Instron 3119-600 Series User manual

3119-600 Series Temperature Controlled Chambers

Operating Instructions M55-16547-EN Revision E

The difference is measurable

®

Electromagnetic Compatibility

Where applicable, this equipment is designed to comply with International Electromagnetic

Compatibility (EMC) standards. To ensure reproduction of this EMC performance, connect this

equipment to a low impedance ground connection. Typical suitable connections are a ground

spike or the steel frame of a building.

Proprietary Rights Notice

This document and the information that it contains are the property of Illinois Tool Works Inc.

(ITW). Rights to duplicate or otherwise copy this document and rights to disclose the document

and the information that it contains to others and the right to use the information contained

therein may be acquired only by written permission signed by a duly authorized officer of ITW.

Trademarks

Instron®is a registered trademark of Illinois Tool Works Inc. (ITW). Other names, logos, icons

and marks identifying Instron products and services referenced herein are trademarks of ITW

and may not be used without the prior written permission of ITW.

Other product and company names listed are trademarks or trade names of their respective

companies.

Original Instructions

Copyright © 2017 Illinois Tool Works Inc. All rights reserved.

All of the specifications shown in this document are subject to change without notice.

Worldwide Headquarters

Instron

825 University Avenue

Norwood,

MA 02062-2643

United States of America

European Headquarters

Instron

Coronation Road

High Wycombe,

Bucks HP12 3SY

United Kingdom

3

Preliminary Pages

Product Support: www.instron.com

Table of Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About 3119-600 Series Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Chamber Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Hazard Warning Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Product Identification Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Panel and Rear Input Panel Labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Warning Signs Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Thermal Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Specimens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cryogenic Gases: Asphyxiation and Toxicity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Glass Fibre Insulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

High Pressure Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rotating Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Physical Testing Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Material Safety Data Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Function of Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chamber Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Door Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Control Panel Buttons and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rear Input Panel Connections and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Removable Wedges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removing the Wedges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacing the Wedges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Preliminary Pages

4M55-16547-EN

Chapter 4 Operating the Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Opening and Closing the Chamber Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Switching On the Chamber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Enabling Low Speed Fan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Checking Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Switching the Chamber Light On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Heating or Cooling to a Temperature Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

About the Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Stopping Heating or Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Returning the Chamber to Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Shutting Down the Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Changing the Eurotherm 3208 Controller Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Changing the Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Auxiliary Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Resetting a Tripped Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing the Temperature Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing the Ramp Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Using the Timer/Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

About the Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Running, Holding or Stopping a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting the Chamber to a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix A Additional Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Changing User Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3208 Controller Access Level Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Changing from Level 1 to Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5

Preliminary Pages

Product Support: www.instron.com

Setting Level 2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Run Recipe (Factory Reset and DC Output Calibration) . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Resetting the Chamber to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Calibrating an External Device using the Controller’s DC Output . . . . . . . . . . . . . . . . 55

DC Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Appendix B Hints and Tips for Using Chambers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Minimising Energy and Coolant Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Looking after your Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Ease of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Optimising Your Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Preliminary Pages

6M55-16547-EN

7

Product Support: www.instron.com

Chapter 1

Introduction

This chapter introduces the chamber and contains the following sections:

•About 3119-600 Series Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

•About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

•Additional Chamber Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

•Product Labelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

About 3119-600 Series Chambers

The Instron 3119-600 Series environmental chamber provides a means of carrying out

materials tests in an accurately controlled air temperature environment.

The chamber (see Figure 1) is designed to fit between the columns of a physical testing

machine. Pullrod access is provided on the top and bottom surfaces of the chamber and

an integrated control panel provides the user interface for all of the chamber functions.

The chamber is supplied with removable wedges to allow easy removal of the chamber

from the test area without dismantling the load string.

Different height chambers are available; these are selected to suit the required

application. All chambers operate from ambient temperature to the top of their

temperature range. An optional cooling module can be supplied if testing at below

ambient temperatures is required.

The chamber window is heated to keep it frost free at below ambient temperatures. The

limit of this feature is -30°C. Below this limit window clarity may degrade, however,

depending on ambient temperature, humidity and other influencing factors, the central

third of the window is expected to remain frost free.

The chamber can be mounted onto the load frame in a fixed position or on a roller

mounting assembly, which enables the chamber to be moved clear of the working area.

