Instron 2630-100 Series User manual

2630-100 Series

Clip-On Extensometer

Reference Manual - Equipment

M20-52630-1 Revision H

The difference is measurable ®

Electromagnetic Compatibility

Where applicable, this equipment is designed to comply with

International Electromagnetic Compatibility (EMC) standards.

To ensure reproduction of this EMC performance, connect this

equipment to a low impedance ground connection. Typical

suitable connections are a ground spike or the steel frame of a

building.

Proprietary Rights Notice

This document and the information that it contains are the

property of Illinois Tool Works Inc. (ITW). Rights to duplicate or

otherwise copy this document and rights to disclose the

document and the information that it contains to others and the

right to use the information contained therein may be acquired

only by written permission signed by a duly authorized officer of

ITW.

Trademarks

Instron® is a registered trademark of Illinois Tool Works Inc.

(ITW). Other names, logos, icons and marks identifying Instron

products and services referenced herein are trademarks of ITW

and may not be used without the prior written permission of ITW.

Other product and company names used herein are trademarks

or trade names of their respective companies.

© Copyright 2016 Illinois Tool Works Inc.

All rights reserved.

All of the specifications shown in this document

are subject to change without notice.

Product Support: www.instron.com

Preliminary Pages

3

Product Support: www.instron.com

General Safety Precautions

Materials testing systems are potentially

hazardous.

Materials testing involves inherent hazards from

high forces, rapid motions, and stored energy.

You must be aware of all moving and operating

components in the testing system that are

potentially hazardous, particularly force actuators

or a moving crosshead.

Before operating the system, ensure you gain a

thorough understanding of the equipment by:

•receiving training on the safe operation

of the system.

•reading and understanding the general

hazards associated with materials testing

systems as detailed on pages 5to 11.

•carefully reading all relevant manuals

and observing all Warnings and Cautions.

The term Warning is used where a hazard

may lead to injury or death. The term

Caution is used where a hazard may lead

to damage to equipment or to loss of

data.

•carrying out your own safety risk

assessment on the use of the test

system, test methods employed,

specimen loading and specimen

behavior at failure.

Preliminary Pages

4 M20-52630-1-EN

General Safety Precautions

Instron products, to the best of its knowledge,

comply with various national and international

safety standards, in as much as they apply to

materials and structural testing. We certify that

our products comply with all relevant EU

directives (CE mark).

Because of the wide range of applications with

which our instruments are used, and over which

we have no control, additional protection devices

and operating procedures may be necessary due

to specific accident prevention regulations, safety

regulations, further EEA directives or locally valid

regulations. The extent of our delivery regarding

protective devices is defined in your initial sales

quotation. We are thus free of liability in this

respect.

At your request, we will gladly provide advice and

quotations for additional safety devices such as

protective shielding, warning signs or methods of

restricting access to the equipment.

Preliminary Pages

5

Product Support: www.instron.com

Warnings

Crush Hazard - Allow only one person to

handle or operate the system at all

times.

Operator injury may result if more than one

person operates the system. Before working

inside the hazard area between the grips or

fixtures, ensure that no other personnel can

operate the computer or any of the system

controls.

Crush Hazard - Take care when installing

or removing a specimen, assembly,

structure, or load string component.

Installation or removal of a specimen, assembly,

structure, or load string component involves

working inside the hazard area between the grips

or fixtures. Keep clear of the jaws of a grip or

fixture at all times. Keep clear of the hazard area

between the grips or fixtures during actuator or

crosshead movement.

Ensure that all actuator or crosshead movements

necessary for installation or removal are slow

and, where possible, at a low force setting.

Preliminary Pages

6 M20-52630-1-EN

Hazard - Press the Emergency Stop

button whenever you consider that an

unsafe condition exists.

