Intelbras IVA 9100 TRI User manual

User manual

IVA 9100 TRI

IVA 9100 TRI

Multi-beam virtual fence sensor

Congratulations, you have just purchased a product with Intelbras quality and safety.

The IVA 9100 TRI sensor is a product of high performance and advanced technology. Equipped with

high performance lenses, which provide greater efciency against unwanted shots, and can be installed

indoors, semi-open and outdoors.The IVA 9100 TRI has an integrated two-digit display, which provides

greater ease and agility in the alignment procedure, eliminating the need for a multimeter. Read the

product introductory information carefully for the correct use of the sensors.

Care and safety

» Install the sensor in a stable location that is not subject to ickering.

» Install the transmitter and receiver so that they are aligned;

» LGPD - General Law for the Protection of Personal Data: Intelbras does not access, transfer, capture, or perform any other

type of treatment of personal data from this product.

» Do not install the sensor in locations where beam obstruction may occur. Check that there are no plants, branches or

other objects that could obstruct the sensor beam;

» Do not install the receiver and transmitter with the lens facing the sun;

» Make sure that the sealing rubbers are installed in order to prevent the entry of water and insects;

» Size the power supply and power cord correctly;

» Do not leave the cable exposed to the sun, rain or moisture;

» Do not install the sensor above the recommended distance;

» Always check that there are no reections on clear and polished surfaces, which can prevent the sensor from triggering.

Do walking tests in different positions along the barrier to make sure there are no reections;

» To clean the outside of the sensor, use a cloth moistened with water; never use chemicals.

» Avoid installing the receiver near sources of electromagnetic noise. After installation, perform tests to verify the correct

functioning of the product. In case of interference, exchange the Transmitter with the Receiver;

» For installation of stacked sensors, the maximum number of sensors installed is 4 (four) and they must be in different

frequency channels, as shown in the image below. For installation in perimeters, follow the channel arrangement also

shown in the gure below;

X

TX

Channel 1

RX

Channel 1

RX

Channel 3

TX

Channel 3

TX

Channel 2

TX

Channel 4

RX

Channel 4

RX

Channel 2

TX

Channel

1

RX

Channel

1

TX

Channel 1

RX

Channel 3

TX

Channel 3

RX

Channel 1

TX

Channel 4

TX

Channel 2

RX

Channel 4

RX

Channel 2

Perimeter

TX

Channel 1

RX

Channel 1

RX

Channel 3

TX

Channel 3

TX

Channel 2

TX

Channel 4

RX

Channel 4

RX

Channel 2

» In order to avoid interference between sensors on the same channel, respect the side protection distance as specied

below.

TX

Channel 1

TX

Channel 1

RX

Channel 1

RX

Channel 1

Side protection distance

Distance between TX and RX

DPL DPL

TX

RX

» For the IVA 9100 TRI sensor, follow the protection distances below:

Distance between TX and RX

20 m 60 m 100 m 200 M

Side Protection Distance (DPL) > 2.5 m > 7.5 m > 12.5 m > 25 M

Vertical Protection Distance (DPV) Maximum stacking of 4 sensors on different frequency channels

That is, the Side Protection Distance is always the distance between RX and TX divided by 8 (eight).

Distance between TX and RX

8

DPL> [m]

In outdoor environments with a high rate of fog or rain, install the sensors at a maximum of 50%

of the distance specied for each model, in order to avoid false alarms.