Refer to the Pre-Installation manual for mounting options.

Chapter: Introduction

8M55-16547-EN

Caution

Eyebolts are included with the chamber to enable initial positioning and installation

of the chamber only.

After installation, certification and maintenance of the eyebolts as lifting equipment

become the customer's responsibility. Refer to relevant local legislation.

Figure 1. 3119-600 Chamber Components

Heated

Window

Door

Handle

Upper

Removable

Wedge

Power

Indicator

High

Temperature

Warning

Label

Circulating

Fan

Internal Light

(Not Shown)

Lower

Removable

Wedge

Pullrod Port

Control

Panel

9

About this Manual

Product Support: www.instron.com

About this Manual

This manual contains the information necessary to operate the chamber by giving safety

information, describing the controls and providing detailed procedures for general

operation.

Further to general operating procedures, Appendix A provides details about additional

configuration procedures. Hints and tips on how to get the best from your chamber are

provided in Appendix B.

Caution

Other than the procedures prescribed in this manual, do not adjust the configuration

parameters of the controller. Configuration parameter errors can seriously impair the

performance of the controller or cause damage to the chamber.

The procedures detailed in this manual have been validated by Instron. You are advised

to use only these specific procedures and in the manner documented. You are advised

not to change any parameters of the controller other than those detailed in this manual.

Key combinations and/or sequences not documented in this manual may result in

configuration parameters being modified. Instron does not accept liability for

configuration changes other than those documented in this manual.

Additional Chamber Documentation

Product specifications and detailed information on installing the chamber are provided

in the Pre-Installation manual.

Refer to other documentation supplied with your testing system for load frame, pullrod,

grips and software operating instructions.

Chapter: Introduction

10 M55-16547-EN

Product Labelling

System Hazard Warning Labels

Various system safety labels are used to identify and draw your attention to potential

hazard areas on your system. See “Safety” on page 11 for illustrations of all hazard

labels and their meaning.

The following labels are visible on all 3119-600 series chambers:

Product Identification Label

The product identification is stamped onto a serial number plate that is attached to the

rear of chamber, above the rear input panel.

Control Panel and Rear Input Panel Labelling

See page 20 for control panel labelling and page 22 for rear input panel labelling.

Label Location Purpose

Door front

above window

High temperature hazard warning label - warns user about

high temperature in vicinity. See page 14 for more details.

Note that the window is heated when cooling is enabled, so

the window can be hot at any time.

Rear of

chamber

Electrical hazard warning label - warns user about dangerous

voltages. See page 13 for more details.

11

Product Support: www.instron.com

Chapter 2

Safety

This chapter gives information on product safety labelling and operational hazards. It

contains the following sections:

•General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

•Warning Signs Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

•Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

•Thermal Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

•Specimens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

•Cryogenic Gases: Asphyxiation and Toxicity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

•Glass Fibre Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

•High Pressure Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

•Rotating Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

•Physical Testing Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

•Material Safety Data Sheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General Safety Precautions

Warning

Hazard - Chambers have inherent critical risks, you are strongly advised to carry out

your own safety risk assessment taking into account all the information provided in

this chapter.

Chambers involve inherent hazards from high temperature and sub-zero temperature

surfaces and components. It is important to be aware of all parts which are potentially

hazardous, particularly the insides of chambers and items which are removed from

them.

Wherever it is considered that safety is compromised, press the fan button OFF on the

touch panel controller or press the mains circuit breaker OFF (O) on the rear panel.

Chapter: Safety

12 M55-16547-EN

Carefully read the operating instructions and observe all Warnings and Cautions. The

term Warning is used where a hazard may lead to injury or death. The term Caution is

used where a hazard may lead to damage to the equipment or to loss of data.

Ensure that the system set-up and the test being performed constitute no hazard to

operators or others (see general guidelines on page 27).

The following pages detail various general warnings that must be heeded at all times.

There are more specific Warnings and Cautions in the text whenever a potential hazard

exists.

The best safety precautions are a thorough understanding of the equipment by reading

the instruction manuals and always using good judgement.

It is our strong recommendation that you carry out your own product safety risk

assessment and use this to determine suitable personal protective equipment.

