New lift FST-2XT MRL User manual

Liftcontrolsystem

MANUAL

0

11

X2

K23

J131

J135

J136

X41X7

SAFETY CCT CLOSED

>A<

01

Enter

Drive

Shift

F1 F2

AA

B

A

EVAC

AUX

FUNC Select

11

SKZU

SP

TKA

TKB

TKC

NHLT

FKNH

X5 X6 X3

BR

TEST R1/R2

1 0

S1000 S141 S140

S143/S207 S206 S205

S25

S998

IN

OUT

E

S

F

X2

HHT

1 2

X4

123 4 5678 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

X1

K37

K38 X30

1

K22

K21

K20

X16

K14

X17

X19

X14

X21

X20

K13

X18 X24 X25 X26

K7

K6

K5

K0

K4

K3

K2

K1

K12

K11

K10

K9

K8

J133

14:03: 02

1 3 4 6 7 8 2 3 5 6 7

1 2 3 4 5 6 7 8 129 10 11 14 15 16 1713

1 2 3 4 5 6 7 8 129 10 11

1234 21 1 2 3 4 1 2 3 4 5 6 7 8 9

1

1 2 3 4

84

91213 11 10 7 6 5

X15

1 2 3 40

3 2 X13 14

2 3 4 5 6 2 3 4 2 3X23 X27 X28

2 3 41

65

D22 X32

X.

+

J2

J120

J110

J90

J131

J133

J135

J136

X2

X3

X1

X4

X5

X6

X14 X15

X12

X11

X43

X9

X30

X20 X21

X16

X13

X32

X17

K0 K1 K2 K3 K4 K5 K6 K7 K8 K9 K10 K11 K12 K13

K23

K22

K21

K20

230 V AC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

24 V DC

X18 X19

JS

X41

J1

X42

X40

CAN

SKZU

SPB

SPA

TKA

TKB

TKC

NH

FKNH

01 14:03:02

>A< '''@'''

SAFETY CCT CLOSED

FST

STATUS

ERROR

USB-Host

USB-Slave

Drive

Enter

Shift

Select

Func

Manual FST-2XT FST-2XTs

Manufacture NEW LIFT Steuerungsbau GmbH

Lochhamer Schlag 8

82166 Graefelfing

Phone +49 89 – 898 66 – 0

Fax +49 89 – 898 66 – 300

Mail [email protected]

www.newlift.de

Serviceline Phone +49 89 – 898 66 – 110

Mail [email protected]

Dateofissue 09.07.2015

Author KH/TB/AL

Release AL

Hardwareversion FST-2XT 3.4 FST-2XTs 3.0

Softwareversion 2.000-0109

Doc.No. hb_fst2XT_XTs_2015-07_en

Copyright © NEW LIFT Steuerungsbau GmbH, 2015.

This manual is protected by copyright. All rights, including those of copying, of

reproduction, of translation and of modification, in whole or in part, are reserved by

the publisher.

No part of this description may be reproduced in any form or copied with an

electronic replication system without written permission.

Although great care has been taken in the production of texts and figures, we

cannot be held legally liable for possible mistakes and their consequences.

