Seikosha GP-550A User manual

WARNING:

“This

eguipment

has

been

certified

to

comply

with

the

limits

for

a

Class

B

computing

device,

pursuant

to

Subpart

J

of

Part

15

of

FCC

Rules.

Only

computers

certified

to

comply

with

the

Class

B

limits

may

be

attached

to

this

printer.

Operation

with

noncertified

computers

is

likely

to

result

in

interference

to

radio

and

TV

reception."

*This

equipment

generates

and

uses

radio

frequency

and

if

not

installed

and

used

properly,

that

is,

in

strict

accordance

with

the

manufacturer's

instructions,

may

cause

interference

to

radio

and

television

reception.

It

has

been

tested

and

found

to

comply

with

the

limits

for

a

Class

B

comput-

ing

device

in

accordance

with

the

specifications

in

Subpart

J

of

Part

15

of

FCC

Rules,

which

are

designed

to

provide

reasonable

protection

against

such

interference

in

a

residential

installation.

However,

there

is

no

guarantee

that

interference

will

not

occur

in

a

particular

installation.

If

this

equipment

does

cause

interference

to

radio

or

television

reception,

which

can

be

determined

by

turning

the

equipment

off

and

on,

the

user

is

encouraged

to

try

to

correct

the

interference

by

one

or

more

of

the

following

measures:

*

Reorient

the

receiving

antenna

*

Relocate

the

computer

with

respect

to

the

receiver

е

Move

the

computer

away

from

the

receiver

е

Plug

the

computer

into

a

different

outlet

so

that

computer

and

receiver

are

on

different

branch

circuits.

If

necessary,

the

user

should

consult

the

dealer

or

an

experienced

radio/

television

technician

for

additional

suggestions.

The

user

may

find

the

following

booklet

prepared

by

the

Federal

Communications

Commission

helpful:

*How

to

Identify

and

Resolve

Radio-TV

Interference

Problems."

This

booklet

is

available

from

the

U.S.

Government

Printing

Office,

Washington,

D.C.

20402,

Stock

No.

004-000-00345-4.

INTRODUCTION

Congratulations

on

your

purchase

of

the

SEIKOSHA

GP-550A

GRAPHIC

PRINTER.

This

Printer

is

a

high-density

dot-matrix

printer

with

a

unique

two-hammer

system

which

can

perform

a

variety

of

different

printing

operations.

Be

sure

to

read

this

Owner's

Man-

ual

carefully

in

order

to

use

the

Printer

to

its

fullest.

Main

Features

*

Various

character

fonts

—

Standard,

Condensed,

Correspondence,

Italic

Cursive,

Super-

script/

Subscript,

and

Proportional

characters.

Graphics

—

standard

and

high-resolution.

Underline

capability.

Minimum

linefeed

is

1/120

inch.

Tractor

feed

and

friction

feed

are

standard.

The

ink

ribbon

cassette

has

an

inker

that

can

be

replaced

as

the

ink

is

used

up.

Automatic

printing

takes

place

when

the

buffer

becomes

full.

Self

test

printing

is

standard

to

provide

self

diagnosis.

CONTENTS

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

GENERAL

SPECIFICATIONS

1

UE

e

a

gh

Ke

eee

yor

1

2,

Paper

feed

specihicati

eissaia

id

Ын,

аланнан

жанча

н

2

Spa

ОВ

ЗАО

CAEL

CONUS

епархии

дандар

кімді»

3

4.

ПИК

прроп

specificatiOliB......-..—.«««

oc

adayi

Беван

3

5.

Орөгайно

Sn

vironment

’scscasscascececcocncvearstesdsecsansstasansapssapssvansngncnnseseuaincae

3

DESCRIPTION

OF

THE

ОР-55ОА

................................................................

4

QR

07

0

gp

oom

rr

5

2.

ВИА

T

E

o

MR

lee

е

но

b

З/

ЕНБ

Switch.

ИЕН

a

e

5

BOR

EE

SWIÉOD.

реечные

N

a

R

5

5.

POWER

lamp

(red)

......

A

15

an

|

gg

С

PRANK

А

5

BADEN

a

kğ

laa

near

REEL

REESE

ER

6

ye

|

ЙТ...

EO

TTC

TREES

6

2:

900155656616

of

DODOF

oorr

rrt

eerog

orae

toos

nort

gil

seno

pasa)

Yoann

qur

8

RIBBON

INSTALLATION/REMOVAL

...............

eren

9

о

ЕО

IDEM

m

9

PB

co

Gn

Tene

İİ

ETIN

SES

10

HEAD'POSHION

ADJUSTMENT.

..............................ььдииидиалдддаивинкинидявани»»

11

INTERFAGING

..........................

12

1.

Connector

on

the

cable

side

12

2.

Connector

on

the

printer

sideanditspinoutchart..........................

