Intellitec 800 User manual

50 AMP EMS MODEL 800 DISTRIBUTION PANEL

P/N 00-00894-300

s a centralized power switching, fusing and distribution center. Power

from the 120/240 volt power source is fed into the box. The potential of lethal electrical shock is present in this

box. Inadvertent shorts at this box could result in damage and/or injury. All servicing of this box should be done

ONLY by a qualified Service Technician.

Diagnostic tools required: Low current Test Light,Accurate Voltmeter (digital read-out preferred),

Clamp-onAC ammeter.

CAUTION

The 50 AMP SMART EMS - Model 800 i

50 AMP

SMART EMS

SMARTENERGYMANAGEMENTSYSTEM

ENCLOSED ENERGY MANAGEMENT EQUIPMENT

MODEL800

50 AMP SERVICE MAIN & SUB PANEL

by

MADE IN THE U.S.A.

Intellitec

222333 444 555 6

DANGER: HAZARD OF ELECTRICAL SHOCK OR BURN. TURN OFF POWER SUPPLY ON THIS EQUIPMENT BEFORE WORKING INSIDE.

INVERTER LOADS SUBPANEL

LINE 2LINE 1

66M

A

I

N

M

A

I

N

111

4L54

R

LISTED

US

C

SERVICE MANUAL

1

50 Amp EMS Display Panel

P/N 00-00903-050 (Ivory)

P/N 00-00903-150 (Black)

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

PRODUCT DESCRIPTION

The consists of two elements: the and the Model

800 The Display Panel is mounted on a wall, or suitable surface remotely from the Distribution Panel

and convenient to the user The Model 800 Distribution Panel is a completely self-contained 120/240 volt power

distribution and energy management system intended to be used in recreational vehicles. It is housed in a sheet metal

enclosure with removable front panel providing circuit protection for all the 120 VAC loads in the RV and a system of energy

management to minimize the over-loading and tripping of circuit breakers. In addition, the Model 800 Distribution Panel

incorporates a sub-panel to accommodate inverter/converter connected loads.

The 50 Amp Smart EMS Model 800 automatically senses the available power to the vehicle and determines whether it is

connected to a 120 VAC - 30 Amp shore power source, 240 VAC - 50 Amp shore power source, or Generator source.

Depending upon available power, it controls the operation of 6 possible loads that may include: the front and rear air

conditioner fan and compressor using low voltage switching and other 120 Volt loads, such as the refrigerator, water heater,

washer/dryer, microwave oven, or other large appliances. These appliances may be any type load, but are typically

heavier loads, those whose use can be “postponed” until a time when current is available for their use. If the available power

source is 120 VAC - 30 Amp shore power, it attempts to keep the total 120 volt current draw to less than 30Amps.

50 Amp Smart EMS Model 800 Display Panel

Distribution Panel.

.

,

ENERGY MANAGEMENT

TM

CIRCUIT BREAKERS

TM

The provides main circuit protection for 120/240 VAC single-phase incoming lines and

branch circuit protection for up to 12 circuits, including Energy Management of up to six selected branch circuits. A sub-

panel is available on the Model 800 for up to 6 sub-breakers for inverter connected loads. If 120 VAC - 30/20 Amp source is

available, the control helps to limit the total current draw of all the appliances in the RV at or below 30/20 Amps provided by

the main power feed.

Circuit protection for ALL the 120 VAC loads is offered by standard, reset-able circuit breakers, provided by the installer.

There are eight positions available for circuit breakers on the Main Distribution Panel. The breakers located in the two

center stab positions must be 50 Amp breakers to act as the main breakers for the entire system. These breakers back-

feed power into the circuit breaker bus to feed power to the branch breakers. The remaining six positions on the Main

Distribution Panel may be occupied by single or dual units. All the loads in the RV, including the inverter/converter, are fed

from the branch breakers. The 120 VAC output of the inverter is fed to a sub-panel containing three positions that may be

occupied by single or dual units

The utilizes Intellitec’s RV Multiplex/PMC (Programmable Multiplex Control)

System as the communications link between the l and the As an additional diagnostic

feature, the system includes two Communication Status LED’s on the Control Module. In normal operation, when the

is configured in the Stand-Alone Mode, or as the RV Multiplex system, the green “IPX OK” LED should be

lit and the red “IPX Fail” LED should not be lit.

Utilizing the RV Multiplex/PMC system, the Smart EMS System can:

1) Operate as a Stand-Alone system.

