INTEGRA Biosciences VacuSafe User manual

Operator‘s Manual ●Bedienungsanleitung ● Mode d’emploi

VacuSafe

Aspiration system

Absaug-System

Système d’aspiration English

Deutsch

Français

2

Declaration of Conformity

INTEGRA Biosciences (Switzerland) hereby confirms that the product

VacuSafe

is in accordance with the following directives and standards:

73/23/EEC Low voltage equipment

89/336/EEC Electromagnetic compatibility

IEC/EN 61010-1:2001-02

IEC/EN 61326-1+A1:1998+A2:2000

Standards for Canada, USA and Australia:

CAN/CSA-C22.2 No. 1010.1-92

UL Std. No. 3101-1

FCC, Part 15, class A

February 21, 2003 Elmar Morscher Thomas Neher

CEO Quality Manager

This equipment has been tested

and found to comply with the

limits for a Class A digital device,

pursuant to both Part 15 of the

FCC Rules and the radio interfer-

ence regulations of the Canadian

Department of Communications.

These limits are designed to

provide reasonable protection

against harmful interference when

the equipment is operated in a

commercial environment.

This equipment generates, uses

and can radiate radio frequency

energy and, if not installed and

used in accordance with the

instruction manual, may cause

harmful interference to radio

communications.

Operation of this equipment in a

residential area is likely to cause

harmful interference in which

case the user will be required to

correct the interface at his own

expense.

ENGLISH

3

Edition 8/2003

© Copyright

INTEGRA Biosciences AG - Switzerland

All rights reserved. This manual may not be copied or

reproduced in whole or in part in any way without the prior

express written permission of INTEGRA Biosciences.

The company reserves the right to make alterations without

prior notice.

Notwithstanding the above statements, INTEGRA

Biosciences accepts no liability for possible mistakes or

their consequences arising from this manual.

Manual article number: 468126_V01

Manual is valid as of Software Version 150

ENGLISH

Contents

1. Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Abridged description . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Overview – front panel . . . . . . . . . . . . . . . . . . . . . 9

2.2 Display / keyboard . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Overview – rear panel . . . . . . . . . . . . . . . . . . . . 11

3. Operating instructions . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Equipment provided . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Connecting to power supply . . . . . . . . . . . . . . . . 13

3.4 Connecting the foot switch . . . . . . . . . . . . . . . . 13

4. Aspirating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6. Combined aspirating and dispensing . . . . . . . . . . 18

7. Setting pressure, vacuum and hysteresis . . . . . . . 21

8. Level monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.1 Operation and instructions on use . . . . . . . . . . . . 23

8.2 Activation and calibration of

level monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.3 Deactivation of level monitor . . . . . . . . . . . . . . . 24

9. Maintenance and cleaning . . . . . . . . . . . . . . . . . . . 25

9.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.3 Autoclaving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10. Trouble-shooting / technical instructions . . . . . . . 27

10.1 Trouble-shooting . . . . . . . . . . . . . . . . . . . . . . . . 27

10.2 Changing fuses . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.3 Setting the power voltage . . . . . . . . . . . . . . . . . 30

10.4 Calibrating the pump to a new sensor cable . . . 31

10.5 Display of current software

version number . . . . . . . . . . . . . . . . . . . . . . . . . 31

11. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13. Manufacturer and service addresses . . . . . . . . . . . 33

14. VACUBOY hand operator accessories . . . . . . . . . 34

4

ENGLISH

1. Safety precautions

Conditions of use

VacuSafe is an instrument for the controlled,

contamination-free aspiration and dispensing of liquids in a

laboratory.

The instrument should not be used for any other purpose.

Dangers involved when safety precautions

are not observed

VacuSafe is a state-of-the-art instrument with respect to

current technology and is safe to use. Some danger may

exist if the instrument is used by untrained personnel. Any

person given the task of operating VacuSafe must first read

the operating and safety instructions and understand them

fully or be thoroughly trained by a superior in the use of the

instruments before operating the instrument.