Manual FST-2XT FST-2XTs I

Inhalt

1 Aboutthismanual 1

1.1 General 1

1.2 Abbreviations,charactersandsymbolsused 1

1.3 Furtherinformation 3

1.4 Howtocontactus 3

2 Generalsafetyregulations 4

2.1 Qualificationsoftheinstallingengineer 4

2.2 Residualdangers 4

2.3 Safetyregulations 5

3 FST-2XT/scontrolleruserinterface 7

3.1 Keypadfunctions 9

3.1.1 When switching on 9

3.1.2 Main screen 9

3.1.3 Main menu and test menu 11

3.1.4 Error list 11

3.1.5 Information page 12

3.1.6 Frequency inverter with DCP interface 12

3.1.7 Guide 12

3.1.8 Front panel / operating and display elements 15

3.1.9 Emergency mode monitor (NBM) 17

3.1.10 Evacuation - function principle 18

3.1.11 Brake test - function principle 18

3.1.12 Shaft door RESET - function principle 19

3.2 LCD-Displayandmessages 19

3.2.1 Main screen 19

3.2.2 Line A – Safety circuit messages 19

3.2.3 Line B – State messages 20

3.2.4 Line C – Status messages 22

3.2.5 Line C - Diagnostic messages 22

3.2.6 Line D - Drive mode messages 32

3.3 Informationtexts 33

3.3.1 Information page 36

3.4 LEDs 37

4 Technicaldata 38

4.1 Componentoverview–busplan 38

4.2 FSTcontroller 39

4.2.1 Technical details and data 39

4.2.2 FST jumpers 44

4.2.3 LEDs 47

4.2.4 Safety circuit bypass control 48

4.2.5 Terminal strips and sockets 49

4.3 CartopcontrolmoduleFSM-2 57

4.3.1 Technical data 57

4.3.2 Jumpers 58

II Manual FST-2XT FST-2XTs

4.3.3 LEDs 59

4.3.4 Terminal strips and sockets 60

4.4 LONbus 66

4.4.1 Technical data 66

4.5 Flattravellingcable 67

4.5.1 Technical data 67

5 Menutree 69

5.1 General 69

5.2 MAINMENU-LockMenu 81

5.3 MAINMENU-Service 82

5.4 MAINMENU-Drive 84

5.4.1 Drive optimisation 87

5.5 MAINMENU-Config 88

5.5.1 Park drive programs 104

5.5.2 Show LON modules 105

5.5.3 ADM bus masks 106

5.5.4 Car ventilation 107

5.5.5 Display 0 ... 2 107

5.5.6 Pin 34 function 107

5.5.7 Speech output codes 108

5.5.8 Loading function 108

5.5.9 Lobby Stop 110

5.5.10 Sel.Door-Security 110

5.5.11 VIP mode 111

5.6 MAINMENU-Positioning 112

5.6.1 Positioning parameters 116

5.6.2 Relevelling limits 118

5.7 MAINMENU-Calls 119

5.7.1 Special call mode 119

5.7.2 Attendant operation 120

5.8 MAINMENU-System 121

5.8.1 Recording filter of FST controller 124

5.8.2 Copy from / to USB 124

5.8.3 Update via USB 125

5.9 MAINMENU-Doors 125

5.9.1 Door-Lock Types 128

5.9.2 Door times diagram 129

5.10 TESTMENU 130

6 ProgrammableI/Oports 132

6.1 General 132

6.2 Bitcalculation 133

6.3 ProgrammableI/Oports 134

6.4 I/Ofunctions 135

6.4.1 Function "landing call" 136

6.4.2 Function "fire signal" 137

6.4.3 Function "landing priority" 137

Manual FST-2XT FST-2XTs III

6.4.4 Function "position indicator" 138

6.4.5 Function "door open button" 139

6.4.6 Function "door close button" 139

6.4.7 Function "flag" 139

6.4.8 Function "signal" 143

6.4.9 Function "evacuation" 145

6.4.10 Function "special drive" 146

6.4.11 Function "emergency call misuse" 147

6.4.12 Function "speed threshold" 147

6.4.13 Function "DRM I/O Port" 148

6.4.14 Function "destination call" 148

6.4.15 Function "ramp drive" 149

6.4.16 Function "bypass floor locking" 149

6.4.17 Function "block floors" 150

7 LONmoduleconfiguration 151

8 Errorlist 158

8.1 Errormessages 158

8.2 Eventmessages 165

9 Index 167

IV Manual FST-2XT FST-2XTs

Aboutthismanual

General

Manual FST-2XT FST-2XTs 1

1 Aboutthismanual

1.1 General

The FST-2XT/s manual is a comprehensive reference work for experienced lift service experts.

Objectives of this manual:

› describe the features of the LON bus technology

› describe the technical data of the FST and its sub-assemblies

› describe the operation of the FST

› describe the conguration of the FST

› describe the FST menu and its settings

› describe the messages of the FST

Note! The product designation FST always refers to both products unless explicitly denoted with FST-

2XT and FST-2XTs.

1.2 Abbreviations,charactersandsymbolsused

ADM

Landing call module

CMM

Critical Module Monitoring

FPM

car operating panel module; is needed for controlling car operating panels and is available in two versions:

FPM-1 and FPM-2.

FSM

car top control module; is always required in combination with an FST controller. The two versions of the FSM

are the FSM-1 (FST-1 controller) and FSM-2 (FST-2 controller).

GND

ground; conductive body that is dened with potential 0 V. Serves as reference potential for all signal and oper-

ating voltages.

HSG

emergency power supply unit

TC

Correction, top

BC

Correction, bottom

L

live wire, external conductor; all electrically conductive parts that are under voltage during normal operation and

are not neutral wires. With three-phase alternating current, the external conductors are designated with L1, L2,

L3.

DRM

Runtime monitoring

PE

Protective earth; earth wire

The characters and symbols used in this manual have the following meaning:

System stop

Marks settings requiring a system stop in case a change becomes necessary. The FST controller displays the

text Lift must be stopped to change the value. OK? If you wish to change the value, conrm with

Aboutthismanual

Abbreviations,charactersandsymbolsused

2 Manual FST-2XT FST-2XTs

YES, if you do not wish to change the value or wish to change it later, then conrm with NO.

Delivery condition

Settings that are supplied as standard are marked with an asterisk .

Symbol + Key combination:

Press the linked keys simultaneously.

Aboutthismanual

Further information

Manual FST-2XT FST-2XTs 3

General warning notice

This sign marks important notices that you should absolutely observe.

Electrostatic charging

› Keep the electronic assembly in its original packaging until installation.

› Before opening the original packaging, a static discharge must be performed. To do this, touch a grounded

piece of metal.

› During work on electronic assemblies, periodically perform this discharge procedure.

Danger of falling

This sign marks activities with danger of falling.

Information notice

Important notes are marked with this symbol.

1.3 Furtherinformation

The following documents are available for the FST control system and its components.

› FST-controller description

› FST installation & commissioning

› FST short instructions

› FST manual (these instructions)

› GST manual

› ADM manual

› EAZ-256 manual

› EAZ-LCD and EAZ-VFD manual

› LCS manual

› SAM manual

› Fireman service manual

› System description – Remote entry

› System description – Pawl-control

› System description – Bank control

› System description – Ramp control

› System description – Safety curtain

› System description – Speech output

› System description – Panel test

These and other current manuals can be found in the download area of our website under Service at http://

www.newlift.de/en/service/download/

1.4 Howtocontactus

If, after referring to this manual, you still require assistance, our service line is there for you:

Phone +49 89 – 898 66 – 110

E-mail [email protected]

Mon. - Thurs.: 8:00 a.m. – 12:00 p.m. and 1:00 p.m. – 5:00 p.m.

Fr: 8:00 a.m. – 3:00 p.m.

Generalsafetyregulations

Qualificationsoftheinstallingengineer

4 Manual FST-2XT FST-2XTs

2 Generalsafetyregulations

All important safety regulations are summarised in this chapter. These safety instructions must always be

adhered to during all work on the installation.

All persons performing installation and commissioning work on the FST controller must read this chapter and

follow its regulations.

Laws, regulations, guidelines and standards that apply in the country of operation must be followed in addition

to the safety regulations mentioned in this manual.

2.1 Qualificationsoftheinstallingengineer

The installing engineer must:

› be over 18 years of age (exception: apprentices who are over 16 years of age and are permanently supervised

by an engineer qualied for training apprentices).

› have rst aid training,

› have theoretical and practical knowledge of regulations and measures for the prevention of re and explosions

in his work area,

› be able to identify, avoid and rectify all dangers that might occur during his work in the shaft and in the operating

rooms,

› be able to identify and rectify all irregularities and faults that might occur during installation and operation of a lift

system,

› have theoretical and practical knowledge of operating principles and requirements of electric controls and drive

systems.

All installation and commissioning work on electric and electronic components of the FST controller must be

performed by or supervised by a qualied electrician.

A qualied electrician has appropriate training and knowledge of regulations that allow him to judge the quality

of the work performed and identify possible dangers (BGV A3).

2.2 Residualdangers

Danger for persons

The following shall always apply during all work on the installation:

Danger to life! Do not touch live parts while working on electrical equipment.

› Before starting work, make sure the system is off circuit.

› Only carry out any installation work on electrical components when these are switched off and in an unpowered

state.

› Only use insulated tools when working on electrical system components.

Risk of injury when lifting or moving the control cabinet if it falls down or tips over.

› Only transport and lift the control cabinet with suitable equipment (lift truck, hoisting gear etc.).

› All workers must be trained in using these aids and must observe all applicable special regulations to avoid

accidents.

Falling parts or parts protruding into the shaft. Risk of serious injury or death.

› Block the shaft access points.

› Before beginning installation work, remove all foreign parts and assembly aids that are not required from the

shaft.