2) Operate as a RV Multiplex System Master in a RV Multiplex System, allowing other devices such as

Inverter/converters, input and output modules, and switch panels, to communicate with each other and the Smart

EMS System.

3) Operate as a PMC Transceiver with the addition of a PMC Central Processing Unit (CPU).

The main neutral line is routed through the magnetically coupled current sensor, which measures the current flowing

through the neutral line. This is the total amount being drawn by all the 120 volt appliances in the RV when the available

power service is 120 VAC. When this current exceeds the "shore" service rating of 30 Amps (20 Amps if the threshold has

been set lower or the generator service rating and 240 VAC service is not available, the will turn off

the controlled loads in an effort to bring the total current to the limit of the incoming service.

50 AMP SMART EMS Model 800

.

SYSTEM COMMUNICATIONS

50 Amp Smart EMS Control Module

Display Pane Distribution Panel.

Control Module

, , 50 AMP SMART EMS

TM

TM

TM

NOTE When connected to 50Amp - 240 VAC service the Energy Management features of the unit are disabled and the

Unit switches all controlled loads"ON".

2

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

CONTROLLED LOADS

50 AMP Smart

EMS

EMS

OPERATION IN VEHICLES USING AVAILABLE SERVICE

The system offers control of up to six powered loads; each one connected to one of the relay circuits of the

system. Four of these relays, relays 1, 2, 3, and 4, are 30 Amp relays with normally-open contacts used to interrupt the

120 volt power to the loads. These circuits are intended to control 120 volt appliances such as refrigerator, water heater,

washer/dryer, coffee maker, etc.

For the 120 VAC switched loads, power is routed from the individual branch circuit breakers to one of these 120 VAC relays on

the Control Module. The controlled load is then fed from that relay.

The remainder of the relays, relays 5 and 6, are intended to switch low voltage loads. Relays 5 and 6 are single-pole, double-

throw relays with all contacts available. These relays are intended to control air conditioners, or other appliances equipped

with low voltage controls or thermostats. The contacts of the relays are typically wired in series with the low voltage controls, or

thermostats of air conditioners so the turns off only the compressor, or the compressor and fan. These circuits could also

control other 120 volt appliances if an additional control relay is added externally.

TM

The is turned on by the presence of 120VAC, or 240VAC at the L1 or L2 inputs (J6, pin 3 and 1 respectively). This feature

is intended to prevent the from drawing excessive current from the +12 VDC battery supply when not in operation.

When 120 VAC or 240 VAC power is applied, the system automatically powers up and determines the nature of the power

source.

If the generator is running, a +12 VDC signal will be present at J2 pin 2 on the Control Module.

If 240 VAC exists between the L1 and L2 inputs, the energy management feature is disabled and all control relay contacts are

closed, energizing all of the controlled loads. The Control Module sends a signal to the Display Module which causes the load

meter to go blank, and all power status indicators to light. If the generator is running, the GEN SET service indicator will light,

otherwise the 50Aservice indicator on the Display Module will light.

If the L1 and L2 inputs are at the same voltage (0 Volts between L1 and L2 and 120 VAC between either L1 or L2 and Neutral)

the Control Module sends a signal to the Display Module causing the load meter to display actual load current and the GEN

SET service indicator to light. If the Genset EMS feature is not enabled all loads will be turned on, independent of the

load rating of the generator, and all power status indicators will light. If the Gen Set EMS featured is enabled ,

loads will turn ON until the load rating of the generator is reached and the status indicators for those loads will light.

If 120 VAC is present at the L1 and L2 inputs and +12 VDC signal is present at J2 pin 2 on the Control Module, the will

assume that 120 VAC, 30 Amp shore power is available and the energy management feature will be enabled. If only 20 Amp

service is available, the user by momentarily pressing the 20/30 Amp select switch on

the Control Panel.

Initially, the control turns all loads on with a one-second interval and the total current is monitored. If the total current should

exceed the service limit, the system will turn off the first load in the shedding table. As it turns the loads off, it calculates the

amount of current that was removed, which is the value for that load. This value is placed in memory. If the current remains

above the service limit, the system will turn off the next load in the shedding table. Again, it calculates the amount of current

that was removed and places the value for that load in memory. The system continues to turn off loads until the total current

falls below the service limit, or all of the six controlled loads have been shed. Through this process, the system has "learned"

the amount of current that each particular load draws. This feature compensates for the differences in current draw over a

range of line voltage and ambient temperature, by re-learning the load each time it is turned off, or "shed".

The now waits until the total current is lower than the service limit and enough current is available

before it will turn that load back on. This assures that there is

sufficient current to operate the load.