The Emergency Stop button removes hydraulic

power or electrical drive from the testing system

and brings the hazardous elements of the system

to a stop as quickly as possible. It does not

isolate the system from electrical power, other

means are provided to disconnect the electrical

supply. Whenever you consider that safety may

be compromised, stop the test using the

Emergency Stop button. Investigate and resolve

the situation that caused the use of the

Emergency Stop button before you reset it.

Flying Debris Hazard - Wear eye

protection and use protective shields or

screens whenever any possibility exists

of a hazard from the failure of a

specimen, assembly or structure under

test.

Wear eye protection and use protective shields or

screens whenever a risk of injury to operators

and observers exists from the failure of a test

specimen, assembly or structure, particularly

where explosive disintegration may occur. Due to

the wide range of specimen materials,

assemblies or structures that may be tested, any

hazard resulting from the failure of a test

specimen, assembly or structure is entirely the

responsibility of the owner and the user of the

equipment.

Warnings

Preliminary Pages

7

Product Support: www.instron.com

Flying Debris Hazard - Make sure that

test specimens are installed correctly in

grips or fixtures in order to eliminate

stresses that can cause breakage of grip

jaws or fixture components.

Incorrect installation of test specimens creates

stresses in grip jaws or fixture components that

can result in breakage of these components. The

high energies involved can cause the broken

parts to be projected forcefully some distance

from the test area. Install specimens in the

center of the grip jaws in line with the load path.

Insert specimens into the jaws by at least the

amount recommended in your grip

documentation. This amount can vary between

66% to 100% insertion depth; refer to supplied

instructions for your specific grips. Use any

centering and alignment devices provided.

Hazard - Protect electrical cables from

damage and inadvertent disconnection.

The loss of controlling and feedback signals that

can result from a disconnected or damaged

cable causes an open loop condition that may

drive the actuator or crosshead rapidly to its

extremes of motion. Protect all electrical cables,

particularly transducer cables, from damage.

Never route cables across the floor without

protection, nor suspend cables overhead under

excessive strain. Use padding to avoid chafing

where cables are routed around corners or

through wall openings.

Warnings

Preliminary Pages

8 M20-52630-1-EN

Hazard - Set the appropriate limits

before performing loop tuning or running

waveforms or tests.

Operational limits are included within your testing

system to suspend motion or shut off the system

when upper and/or lower bounds of actuator or

crosshead travel, or force or strain, are reached

during testing. Correct setting of operational

limits by the operator, prior to testing, will reduce

the risk of damage to test article and system and

associated hazard to the operator.

High/Low Temperature Hazard - Wear

protective clothing when handling

equipment at extremes of temperature.

Materials testing is often carried out at non-

ambient temperatures using ovens, furnaces or

cryogenic chambers. Extreme temperature

means an operating temperature exceeding 60

°C (140 °F) or below 0 °C (32 °F). You must use

protective clothing, such as gloves, when

handling equipment at these temperatures.

Display a warning notice concerning low or high

temperature operation whenever temperature

control equipment is in use. You should note that

the hazard from extreme temperature can extend

beyond the immediate area of the test.

Warnings

Preliminary Pages

9

Product Support: www.instron.com

Electrical Hazard - Disconnect the

electrical power supply before

removing the covers to electrical

equipment.

Disconnect equipment from the electrical power

supply before removing any electrical safety

covers or replacing fuses. Do not reconnect the

power source while the covers are removed. Refit

covers as soon as possible.

Hazard - Do not place a testing system

off-line from computer control without

first ensuring that no actuator or

crosshead movement will occur upon

transfer to manual control.

The actuator or crosshead will immediately

respond to manual control settings when the

system is placed off-line from computer control.

Before transferring to manual control, make sure

that the control settings are such that

unexpected actuator or crosshead movement

cannot occur.

Warnings

Preliminary Pages

10 M20-52630-1-EN

Rotating Machinery Hazard - Disconnect

power supplies before removing the

covers to rotating machinery.