Electrical hazard, leaking gas or water due to pierced supply lines. Risk of serious injury or death.

› Make sure no supply lines are in the installation location before starting any installation work.

Generalsafetyregulations

Safety regulations

Manual FST-2XT FST-2XTs 5

Danger of falling! Installing engineers and unauthorised persons can fall down the shaft. Risk of serious injury or

death.

› Block the shaft access points.

› Use suitable protection (e.g. safety harnesses, scaffoldings) when working on or in the shaft.

Danger of crushing due to intentional or accidental car movement. Risk of serious injury or death.

› Block the shaft access points.

› Before starting any work, make sure that there are no persons in the shaft or in the vicinity of moving parts of

the drive.

› Prevent unauthorised operation of the controller.

Risk of material damage

The following shall always apply during all work on the installation:

Electrostatic charging

› Keep the electronic assembly in its original packaging until installation.

› Before opening the original packaging, a static discharge must be performed. To do this, touch a grounded

piece of metal.

› During work on electronic assemblies, periodically perform this discharge procedure.

Electronic assemblies are destroyed by defective, interchanged or incorrectly mounted connectors, short-

circuiting or excess voltage.

› Check plugs for mechanical damage.

› Never change pre-assembled connectors or cables.

› Only connect loose or torn off wires according to circuit diagram details if this is possible on site (suitable mate-

rial and tools must be available).

› Pay attention to coding pins and latch lugs.

2.3 Safetyregulations

General

› The instructions of the lift manufacturer and the instructions in this manual must be followed during installation

and commissioning of the lift system.

› The shaft must be secured against unauthorised trespassing during installation and commissioning.

› Assemblies, devices and cables must be installed and fastened securely and permanently.

› Loads must be moved with suitable aids (lift trucks, hoisting gear etc.).

› Sharp and pointed tools or other potentially dangerous objects may only be carried along in clothing if suitable

protective measures have been taken to rule out any danger.

› Alcohol and drugs must not be consumed before and during installation and commissioning.

Documentation

› A copy of the installation and commissioning manual must be available to the installing engineer at the time of

installing and commissioning the FST controller and its components.

› A copy of the installation and commissioning manual and the wiring diagrams must be kept in the control cabi-

net at all times after installation.

› The wiring diagrams supplied with the FST controller are binding. Changes must only be made after consulting

NEW LIFT and must be documented in writing on the system.

› The factory test logs of the FST controller remain with NEW LIFT.

Generalsafetyregulations

Safetyregulations

6 Manual FST-2XT FST-2XTs

Electricity

› Regulations for installing and operating electrical equipment (VDE 0100) and regulations of local utilities must

be followed.

› The specied distances between different electrical assemblies must be controlled and maintained.

› All installation work must be carried out with the system shut down and off circuit.

› All cables and wires must be installed with sufcient strain relief.

› The neutral and ground wires must be routed separately.

› The control cabinet must be supplied with a clockwise rotary eld.

Working in the shaft

› Any work in the shaft requires perfect and permanent communication between the supervisor on the FST con-

troller in the motor room and the workers in the shaft.

› Components in the shaft must be arranged or secured in such a way that persons accessing the shaft for

inspection, maintenance or repair purposes are not in danger.

› The maximum load of the lift system must not be exceeded.

› The specied overruns of the emergency end switches in relation to the speed must be observed.

› The emergency installations must not be activated during normal operation.

› All emergency installations and braking systems must be checked for trouble-free operation and all shaft

entrances closed off before beginning work.

› Installation and operation are prohibited if other persons could be in danger.

› Workers must be secured against falling.

› In case of any work interruptions, the car must be moved to the lowest stop position, the control system

switched off and the power supply (e.g. UPS) permanently disconnected.

Personal safety equipment of the installing engineer

› Eye protection

› Safety boots

› Protective helmet

› Safety harness

› Clothing suitable to the ambient conditions of the installation location

› Jewellery, watches and similar items may not be worn; a hair net must be used if applicable.

Handling electronic assemblies

› Leave electronic assemblies in their original packaging until installation.

› Touch a grounded piece of metal prior to opening the original packaging to prevent damage from static charges.

› All bus inputs and outputs not in use must be equipped with a terminal resistor (terminator). Exception: FSM-2

X23 and FST X2 are only for use with the HHT hand-held terminal and must not be terminated with a terminator.

Waste disposal

› All packaging material must be disposed of in an environmentally acceptable manner; paper, plastic, metal,

electronic assemblies etc. must be recycled.