There is a period after a load is shed before the load can be turned back on again, to

prevent air conditioners from turning on with a head of pressure. During this delay period, if there is enough current

available to energize the load, the LED status indicator for that load will flash. After the delay period expires, the load

will be energized and the indicator will turn ON.

EMS

EMS

240 VAC 50A SERVICE

no EMS

50 Amp Smart EMS

two-minute minimum delay

120 VAC GEN-SET SERVICE

120 VAC SHORE POWER

(default)

(installers option)

(as

compared with the amount in memory for the last load shed)

must select the 20 AMP service mode

TM

NOTE:

3

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

DISPLAY PANEL

The Display Panel can be mounted remotely and connects to the main unit with a light gauge, three-wire cable. Six Power

Status LED's indicate power is applied to those loads. These LED's are ON when the power is applied. If 120 VAC service

is available, the Load Meter has a two-digit display to indicate the amount of current actually being drawn by all the

appliances in the coach. If 240 VAC service is available, the two-digit loadmeter goes blank.

Four service type LED's indicate the source for 120/240 VAC power. Three of these sources are automatically detected

and indicated by the , namely; Gen Set service, 50Amp 240 VAC service, and 30 Amp 120 VAC service.

When 120 VAC shore power is first applied, the system will always be in the 30 Amp mode.

The 30/20 Amp indicator LED will be ON when the system is in the 30 Amp mode.

The 20 Amp service mode is not automatically detected. The operator must

manually select the 20 Amp mode, when 20 Amp service is available. The “Service

Select” button allows the current threshold to be set to either 30 Amps, or 20 Amps

to match the incoming service.

If the pictured adaptor is used on the incoming service, press the “Service Select”

button to select the 20Amp mode. Momentarily pressing this button again will switch the system back to the 30Amp mode.

The Display Panel can also be used to display the for each of the six loads. To display

the values of current stored in memory for each of the six loads, push and hold the Service Select button. The uppermost

LED will illuminate and the stored value will appear on the load meter. Pushing Service Select again, will cycle to the next

load. After the last stored value has been displayed, or if the Service Select button has not been pressed during a five

second period, the load meter will return to normal operation and display total current draw.

EMS

value of current stored in memory

“”

“”

50 AMP

SMART EMS

4

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

87654321

CONFIGURATION DIP SWITCH (Factory Default=All On)

COMMUNICATIONS FAILURE IND.

COMMUNICATIONS OK IND.

HI-POT BYPASS JUMPER

POWER CONNECTOR

CURRENT TRANSDUCER INPUT

COMMUNICATION CONNECTOR

TO DISPLAY PANEL, and/or PMC,

or RV/PMC SYSTEM

LOW VOLTAGE RELAY OUTPUTS

50 AMP EMS CONTROL MODULE - LOW VOLTAGE CONNECTION SIDE

INSTALLATION

THE CONTROL MODULE

The first step when installing an EMS, is to determine which loads will be controlled and in what order they will be shed. A

typical scheme would be to control the two air conditioners, the water heater and the washer/dryer. With these loads, the first

load to be shed should be the water heater, as it's loss of operation would be the least noticed

The next would be the bedroom air, the third, the washer dryer and finally the main air. Choosing this

sequence would provide the least inconvenience to the occupants. User discretionary loads, such as microwave ovens,

coffee pots, hair dryers, etc. considered as controlled loads.

The EMS Control Module has an eight position dip-switch on the board to configure the features active in the system. The

switches in positions 1 thru 3 determine the order of shedding of the loads . The switch in position 4

determines if the Gen set EMS feature is enabled. The switch in position 5 establishes the rating of the generator. Additional

switches in positions 6 thru 8 are reserved for future control configurations.

These dip-switches are all preset to “ON” at the factory. Changing the setting of S1-1, S1-2, or S1-3 will alter the order of

shedding to suit the particular need of the installation. The following tables will assist in determining the proper settings for

S1 thru S3. Dip-switch S4 determines if energy management is enabled when 120 VAC Gen-Set service is available. If S4 is

in the “on” position, energy management will be disabled, but the Display Panel will still display total system current. If S4 is

in the “OFF” position, energy management will be enabled and the current rating of the Gen-Set needs to be selected using

dip-switch S5. With S5 set to the “ON” position, system current drawn from the generator will be limited to 45 Amps. With S5

set to the “OFF” position, system current drawn from the generator will be limited to 60Amps.