12

3.

Explanation

of

the

input/output

signals.............................................

13

4.

Electrical

conditions

14

5.

Timing

chart

15

CONTROL

СОО

АМАН

5...2...

cane

MEM

basan

16

GONTROL

GODER

.

18

1.

Print

commands

18

2.

Elongation

18

3.

Print

position

specification

19

4.

Character

set

specification

.

за

5.

Character

repetition

..................

eerte

nennen

tenente

tnter

21

6.

Graphic

mode

22

7.

Graphic

repelition

ossis

dike

ом

23

8:

mese

si

басни;

„аннады

оаза

ох

24

9.

Page

length:

SpecifiGatiOH

5...

cccscececceccacssascessasssssessuncsocuacsccaverssbivessvescoveses

24

10508060

НӨ:

РИА

С

ME

arta)

EYE)

AM

ise

А

дээ

25

TI

(e

2

MEN

Rp

eee

eze

eer

vd

oe

Ne

A

Lo

AR

12.

Bold

funcion

25

[9]

ERROR

CONDITIONS

26

[10]

SELF

TEST

PRINTING

26

[11]

AUTOMATIC

PRINTING

FUNCTION

26

[12]

DIP

SWITCH

SETTINGS

27

ГІЗІССОПРЕСТАВЫЕ,,/

азасы

sra

арын»

28

АТ

PRINT

EXAMPLES

RENNES

ee

el

ка

ананыц

29

1.

СПагастег

Вебе...

г...

n

o

ereesensronaskeskésPa

eba

saya

MA

ca

E

ан

29

PA

A

e

eT

о

ЕАН

PEREAT

ТТТ

29

SOPEBPBDOSIOR

ur

ge

Re

И

29

ELIE

|

a

MM

eee

РИ

И

30

e

e

NUN

анги

p

otn

e

emily

30

af

DENER

MM

A

MM

Ya

Ея

31

7.

16-bit

graphics...

31

8.

Line

feed

spacing

..

2032

С

UY

е

ITO

33

A,

АИ

еее

УИ

33

[15]

TROUBLESHOOTING

...........

а

|

[16]

CARING

FOR

YOUR

PRINTER

..................................................................

35

[1]

GENERAL

SPECIFICATIONS

1.

Printing

specifications

Qo

оо»

СНАВ

СНАВ

NO.

OF

CHAR.

SETS

HxV

DOTS

|

SPACEDOTS

7

мен

/

име|

PRINT

SPEED!

CHARS

—

—

=к——=_=————==———=———=

Standard

Pica

9x8

3

10

80

50cps

139

a

a

ж-ға

та

андах

re

Elongate

Ка

18x8

6

5

40

25

139

Standard

Elite

9х8

1

12

96

60

139

oa

18x8

2

6

48

30

139

Condensed

5x8

2

17

136

86

139

ы

10х8

4

85

68

43

139

ке

машы

Цай

ei

НЕВЕ

шог

ла

olmama

feng

рева

ente

с

екеніне

9х16

3

10

80

139

k

—

т

ri

seri

18x16

6

5

40

12

189

Seen

9x16

1

12

96 30

139

ellere

18x16

2

6

48

15

139

Найс

Cursive

12х16

0

10

80

25

139

и

4

Italic

Cursive

я

24х16

0

5

40

12

139

(RT

Super

Script

5x8

2

17

136

43,

139

борог

5с!

10х8

4

85

68

21

139

—

Sub

Script

5x8

2

17

136

43

139

ч

——

———

|

——

MOM

10x8

4

85

68

21

189

Proportional

nx16

=

= = -

139

—

Proportional

2nx16

= a

5

es

139

(1)

Printing

method

(2)

Character

sets

Impact

type

dot

matrix

(SEIKOSHA's

unique

2-hammer

method)

Elongated

(3)

Graphics

Arbitrary

combinations

of

8

vertical

dots

Arbitrary

combinations

of

16

vertical

dots

(4)

Dot

density

Horizontal

1/120"

(0.21mm)

Vertical

1/120"

(0.21mm)

(5)

Printing

direction

Unidirectional

(left

to

right)

a.

1-pass

printing:

Standard,

Standard

elite,

Condensed

and

8-dot

graphics

b.

2-pass

printing:

Correspondence,

Correspondence

elite,

Italic

cursive,

Super/subscript,

Propor-

tional

and

16-dot

graphics

(6)

Line

spacing

1/6",

1/8",

2/15",

1/12"

and

N/120"

(М-0--99)

(7)

Multiple

copies

Original

plus

опе

copy

(45Kg

+

35Kg

paper

)

(8)

Intermixing

printing

Intermixing

text

and

graphics

on

the

same

line

is

allowed

2.