FST-2XT/scontrolleruserinterface

Safety regulations

Manual FST-2XT FST-2XTs 7

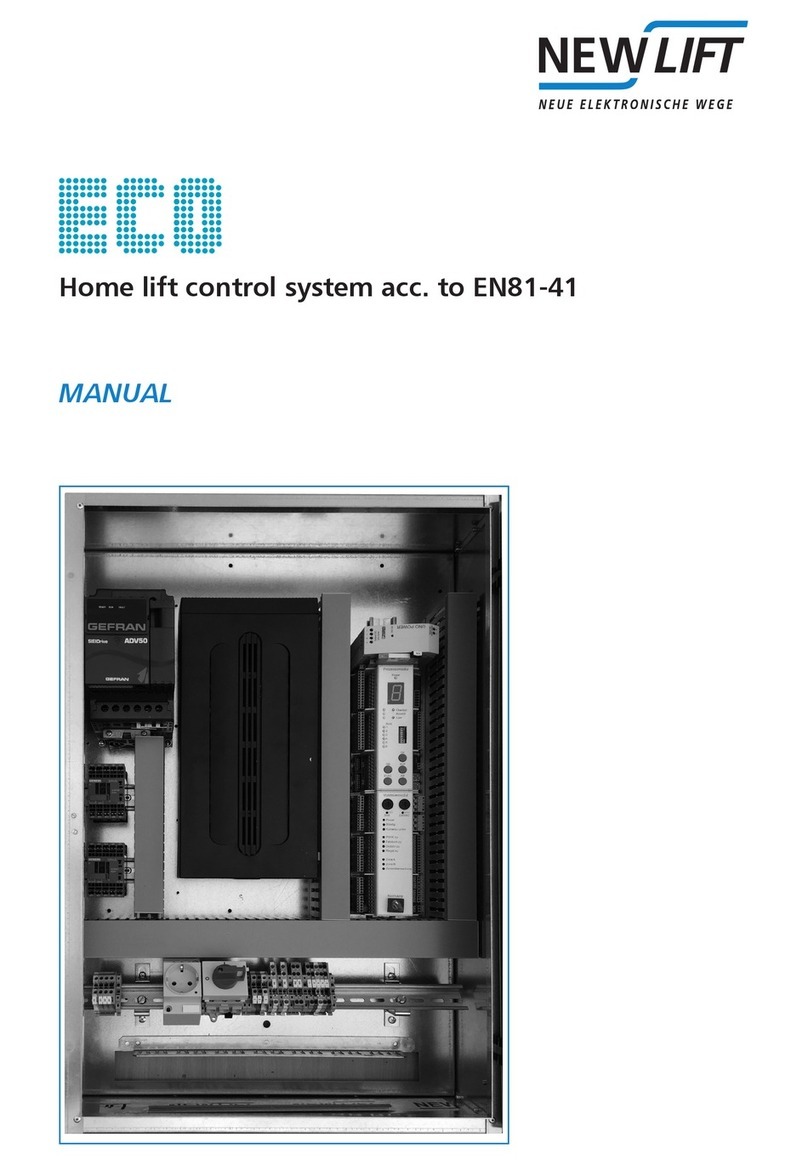

3 FST-2XT/scontrolleruserinterface

The user interface of the FST controller is located on the FST main circuit board in the control cabinet of the lift

system. The FST user interface consists of front panel, LCD-Display, keypad and LEDs.