6

1. Technical specications

Number of beams 3

Power supply voltage 12 ~ 24 Vdc / Vac

Consumption current (TX + RX) ≤ 100 mA @ 12 Vdc

Frequency channels 4 channels - CH1, CH2, CH3 and CH4

Maximum distance between TX

and RX

Indoor: 200 m

External: 100 m

Alarm output Independent NA / NF terminals, 1 A max

Response time Adjustable: 50 ms, 100 ms, 300 ms and 700 ms

Alarm Time ≥ 2s

Detection method Block all 3 beams simultaneously

Alignment indication LED Alignment and 2-digit display

Trigger indication Trigger LED and 2-digit display

Tamper Independent output, without polarity and normally closed on RX and TX

Heater

function Yes, on RX and TX2

Horizontal Alignment 180° (± 90°)

Vertical Alignment 20° (± 10°)

Solar lter for outdoor environments Yes

Operating temperature -10 ºC to + 55 ºC

IP protection grade IP65

Color Black

Weight 1500 g, approx.

Dimensions (B × W × D) 90.5 × 290.8 × 92 mm

1

Current consumed without updating the heater.

2

The heating element is not included with the product.

2. Product

Front Cover

Screw

Intelbras

Shield

2 digit display Brackets for installation on poles

Base

Cover xing screw nut

Passage

installation

screws

Conguration DIP

Switches

Base

Terminals

Passage of the wire

Tamper

Lentes

Adjust vertical alignment

Latch adjustment

horizontal alignment

Status LEDs

7

3. General characteristics

The IVA 9100 TRI sensor is a 3-beam active infrared sensor designed for the most adverse scenarios. Several features and

functionality have been added to the sensor to provide robustness, the main ones being described below:

» High quality optical assembly;

» Visualization of the alignment level by display: in order to facilitate the alignment of the sensors, the product has a 2-digit

display that indicates the alignment level. It is always recommended to align the sensors with the level of 99, reducing

the possibility of unwanted shots;

» Heating output for connection with a resistor in order to avoid dew and/or dirt in the sensor cabinet.There are two modes

of operation of the heater:

» Intelligent: the heating resistor is activated when the temperature drops below +5 ° C and turned off when the temperature exceeds

+10 ° C;

» On: keeps the heating element always on. This mode is recommended only for testing the functioning of the resistor.

The heating resistance is a high power resistor that has the purpose of generating heat in order to

avoid the accumulation of dew and / or dirt on the outside of the cabinet, which is widely used in

barrier sensors. It must follow the following specications:

Product supply voltage: 12 Vdc / Vac Product supply voltage: 24 Vdc / Vac

3 W power 5W power

Maximum current 200 mA Maximum current 200 mA

Recommended resistance from 68Ω / 3 W to 120 Ω / 3 W Recommended resistance from 120Ω / 5 W to 300Ω / 5 W

Whenever the heating resistor is used, function tests must be carried out in the On mode to check the behavior of the

resistor. After testing, it is recommended to keep the Heater in Intelligent operating mode. This function is recommended

only for regions of extreme cold.

Make sure that the amperage of the power supply is sufcient to supply current to the heater.

» Energy saving mode, which turns off the display and the LEDs of the receiver after 30 min without the infrared barrier

being interrupted;

» Response time adjustable from 50 to 700 ms;

» 4 Frequency channels

» Intelbras shield.

8

Below are the congurations of the Receiver and Transmitter.

Receiver Settings

Frequency channels Keys 1 and 2

CH1 - Frequency channel 1

CH2 - Frequency channel 2

CH3 - Frequency channel 3

CH4 - Frequency channel 4

Heater key 3

Intelligent - turns the heater on below + 5 ° C

and turns it off above + 10 ° C

On - the heater is constantly on

Response time Keys 4 and 5

50 ms

100 ms

300 ms

700 ms

Transmitter Settings

Frequency channels Keys 1 and 2

CH1 - Frequency channel 1

CH2 - Frequency channel 2

CH3 - Frequency channel 3

CH4 - Frequency channel 4

Heater key 3

Intelligent - turns the heater on below + 5 ° C

and turns it off above + 10 ° C

On - the heater is constantly on

4. Installation

1. To identify the Transmitter and Receiver, simply check the label located on the back of the product. Below, the step by

step to open the sensor cabinet and perform the installation:

