BÜCHI Labortechnik AG Table of contents

Operation Manual Inert Loop B-295 SE iii

Table of contents

1 About this document...........................................................................................................5

1.1 Warning notices in this document........................................................................................................ 5

1.2 Symbols............................................................................................................................................... 5

1.2.1 Warning symbols .....................................................................................................................5

1.2.2 Mark-ups and symbols.............................................................................................................5

1.3 Connected devices .............................................................................................................................. 6

1.4 Trademarks.......................................................................................................................................... 6

2 Safety....................................................................................................................................7

2.1 Proper use ........................................................................................................................................... 7

2.2 Use other than intended ...................................................................................................................... 7

2.3 Staff qualification ................................................................................................................................. 7

2.4 Residual risks ...................................................................................................................................... 8

2.4.1 Faults during operation ............................................................................................................8

2.5 Personal protective equipment ............................................................................................................ 8

2.6 Modifications........................................................................................................................................ 8

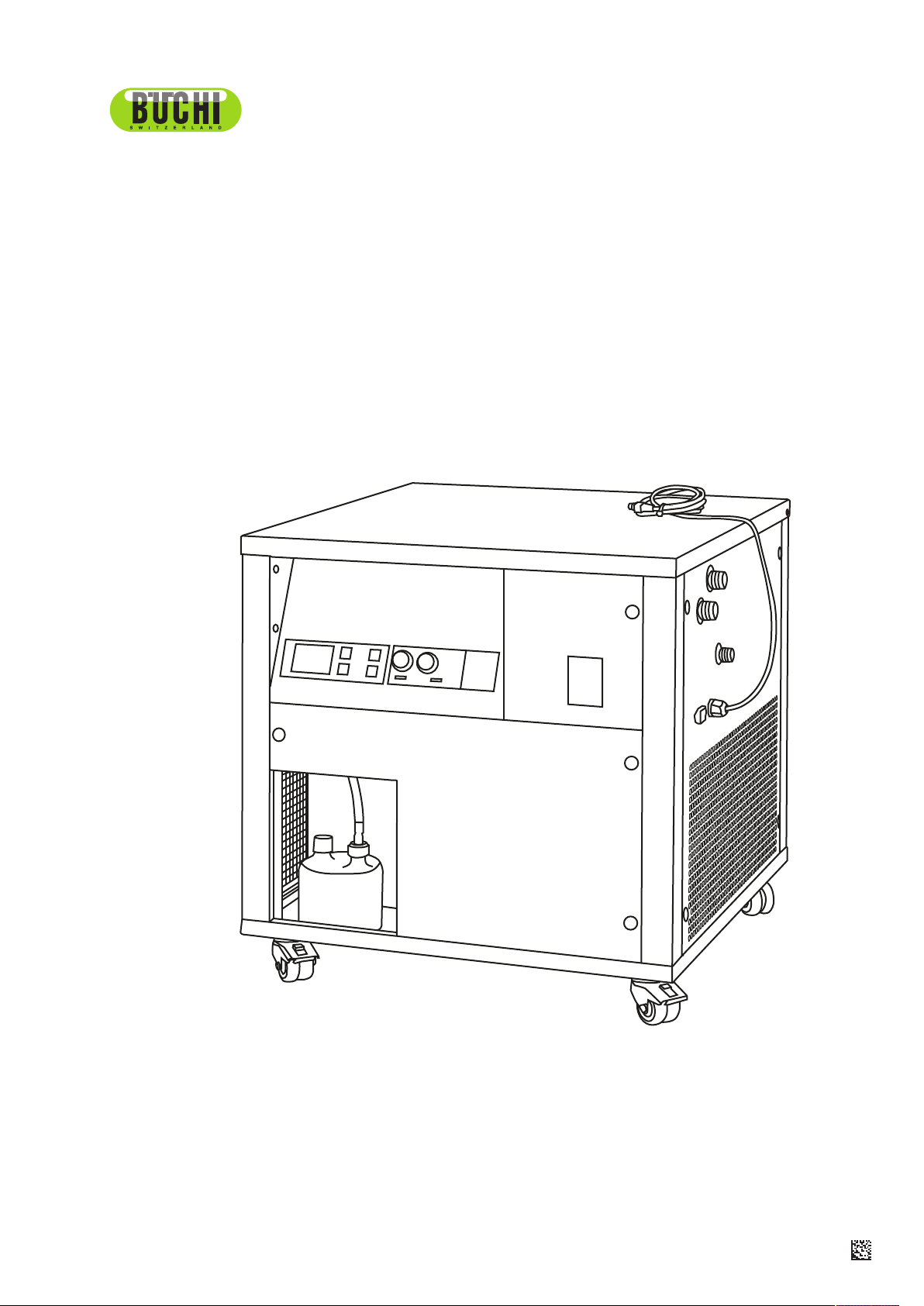

3 Product description...........................................................................................................10

3.1 Description of function ....................................................................................................................... 10

3.2 Configuration ..................................................................................................................................... 11

3.2.1 Front view ..............................................................................................................................11

3.2.2 Side connections....................................................................................................................12

3.2.3 Control elements....................................................................................................................12

3.2.4 Type plate ..............................................................................................................................12

3.3 Scope of delivery ............................................................................................................................... 13

3.4 Technical data ................................................................................................................................... 13

3.4.1 Inert Loop B-295 SE ..............................................................................................................13

3.4.2 Ambient conditions.................................................................................................................14

3.4.3 Materials ................................................................................................................................15

4 Transport and storage ......................................................................................................16

4.1 Transport ........................................................................................................................................... 16

4.2 Storage .............................................................................................................................................. 16

4.3 Lifting the instrument ......................................................................................................................... 16

5 Installation..........................................................................................................................18

5.1 Before installation .............................................................................................................................. 18

5.2 Installation site................................................................................................................................... 18

5.3 Establishing electrical connections.................................................................................................... 18

5.4 Installing the oxygen sensor .............................................................................................................. 19

5.5 Connecting the Inert Loop B-295 SE with a spray drying system...................................................... 20

5.6 Installing the exhaust gas hose ......................................................................................................... 21

5.7 Installing the solvent receiving vessel................................................................................................ 21

6 Operation............................................................................................................................23

6.1 Preparing the instrument ................................................................................................................... 23

6.2 Starting the instrument....................................................................................................................... 23

6.3 Tasks during spray drying.................................................................................................................. 23

6.4 Shutting down the instrument ............................................................................................................ 24

6.5 Switching off the instrument............................................................................................................... 24

6.6 Setting condenser temperature ......................................................................................................... 24