Paper

feed

specifications

(1)

Paper

feed

direction

Forward

direction

only

(2)

Paper

feed

method

Pin

feed......

maximum

10

inch

width

paper

Friction

feed

(3)

Minimum

line

feed

amount

1/120"

(4)

Line

feed

speed

10

lines/sec

(1/6"

line

feed

pitch)

.

Paper

specifications

(1)

Paper

width

4.5

—

10

inches

for

pin

feed

paper

Tractor

width

is

adjustable.

(2)

Paper

thickness

and

weight

recommended

0.07mm

(2.8

mils)

45~55Kg

in

Japan

or

15—18

pounds

in

USA

(3)

Paper

Type

Continuous

form

paper

Single.sheet

paper

.

Ink

ribbon

specifications

Special

single

color

cassette

type.

.

Operating

environment

(1)

Power

supply

120,

220/240

МАС

+

10%,

50/60Hz

(2)

Power

consumption

30

watts

(printing

characters)

11

watts

(stand

by)

(3)

Temperature

5°C~40°C

(4)

Humidity

20%

~

80%

(no

condensation)

(5)

External

dimensions

420W

x

113H

x

305Dmm

(6)

Weight

5.5Kg

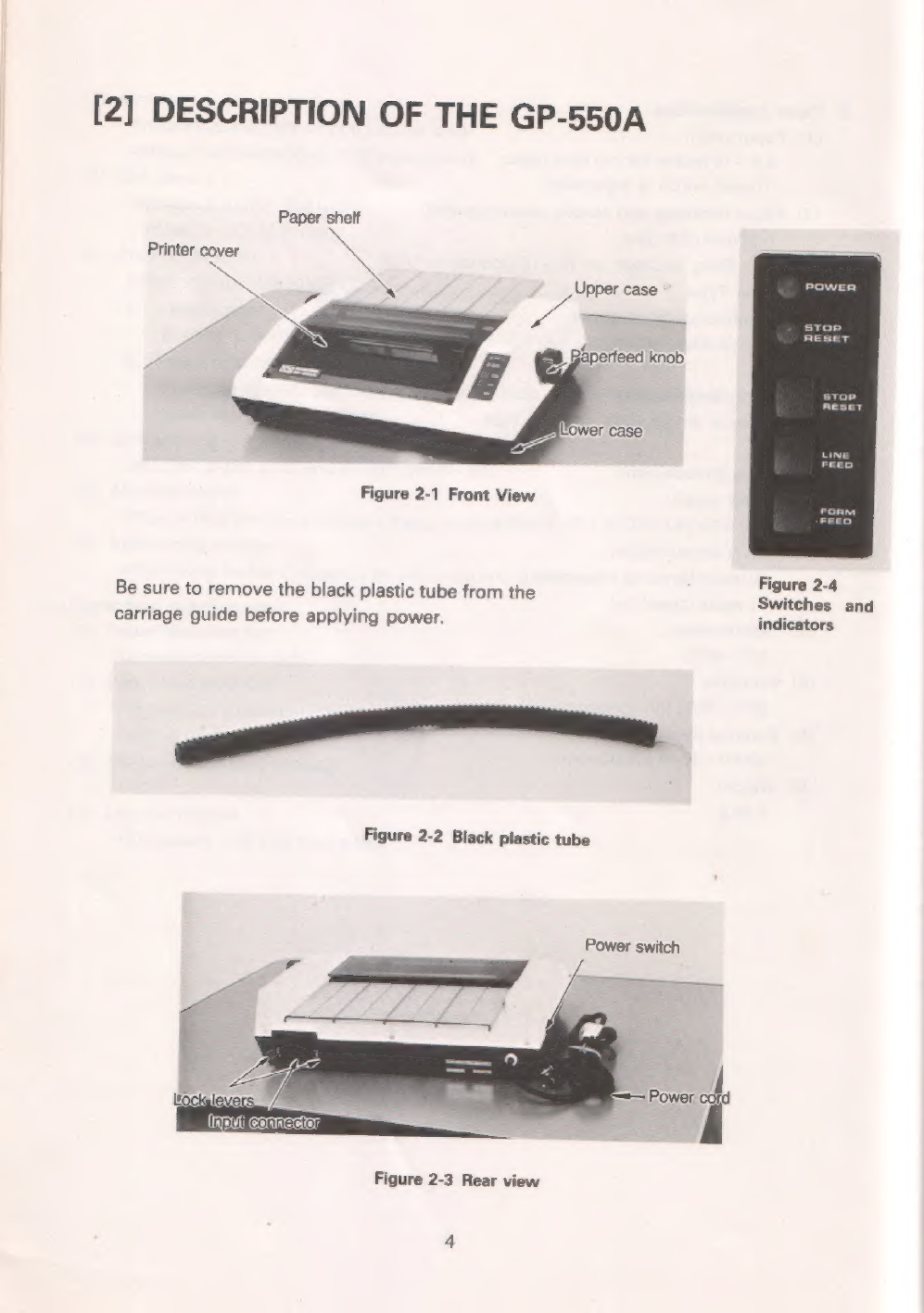

[2]

DESCRIPTION

OF

THE

GP-550A

Paper

shelf

Printer

cover

x

i»

Figure

2-1

Front

View

i

Figure

2-4

Be

sure

to

remove

the

black

plastic

tube

from

the

ae

d

carriage

guide

before

applying

power.

indicators

Figure

2-2

Black

plastic

tube

Power

switch

Figure

2-3

Rear

view

.