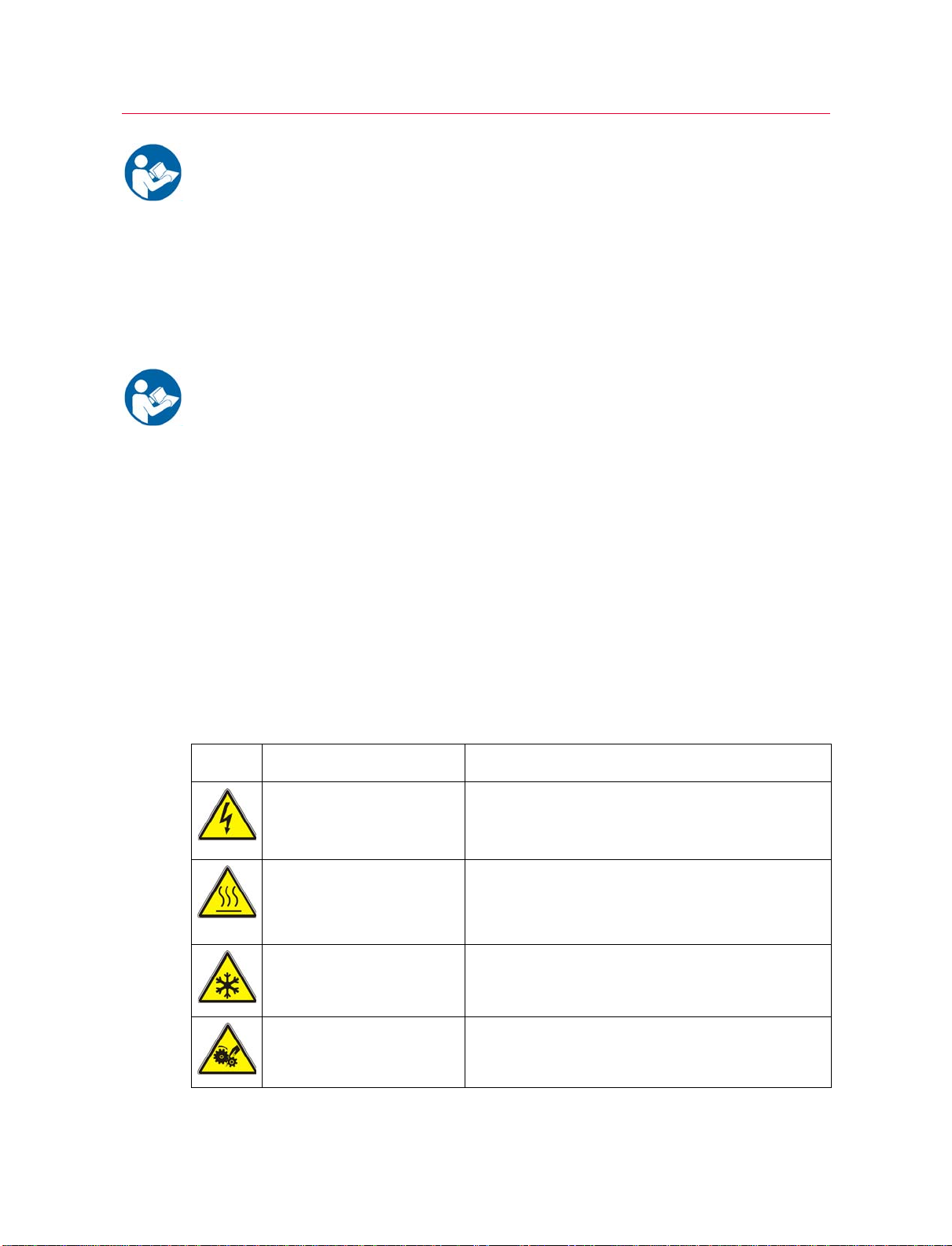

Warning Signs Used

When a symbol is enclosed in a triangle, it becomes a warning sign. A symbol on its own

may be a warning, e.g. the “dangerous voltage” symbol, or may indicate the use of a

control e.g. “Transfer of heat, general” symbol means that the control switches heating

on and off. Chamber controls are shown in the “Function of Controls and Indicators”

chapter.