(it would switch to operate on

gas, if needed).

should never be

(See figure below)

EMS

5

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

SHEDDING ORDER DETERMINATION

First, fill in the blanks with the names of the loads you want the system to shed, in the order they are to be shed, with the first

to be shed at the top. Then, fill in the second "Load Type" column with an "A" or a "D". "A" for a 120 VAC controlled load

such as a washer/dryer, or "D" for DC controlled load, such as a thermostat wire. You can select a maximum of 4 AC and 2

DC relays.

Starting February 23, 2007 (Julian date code 05407), position 7 has been defined for a 3rd air option feature (previously a

reserved position). When position 7 is in the off position, the 3rd air option is enabled. When position 7 is in the on position

,the 3rd air option is disabled. When the 3rd air option is enabled, the functionality of this option is as follows:

When service is 30 Amps or less, relay 1 disabled (off state) where relay 1 has been wired for a 3rd air conditioning unit.

Also, the LED on the display unit will be off for relay 1.

The 00-00903-XYZ displays have had a recent software update to allow the decoding of the relay 1 led indicator.

Displays date coded after Feb. 5, 2007 will have this software update. Intellitec Julian Date code of 030607 or newer. Julian

date code is the following: first three digits are number of days into the year and the last digits is the year.

Next, looking across the other eight columns, find the one that matches the "Load Type" column you just filled in. Using the

number at the top of the column, look in the table below to determine the settings of the three switches, S1-1, S1-2, and

S1-3. An "ON" means the switch should be closed and an "OFF" means the switch should be open.

At the bottom of each column is the Relay Shed Order. This determines which relays will be used for each load. The one at

the top of the column is first to be shed. The one below it will turn off next, and so forth. The loads be wired in this

order for the system to operate as desired.

NOTE:

MUST

Finally, the number and size of the circuit breakers should be selected to meet the needs of the installation. The breakers

can be either single, or dual types. The center two breakers on the Main Distribution Panel be 50 Amp units to act as

the Main breakers. The breakers must be obtained and then installed in the box.

MUST

(See information on breaker types later in

this manual.)

LOAD NAME

(First to Shed at Top) LOAD

TYPE

6

COLUMN

NUMBER

12345678

S1-1 ON OFF ON OFF ON OFF ON OFF

S1-2 ON ON OFF OFF ON ON OFF OFF

S1-3 ON ON ON ON OFF OFF OFF OFF

64444644

56333463

45622536

33561352

22256225

RELAY

SHED

ORDER

(Top is

First Shed)

11115111

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

DISTRIBUTION PANEL

The EMS Distribution Panel should be installed in a convenient location where it can get air circulation to keep it from over

heating. There should be a minimum of 7" of depth behind the mounting surface to provide enough room for the box and

wiring.

Cut a hole in the mounting panel as shown here:

Carefully cut opening, allowing enough wood to hold enough clearance around the box

for the front cover screws.

The wiring to the box should be routed through the holes in the back and secured using approved cable connectors. The

wires should be with the appropriate size and insulation to meet N.E.C. requirements.

The main supply cable should be brought through the large hole in the lower center of the box and secured with an

appropriate connector. The "LINE 1" and "LINE 2" supply mains should be connected to the corresponding Main Breaker.

The Main Ground lead should be connected to the nearest GROUND bar terminal strip. The current sensor should be

mounted in a knock-out hole near the insulated NEUTRAL block, so that the signal leads from the current sensor exit the

rear of the box. These signal wires should be routed through the lower right hole into the low voltage section of the EMS

and connected to J3 (a 2-pin connector on the low voltage side of the Control Module). The inverter/converter should be

wired so that the AC input to the inverter/converter is supplied via a branch breaker on the Main Distribution Panel and the

120 VAC output of the inverter/converter wired to the individual lug on the far right side of the sub-panel.

The Main NEUTRAL wire should be routed through the CURRENT SENSOR and connected to an appropriate position on

the insulated NEUTRAL block.

There are 8 positions for circuit breakers on the Main Distribution Panel and 3 positions for circuit breakers on the Sub-

Panel in the box. The circuit breakers can be single or dual types. The breakers in the two center positions of the Main

Distribution Panel be rated at 50Amps to be used as the Main Breakers.

Eaton Cutler-Hammer: BR, BD, GFCB, Filler Plate BRFP

Siemens-DPD: QP, QT, Filler Plate QF3

the mounting screws and to allow

Copper conductors ONLY,

MUST

The following breakers are suitable for MAIN and BRANCH breakers:

Replacement circuit breakers must be of the same type and rating.

7

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

DISTRIBUTION PANEL (continued)

,,

(See box drawing.)

(See box drawing, page 15.)

Connections are as follows:

()

()

Connections are as follows:

Branch circuit wires should be routed through the remaining knock-out holes in the back of the box. The wires should be

stripped and the ground wire of each cable connected to the GROUND bar terminal strip. The white or neutral wires

should all be connected to the NEUTRAL bar terminal strip. The black, or "hot" leads of all the uncontrolled loads should be

connected to their associated breakers.

If removed during installation, the white jumper wire should be re-installed between the NEUTRAL block and J6, terminal 5

of the module labeled "NEUTRAL".

The black wires to the controlled loads should be connected to the proper relay output screw terminals of J6 and J7 on the

EMS control module. Be sure these wires are under the screw terminals and that they are tight.

1 From Circuit Breaker for Relay 2

2 Output of Relay 2

3 From Circuit Breaker for Relay 1

4 Output of Relay 1

5 Neutral

1 Output of Relay 3

2 From Circuit Breaker for Relay 3

3 Output of Relay 4

4 From Circuit Breaker for Relay 4

The 12 VDC voltage connections are made through J2 (3-pin Mate-N-Lok connector on the low voltage side of the Control

Module). The +12 volts should be supplied from a source fused at 3 Amps minimum and capable of delivering up to 1 Amp

of AVERAGE current. Protecting this connection with a higher rated fuse is acceptable since the EMS is internally

protected with a 3Amp fuse.

1 + 12 Volts

2 Gen Set Run Input

3 Ground

Tighten each terminal screw to 16 in.-lb. of torque.

EMS

To insure proper operation of the source sensing circuitry on the 50 AMP EMS Model 800, jumper wires

must always be connected from a Line 1 breaker to J6 terminal 3, and from a Line 2 breaker to J6 terminal 1.

These connections must be made even though Relay 1 or Relay 2 may not be used for controlled loads.

J6 and J7 terminal blocks

NOTE

NOTE

MUST

MUST

TM

will accept up to 12 GA or 14 GA copper wire ONLY.

J6 Terminal Function

J7 Terminal Function

J2 Pin Function

be connected to a LINE 2 Breaker

be connected to a LINE 1 Breaker

8

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

DISTRIBUTION PANEL (continued)

Connections are as follows:

Common Normally Open

Normally Closed

Common Normally Closed In this way, the EMS can interrupt the operation of the

compressor, just as the thermostat does.

Normally Closed

Common Normally Closed In this way, the EMS can interrupt the operation of the

compressor and fans, just as the thermostat does.

Normally Closed

Common Normally Closed

Normally Closed

Common Normally Closed

In this way, the EMS can interrupt the operation of the fan, just as the thermostat does.

The low voltage controlled load connections are made through J4 (6 pin Mate-N-Lok connector on the low voltage side of

the control module).

1 Relay 5 N. O.

2 Relay 5 COMMON

3 Relay 5 N. C.

4 Relay 6 COMMON

5 Relay 6 N. C.

6 Relay 6 N. O.

The low voltage controlled load relay connections are typically made to the thermostat wires of the air conditioners. The

normally open contacts are wired in "series" with the thermostat. This means that the thermostat wire is cut and the two

ends are wired to the and the contacts of the relay/s. In this way, the EMS can interrupt the

operation of the compressor just as the thermostat does. The low voltage wires are brought into the box through the large

hole in the lower right-hand corner of the back of the box.

1) If only the compressors of the front and rear A/C's are to be controlled, connections are typically made to the low voltage

compressor control wires of the air conditioners. The contacts are wired in "series" with the

compressor control lead. This means that the compressor control wire is cut and the two ends are wired to the

and the contacts of Relay 5, or 6.

2) If both the compressors and fans of the front and rear A/C's are to be controlled, connections are typically made to the

low voltage thermostat control wires of the air conditioners. The contacts are wired in "series" with

each thermostat control lead. This means that the thermostat control wire is cut and the two ends are wired to the

and the contacts of Relay 5 or 6.

3) If the compressor and fan for one of the A/C systems are to be controlled individually, connections are typically made to

the individual low voltage thermostat control wires for the fan and compressor of the air conditioner. The Relay 6

connections are typically made to the low voltage compressor control wires of the air conditioner to control the

compressor. The contacts are wired in "series" with the compressor control lead. This means that the

low voltage compressor control wire is cut and the two ends are wired to the and the contacts

on Relay 6. The Relay 5 connections are typically made to the low voltage thermostat control wires of the air conditioner

to control the fan. The contacts are wired in "series" with the thermostat control lead. This means that

the low voltage thermostat control wire is cut and the two ends are wired to the and the

contacts on Relay 5.

Finally, on the Control Module, there is a small 2-pin plug, labeled J1, which is only used for the High Pot Test on the

system. When the two pins are shorted together, the EMS will operate without the presence of 120 VAC.

Now the should be moved into the mounting hole, being careful not to pinch any of the wires. It should be screwed in

place using four # 8, round head screws into the 4 holes in the side flanges. The front cover should be secured into place

with the 6 screws provided in the holes in the top and bottom flanges.

J4 Pin Function

Several methods to utilize Relay 5 and 6 connections for controlling air conditioner systems with the EMS are listed:

EMS

9

NOTE:

Relay5&6areNOTenergized at power up.

Their contacts will remain Normally Closed

between J4 pin2&3andJ4pin4&5.

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

DISPLAY PANEL

Select a convenient location for the panel, where it can be easily viewed by the owner.

The Display Panel is equipped with a six inch long pigtail with a 3-pin Mate-N-Lock female connector. An extension

harness, up to 100 feet long, can be attached between the Display Panel and the EMS Control Module, with a 3-pin

male Mate-N-Lock plug at the Display Panel end and a 4-pin, male, Mate-N-Lock plug at the Control Module end.

1) Stand-Alone Mode - Pins 1 thru 3 on the 3-pin plug connect to the corresponding pins on the 4-pin plug.

In addition, pin 4 on the 4-pin plug should be connected to pin 2.

2) RV Multiplex Master Mode - Pins 1 thru 3 on the 3-pin plug connect to corresponding wires in the RV Multiplex system

and the corresponding pins on the 4-pin plug. In addition, pin 4 on the 4-pin plug should be connected to pin 2.

3) PMC Mode - Pins 1 thru 3 on the 3-pin plug connect to the corresponding pins on the 4-pin plug.

should be made to pin 4 on the 4-pin plug.

The Display Panel should be plugged onto the mating 3-pin, Mate-N-Lock connector in the harness, insuring that it is fully

seated and locked. The panel should then be installed in the hole and screwed in place using two, # 6, flat head screws

through the holes in the panel. A white function label should be lettered to correspond to the order of load shedding and

installed behind the cover label. The cover label should be placed against the front panel and the trim bezel snapped on to

hold the label in place.

Plug the 4-pin plug into J5 on the EMS Control Module, insuring that it is fully seated and locked.

Cut a hole for the panel as shown:

,,

The wiring of the plug at the Control Module end determines the system configuration as follows:

No connection

PERFORMANCE TEST

The system is now ready for testing.

At the installers preference, to assure there are no potential shorts, a Hi-Pot test can be performed on the installation. To do

this, +12 volts must be applied to the system. A jumper wire must be installed to tie the two pins of the “Hi-Pot Test" plug, J1,

to turn the system ON without the presence of 120 volt power. This plug is located on the right side of the EMS Control

module. The relays on the module should be heard clicking as they pull in. On the Display Panel, the LED's should light

and the numeric display should read "0". The Hi-Pot test should now be conducted in accordance with standard

procedures for the tester being used. Assuming the system passes, the covers should be taken off and the jumper

removed from J1.

HI-POT TEST

If not, the problem must be corrected before proceeding further.

10

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

SYSTEM TEST

F1

J1 = 2 pin Molex KK-100 connector - HI-POT TEST Power Up

J2 = 3 pin Amp Mate-n-Lok connector - Power connector

J3 = 2 pin Molex KK-156 - Current Sensor Connector

J4 = 6 pin Amp Mate-n-Lok connector - Control Relays 5 & 6 contacts

All the 120 volt loads should be turned off, or disconnected. Both 120 volt AC and 12 volt DC power should now be applied

to the system. When this is done, the relays should be heard pulling in. On the Display Panel, the numeric display should

read "0", the six Power Status LED's should come ON, and the "30 Amp" service type LED should light. A clamp-on type

ammeter should be used to measure the current being supplied by the 30Amp shore power cord.

Connect, or turn on one of the controlled AC loads. It should operate and the numeric display or the clamp-on ammeter

should show the amount of current that load is drawn. Turn that appliance off and repeat this with each of the others. To

test the load shedding, turn ON all the controlled appliances. The total current drawn should exceed 30 Amps.

When the total amount of current exceeds 30 Amps, the loads should

begin to turn off to bring the total below 30Amps.

- 5 Amp, ATO type, for EMS Control Module circuitry only. .

This could result in severe damage to the circuitry or create a possible fire hazard.

1 Hi-Pot Override

2 Hi-Pot Override

1 +12 Volts Supply

2 +12 Volts Gen-Set Run input

3 Chassis GROUND

1 Current Sensor Input

2 Current Sensor Input

1 Relay 5 N.O.

2 Relay 5 COM.

3 Relay 5 N.C.

4 Relay 6 COM.

5 Relay 6 N.C.

6 Relay 6 N.O.

(If not, add

additional loads to the non-controlled receptacles.)

FUSES

DO NOT replace with a fuse of higher rating

EMS CONTROL MODULE PLUGS, PINS, AND FUNCTIONS

Pin Function

Pin Function

Pin Function

Pin Function

11

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

EMS CONTROL MODULE PLUGS, PINS, AND FUNCTIONS (continued)

J5 = 4 pin Molex KK .156 - Display Panel Connector Mating Housing Molex 09-50-3041

6 = 5 Position Terminal Block

J7 = 4 Position Terminal Block

J6 and J7 terminal blocks -

Pin Function

Term Function

Must be connected to a LINE 2 Breaker

Must be connected to a LINE 1 Breaker

Term Function

1 Power

2 Data IN

3 GROUND

4 RV Master Com OUT

1 From Circuit Breaker for Relay 2 ( )

2 Output of Relay 2

3 From Circuit Breaker for Relay 1 ( )

4 Output of Relay 1

5 NEUTRAL

1 Output of Relay 3

2 From Circuit Breaker for Relay 3

3 Output of Relay 4

4 From Circuit Breaker for Relay 4

J

NOTE Will accept up to 12 GA or 14 GA copper wire ONLY.

12

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

TROUBLE SHOOTING

If the following problems occur, proceed with analysis in the order in which these steps are listed:

A. Check incoming power source.

1. Make sure the shore power cord is plugged into the outlet.

2. Check the circuit breaker at the shore power outlet to be sure it is set.

Turn it off and then back on.

3. Check the 50 Amp Main circuit breakers in the EMS Distribution Panel to be sure they are set.

Turn them off and then back on to be sure.

4. Using a circuit checker, be sure the 30 Amp shore power outlet has 120 VOLTS available.

B. Check” Change-Over” relay, if so equipped.

1. Measure the voltage at the incoming side of the Main 50 Amp breaker.

If voltage is NOT the same as the incoming line, repair the change-over.

A. Check the 12 volt power to the EMS module.

1. Check 12 volt, 3 Amp fuse on EMS Control Module.

Replace if necessary.

B. Check 120 volt circuit breakers in EMS

1. Reset circuit breakers if necessary.

2. Check for presence of voltage at branch circuit breakers with voltmeter.

3. Check for presence of voltage at EMS terminals with voltmeter.

4. Check wire from EMS Control Module to neutral bar is installed.

A. Reduce total current, appliance may be shed.

B. Check wiring to and from EMS Control Module.

1. Check wiring from circuit breakers to EMS Control Module.

2. Check wiring from EMS Control Module to controlled appliance.

3. Check for power at associated EMS relay terminal.

A. Check wiring for shorts.

A. Check thermostat wiring and settings.

B. CheckAir Conditioner

I. No 120 VOLT appliances working.

II. 120 VOLTS available at non-controlled appliances and receptacles.

Controlled appliances do not operate.

III. Some controlled appliances turn on, others do not.

IV. Branch circuit breaker trips when power is applied.

V. Air conditioner doesn't work.

(Refer to the service literature for trouble shooting.)Change-Over

13

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

TROUBLE SHOOTING (continued)

VI. Shedding order incorrect.

VII. Remote Display out, or strange characters are displayed.

VIII. Remote Display does not indicate "GEN SET" service source when generator is running.

VIX. Remote Display does not indicate "50 AMP" service source when 50 Amp 240 VAC shore power is connected.

A. Check jumper setting

B. Check relay wiring per Table on page 6.

Check wiring between J5 on EMS Control Module and Display Panel.

1 Power 12 VDC

2 Data IN ~9 VDC

3 Ground GROUND

4 RV Master OUT ~9 VDC

Both the EMS Control Module and Display Panel have internal protection.

Shorts, or mis-wiring, should not cause the units to fail.

Check wiring between generator run light circuit and J2, pin 2, on the EMS Control Module. J2, pin 2, should measure

12 VDC, or greater when generator is running and 0 VDC, otherwise.

Check to make sure that jumpers are present between any LINE 1 breaker and J6, terminal 3, and any LINE 2 breaker

and J6, terminal 1. Also, check that the "NEUTRAL" jumper is in place, between J6, terminal 5 and a position on

the NEUTRAL block.

With "50Amp" service available, the voltage between J6-3 and J6-1 should measure 240 VAC. With any other source,

the voltage between J6-3 and J6-1 should measure 0 VAC. In addition, the voltage measured between J6-3 and J6-5

should be 120 VAC and the voltage measured between J6-1 and J6-5 should be 120 VAC.

(Figure on page 5 and Tables on page 6.)

Pin Function Voltage

14

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

15

Cond. Torque

AWG In.Lb.

Equip. Ground 10-14 35

Neutral Bar 10-14 35

Line Terminal 10-14 35

FROM INVERTER

TO INVERTER

EMS

CIR 3

EMS

CIR 4

INSULATED NEUTRAL

EMS

CIR 1 EMS

CIR 2

50/30

AMP

MAIN

CURRENT

SENSOR

LINE 1

LINE 2

GROUND GROUND

BRKR #2

RELAY #2

BRKR #1

RELAY #1

NEUTRAL

12 VOLT SIDE

J3 To Current Sensor

120/240 VOLT SIDE

BRKR #4

RELAY #4

BRKR #3

RELAY #3

EMS Controlled

Loads 1HP, 15A,

120VAC,60HZ

ENERGY MANAGEMENT

CONTROL ELECTRONICS

BARRIER

RELAY #5 N.O.

RELAY #5 COM

RELAY #5 N.C.

RELAY #6 COM

RELAY #6 N.C

RELAY #6 N.O.

Remote Display Connector

AIR-CONDITIONERS

THERMOSTAT LEADS

LOAD 1.0A, 24VDC

OPTION JUMPER:

SEE OWNERS GUIDE

J5

J2

+12 VOLTS

+12V GEN RUN

GROUND

_

J1 Hi-Pot Test

1

2

3

1

2

3

4

5

6

TYPICAL WIRING DIAGRAM

120 VAC, 20/30 AMP SERVICE

All Neutral current must pass thru

EMS Current Sensor.

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

16

131 Eisenhower Lane North

Lombard, IL 60148

630.268.0010 / 1.800.251.2408

50 AMP Smart Energy Management System Model 800

TM

P/N 53-00894-100 Rev. E 030807

www.intellitec.com

Intellitec

Table of contents

Other Intellitec Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

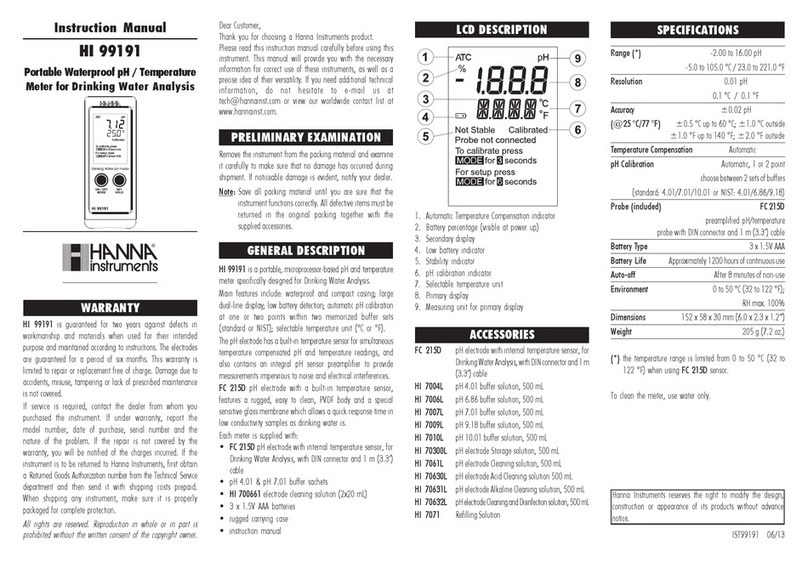

Hanna Instruments

Hanna Instruments HI 99191 instruction manual

Ingersoll-Rand

Ingersoll-Rand THERMO KING TriPac EVOLUTION installation instructions

Shinko

Shinko CLT-200 instruction manual

Sensus

Sensus HRI Installation and operating instructions

Thermo Scientific

Thermo Scientific NITON XL3t 500 user guide

Edwards

Edwards AIM-S-NW25 instruction manual