intermountain AC-8 User manual

Baldwin Locomotive Works

SOUTHERN PACI IC

AC-8/10/11/12

4-8-8-2 Cab orward

Articulated Steam Locomotive

Operators

Manual

AC-12 LokSound Documentation Insert - V2.3.odt

1

Operators Manual

Your Presentation Quality Collectors Box Includes:

•N Scale Baldwin Locomoti e Works Model

AC-8/10/11/12 4-8-8-2 Articulated Locomoti e

•Oil Tender with Electronics

•Operators Manual

•Warranty Information

•Traction Tire & Coupler Pack

Table of Contents:

•N Scale AC-8/10/11/12 4-8-8-2 Articulated Steam Locomoti e Features

•Oil Tender Features

•Preparing The InterMountain AC-8/10/11/12 Steam Locomoti e For Operation

•DC (Basic Analog Mode) Operation

•Digital Command Control (DCC) Operation

•Ongoing Maintenance Acti ities

•Pilot Coupler Con ersion

N Scale AC-8/10/11/12 4-8-8-2 Articulated Steam Locomotive eatures:

•Detailed cab interior

•Painted gauge faces

•Detailed boiler back-head

•Directional lighting and lighted number boards

•Highly detailed piping including flexible high

pressure piping

•Operating side rods, eccentric cranks and al e

gear

•Detailed feed-water system, air pumps, generator

and brake gear

•Formed wire railings and grab irons

•Diamond Plate patterned walkways and deck plate

•Prototypically correct articulation of the trailing

engine

•Recommend operation on 15” Radius minimum

cur e

•10 Pin NMRA Standard Plug for quick & easy

DCC Installation

•Micro-Trains® Pilot Coupler

Oil Tender eatures:

•Formed wire railings and grab irons

•Detailed trucks and brake piping

•Diamond Plate patterned deck plate

•Operating directional back-up light

•Micro-Trains® Coupler

AC-12 LokSound Documentation Insert - V2.3.odt

2

Preparing the InterMountain AC-8/10/11/12 Steam Locomotive for Operation:

E ery InterMountain AC-8/10/11/12 Steam Locomoti e is factory tested prior to release. The InterMountain

AC-8/10/11/12 Steam Locomoti e is factory lubricated on all internal dri eline components. The external

dri eline components are not factory lubricated to protect the finished model in its presentation packaging.

Once initial set-up and test run is complete the following lubrication is required prior to normal

operation of the locomotive:

•Using high quality plastic compatible lubricating oil, carefully (but sparingly) lubricate all mo ing parts of

the external side rod assemblies. InterMountain Railway recommends Labelle® 108 - Synthetic Oil Multi-

Purpose Light Weight.