IVA 9100 TRI - RECEPTOR

Remova o

parafuso

Etiqueta de

Identificação

Remova a tampa frontal

conforme movimento

indicado na figura

Identica-

tion Tag

Remove the screw

Remove the front cover as

shown in the gure

9

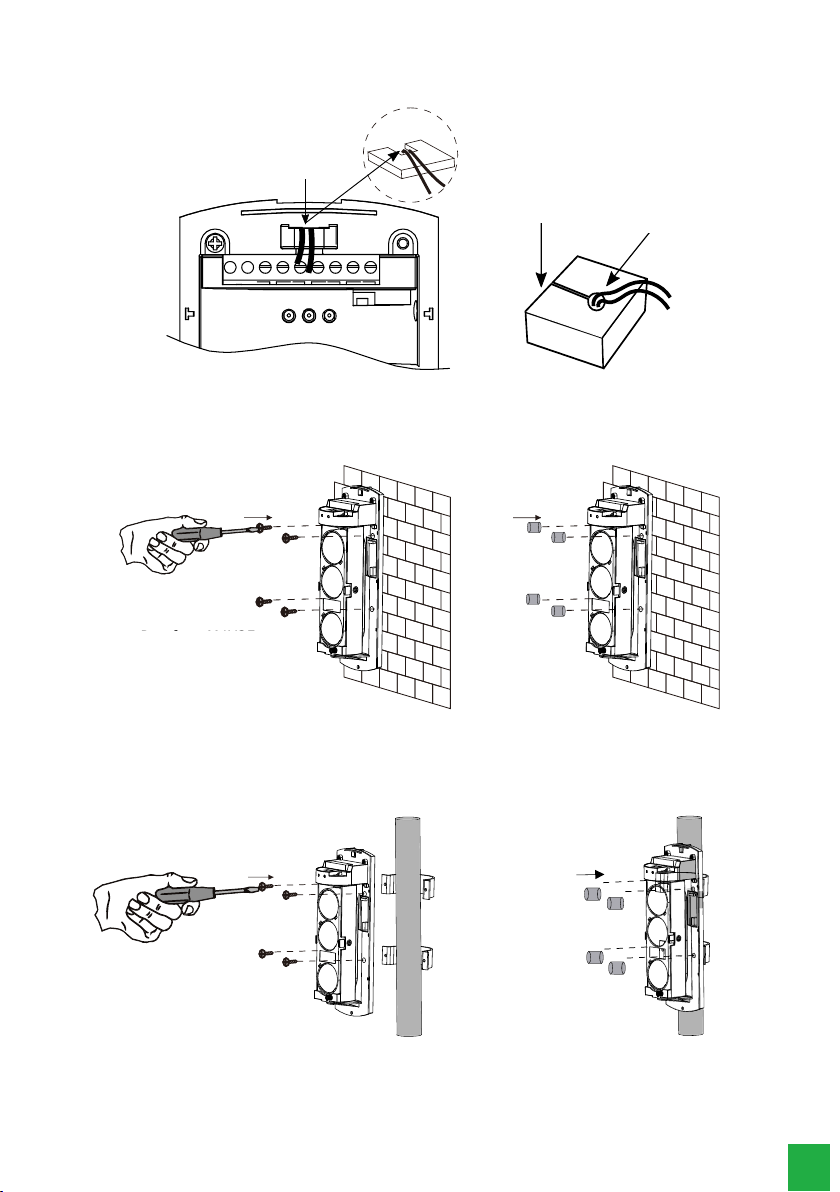

2. After identication, run the cable as shown in the following image to connect it to the terminal block: Use the sealing

rubber to prevent insects from entering the sensor:

Passagem

de cabo

Borracha de

vedação Cabo

passage of the cable

Sealing Rubber

Cable

3. Attach the sensors in the installation position and then use the screw sealing rubbers, following the recommendations

below:

a) Wall installation

Parafuso M4X25mm Borracha de

vedação

1ª 2ª

Screw M4 × 25 mm

2nd1st

Sealing Rubber

b) Pole installation

Note:

it is recommended to use a pole with a diameter of Ø38 ~ Ø50 mm.