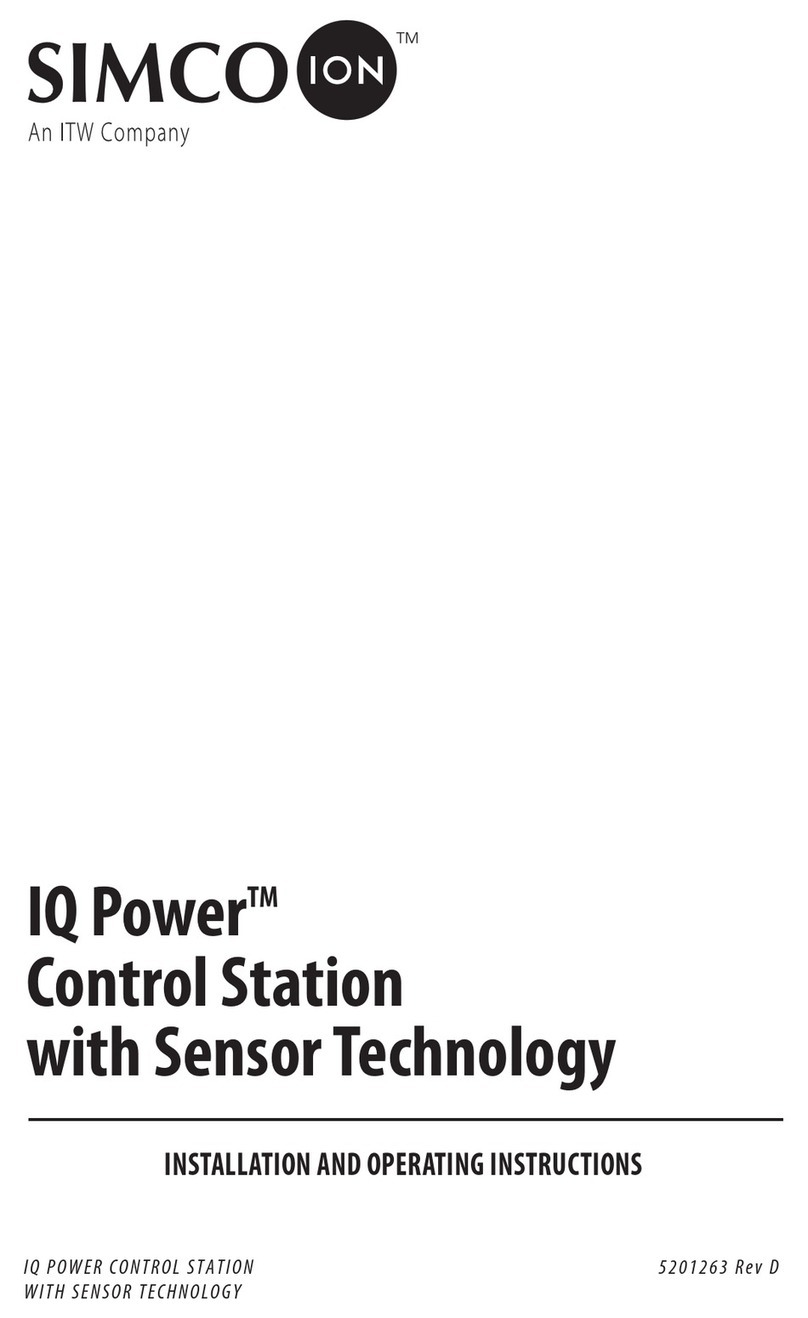

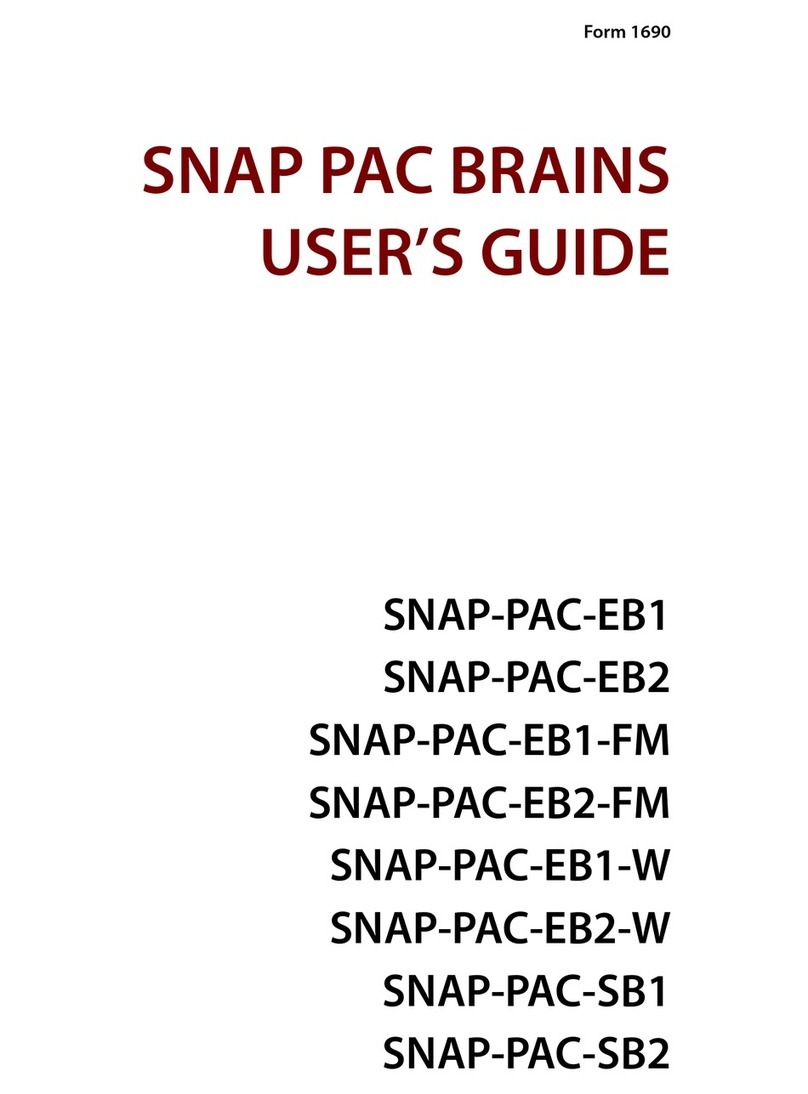

Fig. 3.1: FST-2XT controller user interface

SKZU

SPB

SPA

TKA

TKB

TKC

NH

FKNH

01 14:03:02

>A< '''@'''

GESCHLOSSEN

FST

STATUS

ERROR

USB-Host

USB-Slave

Drive

Enter

Shift

Select

Func

SAFETY CCT CLOSED

>AX< >BX< '''@'''