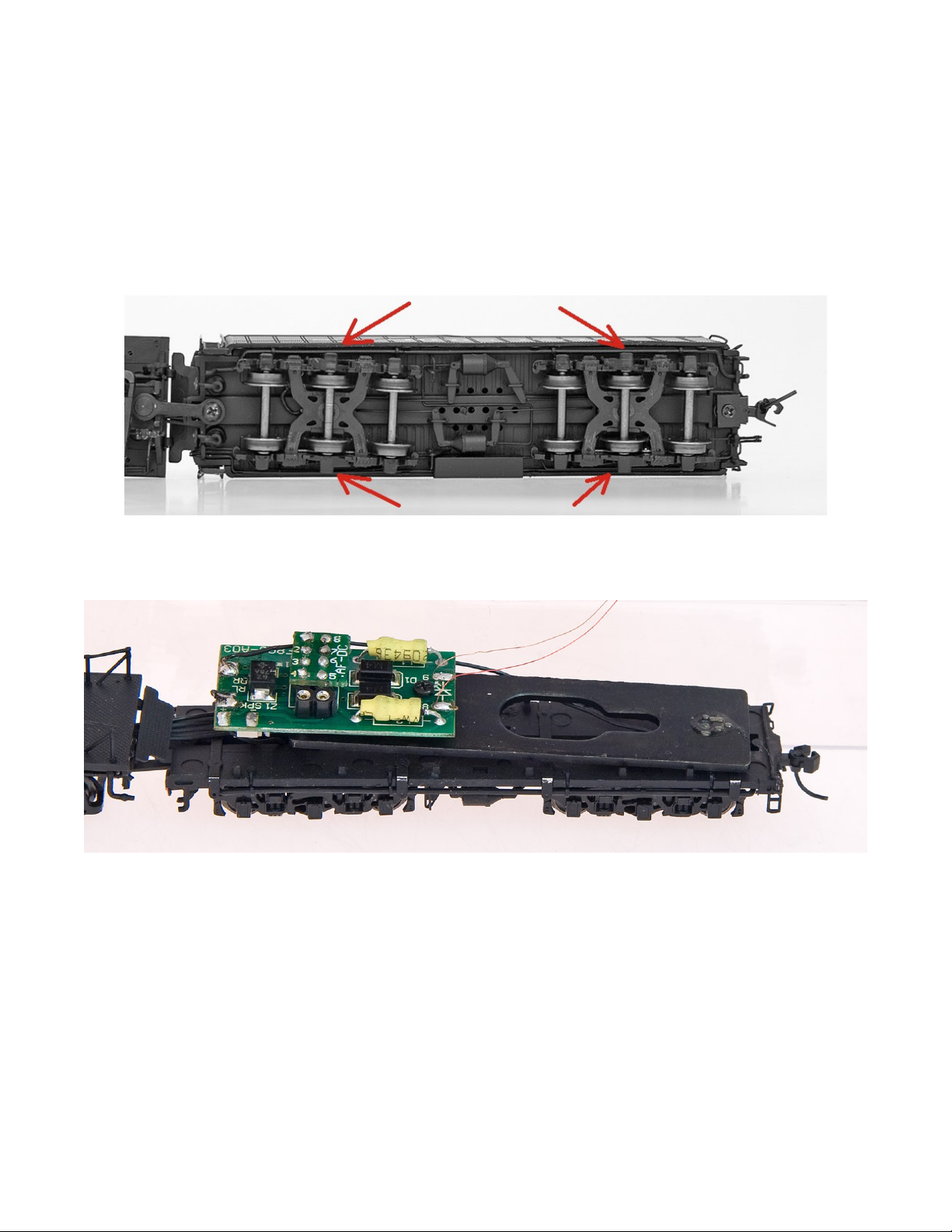

•Lubricating the dri e axles at their bearings is also recommended (see image below).

•A oid and remo e any excess oil prior to normal operation of the locomoti e.

Lubrication Locations

DC (Basic Analog Mode) Operation:

Operating the Locomotive with a standard N Scale Compatible (DC Analog) power pack:

•Set the DC Power pack direction control switch to forward.

•Set the DC Power pack throttle to Zero/Stop position.

•Turn on the N Scale Compatible DC Power pack.

•To Accelerate: Ad ance the throttle control slowly until the locomoti e mo es forward. Adjust the throttle as

required to achie e the desired speed.

•To Decelerate: Reduce the throttle control slowly. Adjust the throttle as required to achie e the desired speed.

•To Stop: Reduce the throttle control slowly to the Zero/Stop position.

•To Re erse or Change Direction: With the throttle in the Zero/Stop position, change the power pack direction

control switch to re erse or opposite position. Then accelerate, decelerate, and stop as described abo e.

Important Notes:

•NEVER Re erse or Change direction while the locomoti e is mo ing as this may damage the dri eline

components.

•A oid rapid throttle changes and abrupt stops to reduce excessi e strain on dri eline components.

AC-12 LokSound Documentation Insert - V2.3.odt

3

Digital Command Control (DCC) Installation & Operation:

Your N Scale AC-8/10/11/12 is equipped with a 10 pin NMRA compliant plug for the installation of a decoder

in your locomoti e. The following instructions will guide you in the installation of your decoder. To install a

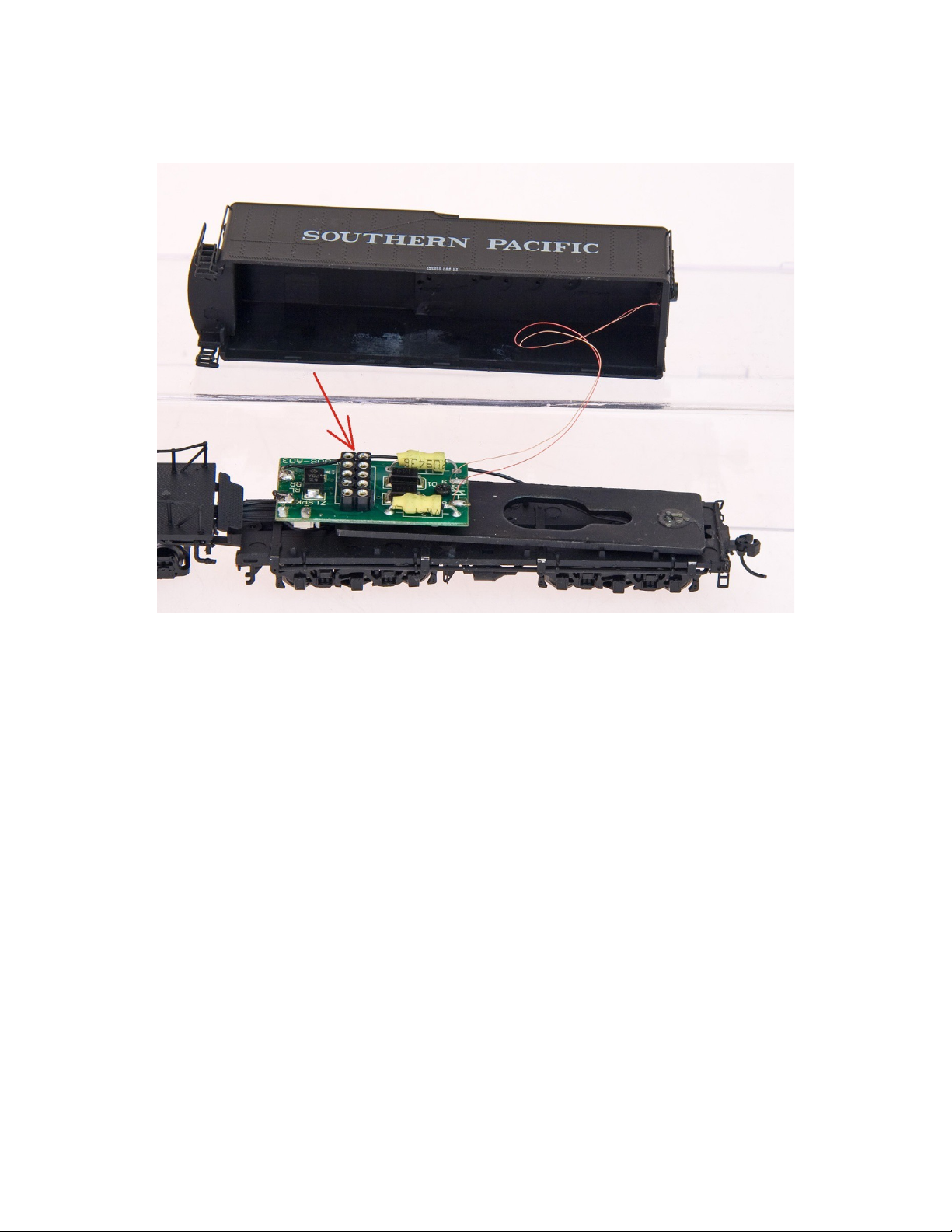

decoder in your AC-8/10/11/12 locomoti e requires only the remo al of the tender body.

1.Prepare the locomoti e by placing it on a protected surface. The foam pad included in your presentation

package would work just fine.

2.Remo e the tender body by inserting a flat tool between the edges of the body and sliding it back and forth.

This will release the body from the base frame. You will need to do this on both sides.

3.Remo e the tender body, being careful not to pull on the tender light wires.

AC-12 LokSound Documentation Insert - V2.3.odt

4

4.Remo e the NMRA dummy plug and plug in your decoder. Align Pin-1 from the decoder (orange wire) to

Pin-1 on the plug (marked with a *1). Backwards installation of the decoder is harmless and will only result

in the locomoti e operating opposite to the direction indicator on your DCC system.

5.Replace the tender body.

Operating the DCC Equipped Locomotive with a qualified NMRA Command Station:

•Select the factory default locomoti e address. (Address 3 with most brands of decoders)

•Set the controller to the preferred speed-step range.

•To Accelerate: Ad ance the throttle control slowly until the locomoti e mo es forward. Adjust the throttle as

required to achie e the desired speed.

•To Decelerate: Reduce the throttle control slowly. Adjust the throttle to achie e the desired speed.

•To Stop: Reduce the throttle control slowly to the Zero/Stop position.

•To Re erse or Change Direction: With the throttle in the Zero/Stop position, change the direction control to

re erse or opposite position. Then accelerate, decelerate, and stop as described abo e.

Important Notes:

•NEVER Re erse or Change direction while the locomoti e is mo ing to a oid damaging dri eline

components.

•A oid rapid throttle changes and abrupt stops to reduce excessi e strain on dri eline components.

AC-12 LokSound Documentation Insert - V2.3.odt

5

Operational and Decoder unctions:

Sound Equipped Locomotive Only-

Your new locomoti e comes equipped with a LokSound Select Micro DCC & DC “Dual Mode” decoder

integrating a full-featured, 8 channel sound system, and a .75A motor controller. The LokSound Select follows

all NMRA DCC standards and recommended practices. It can be used with 14, 28, or 128 speed steps,

supports two digit as well as “4-digit” addressing. Up to 29 function keys are supported.

The LokSound Select supports all DCC-programming modes including Programming on the Main Track.

Because of its unique low-power design, the LokSound Select can be programmed on the programming track

of all popular DCC systems. No programming track boosters or other circuitry is required.

•O er 20 sound effects, including the bell, playable whistle, air pump, exhaust chuff, coupler, steam release,

cylinder cocks, brake release, side rod clank, blower, injector, dynamo, firebox blower, synchronized brake

squeal, and more!

•8 channel sound: The LokSound Select can playback up to 8 sounds at a time.

•5th generation motor control with load compensation for smooth and precise operation.

Default Address = 3. Decoder Reset CV8 = 8, then interrupt track power for approximately 5 seconds and

restore power. The decoder will re ert back to address 3 after a decoder reset.

Your sound equipped locomoti e comes with the following DCC function key commands:

F0 (f) Headlight/Dynamo

F0 (r) Backup light

F1 Bell

F2 Steam Whistle

F3 Single Chime Air horn

F4 Short Steam Whistle

F5 Coupler Clank

F6 Injector

F7 Number Board Lights/Dynamo

F8 Shut Down / Mute

F10 Air Pump

F11 Oil Burner

F12 Blower

F15 Crossing Communication

F16 Rail Clank (Loco must be mo ing)

F17 Brake Release

F18 Sand Val e

F19 Headlight/Re erse Light Dimmer

Chuff Rate at speed step 1: CV57 Default 87 (Range 0-255) Lower numbers = Faster Chuff

Chuff Rate at higher speed steps: CV58 Default 40 (Range 0-255) Lower numbers = Faster Chuff

Master Volume: CV63 Default=192 (Range 0-192)

Indivdual Sound Volume Control (MUST SET CV32=1 IRST):

Chuff: CV259 Default=128 (Range 0-128)

Steam Whistle: CV275 Default=128 (Range 0-128)

Bell: CV283 Default = 99 (Range 0-128)

Dynamo: CV299 Default=128 (Range 0-128)

Air Pump: CV307 Default=120 (Range 0-128)

Air Horn: CV371 Default=128 (Range 0-128)

A complete list of the sound olume CVs can be found on our website as well as other helpful LokSound tips:

http://intermountain-railway.com/customerser ice/dccwebpage/ESU-FAQ-Page.html

AC-12 LokSound Documentation Insert - V2.3.odt

6

Ongoing Maintenance Activities:

Apply the following recommendations as needed.

Cleaning Wheels:

Use a small amount of rubbing alcohol as needed to remo e most normal build up on wheels. The

frequency of wheel cleaning can ary depending on factors such as track condition, duration of

running time, etc.

External Lubrication:

Using high quality plastic compatible lubricating oil, carefully (but sparingly) lubricate all mo ing

parts of the external side rod assembly. Lubricating the dri e axles at their bearings is also

recommended. Always a oid excessi e lubrication and remo e any excess oil prior to normal

operation of the locomoti e.

Internal Driver Set – Gear Lubrication:

After extended operational ser ice, inspect and lubricate the dri e gears in each dri er set with high

quality plastic compatible gear oil or light grease. Again, light application of the lubricant is best. An

experienced modeler or technician should perform the dri e gear lubrication as remo al and

reassembly of the dri er set co er plates and brake gear detail is required to access these components.

Drive Motor:

The Dri e Motor in this locomoti e is permanently lubricated and requires no additional lubrication.

We hope you enjoy the operation of your InterMountain N Scale AC-8/10/11/12. If you ha e any questions

about your locomoti e, or any other InterMountain product, feel free to contact us by phone at (800) 472-2530

or by e-mail at intermountain@intermountain-railway.com.

AC-12 LokSound Documentation Insert - V2.3.odt

7

Pilot Coupler Conversion

Your N scale AC-8/10/11/12 comes with a pilot coupler con ersion allowing for issue free double-headed

operation. The extended coupler can be exchanged for a short shank coupler by following these simple steps:

1.Included in your locomoti e presentation box is a packet containing replacement couplers and traction tires.

2.Remo e the coupler from the package and assemble as shown.

3.Remo e the coupler mounting screw and slide the coupler out the front of the pilot.

4.Assemble the coupler in the box and reinstall by sliding the coupler into the front. Tighten the screw to hold

the coupler in place.

AC-12 LokSound Documentation Insert - V2.3.odt

8

Traction Tire Replacement

Your locomoti e comes with traction tires on the leading dri er of each 'engine'. Each set of 4 dri ing axles is

called an 'engine'. There are two 'engines' on the Cab Forward. Should these tires need to be replaced, an extra

set of 4 tires is included. This process requires patience and the need to work extremely carefully. Do this

work on a clean work space so as not to loose any of the small parts. Please read through the steps below

before starting the work.

1. Included in your locomoti e presentation box is a packet containing replacement couplers and traction

tires. Ha e this packet handy but don't remo e the tires from the packet until you are ready to replace

them.

2. There is one traction tired dri er axle on both 'engines'. Replace the traction tires on one dri er axle at

a time. It is not required to replace more tires than necessary, howe er these instructions are the same

for the traction tired dri ers on both 'engines'.

3. Using a small pair of side cutters, slide the cutter head between the hex-head pin holding the side rod

to the dri er and the side rod. This is a press-fit hex-head pin and NOT a screw. Do not cut the pin

with the side cutters! Use a small flat blade screwdri er under the cutters. Twisting the screwdri er

while pulling STRAIGHT up on the pin with the cutters will release the pin. It is extremely important

that the pin is pulled STRAIGHT up and completely out without rocking it. If it is rocked, the hole that

the pin fits into will elongate and the pin will not hold when re-inserted. Set the pins in a safe place as

they'll be re-inserted later.

4. Do the abo e for both sides of the dri er.

5. Turn the locomoti e upside-down and gently pry the brake hanger off the bottom of the 'engine' you

are working on with a small flat blade screwdri er. Pull it straight out.

6. Remo e the two Phillips head screws and remo e the bottom plate from the dri ers. The traction tired

dri er can now be pulled out. No other dri ers should be pulled out.

7. Using a #11 X-acto blade, scrape out the old traction tire from the groo e. Be sure to clean the groo e

completely or the new traction tire will not lay flat causing the locomoti e to wobble.

8. Remo e one new traction tire from the included package. Using a round smooth pointed tool, re-install

the new traction tire. The tool will help guide the tire into the groo e. Make sure the tire is fully seated

and does not twist as it is going into the groo e. It should be completely flat in the groo e. Install one

tire completely before doing another one (if necessary).

9. Set the dri er back in the locomoti e with the hole for the pin aligned to the side rod, and re-assemble

the locomoti e in the re erse order from abo e. Do not try to turn the wheels on the axle to align the

pin holes. If the wheels get turned on the axle, they'll ha e to be re-quartered.

10. Re-insert the hex-head pins last. Be extremely careful to re-insert the pins into the side rod and dri er

completely STRAIGHT!

If you should elongate the hole in the dri er and the pin will not hold, a replacement dri er is required.

Contact us for information on a ailability of replacement dri ers. Limited supply. There is a fee for a

replacement dri er and is subject to a ailability.

AC-12 LokSound Documentation Insert - V2.3.odt

9

InterMountain N Scale Cab orward Warranty

(AC-8/10/11/12)

InterMountain Railway Company will repair or replace, at our discretion, any part which it finds faulty in

workmanship or material, pro ided these instructions are followed:

1. If you feel that you ha e a warranty issue, please contact InterMountain Railway Company to discuss the

problem at 800-472-2530 or intermountain@intermountain-railway.com. If needed, we will then ad ise you

to send your locomoti e in for ser ice.

2. Upon our instruction, send locomoti e with written note¹ to: Customer Ser ice Department, InterMountain

Railway Co., 1336 Sherman Dr., Unit C, Longmont, CO 80501-6174.

3. Please be sure to include your full name, return address, email address, telephone number, and any other

contact information should we need to reach you.

4. Please pack the locomotive in its original box to pre ent damage during shipping. Please make certain

the outer carton has enough packing material to ensure a safe shipment. Any product not returned in the

complete original packaging will be subject to a minimum $40 repair fee!

This warranty co ers defects in workmanship and materials for as long as it is in possession of the original

owner. This warranty does not co er the cost of any incon enience, transportation damage, misuse, accident

or any item that has been modified from its original configuration. This warranty also does not co er any

damage caused to the locomoti e or tender by a user installed aftermarket produced decoder. Replacement

parts for any non-warranty issues may be obtained for a fee depending on a ailability.

¹A form that can be printed, filled out, and returned with your locomoti e in lieu of the written note can be

found on our website (www.intermountain-railway.com) under the Customer Ser ice button and then the

Ser ice and Repair link.

