under law or equity or custom or usage, including

any implied warranty of merchantability, tness for a particular purpose, non-infringement, satisfactory quality, or quiet

enjoyment, and any warranty that the product supplied may not be compromised, or that the product will in all cases provide

the function for which it is intended.

EC Warning

This is a Class B product. In a domestic environment this product may cause radio interference in which case the user may

be required to take adequate measures.

This manual suits for next models

1

Table of contents

Other Instantel Microphone manuals

Popular Microphone manuals by other brands

Devine

Devine BM-1000 user guide

Sony

Sony ECM 330 operating instructions

Mobility Sound

Mobility Sound C600-M12 quick start guide

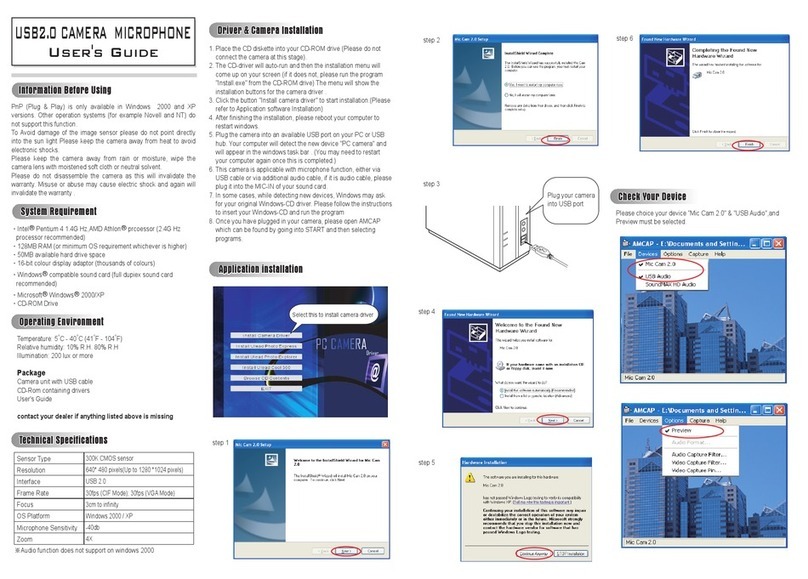

ABL electronic

ABL electronic USB 2.0 Camera Microphone none user guide

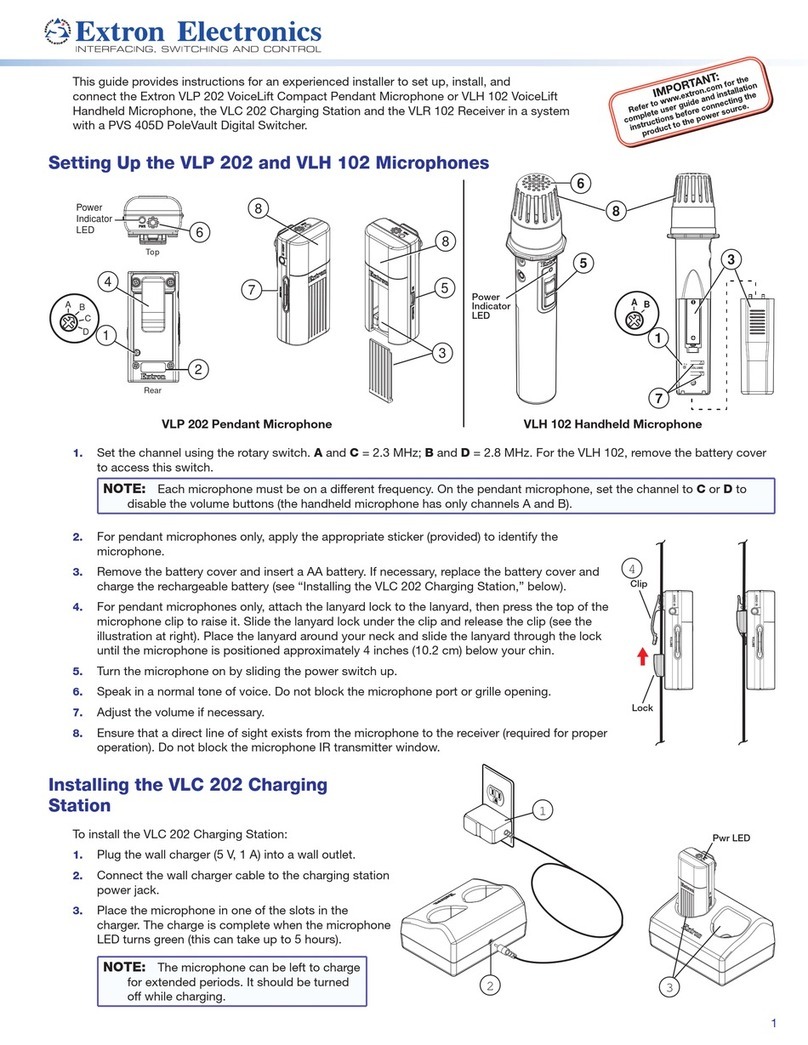

Extron electronics

Extron electronics VoiceLift VLP 202 Setting up

Opvimus

Opvimus DC-700ETH operating instructions