Table 1. Warning Signs

Sign Meaning Standard

Warning - dangerous voltage Symbol derived from BS6217:1981

(417-IEC-5036-a)

“Dangerous voltage”

Warning – hot surface Symbol derived from ISO7000-0535

“Transfer of heat, general”

Warning sign derived from BS 6217:1981

(417-IEC-5041)

Warning – cold surface Symbol derived from

ISO 7000:1989

022 – graphical symbol for use on equipment cooling

Warning – keep fingers away

from rotating machinery

Symbol designed to ISO 3864 - international design

standard for safety symbols.

13

Electrical

Product Support: www.instron.com

Electrical

Warnings

Electrical Hazard – Ensure that the electrical socket used by the chamber power

cable is connected to a suitably grounded point. Disconnect the unit from the power

supply before removing any panel/cover or changing any fuse.

Repairs should only be carried out by an Instron Service Engineer, contact your local

Instron representative if you suspect an electrical fault. Disconnect equipment from the

electrical power supply before removing any electrical safety covers or replacing fuses.

Do not reconnect the power source while the covers are removed. Refit the covers as

soon as possible.

Electrical Disconnection Hazard – After disconnection from the power supply, leave

adequate time for any residual charge to dissipate before touching the conductors

of the power cable attached to the chamber.

When the chamber is disconnected from the mains power supply there may be a

residual charge due to capacitance which gives a risk of electrical shock if the mains

leads are touched. Until this charge has had sufficient time to dissipate, do not touch

the power lead conductors even when the unit is disconnected from the power supply.

Usually the charge dissipates in less than five minutes but the time is strongly

dependent on atmospheric conditions. If in doubt consult a qualified electrician before

disconnecting the unit mains supply.

Chapter: Safety

14 M55-16547-EN

Thermal Contact

Warning

Warning

Take particular care with items that are removed from chambers whilst still hot or cold.

Provide receptacles for such items as they can maintain their temperature for long

periods. When removing items from the chamber use the door as a shield from hot air or

cold cryogenic gases. Cold vapours can cause burns similar to heat burns and provoke

respiratory problems. Depending on the chamber mounting and any attached

accessories, the door may open or close under its own weight (when unlatched).

Specimens

Warning

Hazard - The operator MUST consult their supplier’s Material Safety Data Sheet on the

particular cryogenic gas being used before using this equipment at sub-ambient

temperatures. Instron advise that you receive training in the handling of cryogenic

gases from your supplier.

High/Low Temperature Hazard - Wear adequate personal protective equipment

when using equipment at extremes of temperature. This hazard applies to the

physical parts of the chamber, items in or removed from the chamber and the hot

air/cold cryogenic gases from inside the chamber.

Temperatures above 60°C and below 0°C can cause burns and serious injury. The

chamber has been designed to eliminate possible hazards, but it is inevitable that the

points where specimens or processed items leave the chamber can be at temperatures

outside these limits.

Hazard - Certain materials may become flammable, explosive or toxic when

exposed to extreme temperatures.

The 600 series environmental chambers are not intended for use with unstable

materials that may be flammable, explosive or toxic under extreme conditions. Any

hazard resulting from the failure of a test specimen, assembly, or structure is entirely

the responsibility of the owner and the user of the equipment.

15

Cryogenic Gases: Asphyxiation and Toxicity

Product Support: www.instron.com

Cryogenic Gases: Asphyxiation and Toxicity

Warning

Warning

When cryogenic gases are used with the chamber reduce all spaces around the pullrods

as much as possible, or seal them. Routing the exhaust hose to a well ventilated area

will reduce, but not eliminate, leakage of cryogenic gas around the chamber. Ensure

that the area around the system is suitably ventilated to avoid asphyxiation / toxicity

hazards.

Glass Fibre Insulation

Warning

Asphyxiation Hazard - Cryogenic gases can reduce the amount of oxygen in the

working environment to dangerous levels.

Refer to your supplier’s Material Safety Data Sheet for limits and monitoring information.

Toxicity Hazard - Carbon dioxide is toxic.

In certain concentrations carbon dioxide can be dangerous. Refer to your supplier’s

Material Safety Data Sheet for limits and monitoring information.

Extraction systems may need to meet legislative requirements. Refer to pertinent

government publications for details.

Hazard - Do not disassemble the chamber. Glass fibre insulation can cause skin, eye

or upper respiratory tract irritation in some individuals. Refer to the “Material Safety

Data Sheets” on page 17.