InterMountain Railway Company

1336 Sherman Dr. Unit C, Longmont, CO 8 5 1-6174

Toll Free: (8 ) 472-253

Local: (3 3) 772-19 1 Fax (3 3) 532-2352

Web Site: http://www.intermountain-railway.com

Modeler’s Club: http://intermountain-railway.com/modelersclub/

AC-12 LokSound Documentation Insert - V2.3.odt

10

This manual suits for next models

3

Table of contents

Other intermountain Toy manuals

Popular Toy manuals by other brands

LCUT Creative

LCUT Creative B 00-34 OO quick start guide

SIG

SIG KADET LT-25 Instruction book

Fisher-Price

Fisher-Price M4042 Consumer information

Fisher-Price

Fisher-Price LittlePeople J0000 instructions

MTHTrains

MTHTrains 2-8-2 L-1 Mikado Steam Locomotive Operator's manual

Eduard

Eduard Pz.Kpfw III Ausf.M Assembly instructions

Fisher-Price

Fisher-Price FIREROCK 73610 Owner's manual & assembly instructions

Cranium

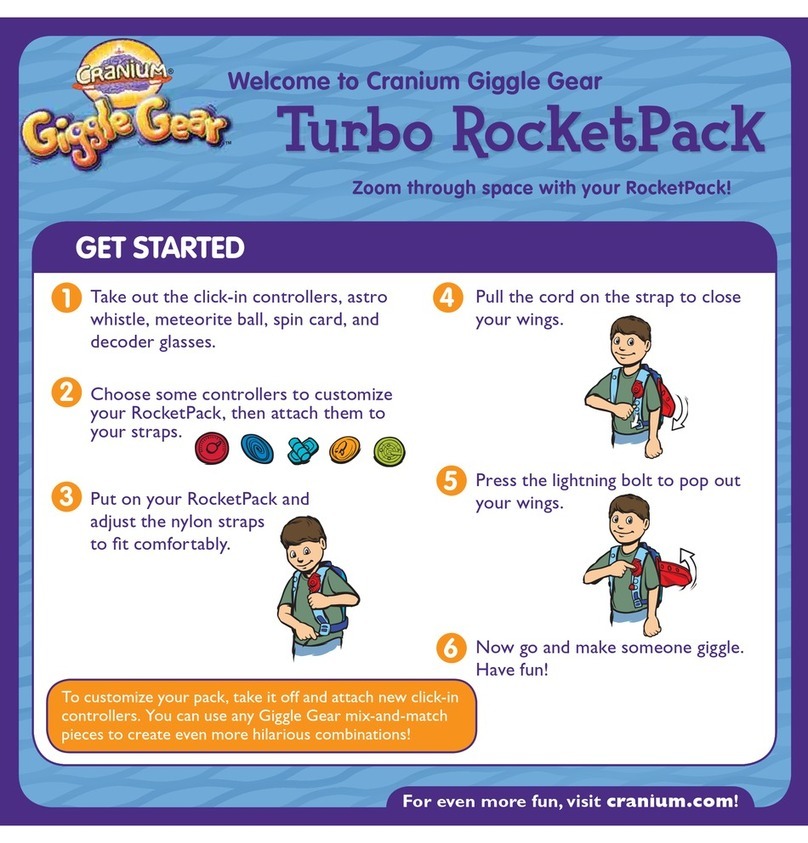

Cranium Turbo Rocket Pack instructions

Eduard

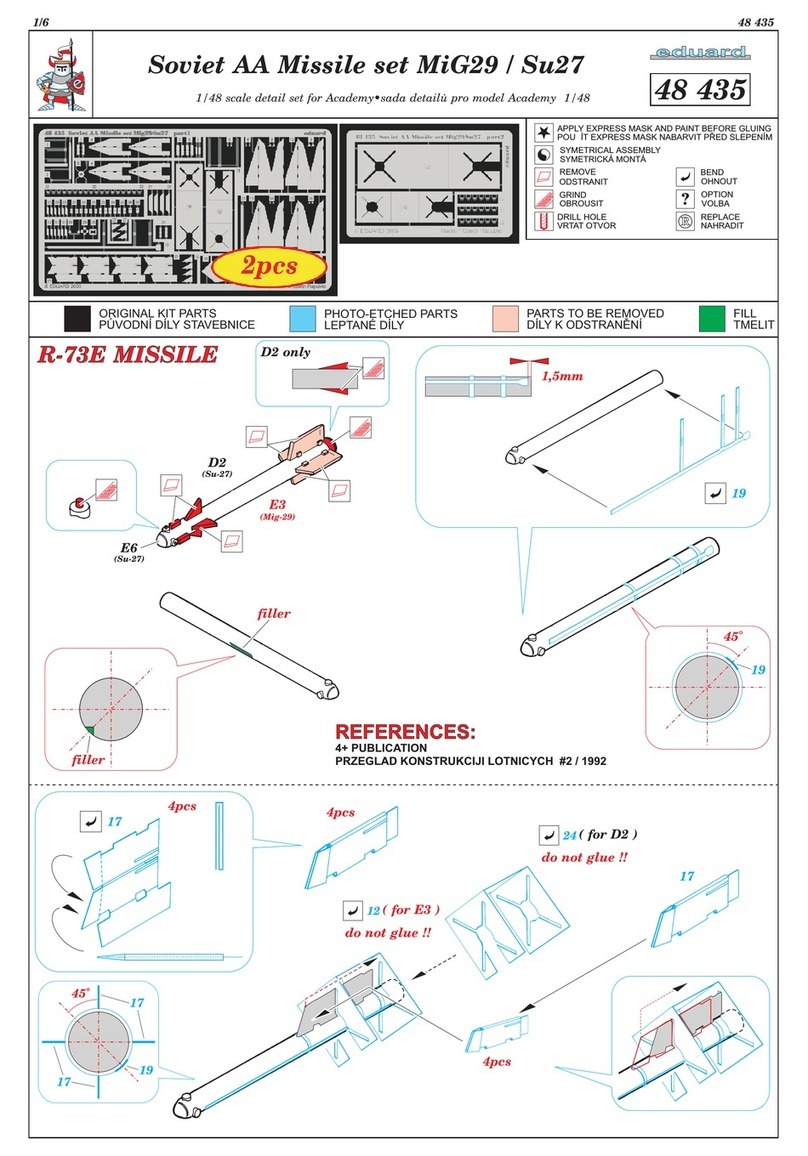

Eduard Soviet AA Missile set MiG29/Su27 quick start guide

LEGO

LEGO Jack Stone 4620 Building instructions

FREE AIR

FREE AIR Piranha Building instructions

KNEX

KNEX MARIOKART 8 manual