Power

switch

The

power

switch

is

located

on

the

left

of

the

printer.

.

STOP/RESET

switch

(1)

Pushing

the

switch

causes

the

printer

to

stop,

or

if

stopped,

it

clears

the

STOP

condition.

.

(2)

In

the

STOP

condition,

the

STOP/RESET

lamp

is

on,

the

P.

EMP

signal

is

output,

and

printing

is

temporarily

stopped.

The

LINE

FEED

switch

and

the

FORM

FEED

Switch

are

both

invalid

during

this

condition.

.

LINE

FEED

switch

(1)

A

1/6

inch

line

feed

is

executed

each

time

it

is

pushed.

(2)

If

held

down,

line

feeds

are

continuously

executed.

(3)

Line

feeds

are

performed

even

when

paper

is

out.

FORM

FEED

switch

(1)

Pressing

this

switch

causes

a

formfeed

to

be

executed

to

the

top

of

the

next

page.

(2)

A

formfeed

is

conducted

regardless

of

paper

out.

.

POWER

lamp

(red)

(1)

This

lamp

is

on

when

power

is

on.

(2)

It

blinks

during

an

error

condition.

.

STOP/RESET

lamp

(red)

(1)

This

lamp

is

lit

and

the

P.EMP

signal

is

output

either

when

the

STOP/RESET

switch

is

pushed

or

when

paper

is

out.

(2)

When

paper

is

out,

insert

paper

and

press

the

STOP/RESET

switch

to

turn

this

lamp

off

and

to

clear

the

PAPER

EMPTY

condition.

When

a

PAPER

EMPTY

condition

occurs,

pushing

the

STOP/RESET

switch

clears

the

PAPER

EMPTY

condition

enabling

the

printer

to

receive

more

data

including

a

print

command

which

is

a

last

input

data,

and

to

print

them

out.

After

printing

the

line,

it

returns

to

the

PAPER

EMPTY

condition.

Cancellations

of

the

PAPER

EMPTY

condition

by

the

switch

are

valid

up

to

the

total

line

feed

of

128/120

inch

fed

after

the

first

PAPER

EMPTY

condition.

Pushing

the

switch

again

turns

the

lamp

off

when

it

has

been

turned

on

by

the

Switch.

(3

(4

[3]

PAPER

LOADING

1.

Continuous

forms

(1)

Grasp

the

back

of

the

printer

cover

and

remove

it

by

lifting

upwards.

paper

shelf

(2)

Turn

the

paper

shelf

upright

and

pull

it

up

to

remove

it.

Move

the

head

adjustment

lever

all

the

way

toward

the

front

of

the

printer.

Refer

to

"

HEAD

POSITION

ADJUST-

MENT"

Figure

3-2

(3)

Use

both

hands

to

insert

the

paper

from

the

rear

and

then

use

the

right

hand

to

turn

the

paperfeed

knob

in

a

clockwise

direction

until

it

appears

bet-

ween

the

platen

and

the

print

head.

Figure

3-3

Note:

If

the

paper

does

not

appear

by

turning

only

the

knob,

use

your

hand

to

push

the

paper

into

the

printer

while

turning

the

knob.

(4)

Lift

up

the

friction

roller

bar

and

open

the

tractor

covers

to

the

side.

Figure

3-4

(5)

With

the

holes

along

both

sides

of

the

paper

matched

up

with

the

paper

feed

pins

on

the

left

and

right

tractors,

close

the

tractor

covers.

Lower

the

friction

roller

bar,

positioning

the

friction

rollers

on

the

bar

so

that

they

rest

directly

on

top

of

the

two

large

rubber

tractor

rings.

Use

the

LINE

FEED

switch

to

perform

line

feeds

in

order

to

tighten

the

paper.

If

the

tactor

spacing

does

not

match

the

paper

width,

slide

the

tactors

to

the

left

or

right

as

needed.

Make

sure

that

the

paper

is

positioned

so

that

the

first

and

last

print

positions

are

on

the

paper.

Figure

3-5

(6)

Return

the

head

adjustment

lever

to

its

original

position.

Replace

the

paper

shelf

and

printer

cover

in

that

order.

Adjust

the

print

position

by

pushing

the

LINE

FEED

switch.