Repairs should only be carried out by an Instron Service Engineer. The glass fibre

insulation used in the chamber is retained within its panels and does not represent a

hazard in normal use. Contact your local Instron representative if any glass fibre

insulation is exposed.

Chapter: Safety

16 M55-16547-EN

High Pressure Gases

Warning

Rotating Parts

Warning

Physical Testing Machine

Warning

High Pressure Gas Hazard - Shutting off a gas cylinder may leave high pressure gas

in pipe work. Always de-pressurise pipe work before disconnection.

Instron advise that you receive training in the handling of high pressure gases from your

gas supplier. Never disconnect high pressure pipe work until you are sure that it is safe

to do so.

Rotating Machinery Hazard - Disconnect power supply before removing the covers.

Repairs should only be carried out by an Instron Service Engineer; contact your local

Instron representative if you suspect a fault with the chamber. There are exposed

rotating parts of the fan in the rear electrical compartment of the chamber. In normal

operation access to the rear compartment is not required. Do not access the rear

electrical compartment without first disconnecting the chamber from the power supply.

Do not reconnect any power supply while the covers are removed.

Moving Parts Hazard - The moving parts of physical testing machines on which

chambers are fitted can give rise to severe moving part hazards.

When using environmental chambers on testing machines the operator must be aware

of all of the moving part hazards and use the environmental chamber taking all

necessary precautions. Consult the safety section of the physical-testing machine

operating instructions.

17

Material Safety Data Sheets

Product Support: www.instron.com

Material Safety Data Sheets

This section contains information to allow you to obtain current Material Safety Data

Sheets (MSDS) directly from the manufacturers. Instron is not responsible for the

content or accuracy of these MSDSs.

Material Location Manufacturer MSDS information

Microtherm

Standard Panel

(Microtherm G).

Microtherm G block is

used in the chamber's

removable wedges on

the 3119-607, 3119-

608 and 3119-610

models only.

Microtherm G block is

contained between the

3119-608 chamber's

outer panels and inner

case.

Belgium

MICROTHERM N V

INDUSTRIEPARK-NOORD 1,

B-9100 SINT-NIKLAAS

Phone : + 32 (0)3 760 19 80

Fax : + 32 (0) 3 760 19 99

Panel MSDS No: msds_G_SG_UK

For the most up to date MSDS for the product

visit the web page

[www.microthermgroup.com].

Sindanyo H91 Sindanyo H91 is used

in the chamber’s

removable wedges on

the 3119-605, 3119-

606 and 3119-609

models only.

Tenmat Limited

Ashburton Road West

Trafford Park, Manchester

M17 1RU

United Kingdom

Phone: +44 (0)161 872 2181

Fax: +44 (0)161 872 7596

e-mail: [email protected]

For the most up to date MSDS Information for

the product visit the web page

[www.tenmat.com].

Chapter: Safety

18 M55-16547-EN

SUPERWOOL 607

Blanket

SUPERWOOL 607

Blanket is contained

between all chamber

outer panels and inner

case.

THERMAL CERAMICS LIMITED

Tebay Road, Bromborough

Wirral, Merseyside CH62 3PH

United Kingdom

Phone: +44 (0) 151 334 4030

Fax: +44 (0) 151 334 1684

THERMAL CERAMICS HSE Department

Route de Lauterbourg - BP 148

67163 WISSEMBOURG Cedex

France

Phone: +33 (0)3 88 54 95 50

Fax: +33 (0)3 88 54 29 20

Blanket MSDS No: 105

Paper MSDS No: 357

To confirm this is the most up to date MSDS

for the product, visit the web page

[www.thermalceramics.com]

SUPERWOOL

Paper 332-E

SUPERWOOL Paper

332-E is contained

within all the chamber

doors.

CO2/LN2Where option is fitted to

your chamber.

Contact your local supplier for information on

material safety.

Material Location Manufacturer MSDS information

19

Product Support: www.instron.com

Chapter 3

Function of Controls and Indicators

•Chamber Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

•Control Panel Buttons and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

•Rear Input Panel Connections and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

•Removable Wedges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chamber Door

Power Indicator

The white LED power indicator is located at the top right hand side of the door. It

illuminates when the circuit breaker is switched on (see “Rear Input Panel

Connections and Labels” on page 22).