Other possible dangers

Throughout the manual, the following symbols will be used

to indicate general precautionary measures:

NB: information on the correct use of VacuSafe.

Warning: Warning that, if safety precautions are not

observed, damage may result to the instrument.

Danger: Warning that, if safety precautions are not

observed, injury to personnel may result.

Independent of any precautionary information given above,

potential dangers with respect to the aspiration and dispens-

ing of liquids should be assessed prior to carrying out and

appropriate safety precautions taken.

5

ENGLISH

Safety at work

Independent of any safety precautions listed here, all other

relevant safety aspects - e.g. GLP, GMP, and those issued

by professional trade associations, the Department of

Health and trade supervisory authorities must be observed.

Qualification of operating personnel

Normally, a technical qualification is required. Specialist

knowledge is required when using VacuSafe for aspirating

or dispensing liquids if all danger is to be avoided. This

particularly applies to the selection of liquids to be aspirat-

ed or dispensed with respect to potential danger involved

and the decision as to whether VacuSafe should be used for

such procedures.

Personnel with no formal laboratory qualification do not, as

a rule, possess the degree of specialist knowledge required

and must hence be trained by qualified personnel and

subsequently supervised.

Safety aspects for the user company

The supervisors of operating personnel must have read and

understood all the safety precautions involved and must

ensure that these are adhered to. They must also ensure that

operating personnel also understand and observe all safety

rules.

Prior to operating VacuSafe, the supervisor must ensure that

no other dangers exist, especially if other instruments and

systems are also being used and if the liquids to be aspirat-

ed or dispensed represent additional potential danger.

If necessary, additional safety instructions must be

compiled by the supervisor. The user company must, if nec-

essary, in order to exclude all possible danger, compile

explicit safety instructions and have these signed by the

staff responsible. In addition, clear competences must be

established as to who is responsible for the operation of

VacuSafe so that clear responsibilities exist for questions of

safety.

6

ENGLISH

Changes in configuration / design by user

No changes may be made to VacuSafe. Any parts that

become defective must be replaced by original INTEGRA

Biosciences parts. Repairs must be carried out by

INTEGRA Biosciences service personnel.

VacuSafe may not be altered in design or in any of their

safety aspects without the express written permission of

INTEGRA Biosciences. In particular, no alterations may be

made to any of the protective functions. Any alteration

made releases INTEGRA Biosciences from any liability for

damage caused.

7

ENGLISH

2. Abridged description

VacuSafe is a controllable aspiration device with integrated

pump and controller and a vacuum/pressure bottle. It is

designed for laboratory use, for aspirating and dispensing

liquids with presettable vacuum and pressure. In

combination with the VACUBOY handoperator or tubing

fitted with a pipette tip, liquids can be aspirated or

dispensed completely contamination-free.

The operating modes "aspirate" and "dispense" can be

selected either individually or in combination.

In the combination mode, a second bottle must be connect-

ed to the pump so that both a vacuum and a pressure source

can be used simultaneously. The MODE key or foot switch

(optional) can be used to switch between the aspirating and

dispensing modes.

Tubing connectors are self-closing. The bottles can thus be

separated, contamination-free, from tubing and pump for

autoclaving or disposal.