7

Figure

3-6

Note:

After

manually

advancing

paper

by

the

paper

feed

knob,

it

is

recommended

that

the

LINE

FEED

switch

be

pushed

at

least

once

in

order

to

avoid

having

abnormal

double

pass

printing

for

the

first

line.

2.

Single

sheets

of

paper

Except

for

those

involving

the

tractors,

all

of

the

operations

are

the

same

and

follow

the

order

of

section

[3]-1.

Note:

1.

For

proper

friction

feeding,

be

sure

that

the

friction

rollers

are

positioned

directly

on

top

of

the

rubber

tractor

rings

and

that

these

two

sets

of

rollers

properly

grasp

the

paper.

2.

The

paper

empty

switch

is

located

at

a

position

about

11/2”

away

from

the

metal

side

plate

on

the

left.

The

left

edge

of

the

single

sheet

of

paper

must

cover

the

switch

in

order

to

avoid

the

PAPER

EMPTY

condition.

Figure

3-7

8

[4]

RIBBON

INSTALLATION/REMOVAL

1.

Installation

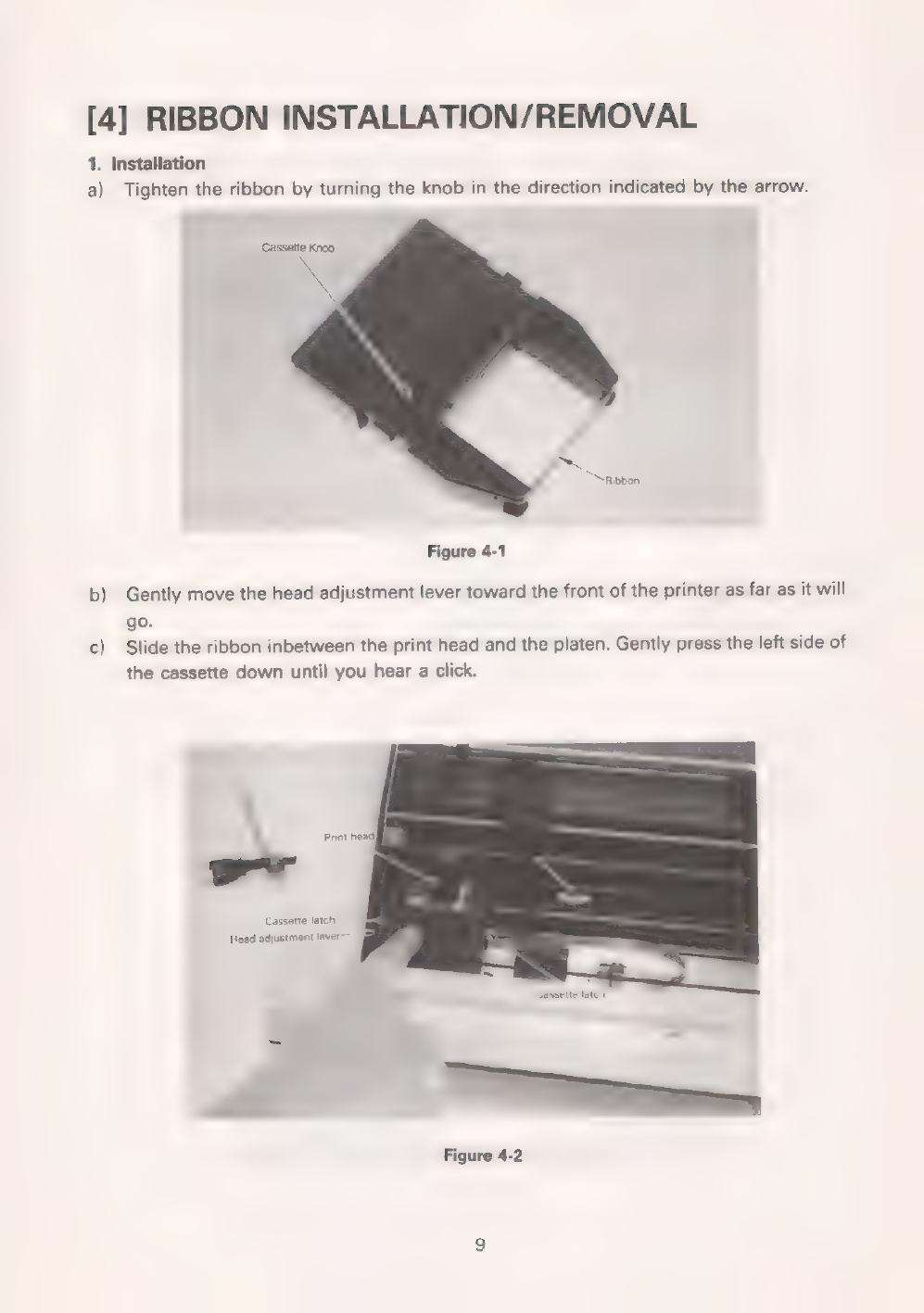

a)

Tighten

the

ribbon

by

turning

the

knob

in

the

direction

indicated

by

the

arrow.