Door Handle

The door handle has a two stage operation, i.e. latch and seal. See “Opening and

Closing the Chamber Door” on page 27 for details.

Chapter: Function of Controls and Indicators

20 M55-16547-EN

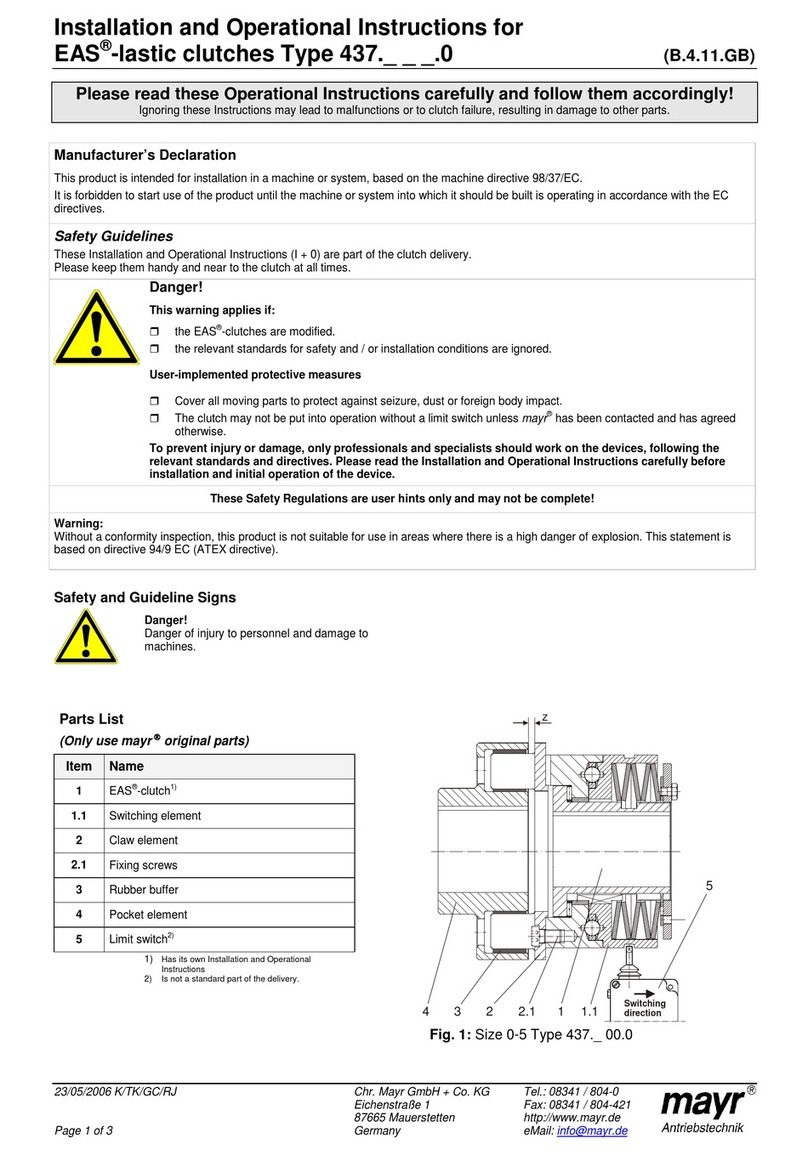

Control Panel Buttons and Indicators

The control panel buttons and indicators are described below.

Figure 2. Control Panel

Eurotherm 3208

Temperature

Controller

Page Button

Heating Button

(Indicator above)

Door Open

Indicator

Up Button

Cooling Button

(Indicator above)

Scroll Button

Down Button

Fan Button

(Indicator above)

Light Button

(Indicator above)

Alarm Tripped

Indicator

Upper Indicators

Upper Display

Lower Display

Lower Indicators

Other manuals for 3119-600 Series

1

Table of contents

Other Instron Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Skimz

Skimz FM 100 quick guide

KTR-Group

KTR-Group CLAMPEX KTR 125 Operating & assembly instructions

Mitsubishi Electric

Mitsubishi Electric M800VW Series Connection and set up manual

Petersen

Petersen PeteStop 129 Series instruction manual

Wieland

Wieland SNA 4043K operating instructions

EXPO

EXPO D760-ET MiniPurge manual