Disconnect equipment from all power supplies

before removing any cover which gives access to

rotating machinery. Do not reconnect any power

supply while the covers are removed unless you

are specifically instructed to do so in the manual.

If the equipment needs to be operated to perform

maintenance tasks with the covers removed,

ensure that all loose clothing, long hair, etc. is

tied back. Refit covers as soon as possible.

Hazard - Shut down the hydraulic power

supply and discharge hydraulic pressure

before disconnection of any hydraulic

fluid coupling.

Do not disconnect any hydraulic coupling without

first shutting down the hydraulic power supply

and discharging stored pressure to zero. Tie

down or otherwise secure all pressurized hoses

to prevent movement during system operation

and to prevent the hose from whipping about in

the event of a rupture.

Hazard - Shut off the supply of

compressed gas and discharge residual

gas pressure before you disconnect any

compressed gas coupling.

Do not release gas connections without first

disconnecting the gas supply and discharging

any residual pressure to zero.

Warnings

Preliminary Pages

11

Product Support: www.instron.com

Hazard - Ensure components of the load

string are correctly pre-loaded to

minimize the risk of fatigue failure.

Dynamic systems, especially where load

reversals through zero are occurring, are at risk

of fatigue cracks developing if components of the

load string are not correctly pre-loaded to one

another. Apply the specified torque to all load

string fasteners and the correct setting to wedge

washers or spiral washers. Visually inspect highly

stressed components such as grips and threaded

adapters prior to every fatigue test for signs of

wear or fatigue damage.

Warnings

Preliminary Pages

12 M20-52630-1-EN

Preliminary Pages

13

Product Support: www.instron.com

Table of Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . 15

About the Extensometers . . . . . . . . . . . . . . . . . 15

Extensometer Features. . . . . . . . . . . . . . . . . . . 16

Equipment Supplied . . . . . . . . . . . . . . . . . . . . . 18

Chapter 2 Preparation for Testing . . . . . . . 21

About Preparation . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring the Extensometer . . . . . . . . . . . . . 22

Fitting Wire Clips . . . . . . . . . . . . . . . . . . . . . 22

Knife Edge Changing . . . . . . . . . . . . . . . . . . 23

Specimen Centering Stops . . . . . . . . . . . . . 24

Attaching the Extensometer . . . . . . . . . . . . . . . 25

Gauge Length Setting . . . . . . . . . . . . . . . . . 25

About Mounting to Specimen . . . . . . . . . . . 28

Mounting to the Specimen using Both Hands 29

Mounting to the Specimen using One Hand . 30

Elastic Bands or O-Rings . . . . . . . . . . . . . . . 31

Variable Pressure Specimen Clamp. . . . . . 32

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Electrical Calibration . . . . . . . . . 34

Manual Electrical Calibration . . . . . . . . . . . 35

Manual Mechanical Calibration . . . . . . . . . 36

Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Preliminary Pages

14 M20-52630-1

Care of the Extensometer. . . . . . . . . . . . . . . . . 37

Routine Maintenance . . . . . . . . . . . . . . . . . 37

Storing your Extensometer . . . . . . . . . . . . . 37

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Extensometer Holder. . . . . . . . . . . . . . . . . . 38

Chapter 3 Testing . . . . . . . . . . . . . . . . . . . . 43

About Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Working in Strain Control . . . . . . . . . . . . . . . . . 44

Appendix A Specifications . . . . . . . . . . . . . . 47

Gauge Lengths and Travel . . . . . . . . . . . . . . . . 48

System Compatibility . . . . . . . . . . . . . . . . . . . . 50

General Specifications . . . . . . . . . . . . . . . . . . . 52

Environmental Conditions . . . . . . . . . . . . . . . . 53

Appendix B Options and Accessories . . . . . 57

Optional Accessories and Spares. . . . . . . . . . . 57

Variable Pressure Specimen Clamp. . . . . . . . . 58

Clips for Round Specimens . . . . . . . . . . . . . . . 60

Clips for Rectangular Specimens . . . . . . . . . . . 62

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

15Product Support: www.instron.com

Chapter 1

Introduction

•About the Extensometers . . . . . . 15

•Extensometer Features . . . . . . . . 16

•Equipment Supplied. . . . . . . . . . . 18

About the Extensometers

The 2630-100 series extensometers

convert the mechanical displacement of a

strained test specimen into an electrical

signal. When used with the current range

of Instron testing machines, each

extensometer is automatically recognised,

and can be calibrated at the touch of a

button.