Саззейе

Knob

Ribbon

Figure

4-1

b)

Gently

move

the

head

adjustment

lever

toward

the

front

of

the

printer

as

far

as

it

will

go.

c)

Slide

the

ribbon

inbetween

the

print

head

and

the

platen.

Gently

press

the

left

side

of

the

cassette

down

until

you

hear

a

click.

Print

head]

Cassette

latch.

Head

adjustment

lever

—

Figure

4-2

d)

Then,

while

rotating

the

cassette

knob

in

the

direction

indicated

by

the

arrow,

press

the

right

side

of

the

cassette.

Do

not

force

the

cassette

down.

Push

it

in

gradually

while

turning

the

cassette

knob

in

the

indicated

direction.

Once

the

new

cassette

is

installed,

tighten

the

ribbon

by

turning

the

cassette

knob

in

the

indicated

direction.

Figure

4-3

e)

Set

the

head

adjustment

lever

to

its

original

position.

Note:

Do

not

print

without

paper

and/or

ribbon.

The

print

head

or

platen

will

be

damaged.

2.

Removal

a)

Move

the

head

adjustment

lever

toward

the

front

of

the

printer

as

far

as

it

will

go.

b)

Gently

push

the

ribbon

cassette

latch

on

the

right

side

outward

using

your

thumb,

and

remove

the

cassette

by

lifting

it

upwards

using

your

middle

finger.

Figure

4-4

10

[5]

HEAD

POSITION

ADJUSTMENT

The

head

adjustment

lever

is

used

to

adjust

for

varying

thicknesses

of

paper

and

varying

printing

conditions.

The

head

adjustment

lever

is

moved

by

pressing

it

toward

the

outside

as

it

is

moved

back

and

forth.

When

adjusting,

make

sure

that

the

foot

of

the

lever

is

set

in

one

of

the

click

holes.

The

head

is

adjusted

by

moving

the

lever

toward

for

thick

paper

and

toward

©

for

thin

paper.

The

printer

is

shipped

with

the

lever

foot

set

to

position

(3).

The

lever

foot

should

be

set

to

(8)

(©)

for

insertion

and

removal

of

the

ribbon

and

the

paper.

Red

mark

Head

adjustment

lever

Lever

foot

08

(

өв

holes

0090

N

Figure

5-1

Internal

left

side

view

[6]