8

ENGLISH

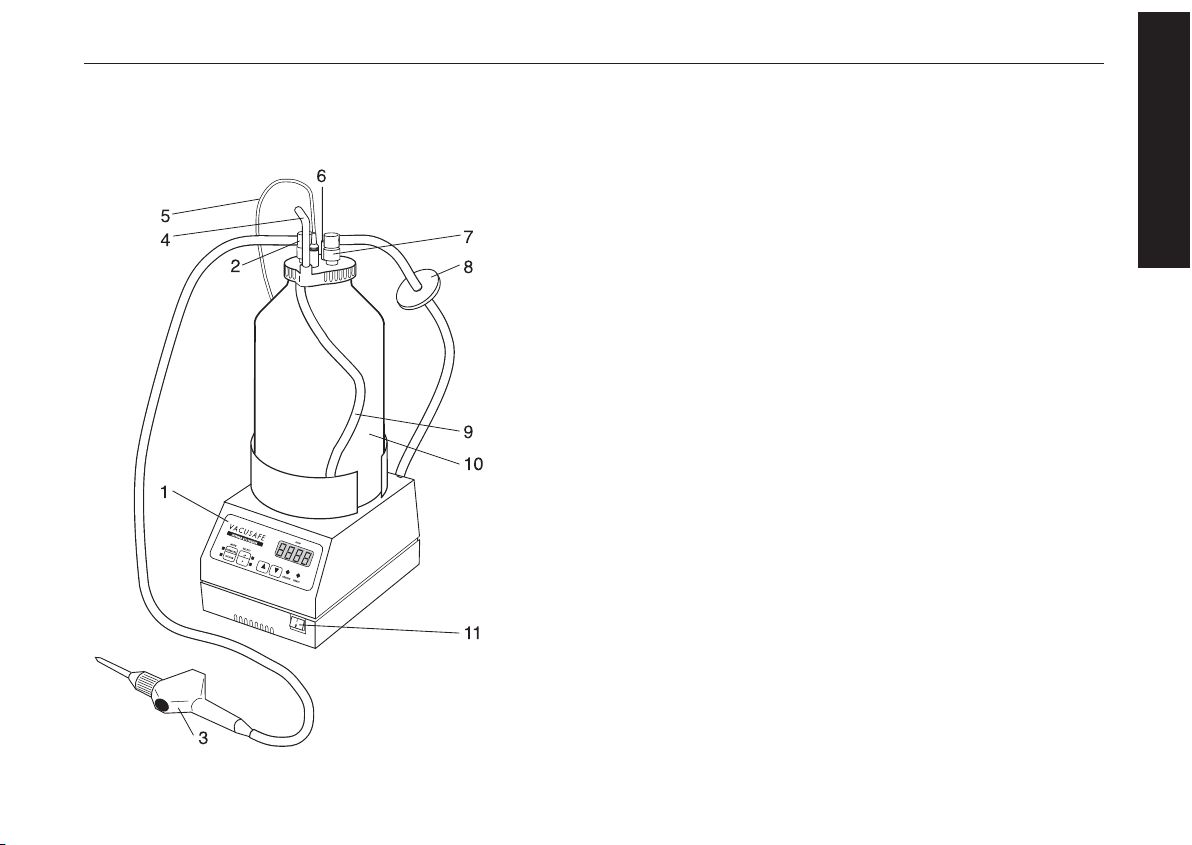

2.1 Overview – front panel 1 Keyboard/display, on/off

2 Tube connector, media side (red)

3 VACUBOY handoperator

(not delivered with system)

4 Grip

5 Sensor cable

6 Venting screw

7 Tube connector, pump side (blue)

8 Pump tubing with filter

9 Siphon tubing

10 Pressure/vacuum bottle

11 Power switch

9

ENGLISH

2.2 Display / keyboard 1 Display pressure/vacuum in mbar (minus sign in

the case of vacuum)

2 LED READY: lights when set pressure/vacuum in

the bottle is within set range

3 LED SENSOR: active only (blinks) in aspiration

mode (VACUUM):

●when medium reaches maximum level in the

bottle and the bottle has to be emptied

●when the sensor cable is not properly connected

4 Keys UP and DOWN for setting hysteresis and

pressure/vacuum and switching off level monitor

5 SELECT key: for setting hysteresis (∆P) or

pressure/vacuum (P) and calibration level monitor

6 MODE key: for switching between the modes

"aspirate" (VACUUM) and "dispense"

(PRESSURE).