00 13:06:56

FST-2XT/scontrolleruserinterface

Safetyregulations

8 Manual FST-2XT FST-2XTs

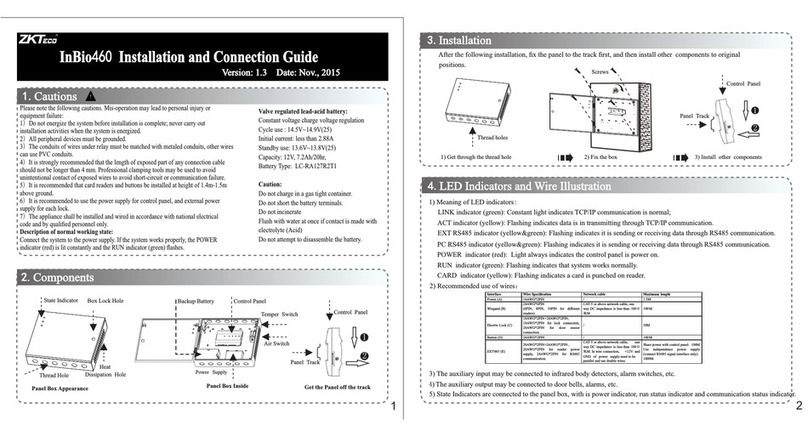

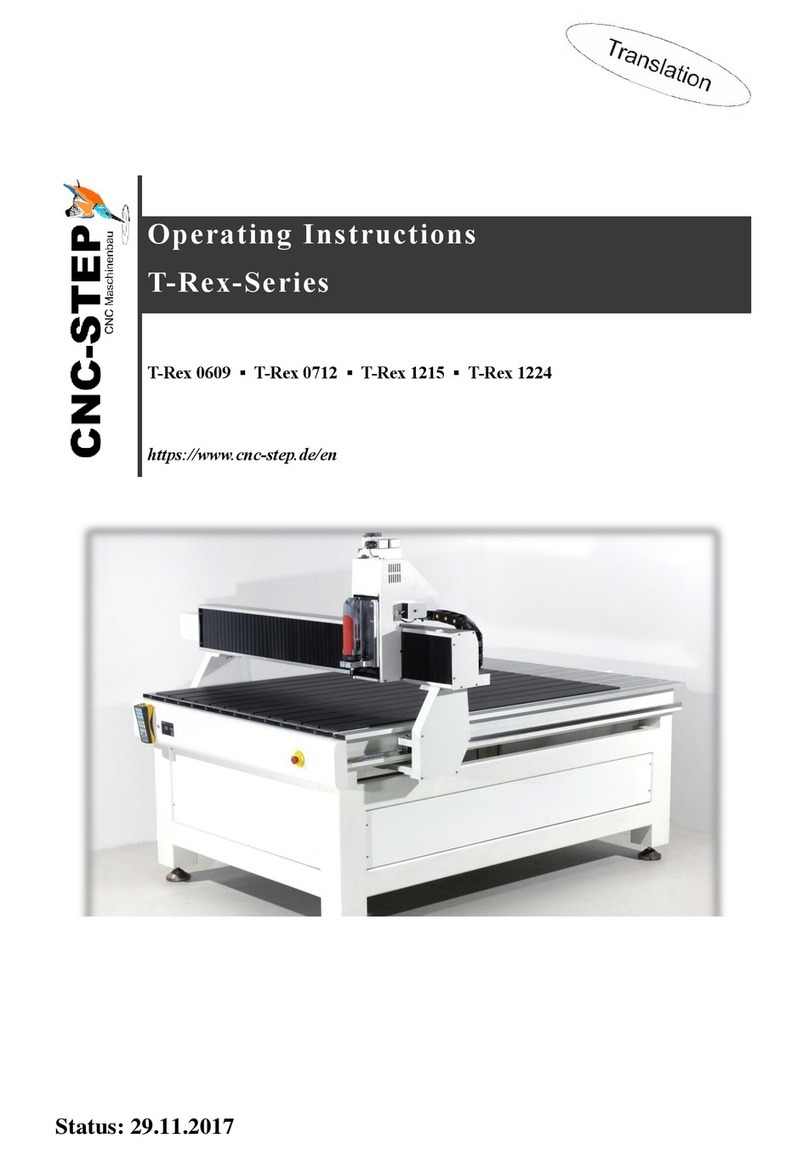

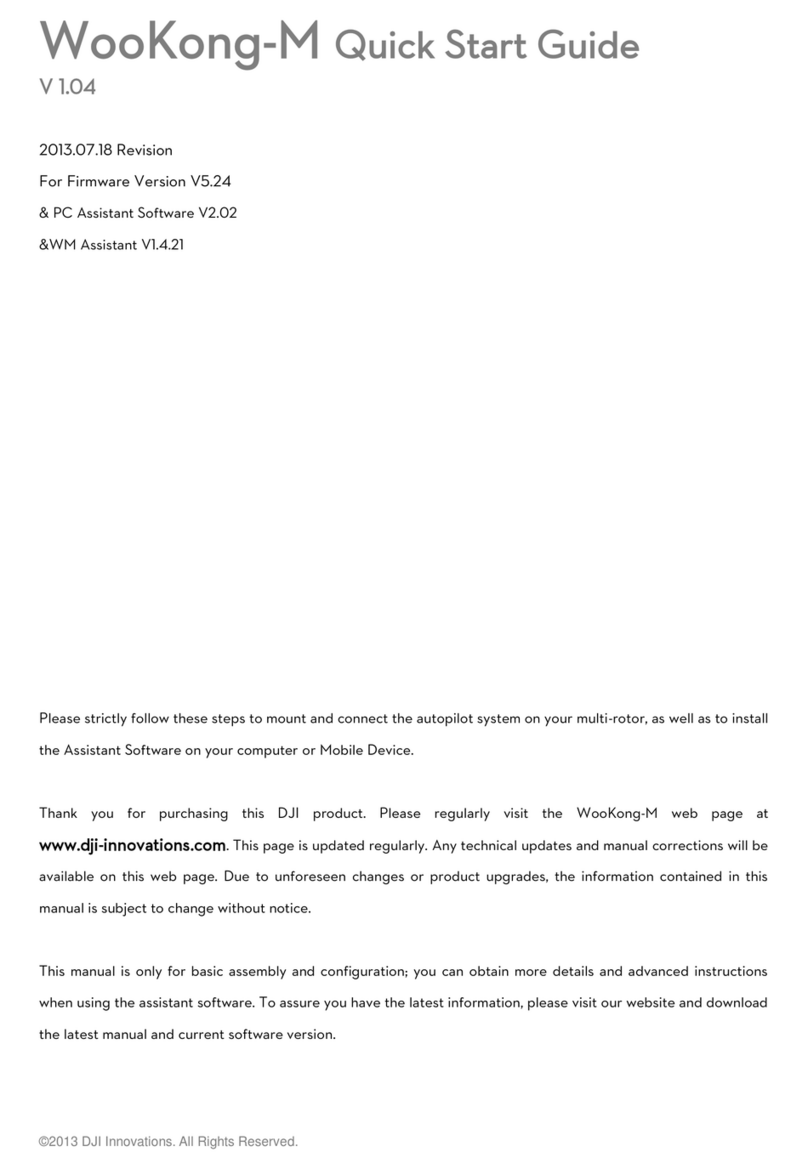

Fig. 3.2: FST-2XTs controller user interface

0

11

X2

X41X7

SAFETY CCT CLOSED

>A<

01

Enter

Drive

Shift

F1 F2

AA

B

A

EVAC

AUX

FUNC Select

11

SKZU

SP

TKA

TKB

TKC

NHLT

FKNH

X5 X6 X3

BR

TEST R1/R2

1 0

S1000 S141 S140

S143/S207 S206 S205

S25

S998

IN

OUT

E

S

F

X2

HHT

14:03: 02

1

FST-2XT/scontrolleruserinterface

Keypad functions

Manual FST-2XT FST-2XTs 9

3.1 Keypadfunctions

The FST controller is operated using seven buttons. The button have different functions in the different displays.

3.1.1 Whenswitchingon

SAFETY CCT CLOSED

>AX< >BX< '''@'''

00 13:06:56

Pressing and holding the button during the switch-on sequence of the FST starts emergency

operation. In emergency operation, no drives are possible. Emergency operation is required if the

FST cannot be switched on in normal mode due to a malfunction. The complete FST menu and the

USB interface are active in emergency operation!

3.1.2 Mainscreen

SAFETY CCT CLOSED

<A> '''@'''

00 13:06:56

Set car call to top oor

Set car call to bottom oor

Switch landing control on and off (switch function)

Open test menu

Open main menu

Activating emergency operation: before switching on, press and hold down until the FST

has completely started up (see FST manual)

+Set car call to next oor up

+Set car call to next oor down

+Scroll through the right status messages in line C

+Scroll through the left status messages in line C

+Display information page

++Switch diagnostic message in line C on or off

+++Perform controller RESET

Switch over to converter menu (DCP)

FST-2XT/scontrolleruserinterface

Keypadfunctions

10 Manual FST-2XT FST-2XTs

Guide functions menu button

Selection / Enter button for conrming the function in the Guide menu

Menu navigation: scroll UP

Menu navigation: scroll DOWN

Function button F1 (S25)*

Function button F2, currently without function (S998)*

AAA Button for manual activation of brake A (S140)*

BButton for manual activation of brake B (S141)*

Key switch with three positions; BT = brake test (S143); contact connected in series

upstream of R1/R2 for resetting shaft head or shaft pit (S207)*

EAC switch (S1000) for switching evacuation ON/OFF; the toggle ashes* in the ON

setting

Button for resetting an access monitor of the shaft head*

Button for resetting an access monitor of the shaft pit*

Auxiliary control switch ON/OFF/DOWN/UP S21/22/23*

Notice: * only with FST-2XTs

F1

F2

0

11

FST-2XT/scontrolleruserinterface

Keypad functions

Manual FST-2XT FST-2XTs 11

3.1.3 Mainmenuandtestmenu

MAIN MENU

Drive

Config

>Positioning

Move cursor up

Move cursor down

Exit submenu

Change menu level

Select submenu / menu item

+Sets all places of a value to "_"

Clock Setting

13:45:01

Increase value

Decrease value

Move cursor left

Move cursor right

Conrm setting

3.1.4 Errorlist

ERROR[00037/00040]

28.09 10:18:26 [012]

Door close failed

FLOOR:03 V00 R01 I00

Switch to 2nd to 8th information byte in line D

Switch to initial display in line D

+To previous error message

+To next error message

FST-2XT/scontrolleruserinterface

Keypadfunctions

12 Manual FST-2XT FST-2XTs

3.1.5 Informationpage

-- FST Information ---

HW Ver. :FST-2XT

SW Ver. :V 2.000-0107

: 26/11/2014

Scroll one line up

Scroll one line down

Back to main screen

3.1.6 FrequencyinverterwithDCPinterface

Frequency inverters with DCP interface can be operated and con gured from the FST menu (FST

X11 connected). The menu of the frequency inverter is simulated on the FST display by pressing the

button once. The FST buttons then perform the function of the frequency inverter buttons. The

FST display is restored by pressing the buttons again.