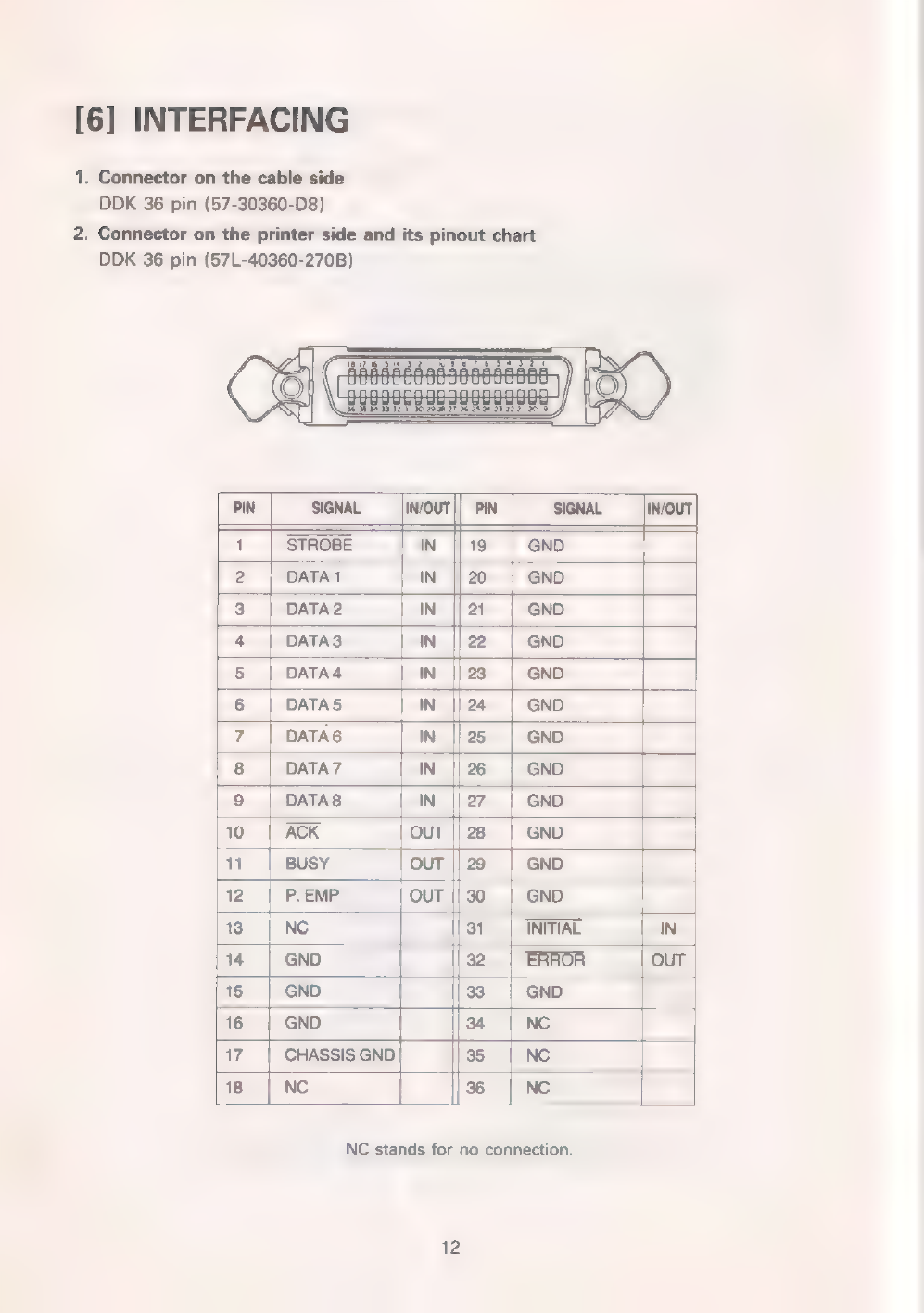

INTERFACING

1.

Connector

on

the

cable

side

DDK

36

pin

(57-30360-D8)

2.

Connector

on

the

printer

side

and

its

pinout

chart

DDK

36

pin

(57L-40360-270B)

2

3

|

DATA2

IN

||21

|

GND

4

|

DATAS

IN

||22

|

GND

5

|

DATA4

ІМ

|23

|

GND

6

|

DATAS

IN

||24

|

GND

7

|

DATA6

IN

||25

|

GND

8

|

DATA7

ІМ

||26

|

GND

9

|

ПАТАВ

IN

|27

|

GND

10

|

ACK

OUT

|

28

|

GND

11

|

BUSY

Тол

|29

|

емо

12

|

Р.ЕМР

OUT

|30

|

GND

13

|

NC

31

|

INITIAL

IN

14

GND

32

|

ERROR

OUT

15

|

GND

83

|

GND

16

|

GND

34

|

NC

Цэр

17

|

CHASSIS

GND

35

|

Nc

18

|

Nc

|ж

|

ме

NC

stands

for

no

connection.

12

3.

Explanation

of

the

input/output

signals

a)

Input

signals

to

the

printer

@DATA1~DATA8

These

form

the

8

bit

data

signal.

A

given

line

is

“HIGH”

if

the

data

bit

is

“1”,

®

STROBE

This

signal

is

used

to

strobe

the

8

bits

of

data

into

the

printer.

The

data

is

read

in

when

this

line

goes

“LOW”.

®

INITIAL

This

signal

is

used

to

set

the

printer

to

its

initial

state.

This

pin

is

normally

“HIGH”.

Bringing

it

“LOW”

stops

the

execution

of

the

printer

and

setting

it

back

to

“HIGH”

starts

the

execution

of

the

clearing

sequence

that

sets

it

to

its

initial

con-

dition.

b)

Output

signals

from

the

printer

е

BUSY

This

signal

indicates

that

the

printer

is

BUSY.

When

"HIGH",

new

data

cannot

be

input.

е

АСК

This

signal

is

always

output

at

the

end

of

the

BUSY

signal

and

indicates

that

data

input

has

been

completed.

The

pulse

width

is

about

7.5us.

e

ERROR

This

signal

goes

"LOW"

when

the

Printer

enters

an

error

condition.

e

P.

EMP

(PAPER

EMPTY)

This

signal

goes

"HIGH"

either

when

the

printer

is

out

of

paper

or

when

the

STOP/RESET

switch

is

pushed.

In

thes

case

the

printer

stops

processing

data.

In

order

to

clear

this

condition,

insert

paper

and

push

the

STOP/RESET

switch.

Refer

to

the

"STOP/RESET

lamp"

on

page

5.