10

PRESSURE

MODE SELECT

VACUUM P

∆

P

READY

SENSOR

mbar

ENGLISH

2.3 Overview – rear panel 1. Fuse housing containing 2 fuses

2. Power voltage display

3. Socket for power cable

4. Socket for sensor cable

5. Socket for foot switch

6. Tubing nipple for "dispense" mode (PRESSURE)

7. Tubing nipple for "aspirate" mode (VACUUM)

11

ENGLISH

3. Operating instructions

3.1 Equipment provided

The equipment provided comprises:

1 VacuSafe pump

2 Pressure/vacuum bottle

3 Lid, complete

4 Tube, pump side, complete with filter and tube

connector

5 Sensor cable

6 Power cable

7 Foot switch (option)

8 Tube media side with connector

9 Siphon tubing

Operator’s Manual

Please check the items delivered for completeness. Should

any of the items be missing, contact INTEGRA

Biosciences.

12

ENGLISH

3.2 Location

VacuSafe is intended for use in a laboratory environment.

The instruments may not be located:

●Near a source of UV-radiation

●In a place susceptible to water spray or where con-

tact with chemicals is possible.

●In a place where explosion potential is present.

The proper location:

●Has a stable, flat base

●Has adequate space for fitting a second bottle for

combined mode aspirate/dispense and for a foot

switch.

●is ventilated sufficiently

3.3 Connecting to power supply

Checking the voltage

Check the local voltage; it must be compatible with the

voltage indicated on VacuSafe.

The instrument voltage is indicated on the rear panel of

VacuSafe.

Warning: Connecting to the wrong voltage may

damage electrical components of VacuSafe.

Connection to power supply

Connect VacuSafe to the power supply using the power

cable provided.

3.4 Connecting the foot switch

Using the foot switch, one can switch between the

"aspirate" and "dispense" modes. It is available as an

optional accessory. The foot switch cable should be

connected to the socket labelled FOOT SWITCH at the rear

of VacuSafe.

13

ENGLISH

4. Aspirating Danger: Aspiration may not be carried out:

●With substances that are potentially explosive

●Aggressive liquids which can attack silicone tubing

●With substances with a temperature in excess of

80°C.

1. Prepare the vacuum bottle

Procedure:

●Switch off the pump with the power switch

●Ensure that no siphon tubing is connected to the

lid.

2. Set "aspirate" mode (VACUUM)

Procedure:

●Switch on the pump with the power switch

●Press the MODE key until the LED for VACUUM

lights.

14

ENGLISH

NB: When aspiration is carried out using a siphon

tube, air bubbles will rise through the medium

during the aspiration process.

●Place lid (1) on the vacuum bottle and ensure that

it fits tightly.

NB: Always keep the lid tight – otherwise a vacuum

cannot be generated in the bottle!

●Connect lid (1) and pump (VACUUM connection)

with tube (4) on the pump side (blue, with filter).

●Ensure that:

- The blue tube connector is fitted to the blue

socket

- The rapid-action connector is properly fitted

(it must click).

NB: Always use the integrated sterile filter on the

pump side (blue). This prevents medium from enter-

ing the pump and causing damage.

●Connect the VACUBOY hand operator tube or

other tube (2) to the tube connector on the red

rapid-action connector

●Connect sensor cable (3) between lid (1) and pump

(SENSOR).

3. Aspiration

●Check that the venting screw is closed

●Switch on the pump with the power switch

●Set values for vacuum and hysteresis if necessary

●The pump will begin to function

●Once the bottle is full, the level indicator will be

activated – the LED SENSOR will blink and an

acoustic alarm starts. The pump stops. The bottle

must be emptied before proceeding further.

NB: For proper operation of the level indicator, and

to prevent the build-up of foam, we recommend the

use of normal commercial anti-foaming agents (for

example Antifoam A from Fluka or Sigma)

15

ENGLISH

5. Dispensing Danger: Dispensing may not be carried out:

●With substances that are potentially explosive

●Aggressive liquids that can attack silicone tubing

●With substances with a temperature in excess of

80°C.