The displacement is transmitted by a light

rigid frame to strain gauges bonded to a

flexural element. The gauges are arranged

in a fully active four-arm Wheatstone

Bridge circuit.

The 2630-100 series of extensometers

includes different gauge lengths/strain

range options to suit a wide range of

specimen characteristics.

Chapter: Introduction

16 M20-52630-1-EN

The robust construction of the

extensometer provides accuracy and

reliability.

When not in use, the extensometer should

be stored in the case supplied with it.

Extensometer Features

•Ergonomic, lightweight, cross-braced

design with overload protection.

•Easy attachment and release from the

specimen facilitate single-handed

operation.

•Simple, cone latch gauge-length setting

method with automatic

disengagement.

•Precise, fixed gauge-lengths with

automatic recognition and calibration

capability.

Extensometer Features

17

Product Support: www.instron.com

•Available in metric and U.S. Customary

versions to meet ISO 9513 and

ASTM E83 standards of accuracy.

•Low operating-force arms with single-

bevel, interchangeable knife edges.

•Suitable for a wide range of specimen

materials, geometry and size with a

choice of attachment methods.

•Combined cable cleat and

extensometer holder with provision for

retaining cord attachment to the

extensometer.

•High impact plastic storage case with a

contour moulded insert to securely

retain the extensometer and accessory

parts together with its Calibration

Certificate and manual.

Chapter: Introduction

18 M20-52630-1-EN

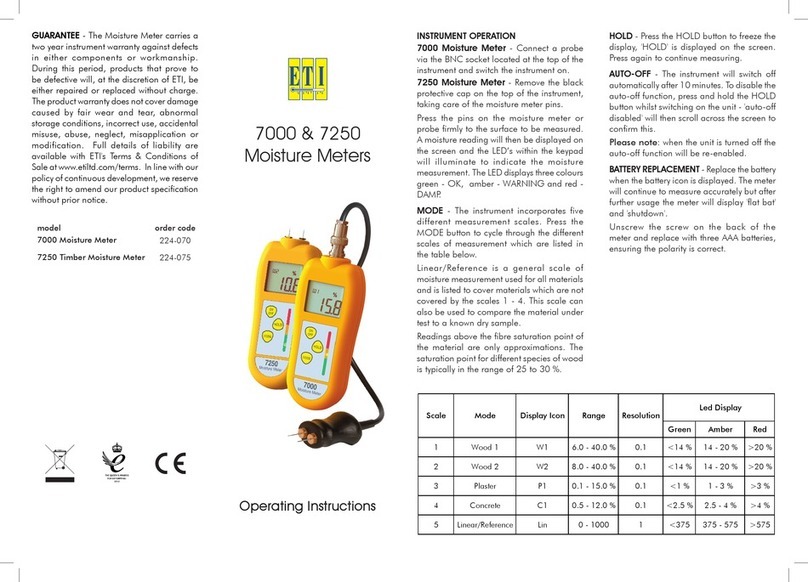

Equipment Supplied

See Figure 1.

1. Extensometer

2. Cable cleat and extensometer holder

3. 1.5 mm hexagon wrench

4. 11 pairs of wire clips

5. Specimen centering stops

6. This manual

7. Calibration certificate

8. Foam lined case

For optional accessories and spares,

see Appendix B.