Parafuso M4x30mm

Borracha de

vedação

1ª 2ª

Screw M4 × 30 mm

1st 2nd

Sealing Rubber

10

4. Connect the wires to the terminals following the guidelines below.

» Connect the power to the receiver and transmitter board (12 ~ 24 Vdc / Vac - no polarity);

» Connect the wires from the sensor’s alarm output to the zone input of your control panel;

» Both the Receiver and the Transmitter have a normally closed and tamper independent output. If desired, connect the wires from the tamper output to the

zone input of your control panel.

12~24

VAC/DC TAMPER AQUECEDOR 12~24

VAC/DC CM NF NA TAMPER AQUECEDOR

FONTE

GND +12V

Connect the

control panel Connect the control panel

Transmissor Receptor

Transmitter Receiver

5. Both the Receiver and the Transmitter have an independent Heater output, which is recommended for extremely cold

areas. If desired, connect the heater output wires to a resistor.

key 3 Intelligent - turns the heater on below + 5 ° C and turns it off above + 10 ° C

On - the heater is constantly on

12~24

VAC/DC TAMPER AQUECEDOR 12~24

VAC/DC CM NF NA TAMPER AQUECEDOR

Transmissor Receptor

Resistance Resistance

Transmitter Receiver

6. Congure the frequency channel using the keys (Keys 1 and 2) Frequency channels. For the sensor to function correctly, the

transmitter (TX) and receiver (RX) must be on the same frequency channel:The factory default is frequency channel 1 (CH1).

123

ON 123

ON 45

Transmissor

12

Canais de Frequência

CH1

CH2

CH3

CH4

12

Canais de Frequência

CH1

CH2

CH3

CH4

Receptor

Transmitter Receiver

Frequency channels

Frequency channels

7. Congure the response time using the keys (Keys 4 and 5) Response time. This setting determines the time that the bea-

ms must be blocked to trigger the sensor, being congured only at the receiver. The table below associates the response

time with the interruption speed of the beams to assist in choosing the response time. The factory default is 50 ms.

123

ON 45

Receptor

45

Tempo de Resposta

50MS

100MS

300MS

700MS

45

Receiver

Response time

Response time Detection Speed

50 ms Intense running

100 ms Moderate running

300 ms Light running

700 ms Walking

11

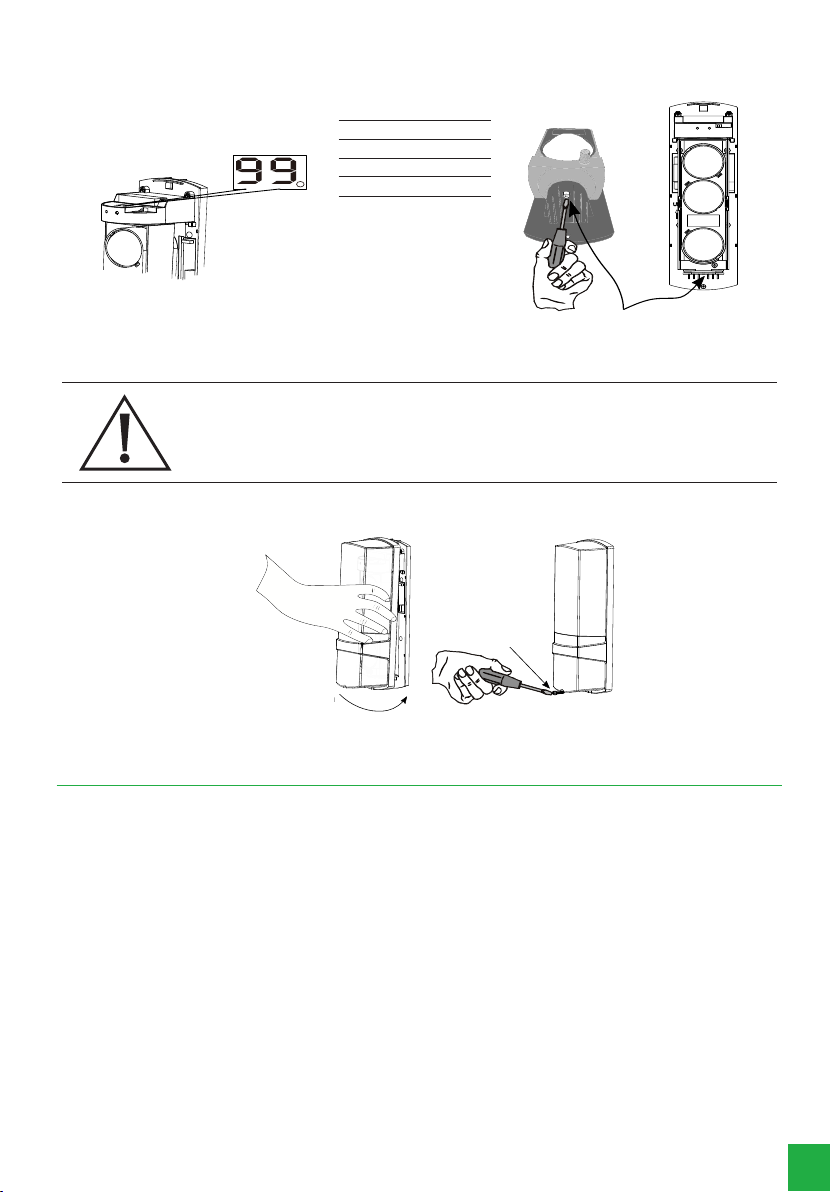

8. Align the sensors. The quality of the sensor alignment is identied by the 2-digit display located on the Receiver according

to the table below. After aligning, tighten the horizontal adjustment screw.

Trava ajuste alinhamento

horizontal

Signal level

95 ~ 99 Great

90 - 94 Good

80-89 Poor

01 ~ 79 Very Poor

Lock adjustment horizon-

tal alignment

It is recommended that when aligning the sensors, the level observed on the display is 99.

Perform walking tests at various points on the barrier to make sure that there is no reection from

the infrared beams on the oor, wall or reective objects. If reection is found, it will be necessary to

change the installation position of the sensor.

9. After completing the conguration, t the top of the cover to the base and tighten the cover xing screw on the trans-

mitter and receiver, as shown in the gure below:

Aperte o

parafuso

Coloque a tampa

frontal conforme

indicado na figura

Tighten

the screw.

Place the front

cover as shown in

the gure

5. Troubleshooting

Follow the steps outlined below to troubleshoot your sensor:

1. Check that the installation distance is within the specied. In environments with a high rate of rain or fog, it is recom-

mended that the installation distance be 50% of the maximum distance for outdoor environments;

2. Check the installation wiring and that the supply voltage in the TX and RX is between 12 and 24 Vdc / Vac;

3. Check that both TX and RX are on the same frequency channel, which is selected using the frequency channel switches;

4. Check that the Response Time setting, which is selected using the Response Time switches from 50 ms to 700 ms, is in

accordance with the speed expected to cross the infrared beam;

5. If the heater is being used, change it to

On

using the heater conguration switch and check again that the supply voltage

on the TX and RX is between 12 and 24 Vdc / Vac to make sure that the power supply supports the amperage heating

resistance. After this test, return the heater conguration to its initial state;

6. Redo the alignment procedure;

7. Perform the detection test and conrm that there are no reections.

8. Your infrared barrier sensor will be working!

12

Warranty term

It is established that this warranty is granted upon the following conditions:

Client’s name:

Client’s signature:

Invoice number:

Date of purchase:

Model: Serial number:

Retailer:

1. All the parts, pieces and components of the product are guaranteed against possible manufacturing defects, which may

arise, for the term of 1 (one) year - this being 90 (ninety) days of legal warranty and 9 (nine) months’ contractual war-

ranty –, counting from the date of purchase of the product by the Consumer, as appears in the product purchase bill of

sale, which is an integral part of this Term throughout the domestic territory. This contractual warranty includes the free

exchange of parts, pieces and components which have a manufacturing defect, including the expenses with labor used in

this repair. If there is no manufacturing defect, but defect(s) arising from misuse, the Consumer shall bear these expenses.

2. The installation of the product shall be executed in accordance with the Product Manual and/or Installation Guide. If your

product requires the installation and conguration by a qualied technician, seek a suitable specialized professional, the

costs of these services not being included in the product amount.

3. Having perceived the defect, the Consumer shall immediately contact the nearest Authorized Service which appears in

the report offered by the manufacturer – they are the only ones authorized to examine and remedy the defect during the

warranty term foreseen herein. If this is not respected, this warranty shall lose its validity, as it shall be characterized as

product infringement.

4. If the Consumer requests home service, it shall contact the nearest Authorized Service to inquire about the technical visit

rate. If it is necessary to remove the product, the ensuing expenses, such as those of transportation and insurance of the

taking and return of the product, shall be the Consumer’s responsibility.

5. The warranty shall lose its validity totally in the occurrence of any of the following cases: a) if the defect is not one of manu-

facture, but is caused by the Consumer or by third parties foreign to the manufacturer; b) if the damage to the product arises

from accidents, disasters, agents of nature (lightning, oods, landslides, etc.), humidity, voltage in the electrical network

(excess voltage caused by accidents or excessive uctuations in the network), installation/use in disagreement with the

user’s manual or arising from natural wear of the parts, pieces and components; c) if the product has undergone effects of a

chemical, electromagnetic, electrical or animal (insects, etc.) nature; d) if the serial number of the product has been falsied

or erased; e) if the appliance has been infringed.

6. This warranty does not cover loss of data; therefore, it is advisable that if it is the case of the product, the Consumer makes

a backup regularly of the data which appears in the product.

7. Intelbras is not responsible for the installation of this product, or for possible attempts at fraud and/or sabotage in its

products. Maintain the updates of the software and applications used up-to-date, if it is the case, as well as the network

protection required for defense against hackers. The equipment is guaranteed against defects in its usual conditions of use,

it being important to bear in mind that, as it is electronic equipment, it Is not free of fraud and scams which may interfere

with its correct functioning.

8. After its useful life, the product must be delivered to an authorized Intelbras service center or directly disposed of in an

environmentally appropriate manner to avoid environmental and health impacts. If you prefer, the battery, as well as other

unused Intelbras brand electronics, can be disposed of at any Green Eletron collection point (waste management facility

to which we are associated). If you have any questions about the reverse logistics process, please contact us at (48) 2106-

0006 or 0800 704 2767 (Monday to Friday 8am to 8pm and Saturdays 8am to 6pm) or via -mail [email protected].

These being the conditions of this complementary Warranty Term, Intelbras S/A reserves the right to alter the general,

technical and esthetic features of its products without prior notice.

The manufacturing process of this product is not covered by the requirements of ISO 14001.

All the images of this manual are illustrative.

01.21

Made in China

Customer Support: (48) 2106 0006

Forum: forum.intelbras.com.br

Support via chat: intelbras.com.br/suporte-tecnico

Support via e-mail: suporte@intelbras.com.br

Customer Service: 0800 7042767

Where to buy? Who installs it? 0800 7245115

Imported to Brazil by: Intelbras S/A – Indústria de Telecomunicação Eletrônica Brasileira

Rodovia SC 281, km 4,5 – Sertão do Maruim – São José/SC – 88122-001

CNPJ 82.901.000/0014-41 – www.intelbras.com.br

Table of contents