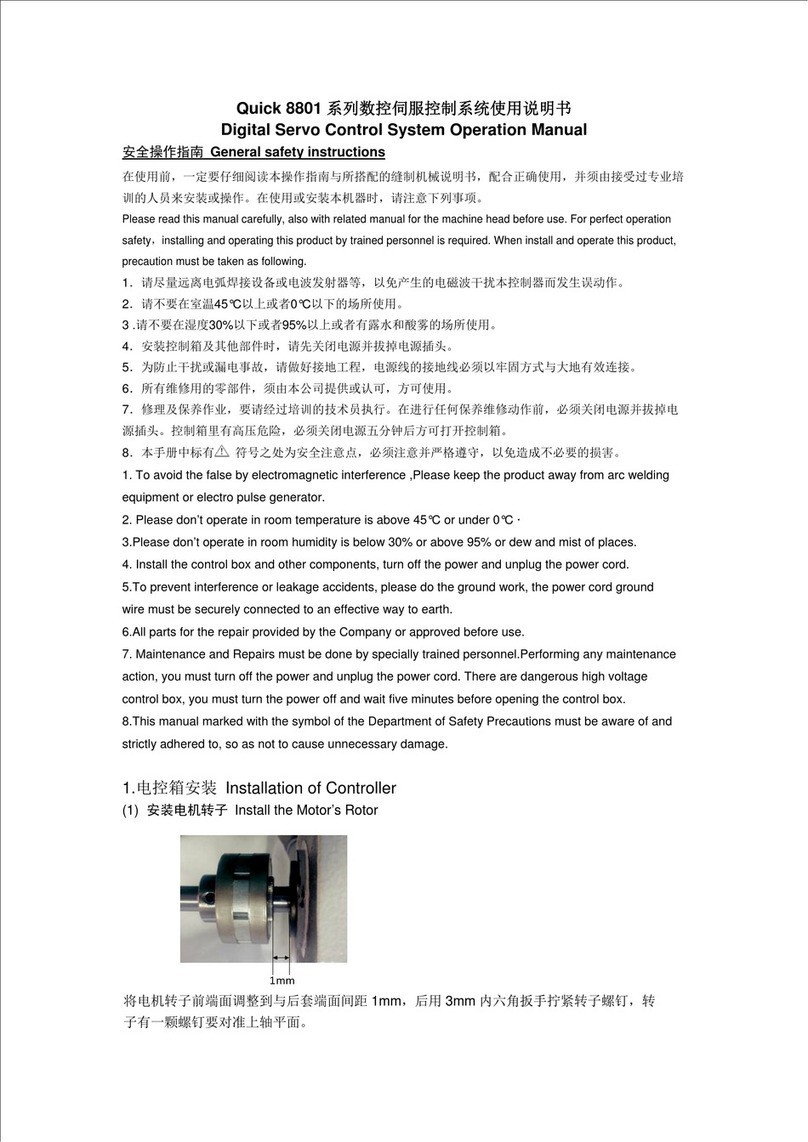

3.1.7 Guide

General

The guide is an extension of the FST-2XT/s. In no way does it intervene in operations performed by the control-

ler and is operated with

a different group of buttons. The four blue buttons, which are responsible for the guide, are located on the right

side of the front panel of the FST-2XT.

Guide

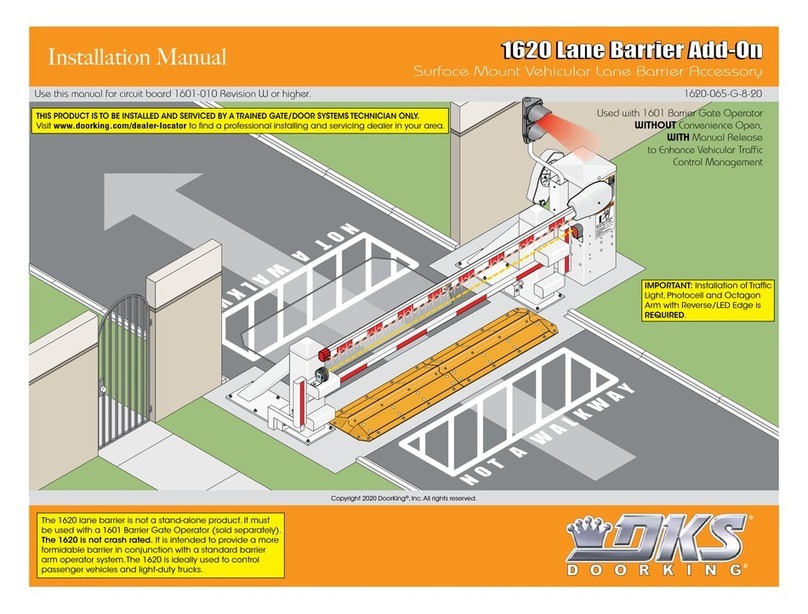

Fig. 3.3: Guide FST-2XT

SKZU

SPB

SPA

TKA

TKB

TKC

NH

FKNH

01 14:03:02

>A< '''@'''