Equipment Supplied

19

Product Support: www.instron.com

Figure 1. Case Layout

Case Manual

Extensometer Cable Cleat and

Extensometer Holder

Hexagon

Wrench

Clips for

Round

Specimens

Clips for

Rectangular

Specimens

Specimen

Stops

Chapter: Introduction

20 M20-52630-1-EN

Other manuals for 2630-100 Series

1

Table of contents

Other Instron Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

COMBA

COMBA CriticalPoint QE Series user manual

Horiba Scientific

Horiba Scientific LAQUAtwin-K-11 instruction manual

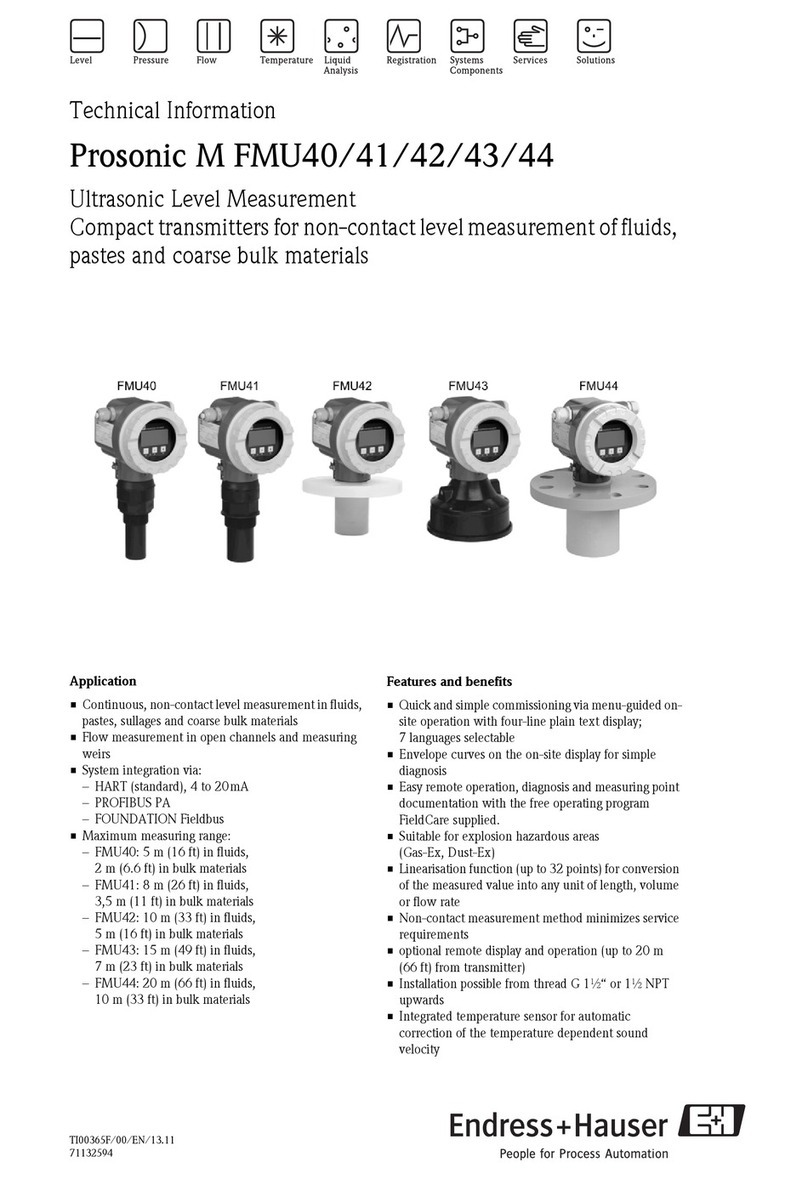

Endress+Hauser

Endress+Hauser Prosonic M FMU40 technical information

Siemens

Siemens multiranger 100 Quick start manual

Laser Atlanta

Laser Atlanta SpeedLaser user guide

Veeder-Root

Veeder-Root TLS RF Wireless 2 Installation and maintenance guide