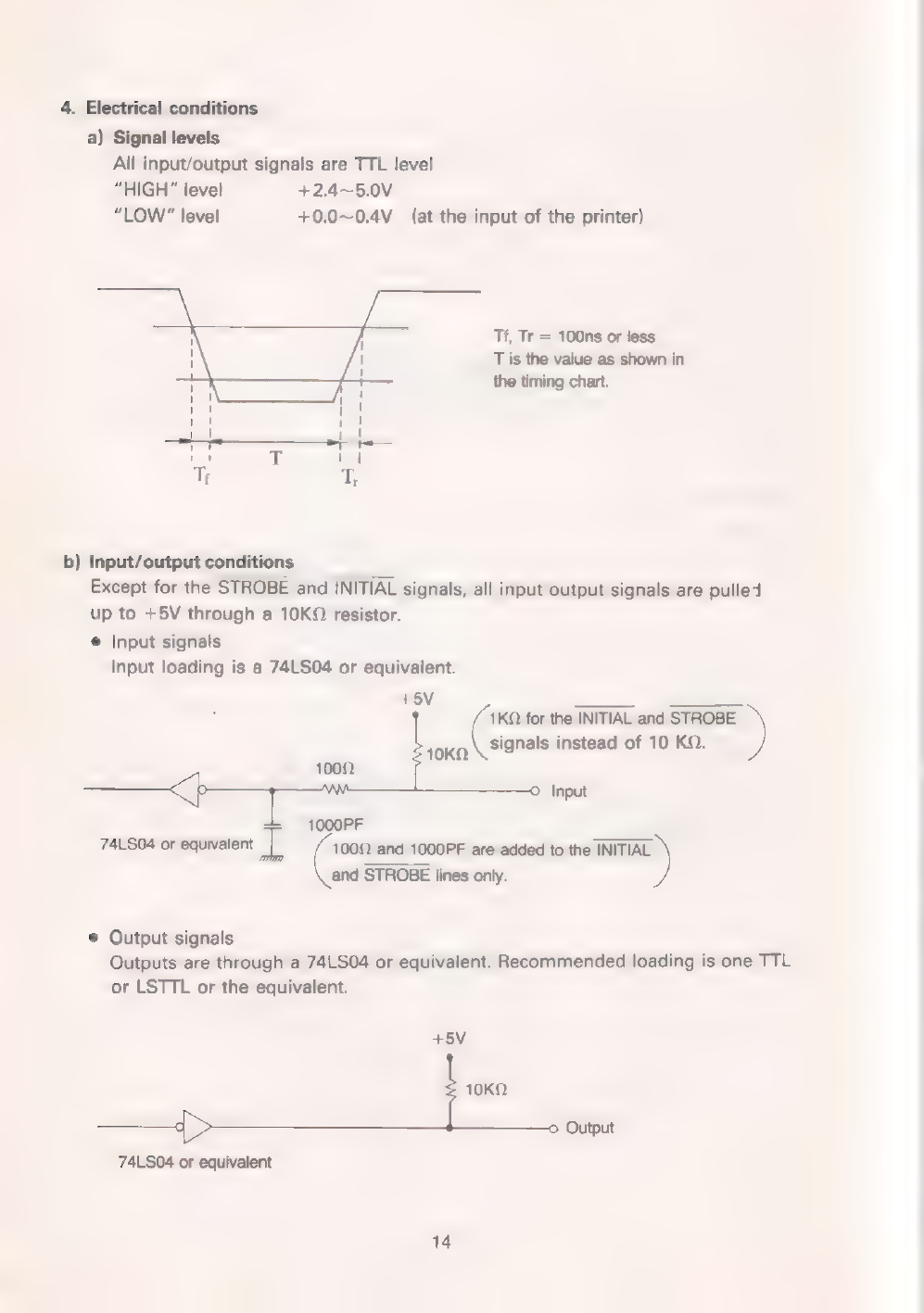

4.

Electrical

conditions

a)

Signal

levels

All

input/output

signals

are

TTL

level

“HIGH”

level

+2.4~5.0V

“LOW”

level

+0.0~0.4V

(at

the

input

of

the

printer)

7

j

Tf,

Tr

=

100ns

or

less

:

1

T

is

the

value

as

shown

in

|

1

the

timing

chart.

"ER:

1

La

ка

|

1

БЭ

T

11

Т;

®

b)

Input/output

conditions

Except

for

the

STROBE

and

INITIAL

signals,

all

input/output

signals

are

pulled

up

to

+5V

through

а

10КО

resistor.

®

Input

signals

Input

loading

is

a

74LS04

or

eguivalent.

+5V

———

=.

for

the

INITIAL

and

STROBE

)

лока

signals

instead

of

10

КО.

Input

1000PF

74LS04

or

eguivalent

ар

1000

and

1000РЕ

are

added

to

the

INITIAL

and

STROBE

lines

only.

*

Output

signals

Outputs

are

through

a

74LS04

or

equivalent.

Recommended

loading

is

one

TTL

or

LSTTL

or

the

equivalent.

45V

токо

Output

74LS04

or

eguivalent

Table of contents

Other Seikosha Printer manuals