1. Prepare the pressure bottle

Procedure:

●Switch off the pump with the power switch

●Ensure that the siphon tubing (1) is connected

●Place lid (2) on the pressure bottle.

2. Set "dispense" mode (PRESSURE)

Procedure:

●Switch on the pump with the power switch

●Press the MODE key until the LED for

PRESSURE lights.

Ensure that the lid is tightly fastened.

16

ENGLISH

NB: Always keep the lid tight – otherwise a

pressure cannot be generated in the bottle!

●Connect lid (2) and pump (PRESSURE

connection) with tube (4) on the pump side (blue,

with filter)

●Ensure that:

- The blue tube connector is fitted to the blue

socket

- The rapid-action connector is properly fitted

(it must click).

NB: Always use the integrated sterile filter on the

pump side (blue). This prevents medium from enter-

ing the pump and causing damage.

●Connect the VACUBOY hand operator tube or

other tube (3) to the tube connector on the red

rapid-action connector.

3. Dispensing

●Check that the venting screw is closed.

●Switch on the pump with the power switch

●Set values for pressure and hysteresis if necessary

●The pump will begin to function.

17

ENGLISH

6. Combined aspirating

and dispensing

In this combined mode, a vacuum and a pressure bottle are

required.

Danger: Aspiration or dispensing may not be

carried out:

●With substances that are potentially explosive

●Aggressive liquids which that can attack silicone

tubing

●With substances with a temperature in excess of

80°C.

1. Prepare the pressure bottle

Procedure:

●Switch off the pump with the power switch

●Ensure that the siphon tubing (1) is connected

●Place lid (2) on the pressure bottle and ensure that

it fits tightly.

18

ENGLISH

NB: Always keep the lid tight – otherwise pressure

cannot be generated in the bottle!

●Connect lid (2) and pump (PRESSURE

connection) with tube (4) on the pump side (blue,

with filter)

●Ensure that:

- The blue tube connector is fitted to the blue

socket

- The rapid-action connector is properly fitted

(it must click).

NB: Always use the integrated sterile filter on the

pump side (blue). This prevents medium from enter-

ing the pump and causing damage.

●Connect the VACUBOY hand operator tube or

other tube (3) to the tube connector on the red

rapid-action connector.

2. Prepare the vacuum bottle

●Ensure that no siphon tubing is connected to the

lid.

NB: When aspiration is carried out using a siphon

tube, air bubbles will rise through the medium

during the aspiration process.

●Place lid (5) on the vacuum bottle and ensure that

it fits tightly.

NB: Always keep the lid tight – otherwise a vacuum

cannot be generated in the bottle!

●Connect lid (5) and pump (VACUUM connection)

with tube (8) on the pump side (blue, with filter)

●Ensure that:

- The blue tube connector is fitted to the blue

socket

- The rapid-action connector is properly fitted

(it must click)

19

ENGLISH

NB: Always use the integrated sterile filter on the

pump side (blue). This prevents medium from enter-

ing the pump and causing damage.

●Connect the VACUBOY hand operator tube or

other tube (6) to the tube connector on the red

rapid-action connector.

●Connect sensor cable (7) between lid (5) and pump

(connection SENSOR).

3. Aspirating and dispensing

Procedure:

●Connect foot switch (9) to the FOOTSWITCH

socket of the pump

●Ensure that the venting screw on both bottles are

closed

●Switch on the pump with the power switch

●If necessary, set values for pressure and vacuum

●The pump will begin to function

●Either the foot switch or the MODE key can be

used to switch between "aspirate" and "dispense"

●Once the bottle is full, the level indicator will be

activated – the red LED SENSOR will blink. The

bottle must be emptied before proceeding further.

NB: For proper operation of the level indicator, and

to prevent the build-up of foam, we recommend the

use of normal commercial anti-foaming agents (for

example Antifoam A from Fluka or Sigma)

20

ENGLISH

Table of contents

Languages:

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual