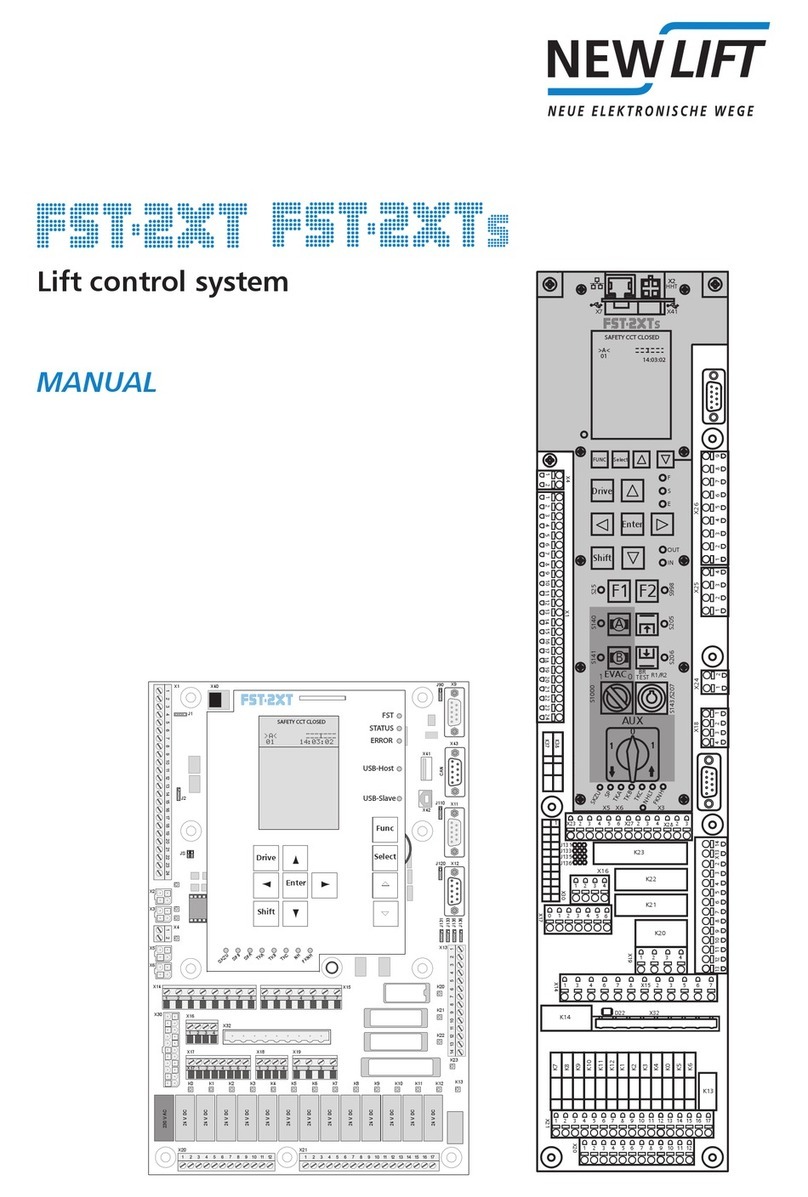

Intelligent Motion Systems MicroLYNX-4 Installation guide

QuickMANUAL

Hardware

Software

Applications

The information in this book has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for inaccuracies.

Intelligent Motion Systems, Inc., reserves the right to make changes without further notice to any products herein to

improve reliability, function or design. Intelligent Motion Systems, Inc., does not assume any liability arising out of the

application or use of any product or circuit described herein; neither does it convey any license under its patent rights of

others. Intelligent Motion Systems and are trademarks of Intelligent Motion Systems, Inc.

Intelligent Motion Systems, Inc.’s general policy does not recommend the use of its products in life support or aircraft

applications wherein a failure or malfunction of the product may directly threaten life or injury. Per Intelligent Motion

Systems, Inc.’s terms and conditions of sales, the user of Intelligent Motion Systems, Inc., products in life support or

aircraft applications assumes all risks of such use and indemnies Intelligent Motion Systems, Inc., against all damages.

TM

MicroLYNX MQuick Manual Revision R051205

Copyright © 2006 Intelligent Motion Systems, Inc., All Rights Reserved

Change Log

Date Revision Changes

1

Table Of Contents

Section 1: Introduction To The MicroLYNX ............................................ 5

Electrical Specifications ................................................................................................................6

Communications Specifications ........................................................................................7

Mechanical Specifications.................................................................................................7

Environmental Specifications ............................................................................................7

Connector Information.......................................................................................................8

Mounting Information ........................................................................................................9

MicroLYNX Terminology Explained...................................................................................9

Shopping List...................................................................................................................10

Section 2: Connecting Power................................................................. 11

Tools and Equipment Required.......................................................................................11

How to Connect Power....................................................................................................11

Section 3: Connecting A Motor.............................................................. 13

Tools and Equipment Required.......................................................................................13

Recommended Stepping Motors.....................................................................................13

How to Connect the Motor ..............................................................................................13

Section 4: Connecting Communications .............................................. 17

Tools and Equipment Required.......................................................................................17

Connecting Communications ..........................................................................................17

Section 5: Establishing Communications............................................. 20

Tools and Equipment Required.......................................................................................20

Installing the IMS Terminal Software ..............................................................................20

Using the IMS Terminal Software ...................................................................................21

Section 6: Controlling Motor Current.................................................... 24

Current Control Variables................................................................................................24

Section 7: Setting The Motor Resolution.............................................. 25

Setting the Motor Resolution Exercise ............................................................................25

Section 8: Using The Isolated Digital I/O .............................................. 26

The Isolated Digital I/O Defined ......................................................................................26

Setting the Pull-up Voltage..............................................................................................27

The Input Output Setup Variable.....................................................................................28

The IO Variable ...............................................................................................................32

Setting the Digital Filtering for the I/O .............................................................................34

Section 9: Expanding The MicroLYNX .................................................. 35

MicroLYNX Expansion Modules......................................................................................35

Choosing the Expansion Modules for Your Application ..................................................35

Expanding the Isolated Digital I/O...................................................................................36

The High-Speed Differential I/O Module .........................................................................38

The Analog Input/Joystick Module ..................................................................................46

The Isolated Communications Module............................................................................50

The Analog Output Module .............................................................................................51

The 12 Channel Isolated Digital I/O Module ...................................................................53

2

Section 10: MicroLYNX Software Components.................................... 56

LYNX Software Components ..........................................................................................56

Variables .........................................................................................................................56

Commonly Used Variables..............................................................................................56

Instructions......................................................................................................................59

Flags................................................................................................................................65

Keywords.........................................................................................................................65

Section 11: MicroLYNX Programming................................................... 66

Introduction to MicroLYNX Programming........................................................................66

Program Development Steps ..........................................................................................67

Program Samples ...........................................................................................................69

Section 12: Sample Applications........................................................... 73

Feed Cut 1.......................................................................................................................73

Read and Feed................................................................................................................76

AND - OR ........................................................................................................................78

On-The-Fly ......................................................................................................................79

Registration .....................................................................................................................81

Traverse ..........................................................................................................................84

Appendix A: Software Summary ........................................................... 87

Appendix B: Troubleshooting................................................................ 93

Beginning to Troubleshoot ..............................................................................................93

Troubleshooting Communications...................................................................................93

Troubleshooting Software ...............................................................................................93

Contacting Application Support.......................................................................................95

Appendix C: Error Table......................................................................... 96

Appendix D: Recommended Cable Configurations ............................. 99

List of Figures

Figure 1.1 Dimensional Information...............................................................................7

Figure 1.2 Connector Pin Configuration ........................................................................8

Figure 1.3 Panel Mounting the MicroLYNX ...................................................................9

Figure 2.1 MicroLYNX Power Connection ...................................................................12

Figure 3.1 8 Lead Motor, Series Connection ...............................................................14

Figure 3.2 8 Lead Motor, Parallel Connection .............................................................15

Figure 3.3 6 Lead Motor, Full Coil Connection ............................................................15

Figure 3.4 6 Lead Motor, Half Coil Connection............................................................16

Figure 3.5 4 Lead Motor Connection ...........................................................................16

Figure 4.1 MicroLYNX with IMS Communications Cable ............................................17

Figure 4.2 RS-232 Interface Connection .....................................................................18

Figure 4.3 RS-485 Interface Connection .....................................................................19

Figure 5.1 IMS Terminal Main Window........................................................................21

Figure 5.2 IMS Terminal Communications Setup Window ..........................................22

Figure 5.3 IMS Terminal Download Dialog ..................................................................23

Figure 5.4 IMS Terminel Upload Dialog.......................................................................23

Figure 6.1 Motor Current Control Variables.................................................................24

Figure 8.1 Isolated I/O Pin Configuration.....................................................................26

Figure 8.2 Isolated I/O Applications.............................................................................27

Figure 8.3 The IOS Variable Settings ..........................................................................28

Figure 8.4 IOS Exercise #1..........................................................................................29

3

Figure 8.5 IOS Exercise #2A .......................................................................................29

Figure 8.6 IOS Exercise #2B .......................................................................................30

Figure 8.6 I/O Variable Exercise Setup .......................................................................33

Figure 9.1 Installing the Isolated Digital I/O Module ....................................................37

Figure 9.2 The Isolated Digital I/O Module, Bottom View............................................37

Figure 9.3 Powering Multiple Isolated Digital I/O Modules ..........................................38

Figure 9.4 Installing the High-Speed Differential I/O Module.......................................39

Figure 9.5 Clock Functions ..........................................................................................40

Figure 9.6 IOS Settings for the High-Speed Differential I/O ........................................41

Figure 9.7 Differential Encoder Connection.................................................................42

Figure 9.8 Differential I/O Connections for Following ..................................................45

Figure 9.9 Installing the Analog Input/Joystick Module................................................47

Figure 9.10 Analog Input Module Exercise Connection.................................................48

Figure 9.11 Installing the Isolated Communications Module .........................................50

Figure 9.12 Installing the Analog Output Module...........................................................51

Figure 9.13 Installing the 12 Channel Isolated I/O Module............................................54

Figure 9.14 12 Channel I/O Module Pull-Up Switches ..................................................54

Figure 9.15 Powering Multiple Isolated Digital I/O Modules ..........................................55

Figure 10.1 Setting the MUNIT Variable........................................................................57

Figure 10.2 Motion Profile Showing Basic Parameters .................................................58

Figure 10.3 MOVA Instruction Modes............................................................................60

Figure 11.1 Flowchart Used for Program Planning........................................................67

Figure 12.1 Feed Cut Application ..................................................................................73

Figure 12.2 Feed Cut Application Flowchart..................................................................74

Figure 12.3 Read and Feed Application ........................................................................76

Figure 12.4 Read and Feed Application Flowchart........................................................76

Figure 12.5 On-The-Fly Application...............................................................................79

Figure 12.6 On-The-Fly Application Flowchart ..............................................................80

Figure 12.7 Registration Application ..............................................................................81

Figure 12.8 Registration Application Flowchart .............................................................82

Figure 12.9 Traverse Application ...................................................................................84

Figure 12.10Traverse Application Flowchart ..................................................................85

List of Tables

Table 4.1 RS-232 Interface Connection .....................................................................18

Table 4.2 RS-485 Interface Connection .....................................................................19

Table 7.1 Microstep Resolution Settings ....................................................................25

Table 8.1 Binary State of Outputs ..............................................................................33

Table 8.2 IOF Settings................................................................................................34

Table 9.1 MicroLYNX Expansion Module Configurations...........................................36

Table 9.2 Isolated Digital I/O Group and Line Locations............................................36

Table 9.3 High Speed Differential Electrical Characteristics ......................................39

Table 9.4 High Speed Differential I/O Pinout..............................................................39

Table 9.5 The Four Clocks and Their Default Line Placement...................................40

Table 9.6 Expansion Slot #2 Encoder Connections ...................................................42

Table 9.7 Analog Input Module Specifications ...........................................................46

Table 9.8 Analog Input/Joystick Module Pin Configuration ........................................46

Table 9.9 RS-232 Pinout ............................................................................................50

Table 9.10 RS-485 Pinout ............................................................................................50

Table 9.11 Analog Output Module Pinout.....................................................................51

Table 9.12 12 Channel Isolated I/O Module Pinout......................................................53

4

This Page Intentionally

Left Blank

5

Introduction To The MicroLYNX

The MicroLYNX is a powerful machine control system

which combines a bipolar microstepping driver with an

expandable programmable controller in a compact

panel mounted assembly.

With the addition of differential I/O modules, the Micro-

LYNX has the capability of driving two additional axes

sequentially or driving a following axis electronically

geared to the on-board driver.

The MicroLYNX includes two independent communica-

tion ports. It will accept commands from either port and

direct output to either as well. A system may be config-

ured to use COMM Port 1 to communicate to a host PC

or PLC while using the COMM Port 2 to communicate

with an operator interface or additional MicroLYNX

systems.

The MicroLYNX comes in two output power ranges

(12-48 VDC, 3 Amp RMS-4Amp Peak, and 24-75 VDC, 5 Amp RMS-7 Amp Peak) to fit a variety

of motor sizes. Features such as 5 to 24VDC isolated I/O, multiple communication types, and

numerous expansion options make the MicroLYNX an effective and powerful machine control

solution.

Plug-on accessory modules allow control system

designers to tailor the MicroLYNX System to their

needs with minimal cost. The MicroLYNX may be field

upgraded by simply removing the side cover and

adding expansion modules.

The MicroLYNX software is upgradeable by using the

IMS Terminal Software. Updates are posted on the

IMS web site at www.imshome.com and may be

downloaded. This allows older units the ability to use

new features and expansion modules as they become

available.

This Quick Guide is a step-by-step usage guide for the

MicroLYNX. While not intended to replace the product

manual, it is essential in acquiring a thorough under-

standing of the MicroLYNX System. This Quick Guide

provides the user with detailed connection and usage

examples for the MicroLYNX and its associated expansion modules, as well as the most com-

monly used components of the MicroLYNX instruction set. It also includes an introduction to

MicroLYNX programming.

1

6

Electrical Specifications

Power Supply Requirements

See Section 2: Connecting Power for the recommended power supplies.

Power Supply Voltage for:

MicroLYNX - 4 (MX-CS100-401)................................. +12 to +48VDC

MicroLYNX - 7 (MX-CS100-701)................................. +24 to +75VDC

Power Supply Output Current for:

MicroLYNX - 4 (MX-CS100-401)................................. 2A Typ., 4A Peak

MicroLYNX - 7 (MX-CS100-701)................................. 3A Typ., 7A Peak

Actual requirements depend on application and programmable current setting.

Motor Drive

See Section 3: Connecting a Motor for recommended motors; Section 6: Controlling the Motor

Current and Section 7: Setting the Motor Resolution for details on the following specifications.

Motor Type .................................................................... 2/4 Phase bipolar stepper

Motor Current (Software Programmable)

MicroLYNX - 4 ................................................ to 4A Peak

MicroLYNX - 7 ................................................ to 7A Peak

Microstep Resolution (# of settings)............................ 14

Steps per Revolution (1.8° Motor)............................... 400, 800, 1000, 1600, 2000,

3200, 5000, 6400, 10000,

12800, 25000, 25600, 50000,

51200.

Isolated Digital I/O

See Section 8: Using the Isolated Digital I/O for usage instructions.

Number of I/O .............................................................. 6 std, expandable to 24

Input Voltage ............................................................... +5 to +24VDC

Output Current Sink .................................................... 350mA per Line

Input Filter Range (Programmable) ............................ 215Hz to 21.5kHz

Pull-up Resistors ......................................................... 7.5 kΩswitchable

Pull-up Voltage (max)

Internal (Not an Output).................................. +5VDC

External .......................................................... +24VDC

Protection .................................................................... Over temp, short circuit,

inductive clamp

Isolated Ground........................................................... Common to the 6 I/O lines

7

Communications Specifications

See Sections 4 & 5 for connection and usage details.

Interface Type

COMM 1 ......................................................... RS-232

COMM 2 ......................................................... RS-485

# Bits per Character .................................................... 8

Parity ........................................................................... None

Handshake .................................................................. None

BAUD Rate.................................................................. 4800 to 38.4kbps (9600 Default)

Error Checking ............................................................ 16 bit Check Sum (binary mode)

Communication Modes ............................................... ASCII Text or Binary

Isolated Ground............................................................. Common to COMM 1 and 2

Mechanical Specifications

Dimensions ................................................................. See figure 1.1

# of Expansion Modules.............................................. 3

Cooling ........................................................................ Built-in fan

Recommended Mounting Hardware ........................... 2 #6 (M3.5) machine screws

Mounting Screw Torque .............................................. 5 to 7 lb-in (0.60 to 0.80 N-m)

Environmental Specifications

Ambient Operating Temperature ................................ 0 to 50°C*

Storage Temperature .................................................. -20 to 70°C

Humidity ...................................................................... 0 to 90% non-condensing

* Can be duty cycle dependent.

Figure 1.1: Dimensional Information, Dimensions in Inches (mm)

8

Figure 1.2: Connector Pin Configuration

Connector Information

MicroLYNX Connections

Communications: 7 Position Phoenix

I/O: 10 Pin Header

I/O LINE 21: PIN 1

VPULLUP: PIN 3

FAULT + INPUT: PIN 5

FAULT - INPUT: PIN 7

I/O Ground (Isolated): PIN 9

PIN 2: I/O LINE 22

PIN 4: I/O LINE 23

PIN 6: I/O LINE 24

PIN 8: I/O LINE 25

PIN 10: I/O LINE 26

PIN 1: RS-232 RX

PIN 2: RS-232 TX

PIN 3: RS-485 RX-

PIN 4: RS-485 RX+

PIN 5: RS-485 TX-

PIN 6: Communications Ground

PIN 7: RS-485 TX+

MOTOR PHASE A

MOTOR PHASE A

MOTOR PHASE B

MOTOR PHASE B

POWER SUPPLY INPUT (+V)

POWER SUPPLY RETURN (GND)

PIN 1: V PULLUP

PIN 2: I/O LINE 21

PIN 3: I/O LINE 22

PIN 4: I/O LINE 23

PIN 5: I/O LINE 24

PIN 6: I/O LINE 25

PIN 7: I/O LINE 26

PIN 8: I/O Ground (Isolated)

PIN 2: RS-232 TX

PIN 4: N.C.

PIN 6: RS-485 RX+

PIN 8: RS-485 TX-

PIN 10: Communications Ground

MOTOR PHASE A

MOTOR PHASE A

MOTOR PHASE B

MOTOR PHASE B

POWER SUPPLY INPUT (+V)

POWER SUPPLY RETURN (GND)

N.C.: PIN 1

RS-232 RX: PIN 3

Communications Ground: PIN 5

RS-485 RX-: PIN 7

RS-485 TX+: PIN 9

MicroLYNX Connections

Communications: 10 Position Header

I/O: 8 Position Phoenix

1 2 3 4 5

6 7 8 9

PIN 2: RS-232 Receive Data (RX)

PIN 3: RS-232 Transmit Data(TX)

PIN 5: Communications Ground

9 Pin Serial COMM Port

PIN 2: RS-232 Receive Data (RX)

PIN 3: RS-232 Transmit Data(TX)

PIN 7: Communications Ground

25 Pin Serial COMM Port

MicroLYNX Terminal/PC

RX

TX

CGND

TX

RX

CGND

RS-232 Communications Connections

MicroLYNX I/O

V PULLUP

IO 2x

IO GND

Current

Limiting

Resistor LED

+5 to +24

VDC

+V

Output To LED

MicroLYNX I/O

IO 2x

IO GND

Normally

Open Switch

Input Controlled ByASwitch

PHASEA

PHASEA

PHASE B

PHASE B

8 Lead Motor - Series Connection

{

Please See the full Product

Manual for Details

Gnd

9

Mounting Information

The MicroLYNX

System may be

mounted to a

panel by using

standard #6 (M3)

hardware. No heatsinking

is necessary as the system has a

built-in cooling fan. When mounting the

MicroLYNX in an enclosure, ensure that

adequate space is available for air flow on

the fan side of the MicroLYNX case. Mount-

ing screws should be tightened to 5 to 7 lb-in

(0.60 to 0.80 N-m) torque.

MicroLYNX Terminology Explained

Throughout this book several terms will be used which apply to the MicroLYNX. They are:

Flag

MicroLYNX software component that may be set to a logic state to indicate status and enable/

disable functions. Flags may be either system or user-defined.

Immediate Mode

MicroLYNX mode of operation where commands are issued directly from IMS Terminal to the

MicroLYNX.

Instruction

MicroLYNX software component used to direct events inside or outside a program.

Isolated Digital I/O

MicroLYNX programmable I/O. Electrically isolated from motor power ground.

Label

1 to 8 character alpha-numeric name that may be assigned to a program, subroutine, or user-

defined variable or flag.

MUNITs

The munit term is derived from the MUNIT, or Motor UNIT variable, which is the scaling factor by

which drive step clock pulses are converted to some unit of distance measure. The MUNIT

variable specifies the number of microsteps per user unit (inches, degrees, millimeters, etc.).

Once MUNIT is established, motion variables (position, velocity, acceleration, etc.) may be

expressed in terms of user units. Almost all the MicroLYNX motion, position, velocity, accelera-

tion and deceleration variables and instructions will be affected by this variable.

Mounting Screw Torque

Specification:

5 to 7 lb-in (0.60 to 0.80 N-m)

Figure 1.3: Panel Mounting the MicroLYNX

10

Party Mode

MicroLYNX mode of operation in which two or more MicroLYNX are networked via RS-485.

Each MicroLYNX node has an address specified by using the “DN” instruction. This address

must preceed the messages intended for a specific node. The default address is the exclama-

tion point character “!”.

Program Mode

MicroLYNX mode of operation where program entry is accomplished.

User Unit

See the definition for munits.

Variable

LYNX software component that acts as a register to contain numeric information. May be used

to effect events in or out of a program. The programmer is required to declare user-defined

variables.

Shopping List

This book contains several exercises designed to aquaint you with the MicroLYNX. Performing

these exercises while reading this guide will help you learn quickly. There are a few items that

you will need to purchase in addition to the MicroLYNX System in order to duplicate these

exercises.

!An Unregulated Power Supply [Section 2].

!Power Cabling [Section 2].

!AC Line Cord* [Section 2].

!Stepping Motor [Section 3].

!Motor Cabling* [Section 3].

!Communications Cable [Section 4].

!IBM compatible Pentium PC w/free COM Port running a 32 bit Windows

version (9x, NT 4.0 SP6, 2000 SP1 or XP). NOTE: This is only required if you

are going to use the IMS Terminal to communicate and program your Micro

LYNX. If not, any platform or OS can be used with its native terminal and text

editor [Section 4].

!Six (6) LED’s: Digikey PN 160-1049-ND (has built-in current limiting resistors)

or equivalent [Section 8].

!Three (3) push button momentary switches [Section 8].

!+5 to +24VDC supply (9V battery will work) [Section 8].

!Small Standard Screwdriver.

*Power supply and motor may come already equipped.

11

Connecting Power

Tools and Equipment Required

!An unregulated power supply.

!Power cabling.

!A small standard screwdriver.

!An AC line cord (if the supply used is not equipped with one).

Power Supply Specifications

The following power supply specifications are recommended for the MicroLYNX

System:

Power Supply for the MicroLYNX-4

Output Voltage .................................................................+12 to +48VDC

Output Current .................................................................2A (typ.), 4A (peak)

Power Supply for the MicroLYNX-7

Output Voltage .................................................................+24 to +75VDC

Output Current .................................................................3A (typ.), 7A (peak)

Recommended IMS Power Supplies

The IP404 is a low-cost unregulated linear power supply which can handle varying load condi-

tions for the MicroLYNX-4. The IP804 is also a low-cost unregulated linear power supply that

has a higher voltage output for the MicroLYNX-7. Both of these power supplies are available in

either 120 or 240 VAC configuration.

Cabling

Please see Appendix D: Recommended Cable Configurations in the back of this

document.

How to Connect Power

IMS suggests the use of unregulated, properly sized power supplies. Refer to the Support

section of the IMS web site (www.imshome.com/app_notes.html) for selection tips.

NOTE: Regulated power supplies may become unstable during current in-rush. This is normal

with electric motors. This instability may cause damage to the MicroLYNX drive.

2

12

When connecting power to the MicroLYNX, ensure the following:

!At least 18 gauge wire is used for the MicroLYNX-4, 16 gauge for the MicroLYNX-7.

!+V and GND are not reversed.

!All connections are tight.

!Shielded twisted pair cabling with at least 1 twist per inch is used.

Figure 2.1: MicroLYNX Power Connection

Ensure the DC output of the power supply does not exceed the

maximum input voltage.

All power supply wiring should be a shielded, twisted pair to reduce

system noise.

Shield to

Earth/Chassis Ground

GROUP 20 I/O COMMUNICATIONS

MICRO

TM

PHASE A

PHASE A

PHASE B

PHASE B

+V

GND

123

J1

J2

J3

IMS Power Supply

AC Power

Connection

WARNING! A characteristic of all motors is back EMF. Back EMF is a source of current that can

push the output of a power supply beyond the maximum operating voltage of the driver. Care

should be taken so that the back EMF does not exceed the maximum input voltage rating of the

MicroLYNX.The maximum Specified Input Voltage of the MicroLYNX-4 and the MicroLYNX-7

includes Motor Back EMF, Power Supply Ripple and High Line.

13

Connecting A Motor

Tools and Equipment Required

The following is required to connect a motor to your

MicroLYNX System:

!A stepping motor.

!Motor cabling (if the motor is not so equipped).

!A small standard screwdriver.

A Stepping Motor

IMS recommends the following 1.8° Hybrid Stepping Motors for the MicroLYNX

System. All IMS motors are CE marked. For more detailed information on these

motors, please see the IMS motor catalog or the IMS web site at

www.imshome.com.

14 Frame (MicroLYNX-4)

Single Shaft Double Shaft

M-1410-0.75S ...........................................................................M-1410-0.75D

17 Frame (MicroLYNX-4)

Single Shaft Double Shaft

M-1713-1.5S.................................................................................M-1713-1.5D

M-1715-1.5S.................................................................................M-1715-1.5D

M-1719-1.5S.................................................................................M-1719-1.5D

23 Frame (MicroLYNX-4/-7)

Single Shaft Double Shaft

M-2218-3.0S.................................................................................M-2218-3.0D

M-2218-6.0S (MicroLYNX-7 only) ................................................M-2218-6.0D

M-2222-3.0S.................................................................................M-2222-3.0D

M-2222-6.0S (MicroLYNX-7 only) ................................................M-2222-6.0D

M-2231-3.0S.................................................................................M-2231-3.0D

M-2231-6.0S (MicroLYNX-7 only) ................................................M-2231-6.0D

34 Frame (MicroLYNX-7)

Single Shaft Double Shaft

M-3424-6.3S.................................................................................M-3424-6.3D

M-3431-6.3S.................................................................................M-3431-6.3D

M-3447-6.3S.................................................................................M-3447-6.3D

3

14

How to Connect the Motor

There are basically three different lead configurations of stepping motors with a total of five

different wiring configurations. These are:

8 Lead Motor

Series Configuration

A series motor configuration would typically be used in

applications where a higher torque at low speeds is

needed. Because this configuration has the most induc-

tance, the performance will start to degrade at higher

speeds. Use the unipolar current rating as the peak

output current.

Figure 3.1: 8 Lead Motor, Series Connection

PHASE A

PHASE A

PHASE A

PHASE A

PHASE B

PHASE B

PHASE B

PHASE B

IMS Inside-Out Stepping Motors

The new Inside Out Stepper (IOS) motors were designed and patented by IMS to bring versatil-

ity to small motors. These motors employ a unique multi-functional, hollow-shaft design. By

mounting a miniature ball screw to the front shaft face, the IOS motor can be converted to a ball

screw linear actuator. In addition to offering long life and high efficiency, ball screw linear actua-

tors may be field retrofitted. There is no need to throw the motor away due to wear of the nut or

screw.

Frame IMS P/N

17 Frame................................................................................................. M3-1713-IOS

23 Frame................................................................................................. M3-2220-IOS

34 Frame................................................................................................. M3-3424-IOS

42 Frame................................................................................................. M3-4247-IOS

Cabling

Shielded twisted pair cabling should be used to make the power supply connections to the

MicroLYNX in the following gauges:

MicroLYNX-4 ................................................................18 gauge

MicroLYNX-7 ................................................................16 gauge

15

NOTE: Typically step motor current ratings are unipolar for 8 and 6 lead motors.

NOTE: If bipolar series current is given, multiply by 1.4 to determine the peak output

current.

Parallel Configuration

An 8 lead motor in a parallel configuration

yields more torque at higher speeds than the

same motor wired in series. Multiply the per

phase (or unipolar) current rating by 2.0, or the

bipolar parallel current rating by 1.4 to deter-

mine the peak output current.

6 Lead Motor

Full Coil Configuration

The full coil configuration on a 6 lead motor should be used in applications where higher

torque at lower speeds is desired. This configuration is also referred to as full copper.

Use the per phase (or unipolar) current rating as the peak output current.

PHASE A

PHASE A

PHASE A

PHASE A

PHASE B

PHASE B

PHASE B

PHASE B

Figure 3.2: 8 Lead Motor, Parallel Connection

PHASE A

PHASE A

PHASE A

PHASE A

NO CONNECTION

PHASE B

PHASE B

PHASE B

PHASE B

NO CONNECTION

Figure 3.3: 6 Lead Motor, Full Coil Connection

16

4 Lead Motor

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding

inductance. In setting the driver output current, multiply the specified phase current by 1.4 to

determine the peak output current.

PHASE B

PHASE B

PHASE B

PHASE B

NO CONNECTION

PHASE A

PHASE A

PHASE A

PHASE A

NO CONNECTION

Figure 3.4: 6 Lead Motor, Half Coil Connection

PHASE A

PHASE A

PHASE A

PHASE A

PHASE B

PHASE B

PHASE B

PHASE B

Figure 3.5: 4 Lead Motor Connections

Half Coil Configuration

As previously stated, the half coil configuration uses 50% of the motor phase windings.

This gives lower inductance, hence, lower torque output at low speeds. As with the

parallel connection of 8 lead motor, the torque output will be increased at higher speeds.

This configuration is also referred to as half copper. In setting the driver output current,

multiply the specified per phase (or unipolar) current rating by 1.4 to determine the peak

output current.

17

Connecting Communications

One of the features that make the MicroLYNX a unique

product is its dual COMM ports. This allows for

simultaneous use of both the RS-232 and the RS-485

interface. This is especially useful in party mode where

several MicroLYNX nodes are networked in a system. This

section will illustrate connecting your MicroLYNX to a

communications host, typically a PC, using a single MicroLYNX and

either the RS-232 interface or the RS-485 interface. For instructions on

connecting communications to multiple MicroLYNX Systems see the

product manual.

Tools and Equipment Required

The following tools and equipment are required to connect communications to

your MicroLYNX System:

!IMS communications cable part # MX-CC100-000 or equivalent (if 10 pin

header version of the MicroLYNX is used).

!Communications cable (if 7 pin terminal version of the MicroLYNX is used).

!A free COM port on a PC.

Connecting Communications

RS-232 Interface

The following diagram and table illustrate the connection of both the RS-232 and the RS-485

interface to the MicroLYNX.

4

Figure 4.1: MicroLYNX with IMS Communications Cable

18

Figure 4.2: RS-232 Interface Connection

noitcennoCXNYLorciM232-SR

XNYLorciM CP

redaeHniP01 xineohPniP7 troPlaireSniP52 troPlaireSniP9

)XR(ataDevieceR3niP)XR(ataDevieceR1niP)XT(ataDtimsnarT2niP)XT(ataDtimsnarT3niP

)XT(ataDtimsnarT2niP )XT(ataDtimsnarT2niP )XR(ataDevieceR3niP )XR(ataDevieceR2niP

DNGC5niPDNGC6niPDNGC7niPDNGC5niP

Table 4.1: RS-232 Interface Connection

When using the RS-232 interface the MicroLYNX must be within 50 feet of the communications

host.

RS-485 Interface

In a system consisting of a single MicroLYNX, the RS-485 interface should be used if the

MicroLYNX will be more than 50 feet from the host PC. Since most PC’s do not come with an

RS-485 interface preinstalled, you may need to install an RS-485 board in an open slot in your

PC, or purchase an RS-232 to RS-485 converter. If you are using a 4 wire RS-485 system, you

can also use the CV-3222 RS-232 to RS-422 converter sold by IMS.

MX-CC100-000

This manual suits for next models

3

Table of contents

Popular Control System manuals by other brands

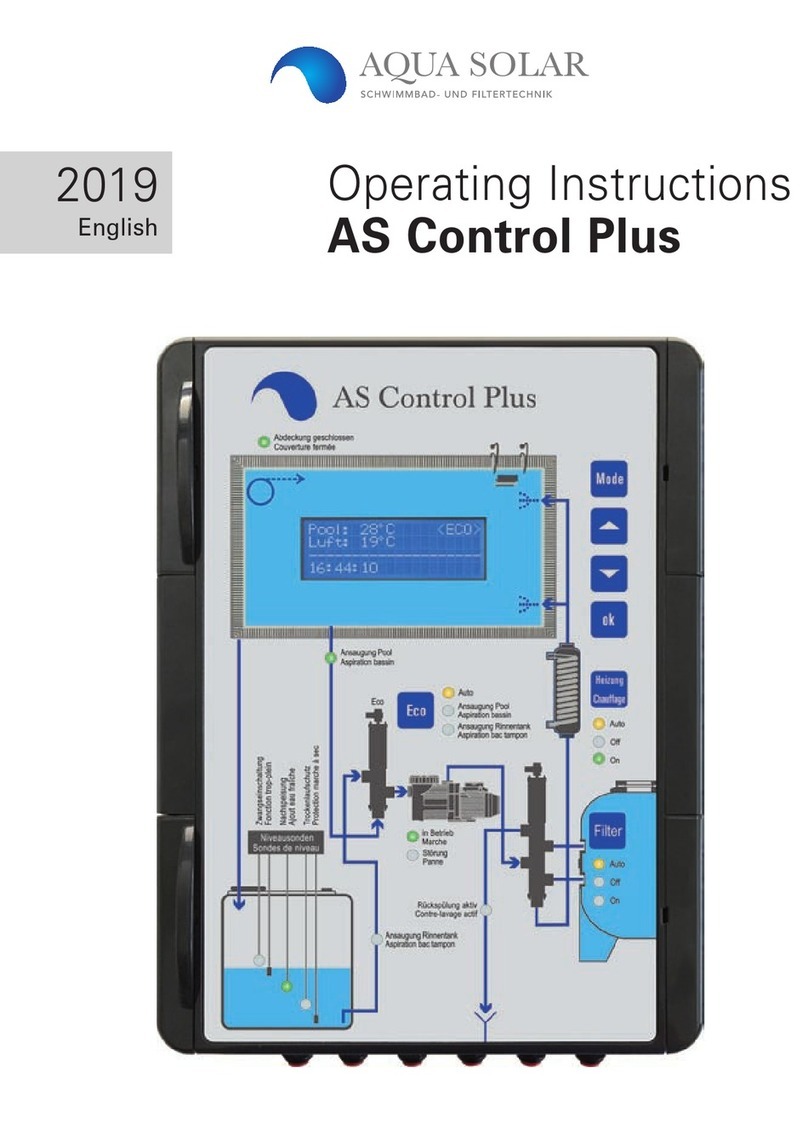

aqua solar

aqua solar AS Control Plus operating instructions

GiBiDi

GiBiDi BARR 600 Instructions for installation

Power Drive

Power Drive P1000FC Quick start instructions

SITGroup

SITGroup PROFLAME 2 Basic Installation and operating instructions

C.P. Electronics

C.P. Electronics DD-LCDHS Product guide

Foxtech

Foxtech T30 user manual

HIK VISION

HIK VISION DS-K3B220X Series user manual

A/DA

A/DA Platinum Elite installation manual

Skytech

Skytech RCTS-MLT-IV Installation and operation instructions

Intelligent Lighting Controls, Inc.

Intelligent Lighting Controls, Inc. LightLEEDer Operation manual

A/DA

A/DA Platinum Elite installation manual

Foxtech

Foxtech GCU user manual