GESCHLOSSEN

FST

STATUS

ERROR

USB-Host

USB-Slave

Drive

Enter

Shift

Select

Func

FST-2XT/scontrolleruserinterface

Keypad functions

Manual FST-2XT FST-2XTs 13

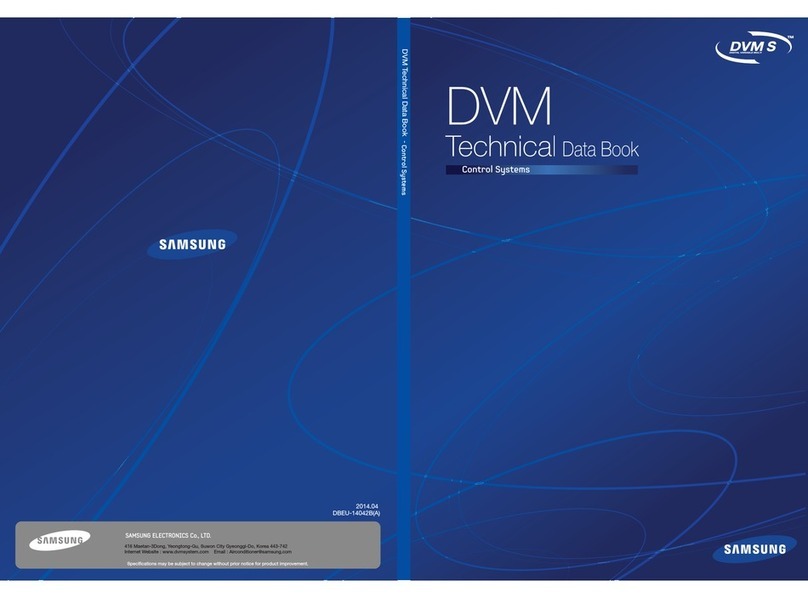

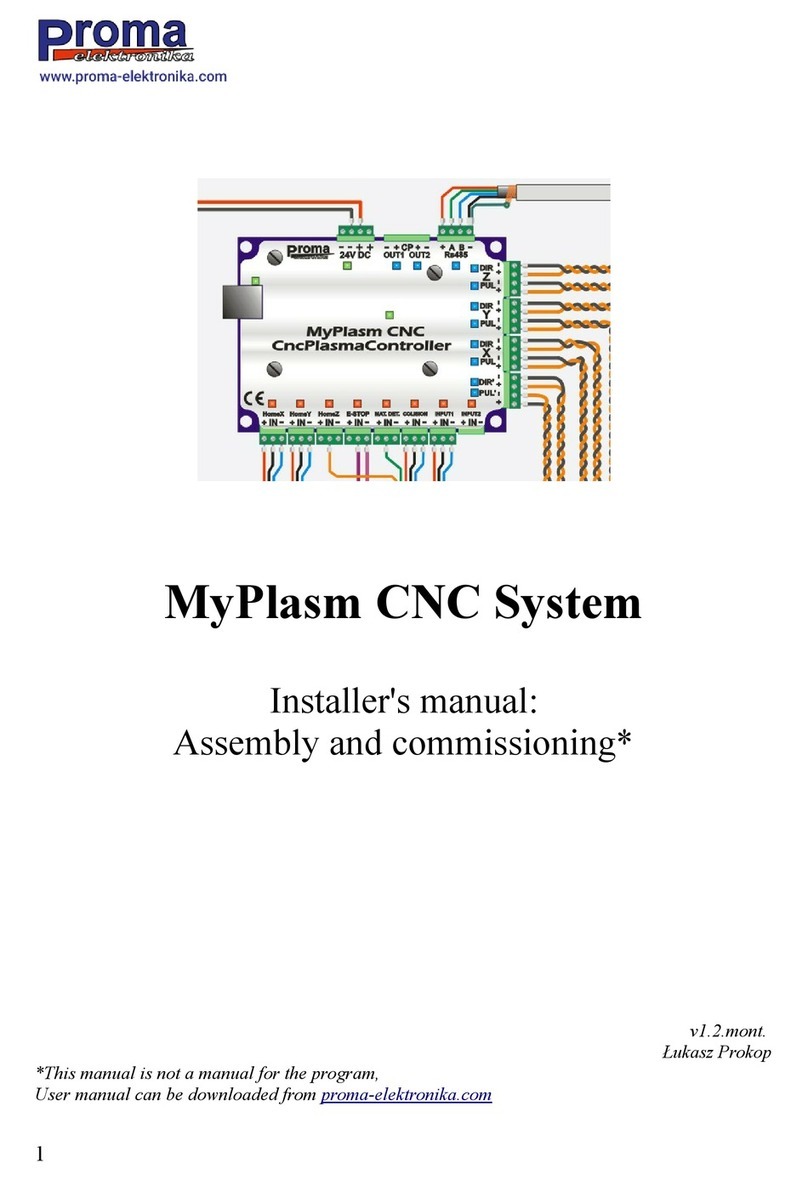

Guide

Fig. 3.4: Guide FST-2XTs

Display

The display is divided into two sections and consists of the following parts:

› FST-2XT/s screen

The top part of the display is the FST-2XT/s screen with the same functions, menus and navigation found in

the previous versions of the FST controllers. These four lines are the familiar display of the FST controllers and

consist of four lines of 20 characters each. They are operated with the four white arrow buttons and three grey

function buttons located underneath. Nothing has changed in the presentation and the keypad functions; every-

thing functions as previously. After switching on and during normal operation, the FST-2XT/s controller displays

the main screen.

› Guide

The lower part of the display shows the guide, which provides information about the individual menu items of

the FST-2XT/s menu and which has additional functions that are described in the following.

Buttons

The , , and buttons are NOT needed for changing the FST-2XT/s parameters in the menu. They are

used only for the navigation of the guide.

Use the / buttons to move the cursor in the text eld. The text sections with a coloured background can

be selected with the button if the cursor is located on top of them. If no text section with a coloured back-

X2

X41X7

GESCHLOSSEN

>A<

01

Enter

Drive

Shift

FUNC Select

IN

OUT

E

S

F

X2

HHT

1 2

X4

123 4 5678 9 10

X26

14:03: 02

4 1 2 3 4 5 6 7 8 9

FST-2XT/scontrolleruserinterface

Keypadfunctions

14 Manual FST-2XT FST-2XTs

ground is selected, the button can be used to move to the previous text section.

Use the button to open the Function menu. Press the button again to exit the menu.

The four functions of the guide can be selected with the button.

› Call List

› Help

› Menu Help

› Event List

Choose the desired function by using the arrow buttons to move the colour highlighting over the terms and con-

rm the selection with the button.

Return to the standard Help menu with the button, use the arrow buttons to move the cursor onto the Help

menu item and select with the button or, if a different parameter or menu item is called up on the FST-2XT/s,

the guide automatically switches to the Help function.

Functions

Call List

Species the position of the car as well as all car calls and landing calls.

The displayed table contains the following three columns:

› In the left column, the existing oors are displayed from bottom to top with their oor name.

› The middle column, IDR (car), shows the received and not-yet-processed car calls; these are marked with an

"x" depending on door side. If no car call is pending, this is indicated with a "-".

› The right column, ADR (landing), shows the received and not-yet-processed landing calls; these are marked

with a "U" (up direction), with a "D" (down direction) or with a "B" (both directions) depending on door side and

direction. If no landing call is pending, this is indicated with a "-".

The current destination is indicated with a "T" next to the corresponding oor name. The position of the car is

indicated by a black rectangle next to the oor name.

Help

General help for operating the FST-2XT/s.

Menu Help

When navigating in the FST-2XT/s menu, a brief description of the current menu item or parameter automati-

cally appears in the guide.

If a different guide function is selected using the Func button while navigating in the FST-2XT/s menu, the Help

menu function appears in the Function menu which can be used to again call up the current FST-2XT/s menu

item.

Event List

Displays a ltered event list on the controller

NBM

Emergency mode monitor, see chapter 3.1.9

Other manuals for FST-2XT MRL

3

This manual suits for next models

1

Table of contents

Other New lift Control System manuals